Safety Section 1-5

SAFETY

© 2003Alamo Group Inc.

SAFETY

SRW800 07/03

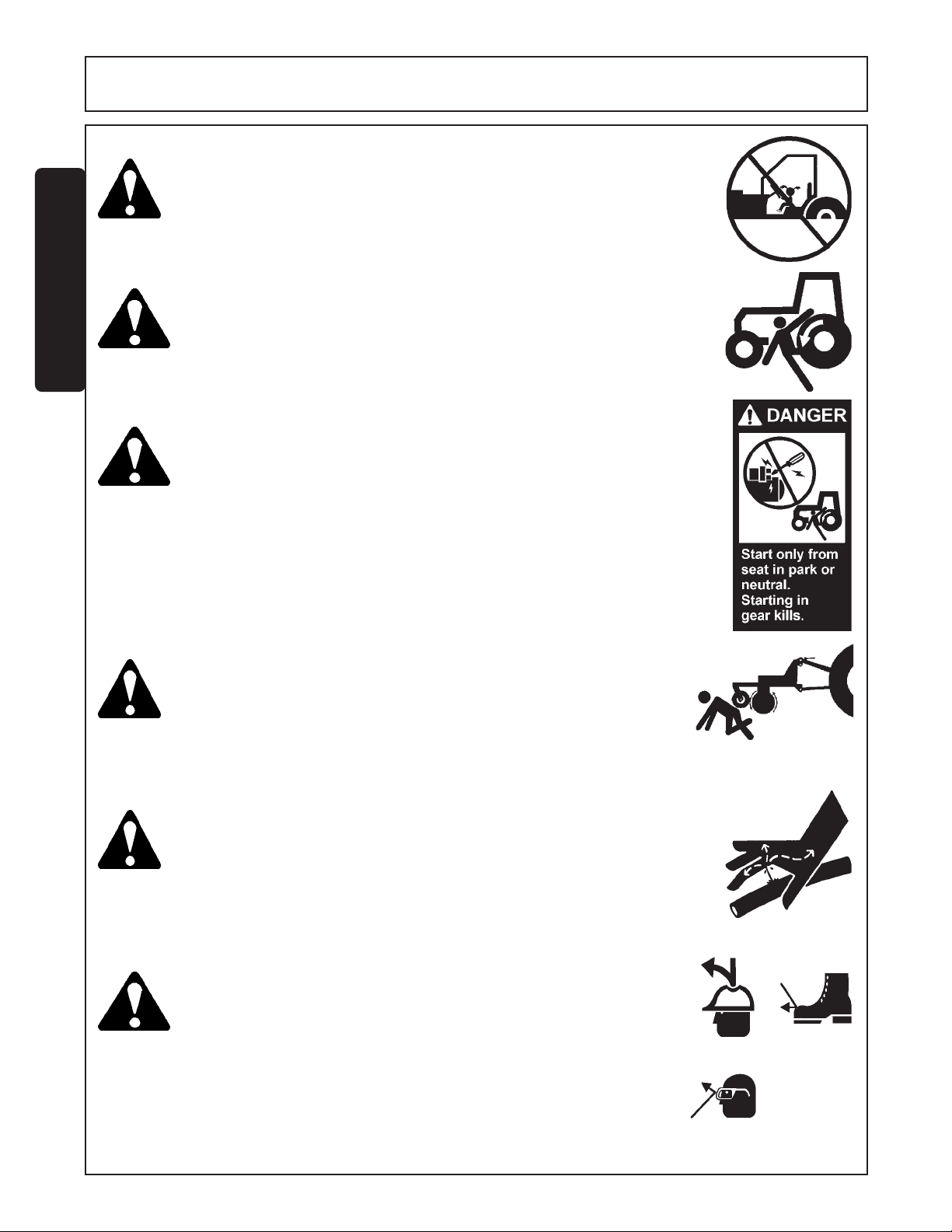

WARNING! Transportonlyat safe speeds. Seriousaccidentsand injuries canresult

fromoperatingthis equipmentatunsafe speeds. UnderstandtheTractor

and Implement and how it handles before transporting on streets and

highways. Makesurethe Tractorsteeringand brakesarein goodcondi-

tionandoperate properly.

Beforetransportingthe TractorandImplement,determine thesafe

transportspeedsforyou and theequipment. Make sure you abide by

thefollowingrules:

Be aware of the operating conditions. Do not operate the Tractor with

weakorfaultybrakes. When operatingdownahill or onwetorrain slick

roads,thebraking distanceincreases:useextremecare andreduceyour

speed. Whenoperatingin traffic alwaysusethe Tractor’sflashingwarn-

ing lights and reduce your speed. Be aware of traffic around you and

watch out for the other guy. (SG-19)

Test the equipment at a slow speed in turns. Increase the speed

through the turn only after you determine that it is safe to operate

at a higher speed. Use extreme care and reduce your speed when

turning sharply to prevent the tractor and implement from turning

over. Determine the maximum safe turning speed for you and this

equipmentbeforeoperatingonroadsoruneven ground.

Only transport the Tractor and Implement at the speeds that you

have determined are safe and which allow you to properly control the

equipment.

Test the tractor at a slow speed and increase the speed slowly.

Apply the Brakes smoothly to determine the stopping

characteristicsoftheTractor and Implement.

As you increase the speed of the Tractor the stopping distance

increases. Determine the maximum safe transport speed for

you and this Equipment.

2.

1.

3.

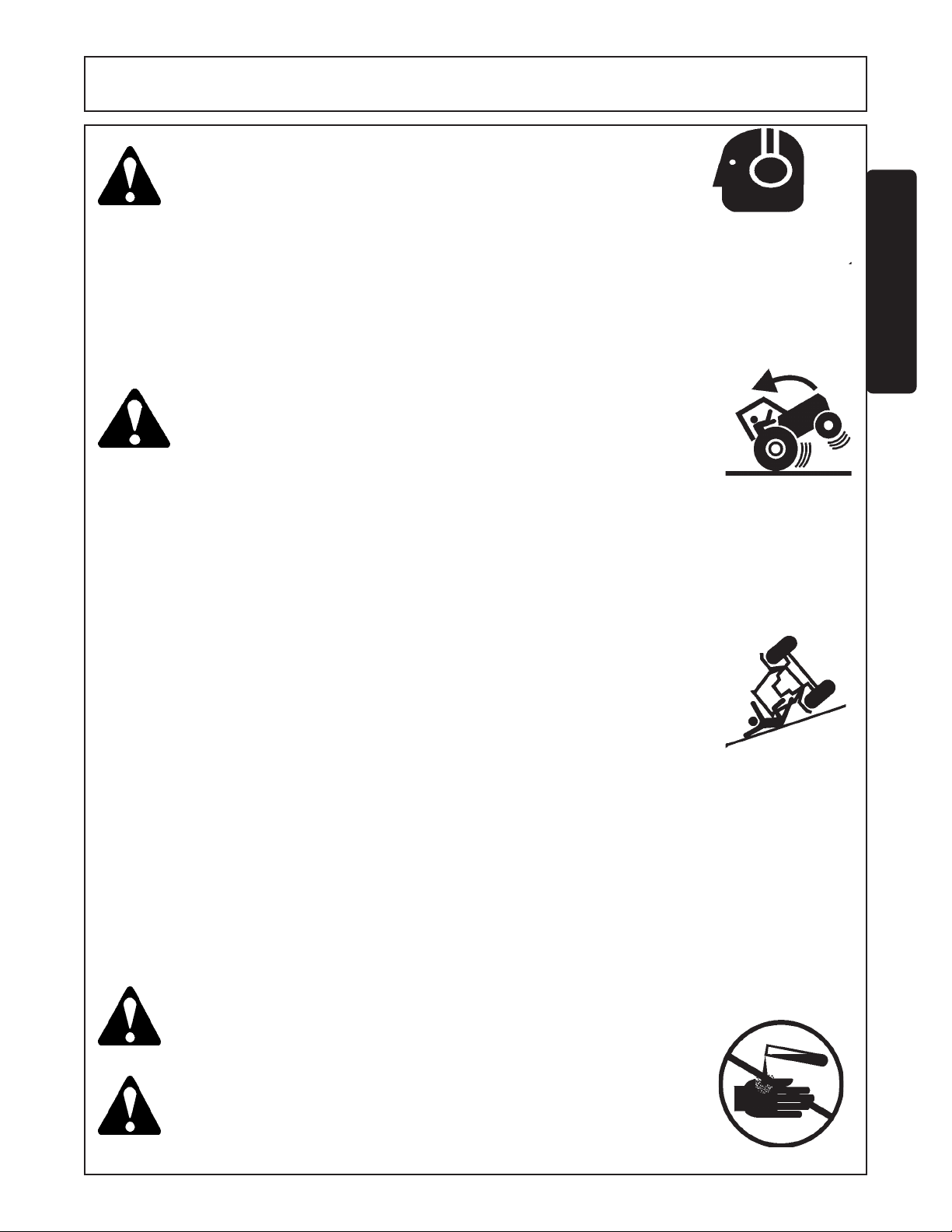

WARNING! Never attempt to lubricate, adjust, or remove material from the

Implementwhileitisinmotionorwhiletractorengineisrunning. Make

sure the tractor engine is off before working on the Implement.

(SG-20)

CAUTION! PROLONGED EXPOSURE TO LOUD NOISE MAY CAUSE

PERMANENT HEARING LOSS! Tractors with or without an

Implement attached can often be noisy enough to cause permanent

hearing loss. We recommend that you always wear hearing

protection if the noise in the Operator’s position exceeds 80db.

Noise over 85db over an extended period of time will cause severe

hearing loss. Noise over 90db adjacent to the Operator over an

extended period of time will cause permanent or total hearing loss.

Note: Hearing loss from loud noise [from tractors, chain saws,

radios, and other such sources close to the ear] is cumulative over a

lifetime without hope of natural recovery. (SG-I7)

WARNING! Alwaysreadcarefullyandcomplyfullywiththemanufacturersinstructions

when handling oil, solvents, cleansers, and any other chemical agent.

(SG-22)