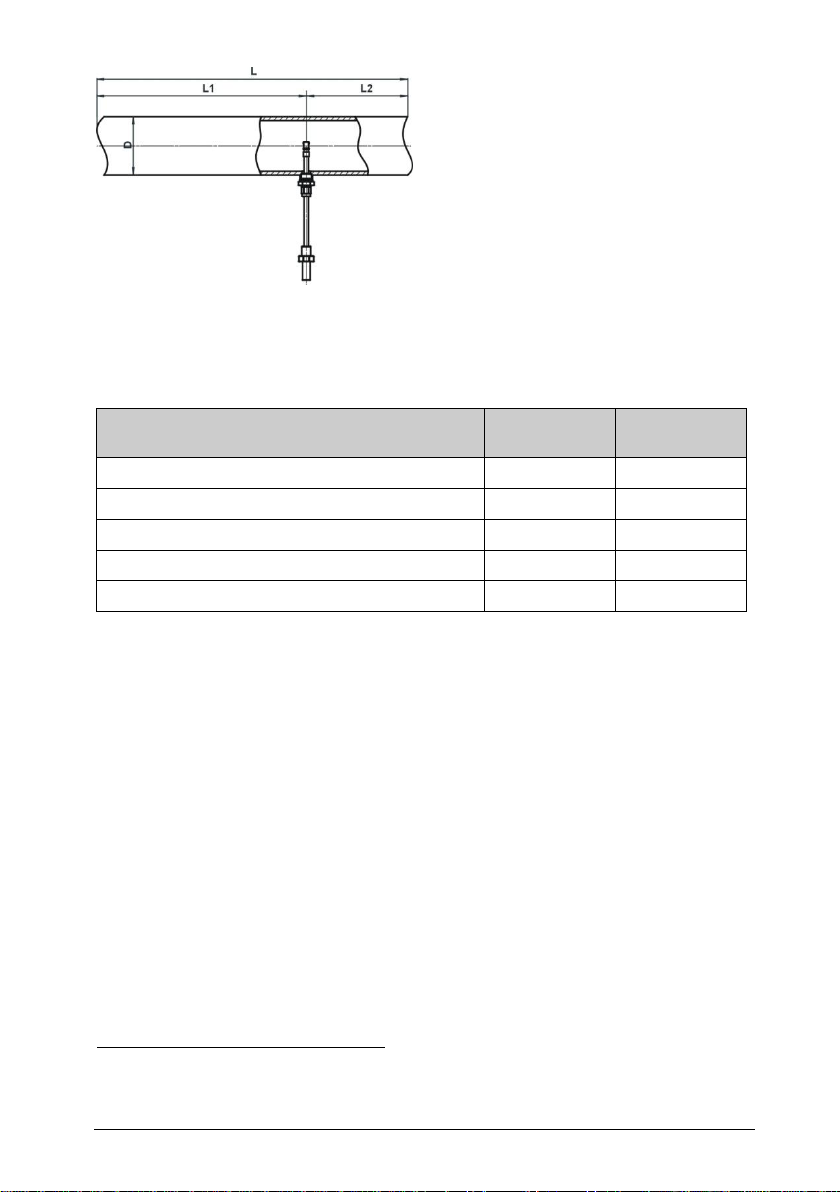

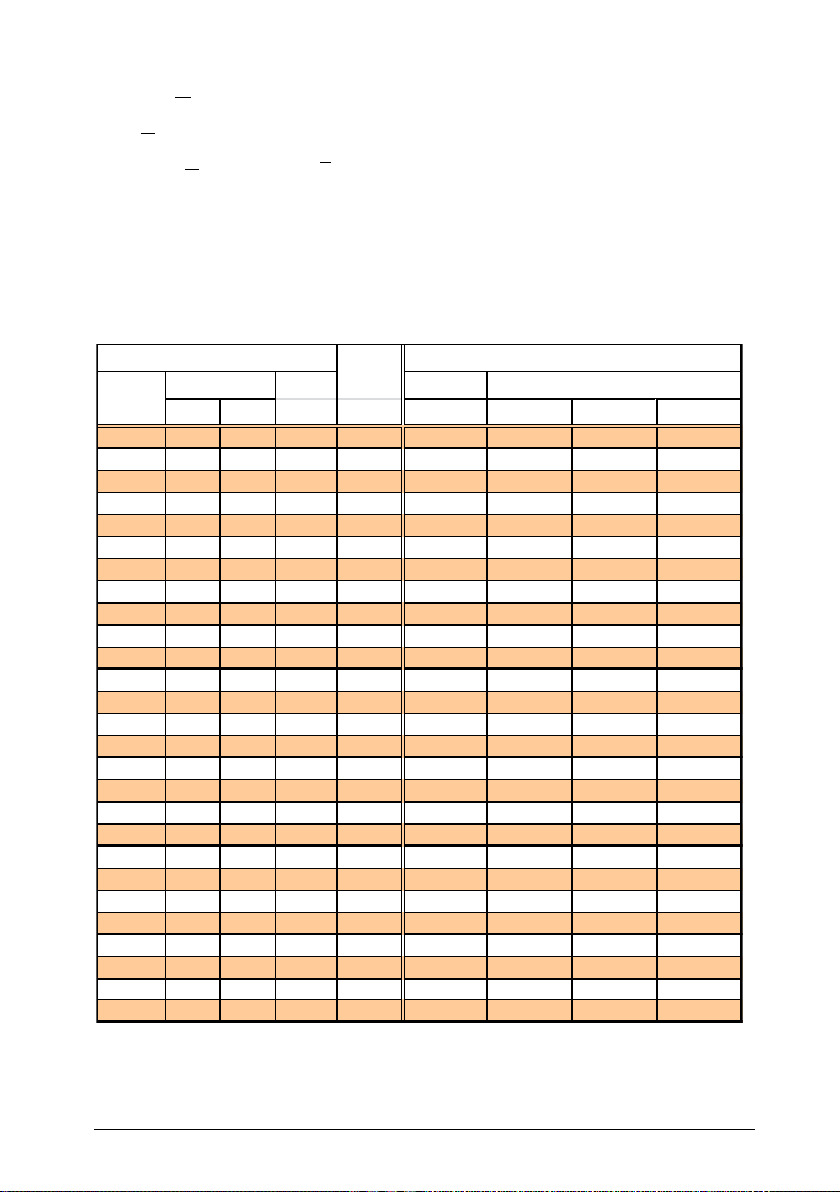

32 32,8 0.796 0.48 6.05 48.4 121

1 1/4 36,3 0.770 0.57 7.17 57.4 143

40 40 1 1/2 39,3 0.748 0.65 8.17 65.3 163

43,1 0.757 0.80 9.94 79.5 199

45,8 0.763 0.91 11.3 90.5 226

50 50 2 51,2 0.772 1.14 14.3 114 286

57,5 0.777 1.45 18.2 145 363

65 65 2 1/2 70,3 0.786 2.20 27.5 220 549

76,1 0.792 2.59 32.4 259 648

80 80 3 82,5 0.797 3.07 38.3 307 767

100 100 4 100,8 0.804 4.62 57.7 462 1.155

125 125 5 125,0 0.812 7.17 89.7 717 1.794

150 150 6 150,0 0.817 10.4 130 1.040 2.599

180 182,5 0.825 15.5 194 1.554 3.885

200 200 8 206,5 0.829 20.0 250 1.999 4.998

250 10 260,4 0.835 32.0 400 3.202 8.004

300 300 12 309,7 0.840 45.6 570 4.556 11.390

350 14 339,6 0.842 54.9 686 5.491 13.728

400 400 16 389 0.845 72.2 903 7.223 18.058

450 450 18 437 0.847 91.5 1.143 9.147 22.867

500 500 20 486 0.850 114 1.419 11.353 28.383

600 600 24 585 0.854 165 2.066 16.527 41.317

700 700 28 684 0.857 227 2.834 22.673 56.683

800 800 32 783 0.859 298 3.723 29.781 74.452

900 900 36 882 0.862 379 4.740 37.920 94.800

1000 1000 40 980 0.864 469 5.865 46.923 117.308