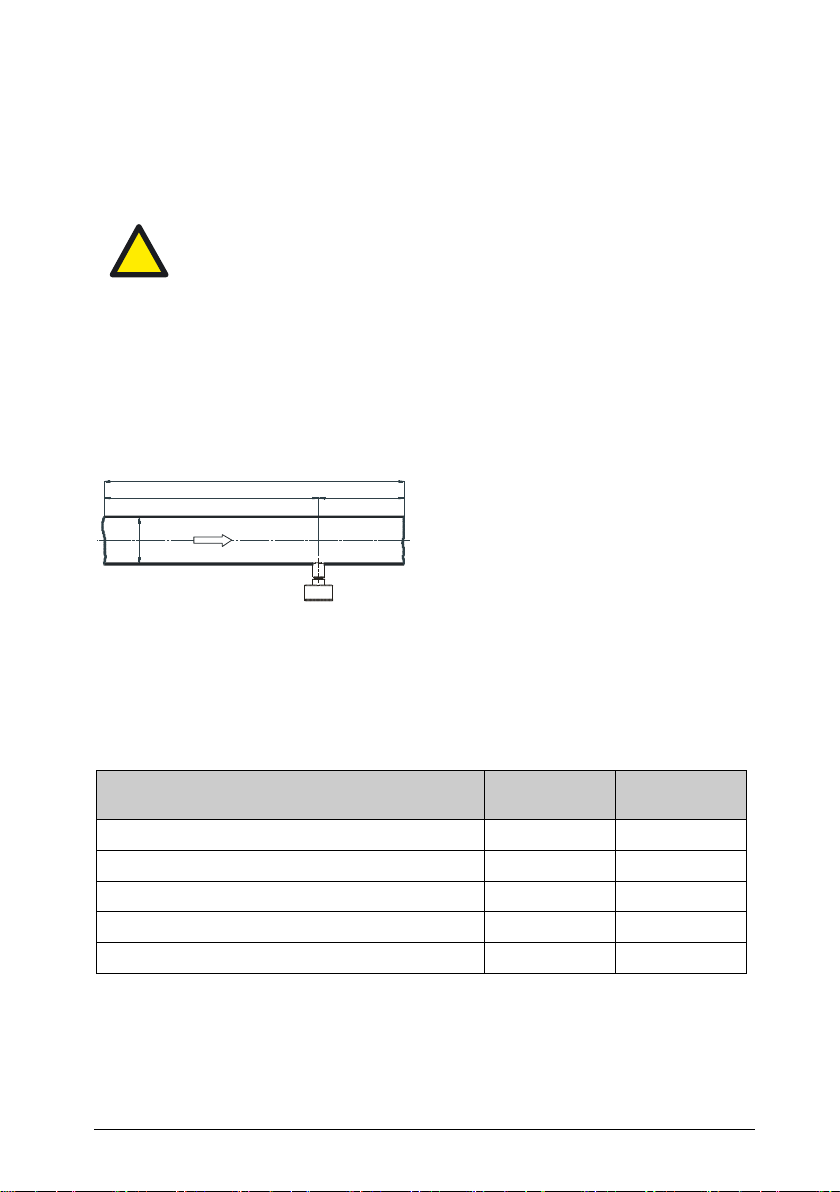

Instructions for Use SS 20.261 Page 9

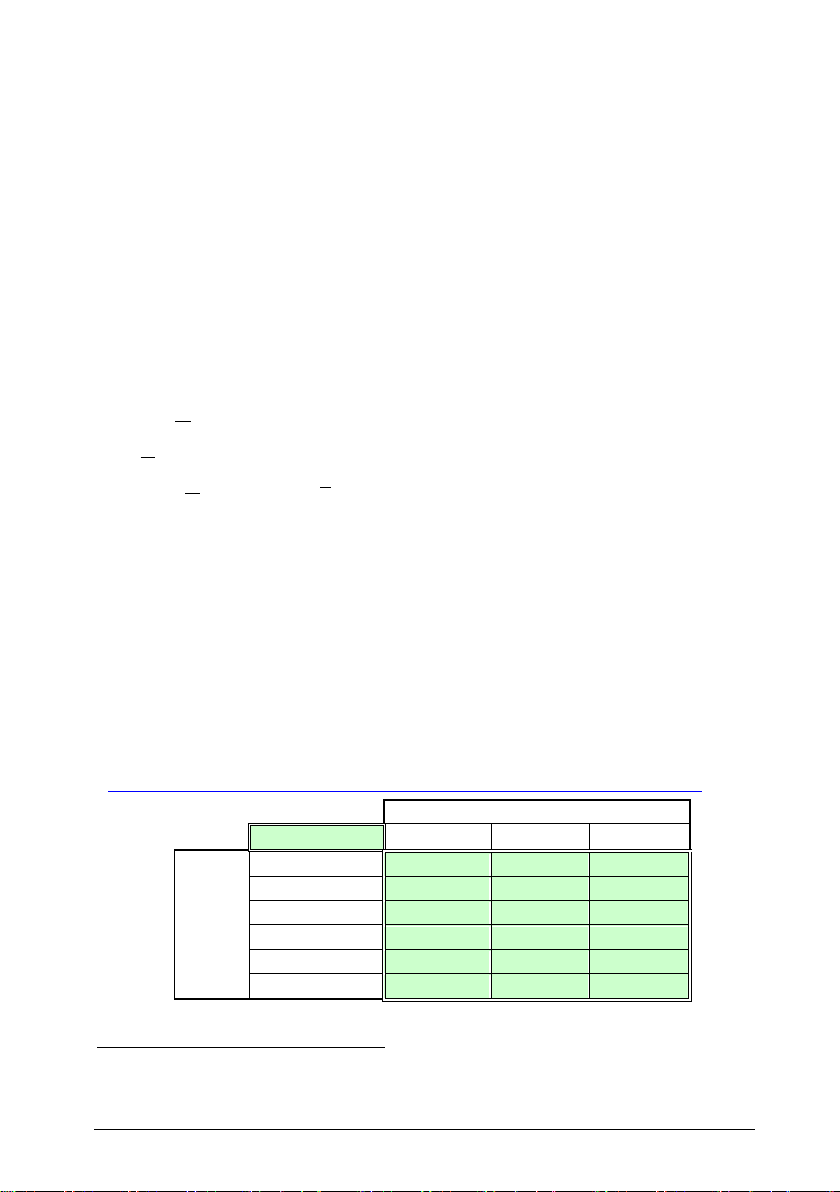

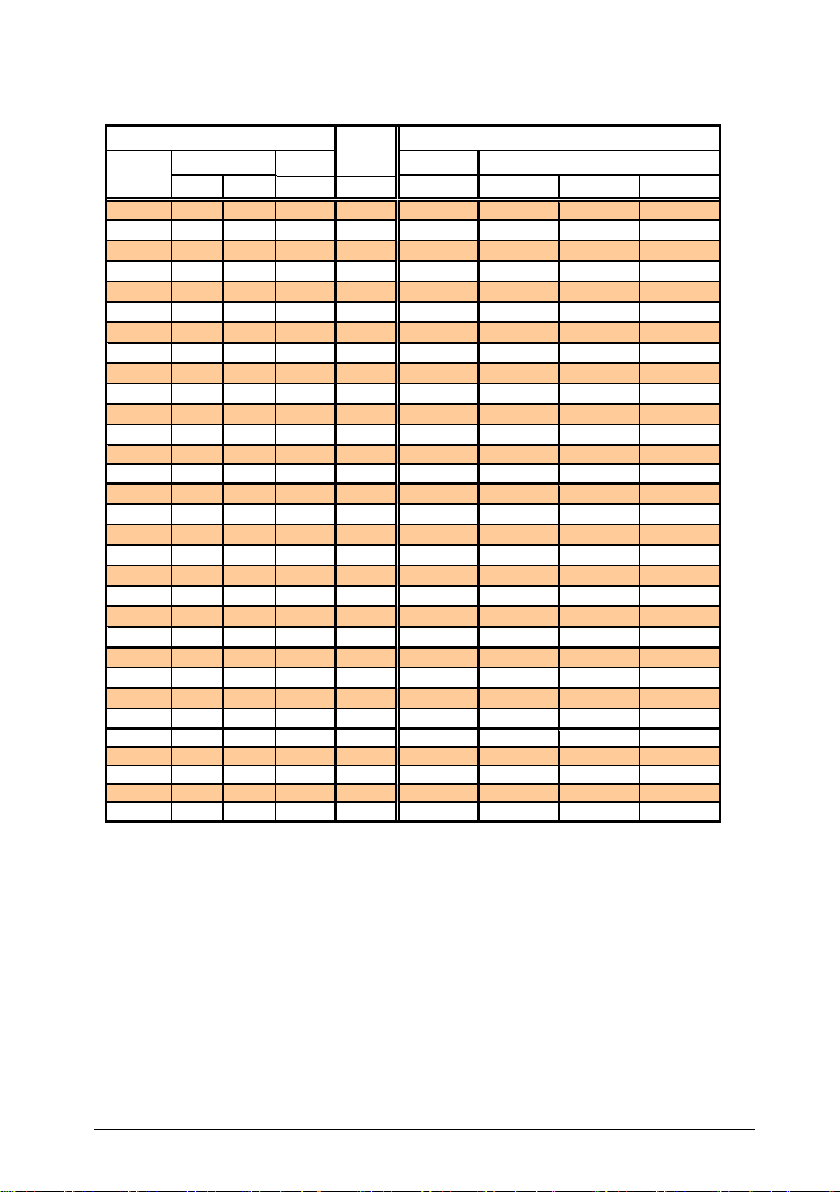

Table 3 lists profile factors and volume flow measuring ranges (with

certain sensor measuring ranges) for standard pipe diameters.

Table 3

[mm] PF 0.2 m/s 40 m/s 60 m/s 90 m/s

25 25 126.0 0.796 0.30 61 91 137

28.5 0.796 0.37 73 110 165

32 32.8 0.796 0.48 97 145 218

1 1/4 36.3 0.770 0.57 115 172 258

40 40 1 1/2 39.3 0.748 0.65 131 196 294

43.1 0.757 0.80 159 239 358

45.8 0.763 0.91 181 272 407

50 50 251.2 0.772 1.14 229 343 515

54.5 0.775 1.30 260 391 586

57.5 0.777 1.45 291 436 654

64.2 0.782 1.82 365 547 820

65 65 2 1/2 70.3 0.786 2.20 439 659 988

76.1 0.792 2.59 519 778 1,167

80 80 382.5 0.797 3.07 614 920 1,380

100 100 4100.8 0.804 4.62 924 1,386 2,079

110 107.1 0.806 5.23 1,046 1,568 2,353

125 125 5125.0 0.812 7.17 1,435 2,152 3,229

130 125 131.7 0.814 7.98 1,597 2,395 3,593

150 150 6150.0 0.817 10.40 2,079 3,119 4,678

160 159.3 0.820 11.77 2,353 3,53 5,295

170 182.5 0.825 15.54 3,108 4,661 6,992

190 190.0 0.826 16.86 3,372 5,059 7,588

200 200 206.5 0.829 19.99 3,998 5,997 8,996

250 260.4 0.835 32.02 6,404 9,605 14,408

300 300 309.7 0.840 45.56 9,112 13,668 20,502

350 339.6 0.842 54.91 10,982 16,474 24,711

400 400 388.8 0.845 72.23 14,446 21,670 32,505

450 450 437.0 0.847 91.47 18,294 27,440 41,161

500 500 486.0 0.850 113.53 22,706 34,059 51,089

550 550 534.0 0.852 137.39 27,477 41,216 61,824

600 600 585.0 0.854 165.27 33,054 49,581 74,371

Diameter of measuring pipe

@ sensor measuring range [m/s]