Assembly and Operating Manual

Gripper actuator GMC

2 Date printed 23.02.2011

Contents

1SAFETY ..........................................................................................................................................3

1.1 SYMBOL KEY ..............................................................................................................................3

1.2 APPROPRIATE USE......................................................................................................................3

1.3 SAFETY NOTES...........................................................................................................................4

1.4 INDICATIONS TO THE OPERATING MANUAL ......................................................................................4

2WARRANTY....................................................................................................................................5

3SCOPE OF DELIVERY....................................................................................................................5

4TECHNICAL DATA..........................................................................................................................5

5OPERATING AND ENVIRONMENTAL CONDITIONS ....................................................................5

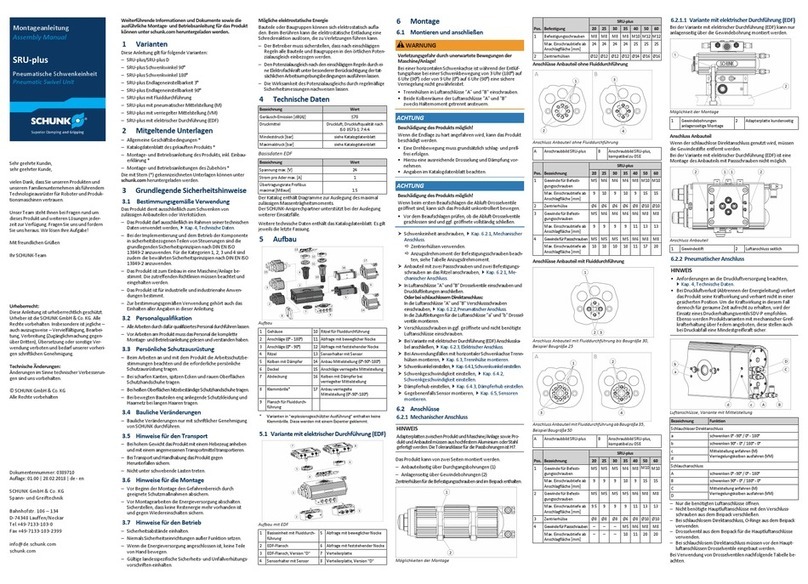

6ASSEMBLY AND INSTALLATION..................................................................................................6

6.1 DESIGN PRECAUTIONS.................................................................................................................6

6.2 COMPRESSED AIR SUPPLY............................................................................................................6

6.3 SPECIAL CONNECTING MEASURES .................................................................................................6

6.4 ASSEMBLY MEASURES .................................................................................................................7

6.5 MEASURES FOR THE INITIAL OPERATION.........................................................................................7

7HANDLING......................................................................................................................................8

7.1 GRIP FORCE SAFETY DEVICE.........................................................................................................8

7.2 ROTARY ADAPTER.......................................................................................................................9

7.3 END POSITION INTERROGATION ....................................................................................................9

7.4 MODULAR DESIGN.....................................................................................................................10

8REPAIRS.......................................................................................................................................11

9RESPONSE TO MALFUNCTIONS................................................................................................11

10 MAINTENANCE AND CARE .........................................................................................................12

11 REPLACEMENT PARTS...............................................................................................................13

12 EC DECLARATION OF INCORPORATION ..................................................................................14

13 CONTACT .....................................................................................................................................15