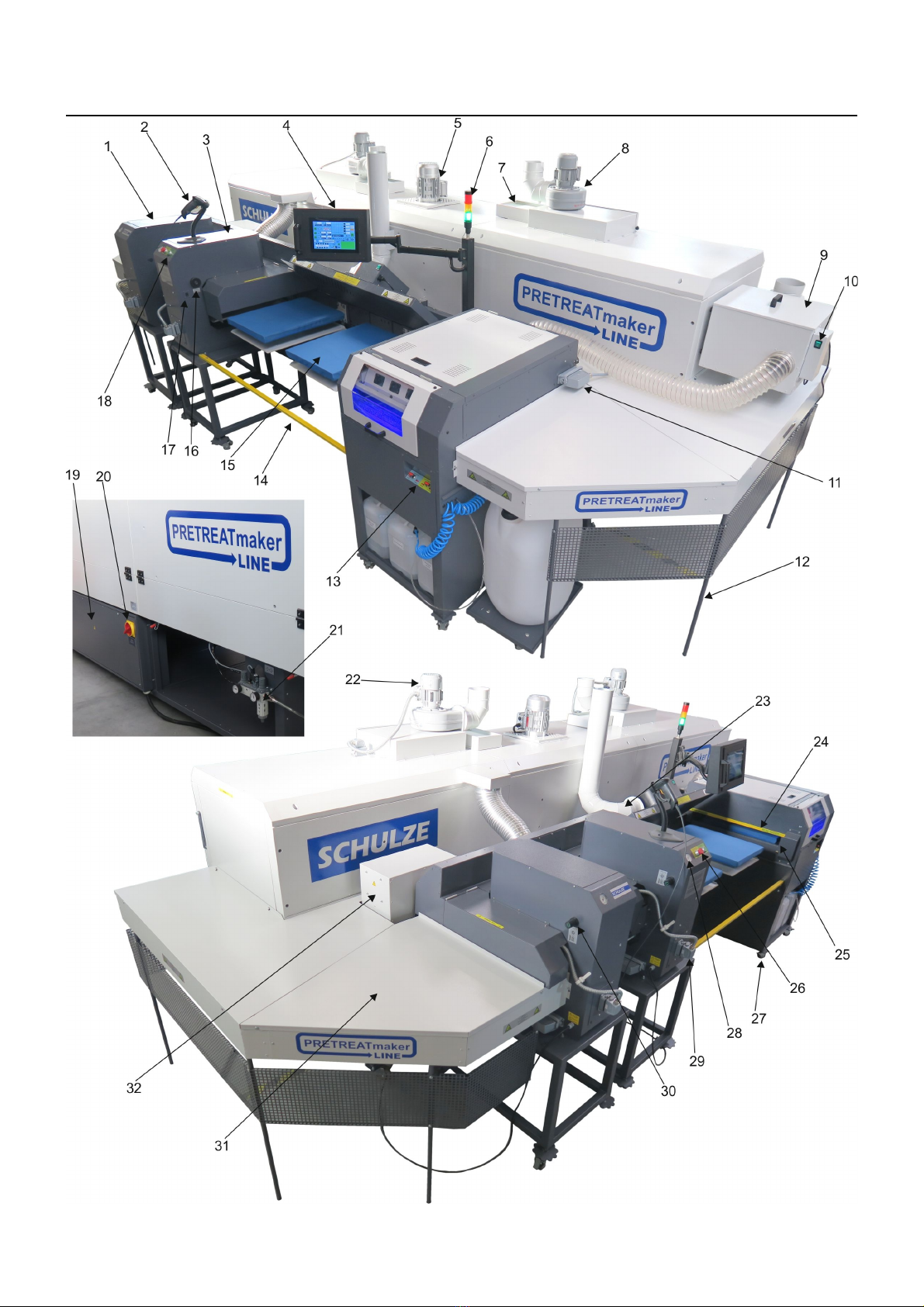

4. Setting the temperature of the IR

After touching the field, the keyboard will appear on the display. Max. temperature of the IR is 350ºC. Recommended temperature is

300ºC.

5. Current power consumption of the IR

Power consumption level, expressed as percentage. While warming up the drying tunnel, the power consumption reaches 100%.

After the programmed tempeature is reached, the power consumption is reduced till around 80%. Power consumption level depends

on the external conditions and on the number of t-shirts that are currently in the drying tunnel.

6. Current temperature of the IR

Current temperature of the heat elements is shown on the display.

7. Switching on the heating of the machine

After touching the icon, the drying tunnel warms up till the programmed temperature (base plates are moving slowly). After the

programmed temperature is reached, the machine goes into standby mode (ready).

8. Switching off the heating of the machine

After touching the icon, the heat elements in the drying tunnel switch off.

9. ECO mode

After touching the icon, the ECO mode gets activated. The temperature of the drying tunnel sinks down by 50ºC, and the base plates

are moving slowly (like when the machine is warming up). To switch off the ECO mode touch the ON icon on the display (7) Then the

machine will warm up again to the programmed temperature. If the machine stays in standby mode longer than 15 minutes, it goes

automatically to the ECO mode.

10. Current condition of the machine

OFF - heat elements are switched off

WARMING - the machine warms up

READY - the machine is ready to work

ECO - ECO mode is activated

11. anual closing / opening the press

When the automatic mode is switched off, it is possible to close the press manually. After pressing the icon press will close. It will

open after the adjusted time runs out. In order to open the press earlier, the icon needs to be pressed again.

12. Setting the temperature of the heat press

After touching the field, the keyboard will appear on the display. Max. temperature of the heat plate is 0 ºC. Recommended

temperature is 180ºC

13. Setting the presstime of the heat press

After touching the field, the keyboard will appear on the display. Time of the pressing can be adjusted between 1 – 5 seconds. It is

recommended to set it on 8 seconds.

14. Current temperature of the heat press

The current temperature of the heat plate is shown on the display.

15. Current power consumption of the heat press

Power consumption level expressed as percentage.

16. Setting of the exhaust ventilator.

After touching the field, the keyboard will appear on the display. The speed of the exhaust ventilator can be settled between 1 and 10.

17. Daily counter

Number of cycles performed during one run.

18. Preview

It can be checked, which plates are covered with t-shirt, and what times of pressing are adjusted for each of them. If the plate without

t-shirt will arrive to the pressing or pretreatment station, the station will not activate.

19. Switching the nozzles on/off (print width)

After touching the right field, the nozzle will switch on or off.

20. Printing range (print length)

Quick adjustment of the printing range (every 10 cm).

21. Setting preview of the pretreatment station

22. Settings selection

This function allows to choose between previously saved settings. To save settings touch and hold for some seconds one of the icons

(F1-F6). Information „settings saved” will show up on the screen.

23. Reset the counter

24. Cycle counter

Number of the performed cycles since last reset will show up on the screen.

25. Automatic mode ON / OFF

This function allows to switch on or off the automatic mode. When the automatic mode is activated, the first cycle has to be switched

on with the START button, which is situated in front part of the press. Next cycles will switch on automatically after the programmed

time runs out. When the automatic mode is switched off, each cycle has to be preceded by pushing the START switch. Next cycle will

begin after the adjusted time of the cycle runs out.

26. Current cycle time

It shows the current time of the cycle. After it runs out the machine will start another cycle automatically (in the automatic mode).

27. Setting the time of the cycle (+/-)

With the icons + i – time of the cycle can be adjusted. Max. time which can be adjusted is 99 seconds. Min. time is moveable but it

cannot be shorter than the time adjusted on the press.

28. Print beginning

Setting the beginning of the printing. After touching the field, the keyboard will appear on the display. It is possible to set the beginning

od the printing between 0 and 48 cm.

29. Print length

After touching the field, the keyboard will appear on the display. It is possible to set the printing range between and 50 cm.

Version 18.04