Instructions for Use SS 20.60 Page 3/16

1 Important Information

These instructions for use must be read completely and observed

carefully, before putting the unit into operation.

Any claims under the manufacturer's liability for damage resulting

from non-observance or non-compliance with these instructions

will become void.

Tampering with the device in any way whatsoever - with the

exception of the designated use and the operations described in

these instructions for use - will forfeit any warranty and exclude

any liability.

The unit is designed exclusively for the use described below (s.

chapter 2 Range of Applications) In particular, it is not designed

for direct or indirect personal protection.

SCHMIDT Technology cannot give any warranty as to its

suitability for a certain purpose and cannot be held liable for errors

contained in these instructions for use or for accidental or

sequential damage in connection with the delivery, performance

or use of this unit.

2 Range of Applications

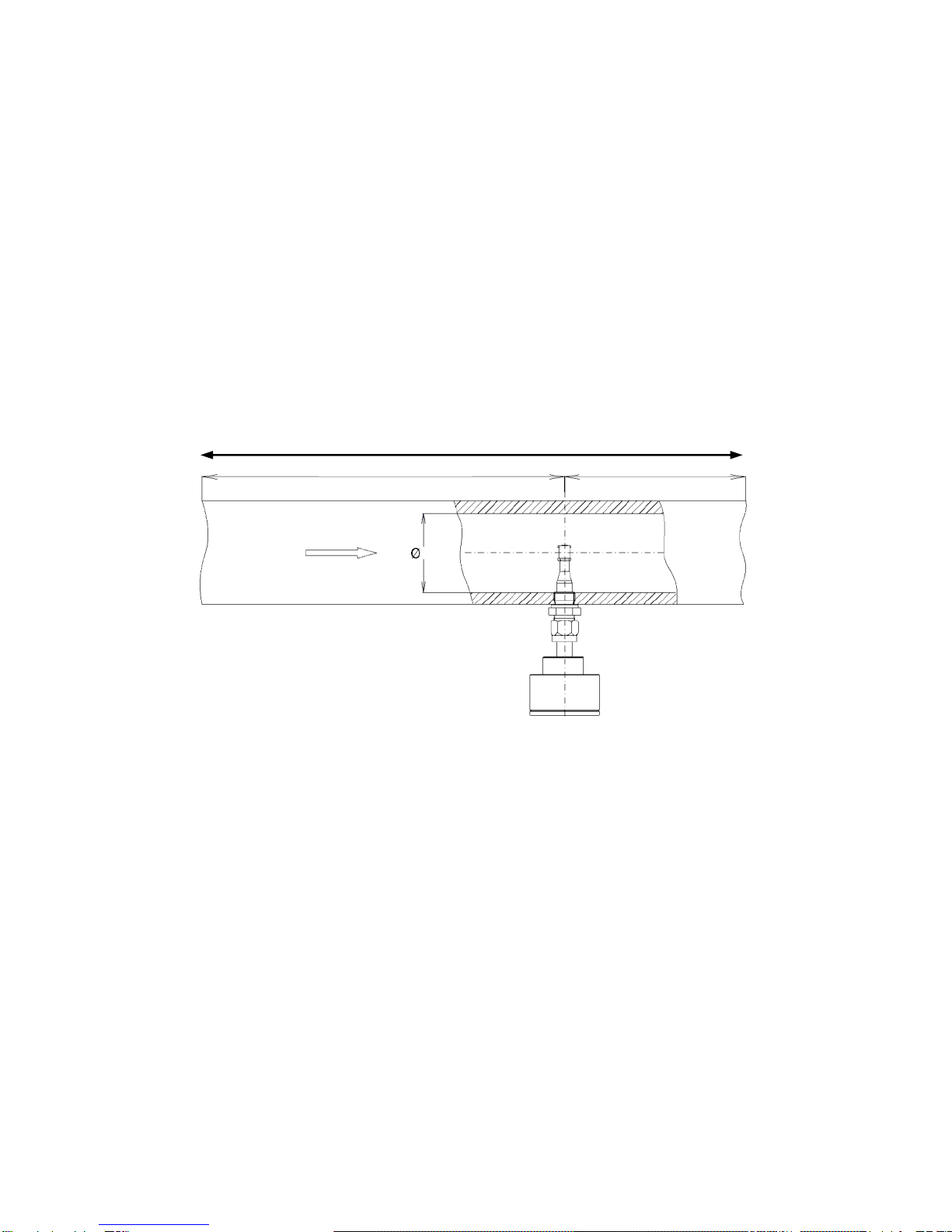

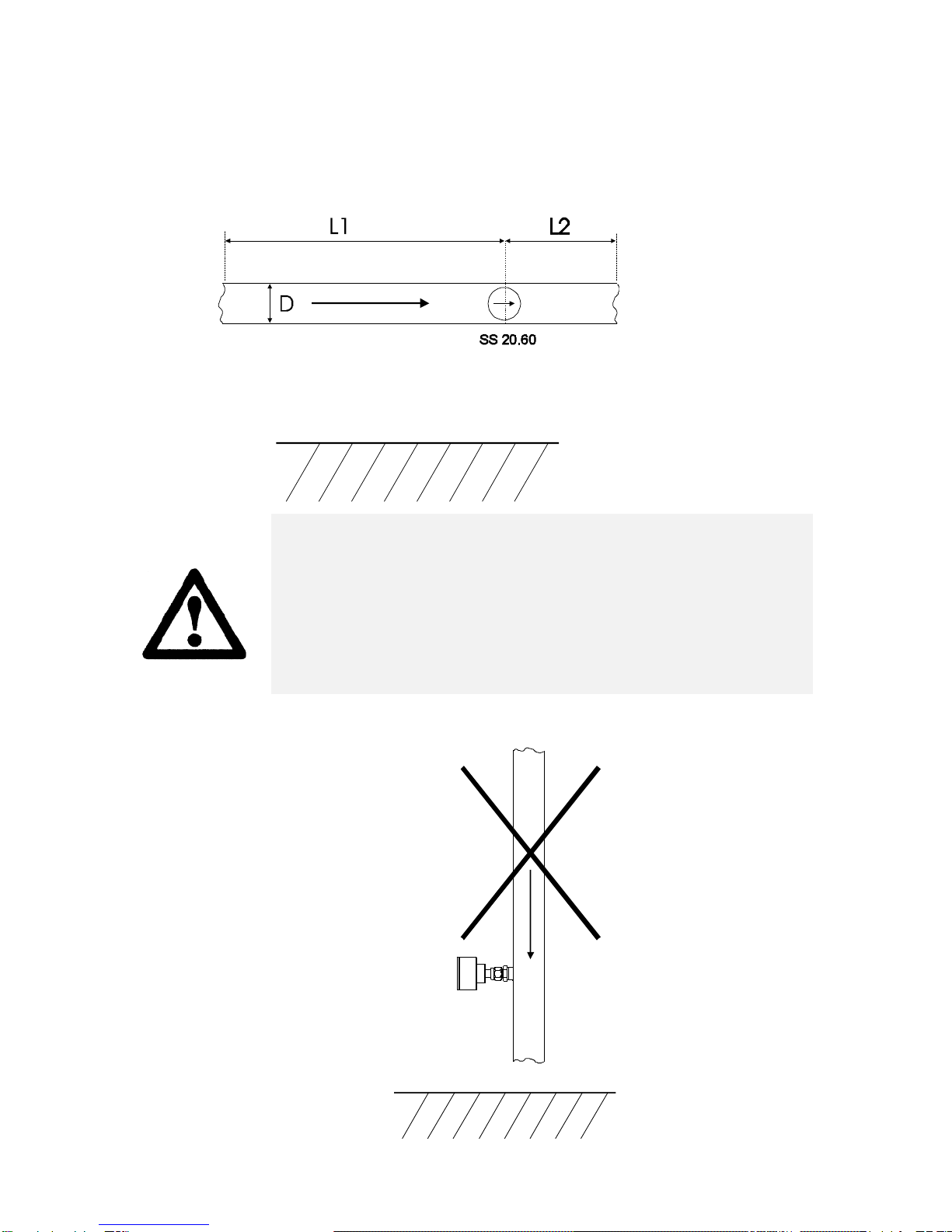

The SCHMIDT®flow sensor SS 20.60 is designed for stationary

use in compressed air pipes, air ducts or air shafts under

atmospheric pressure conditions. The sensor measures the flow

velocity of the measuring medium as standard velocity (unit m/s),

relative to the standard pressure of 1013.25 hPa and the standard

temperature of 20°C. The output signal is linear and independent

of the pressure and temperature of the medium. When mounting

the sensor in a tube, the output signal of the flow velocity can be

used to calculate the standard volumetric flow or the mass flow of

the medium. Please refer to the separate table “SS 20.60 Profile

Factors”.

When using the sensor outdoors, it must be protected against

direct ex-posure to the weather.