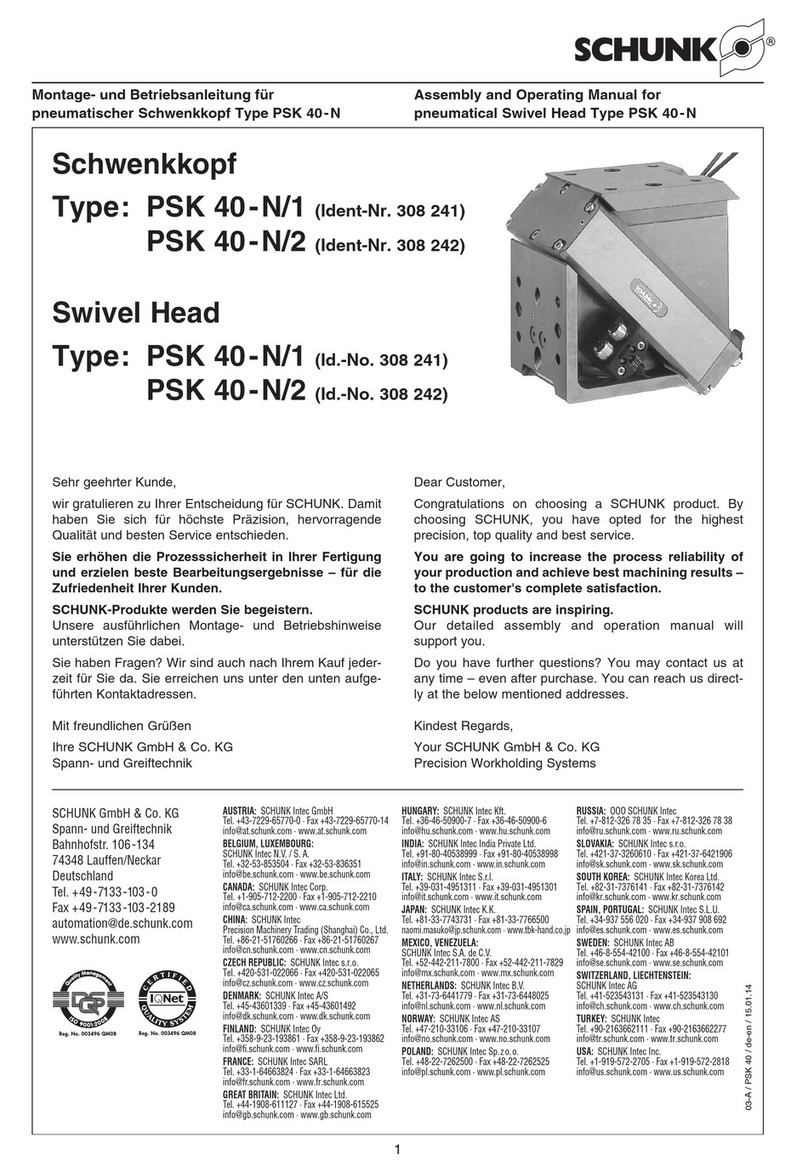

SCHUNK EVG 55 User instructions

Other SCHUNK Controllers manuals

SCHUNK

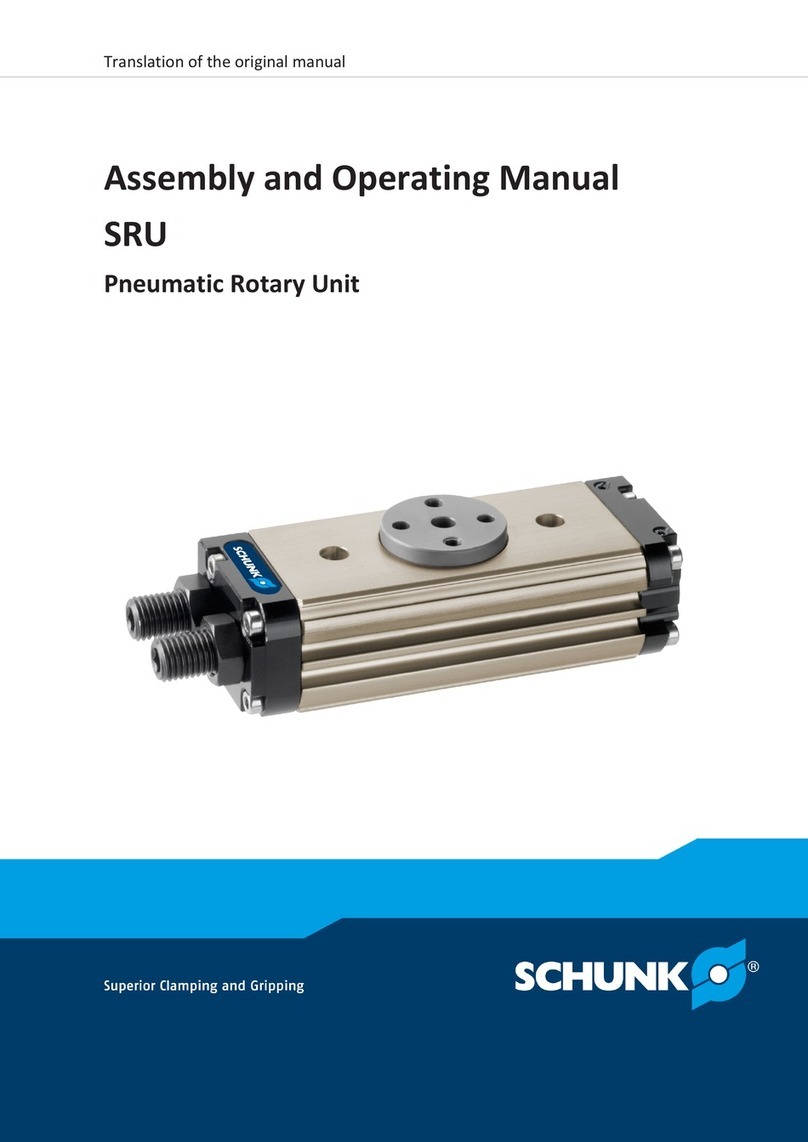

SCHUNK SRU Series User manual

SCHUNK

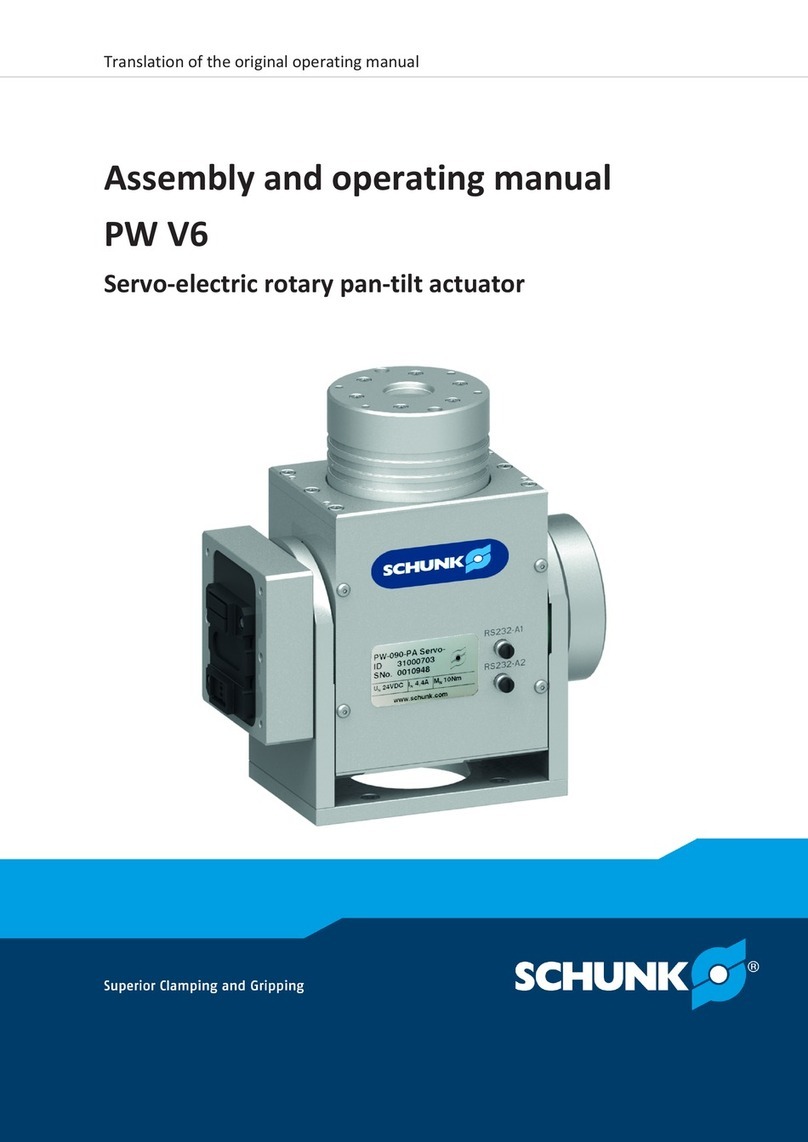

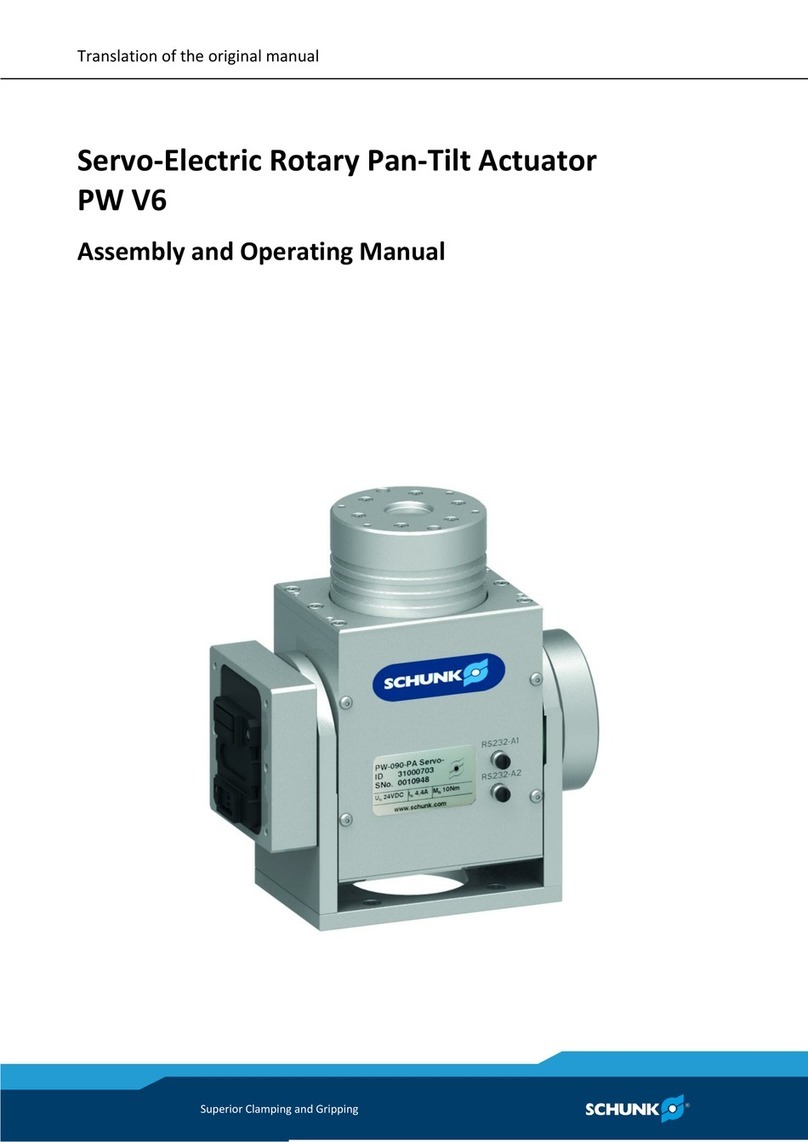

SCHUNK PW V6 User instructions

SCHUNK

SCHUNK GMC 12 User instructions

SCHUNK

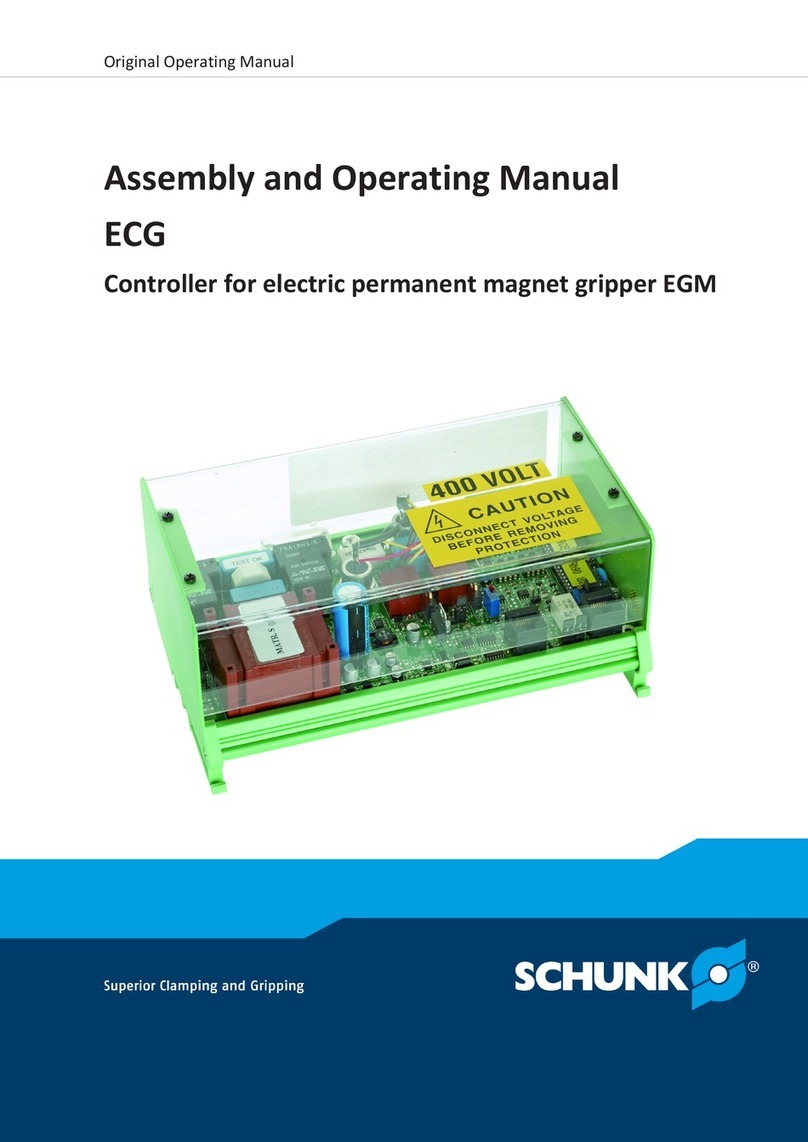

SCHUNK ECG Series User instructions

SCHUNK

SCHUNK UWG Series User manual

SCHUNK

SCHUNK ECM User instructions

SCHUNK

SCHUNK ERD 04 User instructions

SCHUNK

SCHUNK SRU 63 User instructions

SCHUNK

SCHUNK PW V6 User instructions

SCHUNK

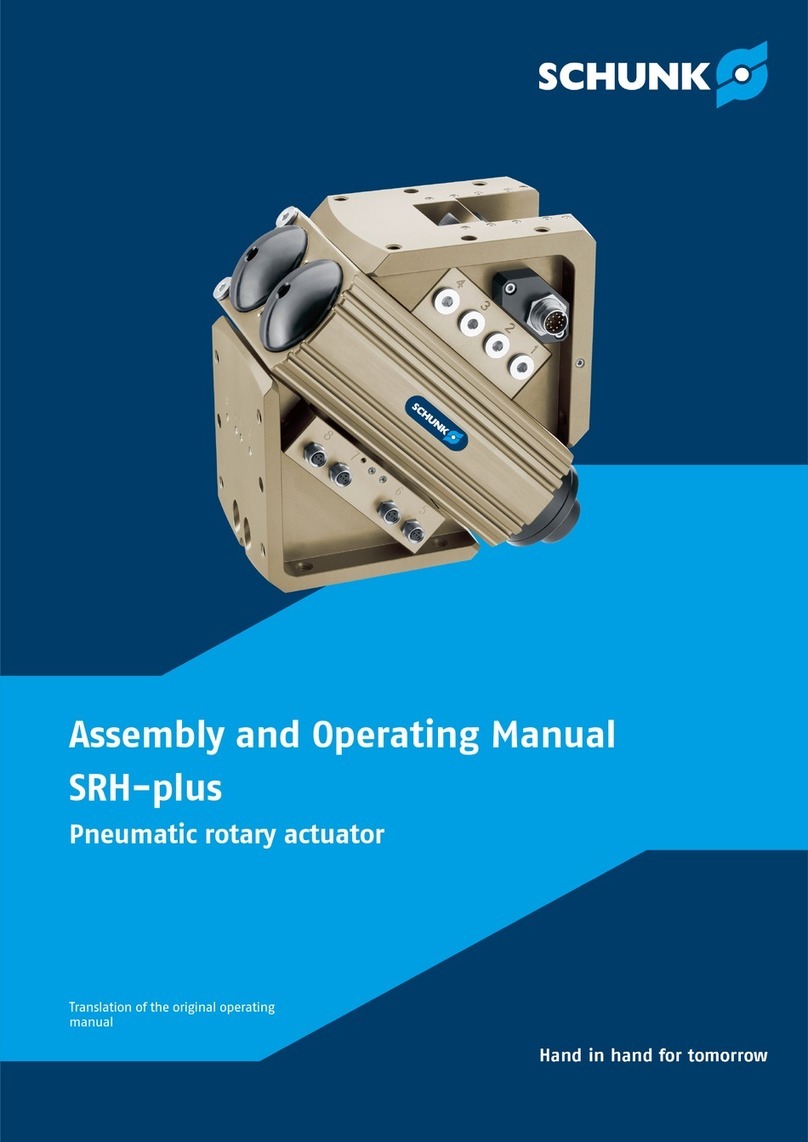

SCHUNK SRH-plus 20 User instructions

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions