INSTRUCTION MANUAL FOR:

PROFESSIONAL CONDUIT BENDER

MODEL No: PCB32

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and

properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

3. ASSEMBLY

2. INTRODUCTION & SPECIFICATION

Ensure the conduit bender is in sound condition and good working order.

Take action for immediate repair or replacement of damaged parts. Use

recommended parts only. The use of improper parts may be dangerous

and will invalidate the warranty.

Keep bender and associated parts clean for best and safest performance.

Locate the conduit bender in a suitable, well lit work area.

Keep work area clean and tidy and free from unrelated materials.

Use on level and solid ground, preferably concrete.

Ensure all non-essential persons keep a safe distance whilst the conduit

bender is in use.

Maintain correct balance and footing. Ensure the floor is not slippery

and wear non slip shoes.

Remove ill fitting clothing. Remove ties, watches, rings and other loose

jewellery and contain and/or tie back long hair.

Wear appropriate safety clothing including gloves and eye protection.

Keep hands away from moving parts when bending conduit.

sCaution! Cut conduit edges may be sharp, take care when handling any cut

steelwork.

DO NOT operate the conduit bender if damaged.

DO NOT allow untrained persons to operate the conduit bender.

DO NOT operate the conduit bender when you are tired, under the

influence of alcohol, drugs or intoxicating medication.

DO NOT use the conduit bender for purposes other than that for which

it is intended.

Store conduit bender in a safe, dry, childproof location.

Anchor the conduit bender to the floor or use assistance to prevent

the conduit bender from lifting during use.

WARNING! Ensure that you have read and understood Section 1

Safety Instructions before operating the conduit bender.

WARNING! When the conduit bender is packed in its box it is

heavy and may require 2 people to move it.

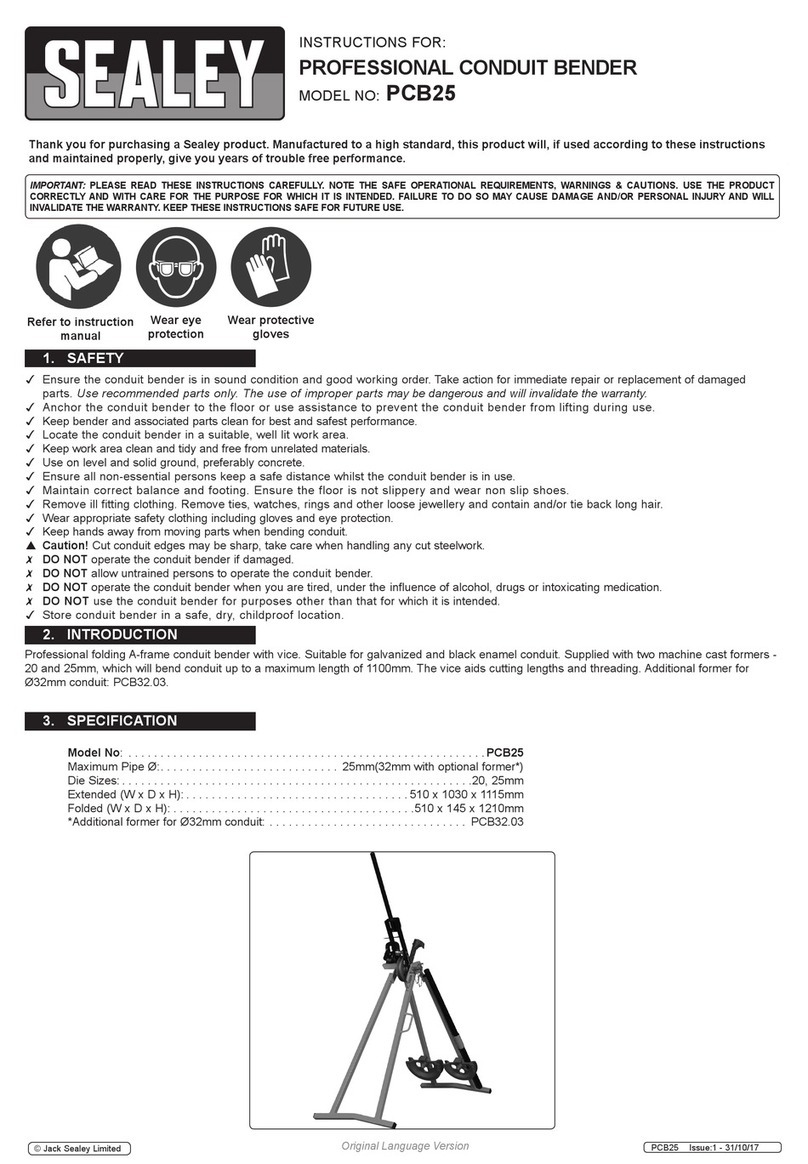

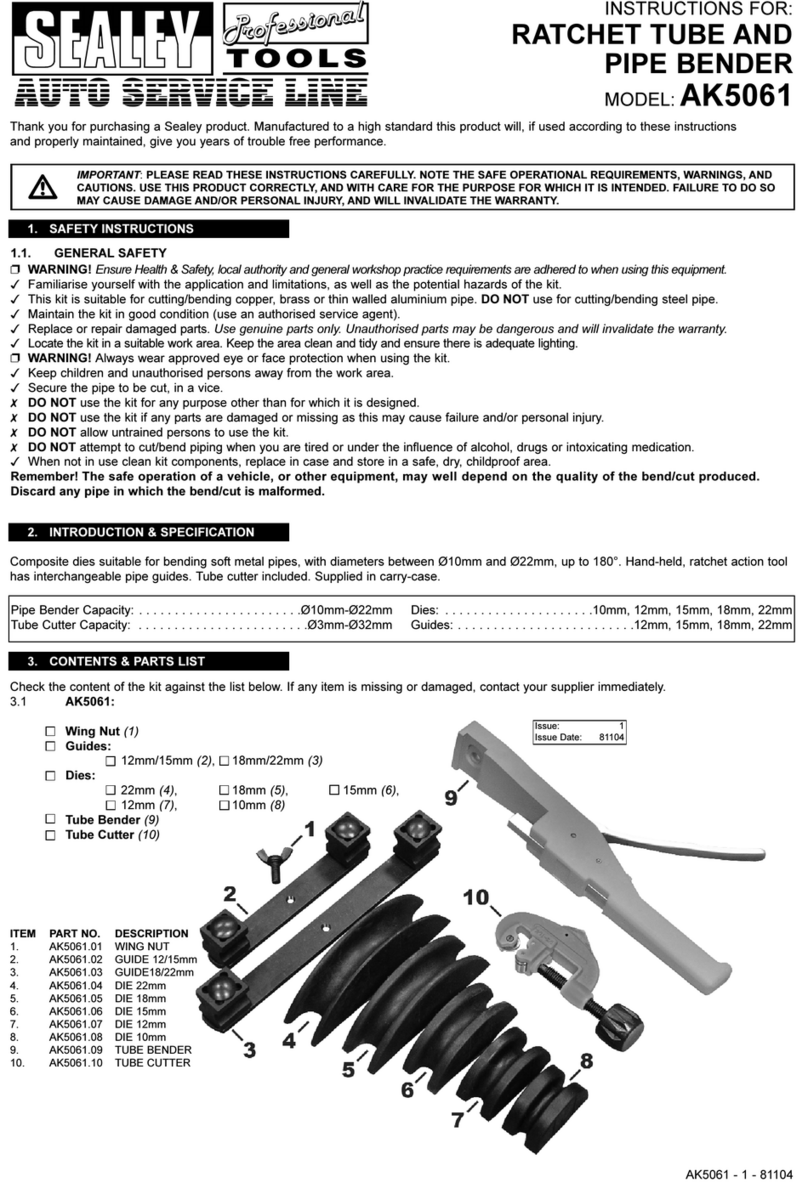

3.1 Remove the conduit bender from the box and check all parts are

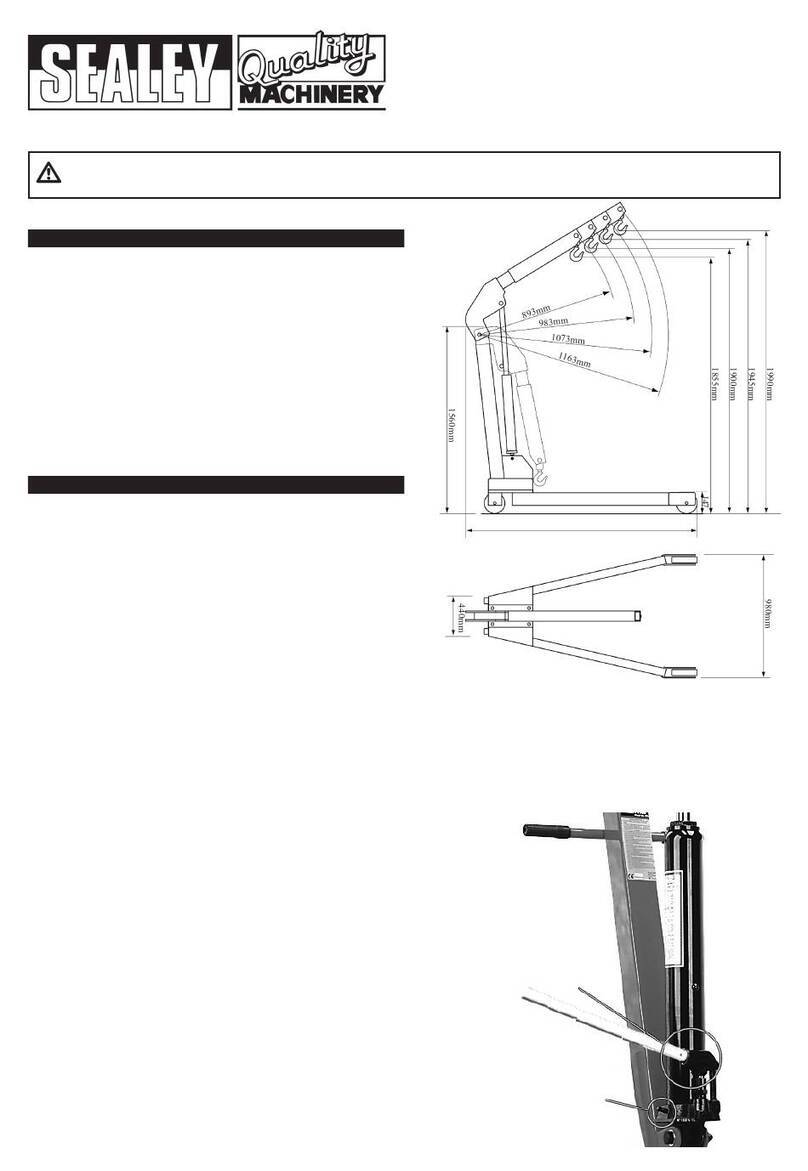

present. Refer to fig.1.

3.2 Remove the leg retaining pin (1) and open the conduit bender to its

fullest extent. Re-insert the leg retaining pin (1) to lock the leg into

position.

3.3 The vice (6) is secured beneath the platform for transit purposes.

Remove the 3 retaining bolts and remove the vice (6). Place it on

top of the platform and bolt into position.

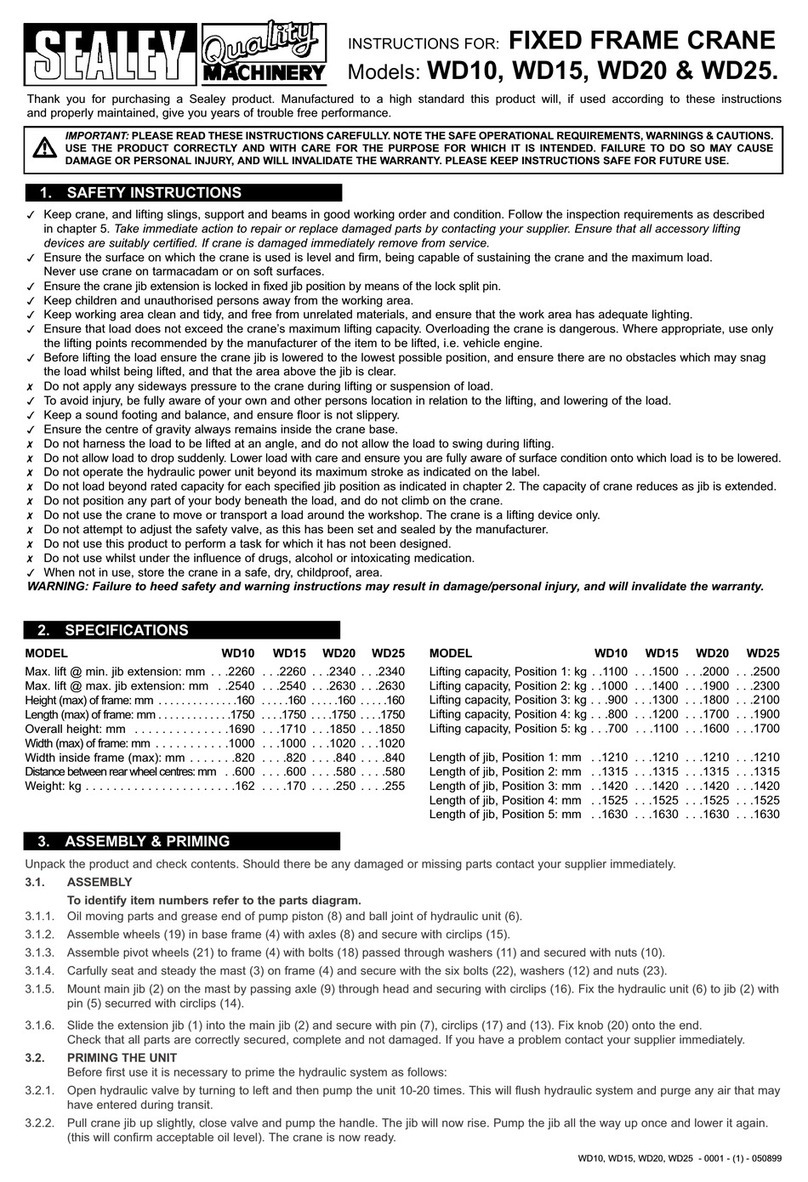

3.4 Remove the bending lever retaining pin (2). Fit the grooved roller and

pin (8) in the appropriate position on the bending lever (7) (fig.2).

Secure the roller pin (8) in place with the R-clip.

3.5 Select the size of former (9) required (fig.2) according to the diameter

of conduit to be bent. Withdraw the centre pin (3), insert the former

(9) and replace the centre pin (3).

3.6 Raise the bending lever (7) to the upright position and lock in place

with the retaining pin (2). Attach the bending lever extension (10).

3.7 Swing the stop bar (4) to the upright position and insert the stop piece

(5) into the appropriate hole required and secure with the R-clip. The

conduit bender is now ready for use.

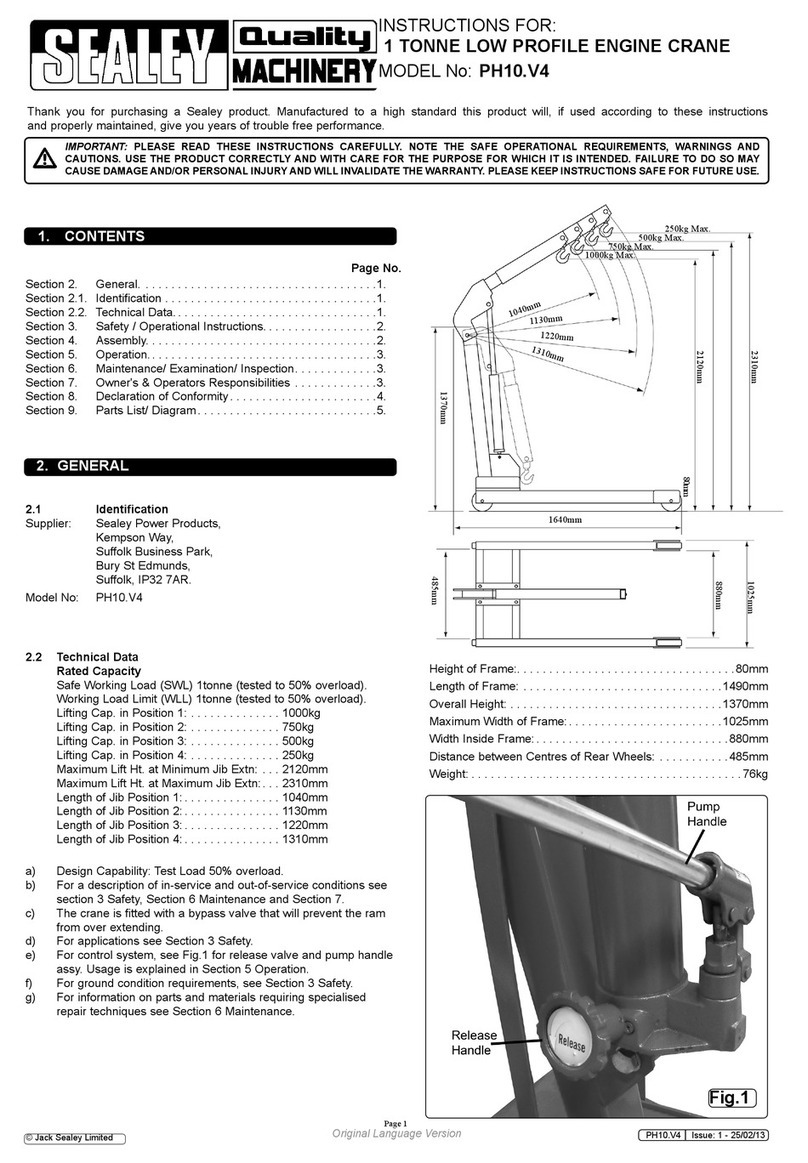

Professional folding A-frame conduit bender with vice. Suitable for galvanised

and black enamel conduit. Supplied with three machine cast formers 20, 25

and 32mm which will bend conduit in accordance with BS4568 up to a

maximum length of 1100mm. The vice aids cutting lengths and threading.

MODEL: .................................................................................................. PCB32

Extended (WxDxH):..............................................................530x1180x1065mm

Folded (WxDxH):................................................................... 530x380x1200mm

Former sizes:.............................................................................................20mm

...................................................................................................................25mm

...................................................................................................................32mm

PCB32 Issue No:1 18/07/11

fig.1

fig.2

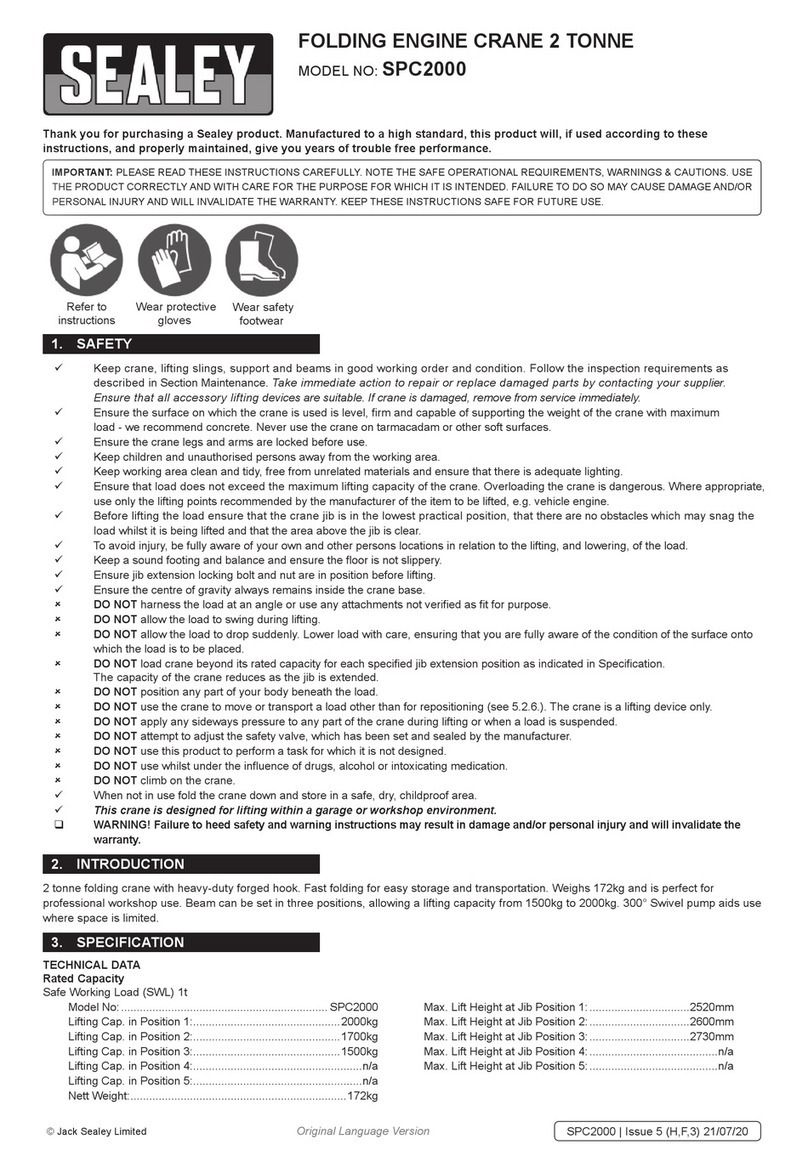

fig.3

1................................ Leg retaining pin.

2................ Bending lever retaining pin.

3...........................................Centre pin.

4..............................................Stop bar.

5.......................................... Stop piece.

6.................................................... Vice.

7..................................... Bending lever.

8............................................Roller pin.

9................................................Former.

10...................Bending lever extension.