9

Environmental and operating conditions

Required ambient conditions and operating conditions

Incorrect ambient and operating conditions can make the product

unsafe, leading to the risk of serious injuries, considerable material

damage and/or a significant reduction to the product's life span.

• Make sure that the product is used only in the context of its

defined application parameters, (3, Page 17).

• Make sure that the product is a sufficient size for the application.

• Only use high-quality cooling emulsions with anti-corrosive ad-

ditives during processing.

Clamping force tester

Depending on the operating conditions, the function and clamping

force must be checked after a certain period of operation (7.2,

Page 36). Only use a calibrated clamping force tester for measur-

ing during the clamping force test.

With the smallest possible actuating pressure (clamping cylinder),

the base jaws should move evenly. This method only provides a

limited indication and is not a substitute for measuring the clamp-

ing force.

If the clamping force has dropped too much or if the base jaws and

pistons no longer move properly, the chuck must be disassembled,

cleaned, and relubricated (7, Page 36).

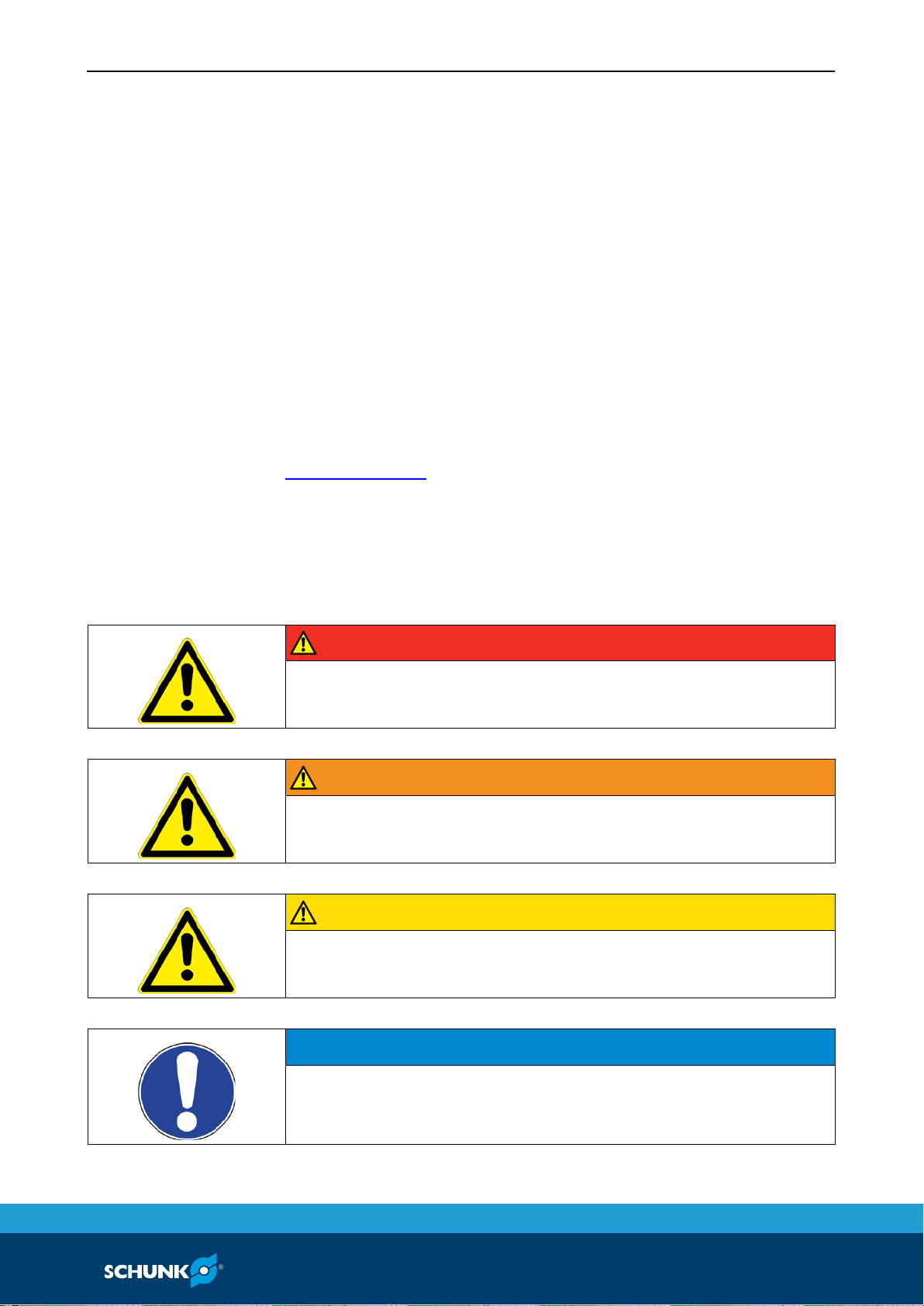

Personnel qualification

Inadequate qualifications of the personnel

If the personnel working with the product is not sufficiently qualified,

the result may be serious injuries and significant property damage.

• All work may only be performed by qualified personnel.

• Before working with the product, the personnel must have read

and understood the complete assembly and operating manual.

• Observe the national safety regulations and rules and general

safety instructions.

The following personal qualifications are necessary for the various

activities related to the product:

Due to their technical training, knowledge and experience, trained

electricians are able to work on electrical systems, recognize and

avoid possible dangers and know the relevant standards and

regulations.