Instructions for Use SS 20.651 page 8

Operating voltage

For proper operation, the sensor requires DC voltage with a nominal val-

ue of 24 VDC with a permitted tolerance of ± 20 %.

Deviating values can lead to measurement errors or even defects and,

therefore, should be avoided.

The operating current of the sensor (including analog signal currents) is

normally approx. 50 mA (max. 250 mA).

The specifications for the operating voltage are valid for the connection

to the sensor. Voltage drops generated due to line resistances must be

taken into account by the customer.

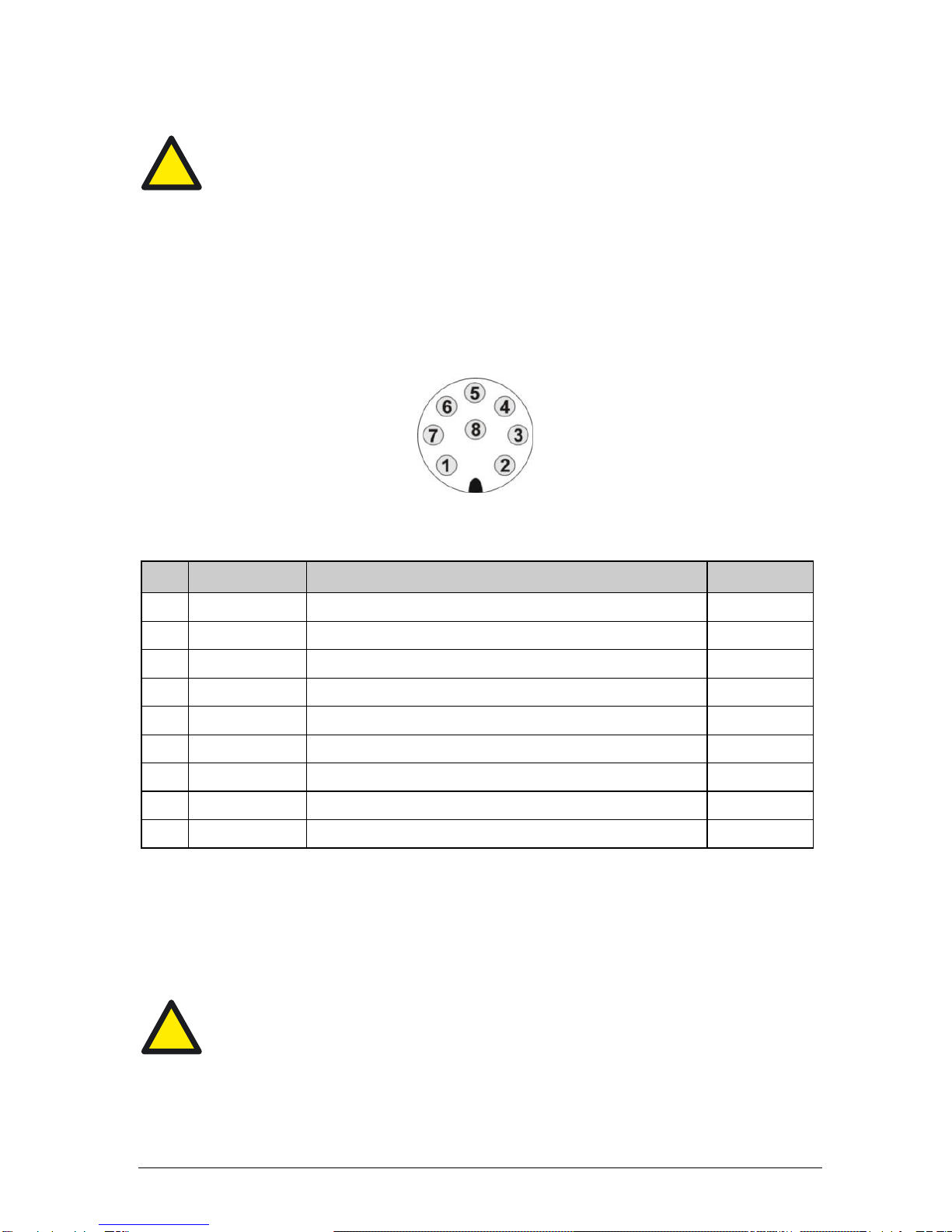

Wiring of analog outputs

Both analog outputs, for flow and temperature, are designed as high-side

drivers with "Auto-U/I" characteristic which are short circuit protected

against both rails of the operating voltage.

The loading resistance RLmust be connected between the correspond-

ing signal output and the electronic reference potential AGND or GND of

the sensor.

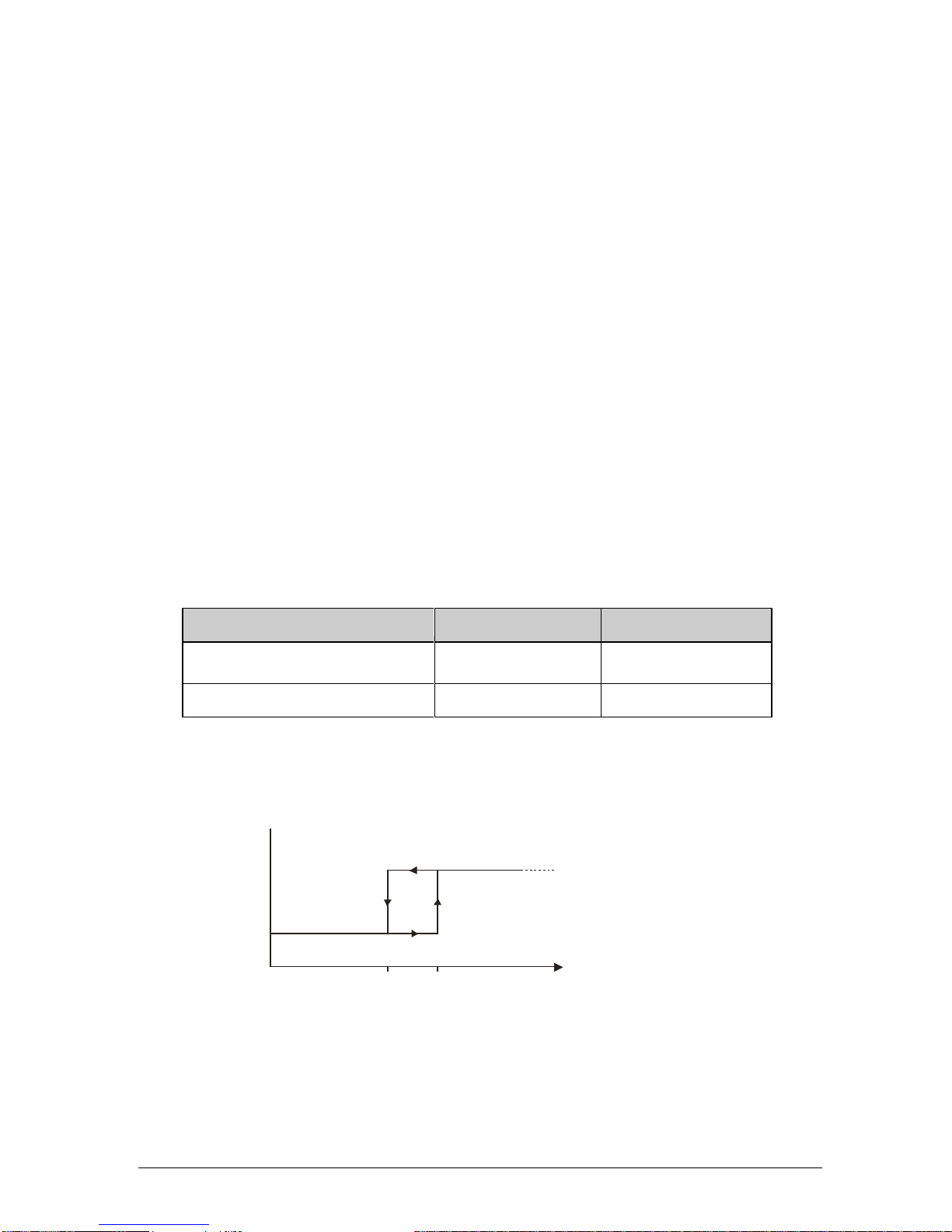

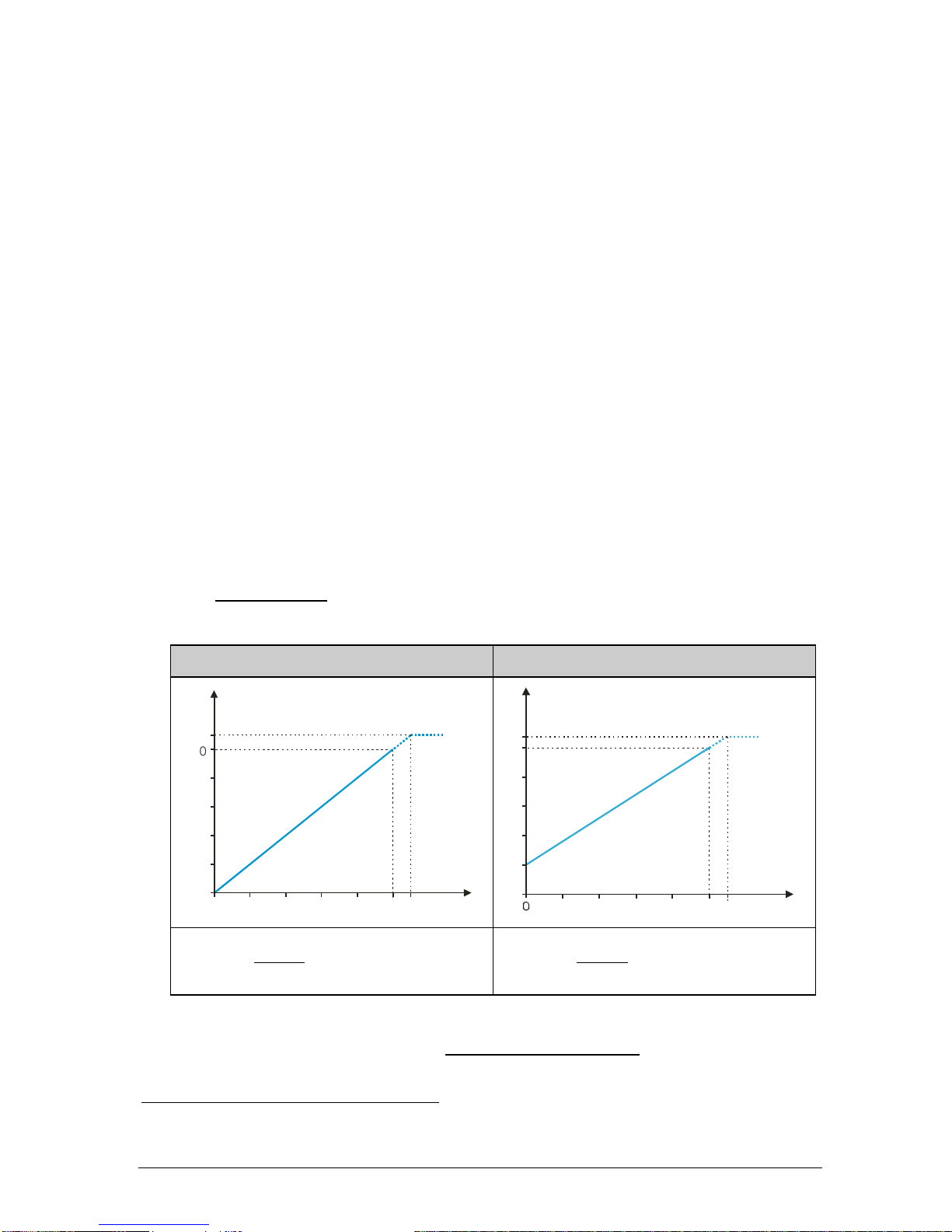

Depending on the resistance value RL, the signal electronics switches

automatically between its operation as voltage interface (mode: U) or

current interface (mode: I), hence the designation "Auto-U/I". The switch-

ing threshold is in range between 500 and 550 (for details, refer to the

next subchapter Signaling of analog outputs).

However, a low load resistance value in voltage mode may cause signifi-

cant voltage losses via line resistances RW,S, which can lead to measur-

ing errors.