Table of contents

01.05|SRU-plus EDF 20 - 60|en

3

Table of contents

1 About this manual .................................................................................................... 5

1.1 Warnings................................................................................................................... 5

1.1.1 Key words...................................................................................................... 5

1.1.2 Symbols ......................................................................................................... 5

1.2 Variants..................................................................................................................... 6

1.3 Applicable documents .............................................................................................. 8

2 Basic safety notes .................................................................................................... 9

2.1 Intended use............................................................................................................. 9

2.2 Not intended use ...................................................................................................... 9

2.3 Environmental and operating conditions................................................................. 9

2.4 Product safety......................................................................................................... 10

2.4.1 Protective equipment ................................................................................. 10

2.4.2 Constructional changes, attachments, or modifications............................ 10

2.5 Personnel qualification........................................................................................... 10

2.6 Using personal protective equipment.................................................................... 11

2.7 Notes on particular risks......................................................................................... 11

3 Warranty................................................................................................................. 13

4 Scope of delivery ..................................................................................................... 13

5 Technical data ......................................................................................................... 14

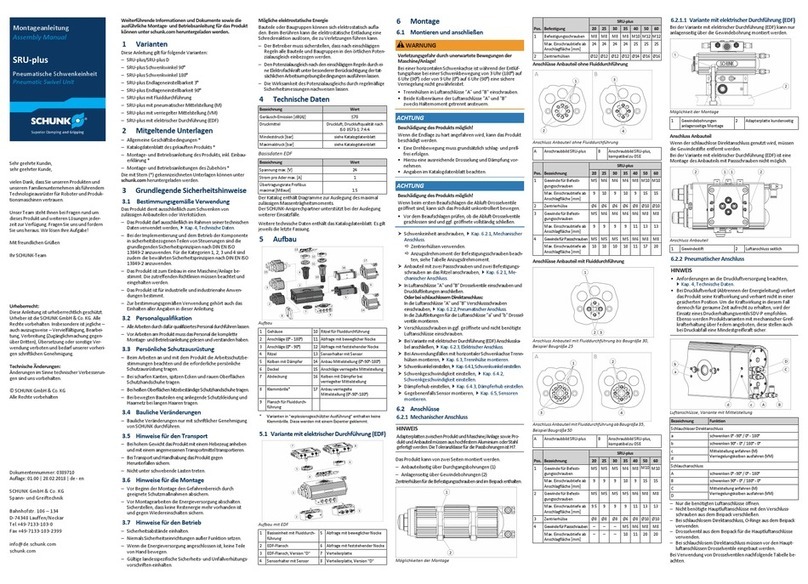

6 Assembly................................................................................................................. 15

6.1 Mechanical connection .......................................................................................... 15

6.1.1 Assembly of the unit on an adapter plate (robot-side) .............................. 15

6.1.2 Assembly of the unit on an adapter plate (tool-side)................................. 16

6.2 Air connection ........................................................................................................ 17

6.3 Adjusting the limit positions................................................................................... 20

6.3.1 Basic setting 0° and 180°............................................................................. 20

6.3.2 Shock absorber stroke fine adjustment 0° and 180° .................................. 21

6.3.3 Adjusting the center position (variant M) .................................................. 23

6.3.4 Adjusting the center position (variant VM) ................................................ 24

6.4 Sensors.................................................................................................................... 25

6.4.1 Magnetic switch MMS 22 ........................................................................... 26

6.4.2 Inductive proximity switch IN 80 ................................................................ 26

6.5 Cable assignments .................................................................................................. 30

6.5.1 Connection overview, SRU-plus 20-60 EDF ................................................ 30

6.5.2 Pin allocation for SRU-plus 20-60 EDF ........................................................ 31

6.5.3 Connection overview, SRU-plus 20-35 Version D....................................... 32