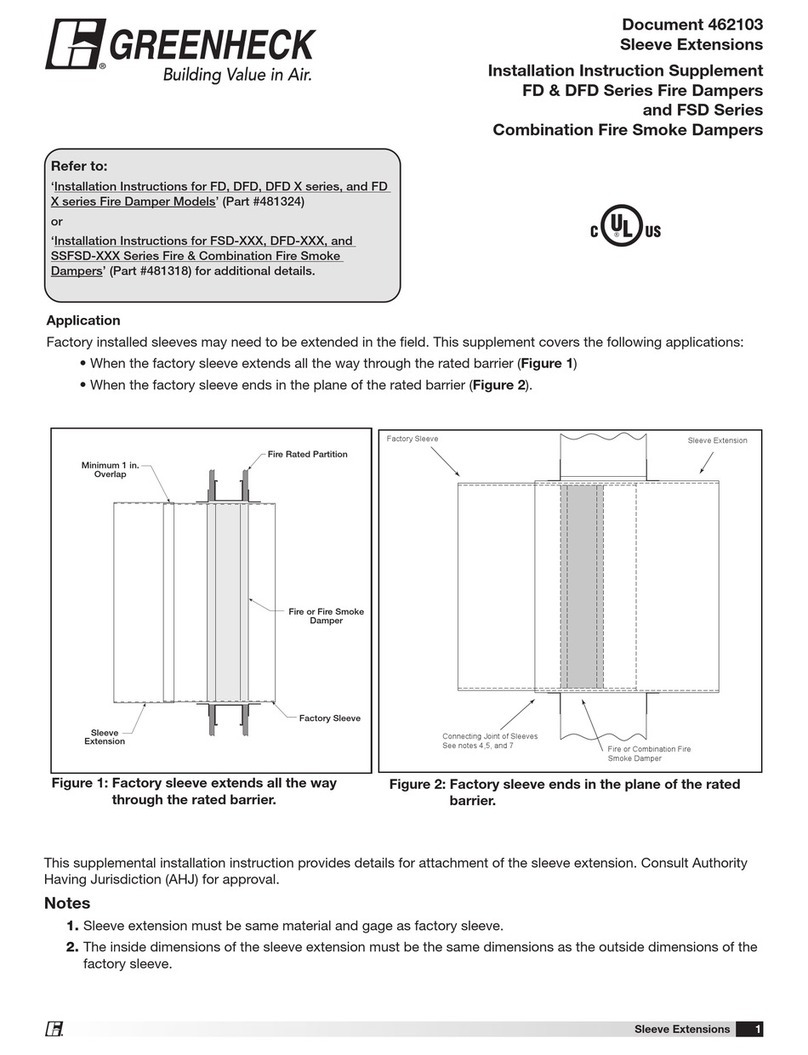

Fire dampers are shutters in ventilation duct systems that preventing spreading the fire and combustion gases from one fire compartment

to the other one by shutting of closing the air duct in the positions of fire separating constructions. In the case of FDMS the fire dampers

blade closes automatically air duct using a shutting spring or an return spring of its actuating mechanism in case of fire. In the case of

FDMS-VAV the fire damper has an additional function of the variable air flow controller. The return spring of the actuator is started when

the thermal fuse is activated or the actuator is without power supply. In the case of thermal electrical fuse the activation (closing)

procedure starts, when a reset button on fuse is pushed or when a power supply of the actuating mechanism is stopped. In case FDMS

of mechanical control with thermal fuse, the return spring is activated after the moment, when thermal fuse is melted. The damper´s blade

is sealed with a silicon gasket/packing preventing smoke penetration after closing the blade. At the same time, the damper´s blade will

be tighten by intumescent tape, which will be expanding in the case of fire. Dampers have no inspection door. For inspection of the

damper, there is an inspection hole for camera. For others service works there must by installed inspection door externally on the duct,

next to the fire damper. The damper is equipped with additional collar, around the position of the blade. On the collar, there are positioned

several metallic plates (fixtures for easy installation on the wall or ceiling construction.

■CE certified acc. to EN 15650

■Tested in accordance with EN 1366-2

■Classified acc. to EN 13501-3+A1

■Fire resistance EIS 45, EIS 60, EIS 90

■External casing leakage class min. C, internal leakage class 2 acc. EN 1751

■In case of FDMS cycling test in class C 10 000 acc. to EN 15650.

■In case of FDMS-VAV cycling test in class C 20 000 acc. to EN 15650 - CMOD classification

■Corrosion resistant acc. to EN 15650

■ES Certificate of conformity No. 1391-CPR-2020/0131

■Declaration of performance No. PM/FDMS/01/20/2, PM/FDMS-VAV/01/20/2

■Hygienic assessment of fire dampers - Report No. 1.6/pos/19/19b

Fire damper´s proper functioning is determined by the following working conditions:

■Maximum air speed: 12m/s.

■Maximum pressure difference: 2500 Pa.

■Operation of the dampers does not depend on the direction of air-flow (circulation). In case of FDMS-VAV the direction of

air-flow is strictly given.

■FDMS can be located in any (arbitrary) position.

■Dampers are suitable for ventilation air systems not containing any abrasive, chemical and adhesive particles.

■Dampers are designed for macroclimatic areas with mild climate according to EN 60721-3-3.

■Temperature in the place of installation is permitted to be in the range from -30°C to +50°C.