Instructions for Use SS 20.500 Ex –Supplement for use ATEX Page 6

The following standards and rules are useful:

oEN 1127-1: Explosion prevention and protection - Basic con-

cepts and methodology

oTRBS series

oStandards for explosive gas ("G") and dust atmospheres ("D"):

- EN 60079-14: Electrical apparatus for explosive atmospheres

- EN 60079-17: Inspection and maintenance

oStandards for explosive gas atmospheres ("G"):

- EN 60079-10-1: Classification of explosive gas atmospheres

oStandards for explosive dust atmospheres ("D"):

- EN 60079-10-2: Classification of explosive dust atmospheres

4 Application range

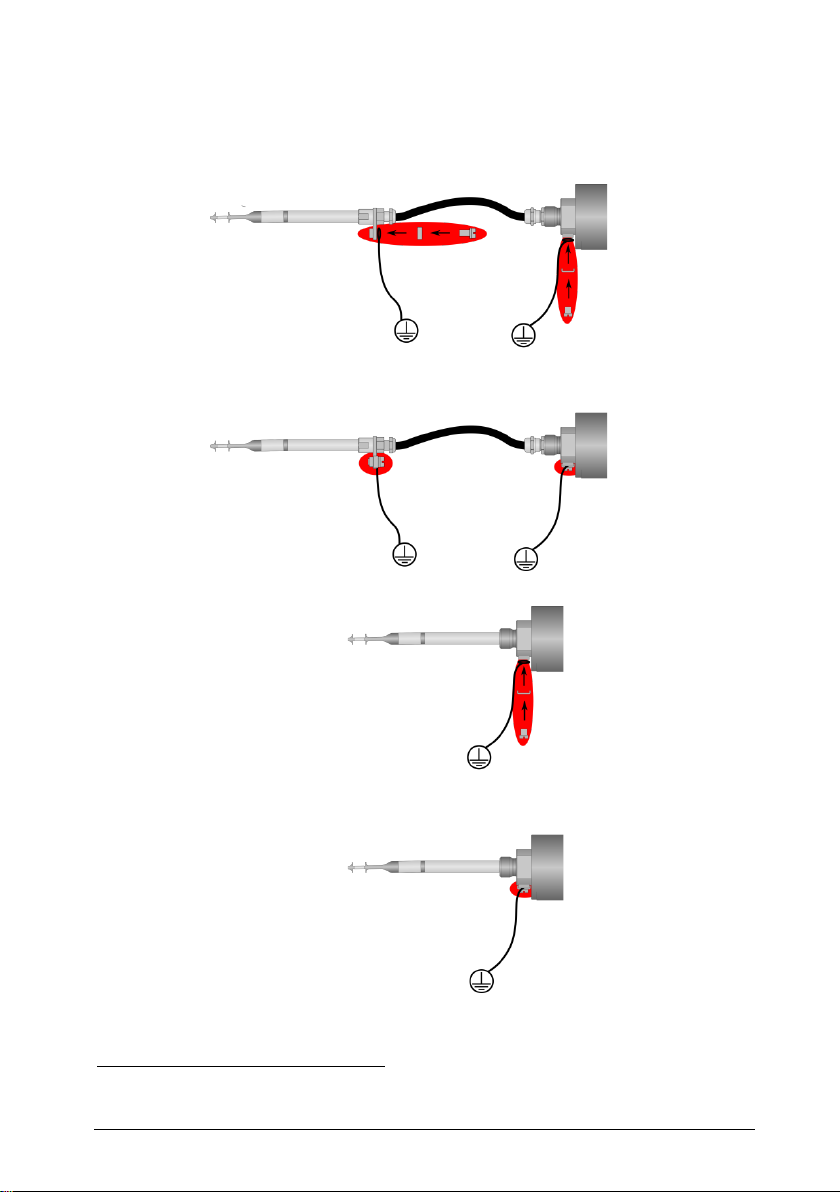

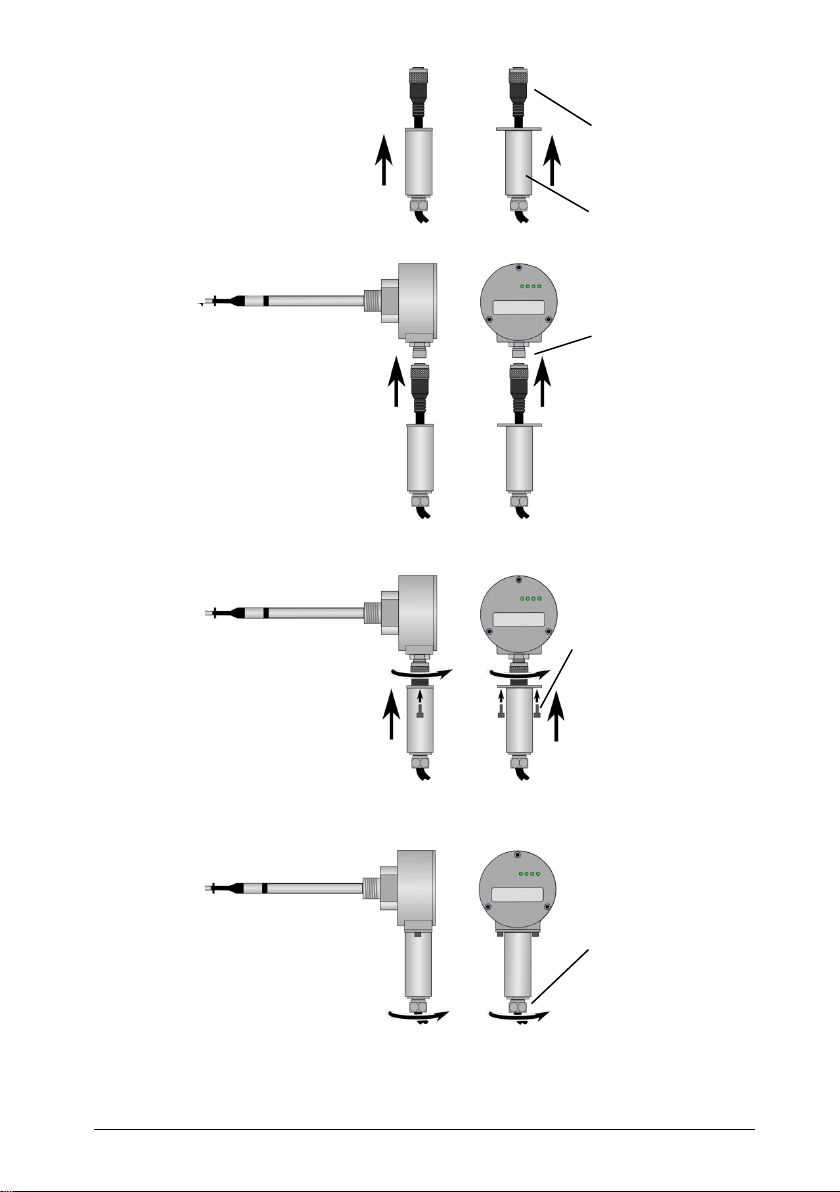

The ATEX version of the category 3 SCHMIDT®Flow sensor SS 20.500

Ex is designed for stationary measurement of the flow velocity as well as

the temperature of air or gas in potentially explosive atmospheres featur-

ing the following types of protection for:

oGases (Zone 2): II 3G Ex ec ic IIC T4 Gc

oDusts (Zone 22): II 3D Ex tc ic IIIC T135°C Dc

The sensor is suitable for use in atmospheres with combustible,

conductive dust with a smoldering temperature higher than 210 °C.

Special condition for use ("X"):

oThe main housing of the sensor may only be operated in an

area with a minimum degree of contamination 2, as defined in

IEC 60991-1.

oThis does not apply to the tube-shaped sensor probe (includ-

ing the connecting cable for the remote version).

The permissible operating temperatures are:

oElectronics : -20 ... +70 °C

oSensor probe: -40 ... +85 °C

Electrical datas:

oRated voltage : 24 VDC/AC ± 20 %

oRated current: 170 mA

oMeasurement outputs: 0 … 10 V / 4 … 20 mA

Enclosure:

oDegree of protecion: IP64