Table of contents

SCHMIDT®HydroPneumaticPress 361-376 –V3.1 3

Table of contents

1Safety..................................................................4

1.1 Designated use.....................................................................................4

1.2 Organizational measures of the owner.................................................4

1.3 Residual risks........................................................................................5

1.4 Noise emission of the press..................................................................6

1.5 Standards and regulations....................................................................6

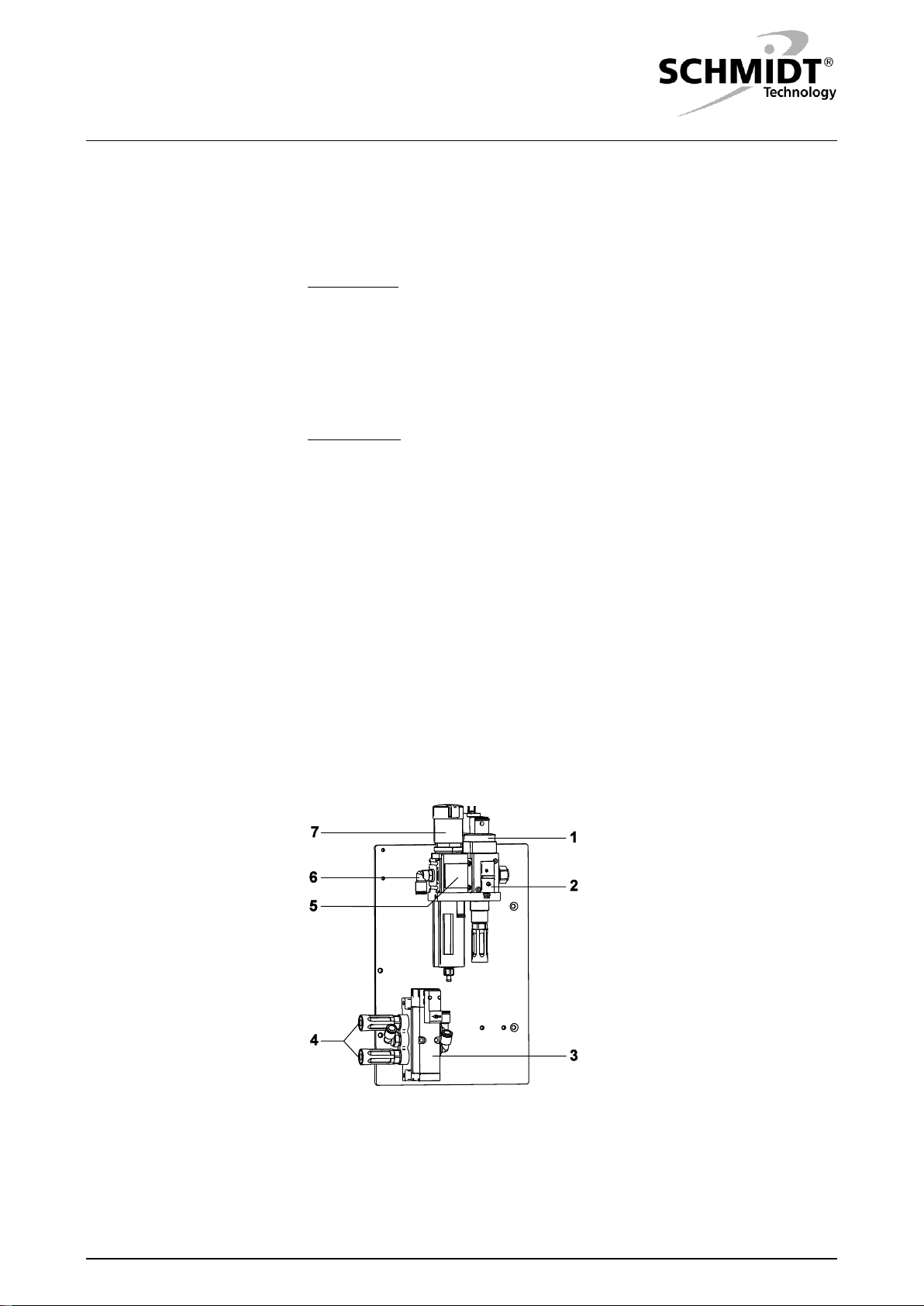

2HydroPneumaticPress.......................................7

2.1 HydroPneumaticPress ..........................................................................7

2.2 Pneumatic block (optional)....................................................................8

3Assembly and start-up....................................11

3.1 Delivery ...............................................................................................11

3.2 Transport.............................................................................................11

3.3 Installation of the press.......................................................................12

3.4 Mounting tools.....................................................................................14

3.5 Adjusting the working height...............................................................16

3.6 Adjusting the working stroke...............................................................19

3.7 Connecting the compressed air..........................................................20

3.8 Setting the stroke takeover .................................................................21

4Maintenance and servicing.............................22

4.1 Checking the compressed air preparation..........................................23

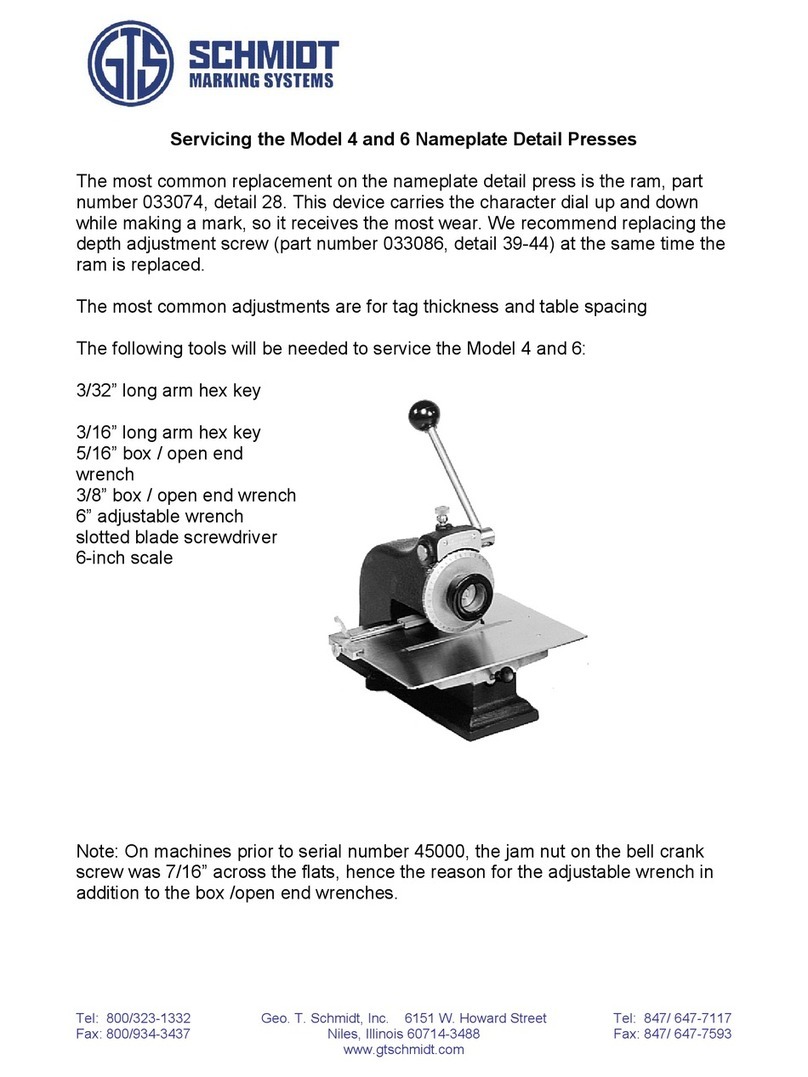

4.2 Cleaning the press and the ram..........................................................23

4.3 Checking the ram guiding ...................................................................23

4.4 Checking the hydraulic hoses.............................................................24

4.5 Adjusting the force measurement.......................................................25

4.6 Checking the stroke sensor ................................................................25

4.7 Checking the oil level..........................................................................26

4.8 Check height adjustment ....................................................................27

4.9 Troubleshooting ..................................................................................28

4.10 Customer service................................................................................29

5Decommissioning and disposal.....................30

5.1 Decommissioning................................................................................30

5.2 Disposal ..............................................................................................30

6Appendix..........................................................32

6.1 Technical data.....................................................................................32

6.2 Pressure/Force diagrams....................................................................33

6.3Air consumption ..................................................................................34

6.4 Tightening torques ..............................................................................34