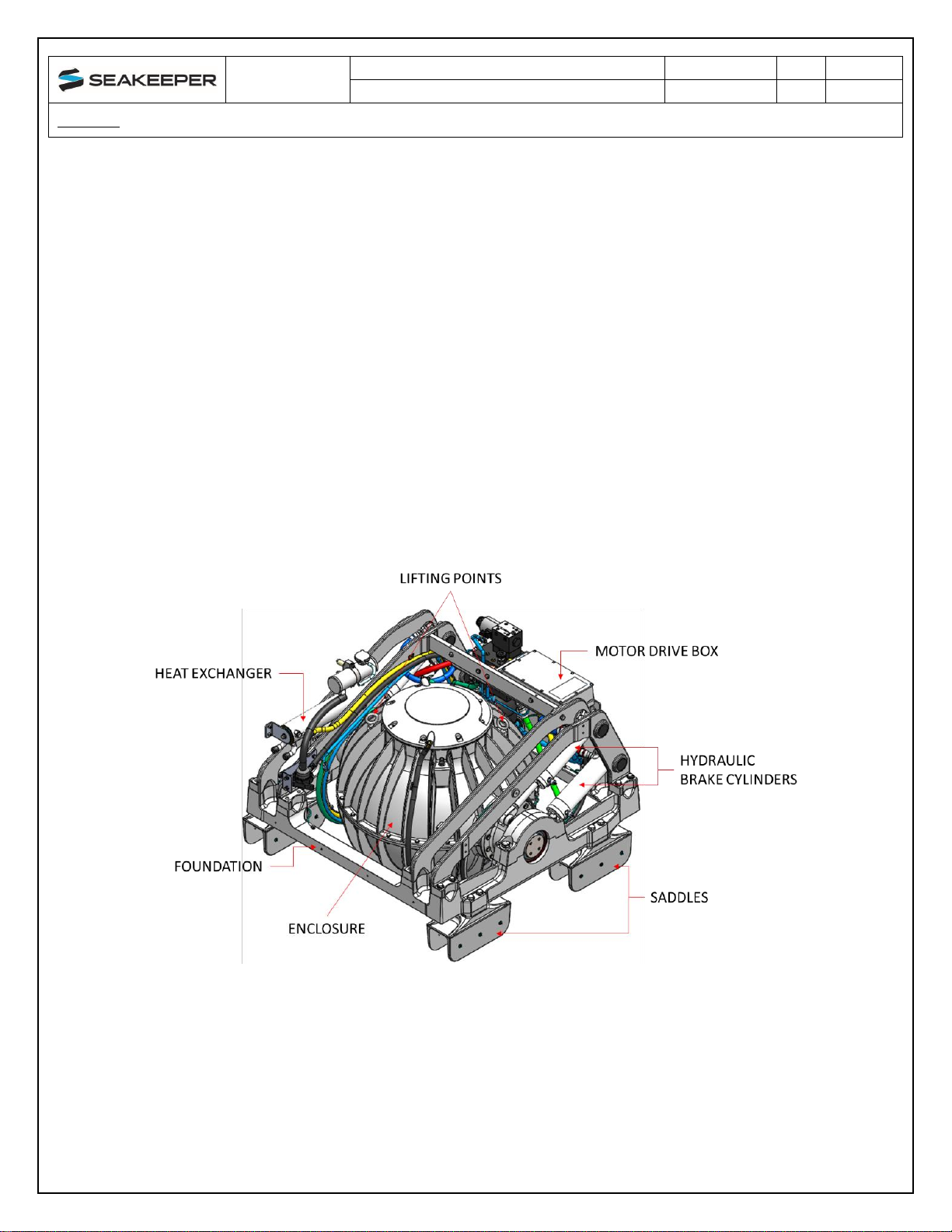

1.0 Introduction

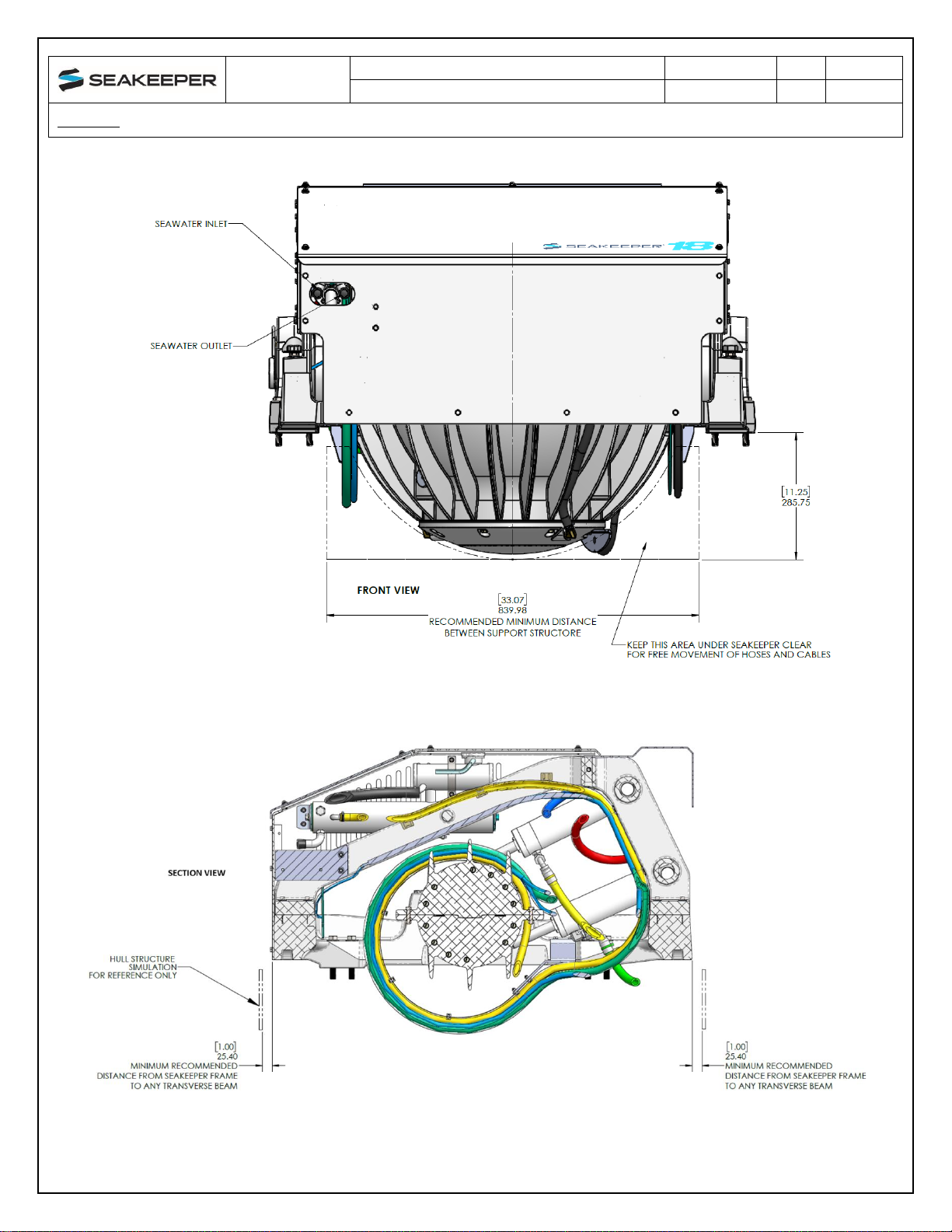

This document is intended to give details and guidance to a boat builder or equipment installer to

install the Seakeeper 16/18. The Seakeeper 16/18 can produce vertical loads up to 26.5KN

(5,965 lbs.), longitudinal loads up to 15.61KN (3,409 lbs.), and transvers loads of 2.22KN (500

lbs.) at each of the four mounts. Careful consideration should be given to foundation design to

insure it is capable of transferring these loads into the hull. These loads do NOT include vessel

motion accelerations, such as vertical slam loads which can be significant for high speed vessels

and vary based upon the longitudinal location.

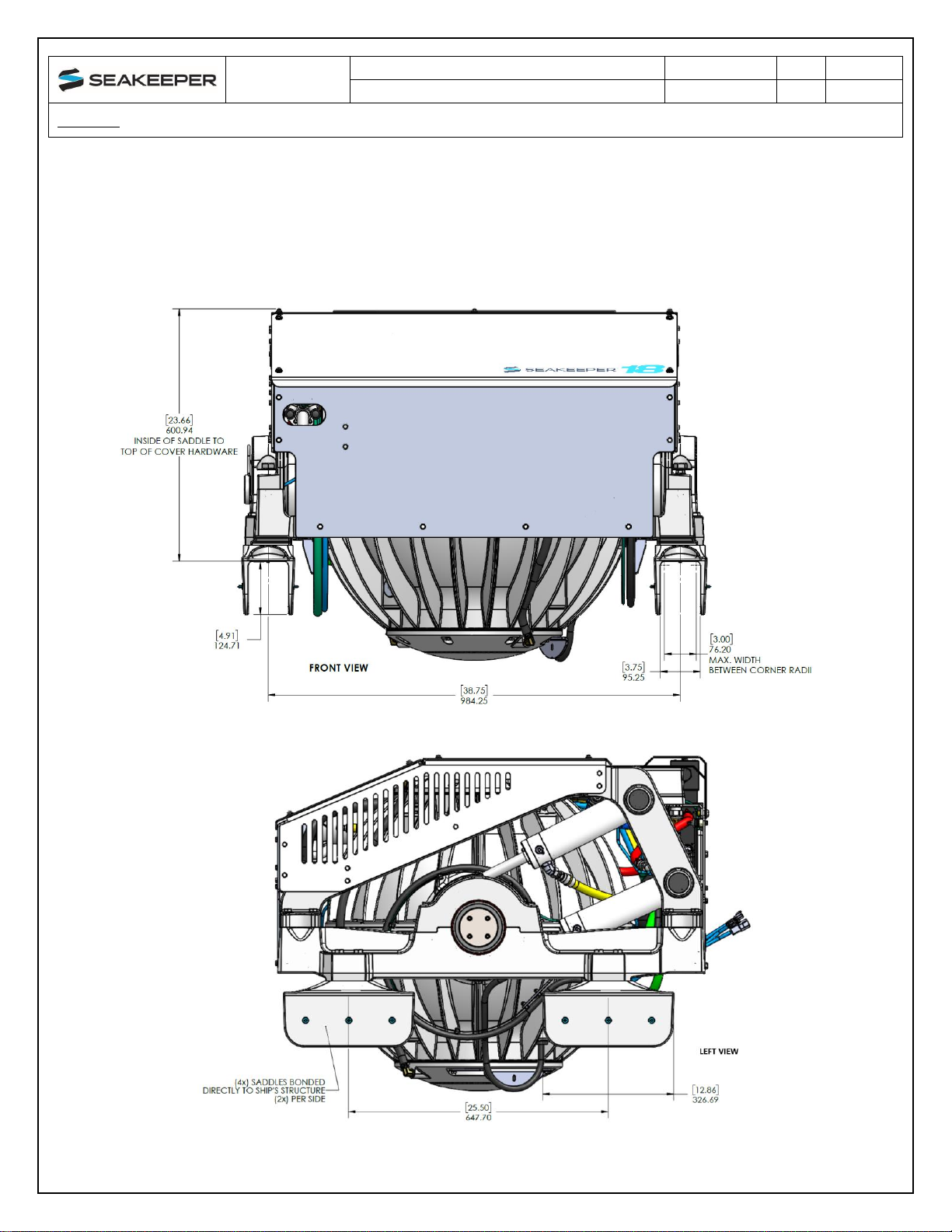

There are two methods of installing the Seakeeper 16/18:

1) Bolt-In Installation

2) Bond-In (Saddle) Installation

It is assumed that the installer is familiar with bonding using high strength adhesives or

mechanical fasteners to marine structures and has performedstructural analysis to assure

the structure to which the Seakeeper mounts can properly transfer the loads the Seakeeper

creates into the hull structure. If the installer has any doubt about the ability of the

structure to transfer the loads to the hull, then a licensed naval architect or marine

engineer should be contacted to do a structural analysis.

The installer should review the following list of reference drawings to ensure the installation

procedure is fully understood.

Reference Drawings

90243 Seakeeper 16 Hardware Scope of Supply

90538 Seakeeper 18 Hardware Scope of Supply

90544 Seakeeper 16/18 Bolt-In Installation Guide

90545 Seakeeper 16/18 Bond-In Installation Guide

90540 Seakeeper 16/18 Cooling Water Schematic

90282 Seakeeper 16/12HD/18 Installation Template Kit

90539 Seakeeper 16/18 Cable Block Diagram

90548 Seakeeper 16/18 Bolt-in Kit

90547 Seakeeper 16/18 Bond-in Kit