Your crane is delivered assembled but in a folded condition. Before using it is necessary to lay the folded crane on its back on the floor

and proceed as follows.

3.1. Lower the crane legs. Lock them in place with the pins and split pins.

3.2. Rotate the assembled crane onto its wheels.

3.3. Open the valve at top of ram by turning to left and pump 10-20 times. This will purge any air that may have entered during transit.

3.4. Pull crane jib up slightly, close valve and pump the handle. The jib will now raise. Pump the jib all the way up once and lower it again (this

will check the oil level).

3.5. Crane is now ready. Ensure that it is complete and not damaged. If you experience any problems contact your supplier immediately.

INSTRUCTIONS FOR:

PROFESSIONAL FOLDING CRANES

Models: 500KCA, 750VA & WF10.

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

3Keep crane, and lifting slings, supports and beams in good working order and condition. Follow the inspection requirements as described

in Section 5. Take immediate action to repair or replace damaged parts by contacting your supplier. Ensure that all accessory lifting

devices are suitably certified. If crane is damaged immediately remove from service.

3Ensure the surface on which the crane is used is level and firm, being capable of sustaining the crane and the maximum load.

7Never use crane on tarmacadam or on soft surfaces.

3Ensure that the crane legs and arms are always locked before use, and jib extension is locked in fixed jib position by means of the lock split pin.

3Keep children and unauthorised persons away from the work area.

3Keep work area clean and tidy, and free from unrelated materials, and ensure that there is adequate lighting.

3Ensure that load does not exceed the cranes maximum lifting capacity. Overloading the crane is dangerous. Where appropriate, use only

the lifting points recommended by the manufacturer of the item to be lifted, i.e. vehicle engine.

3Before lifting the load ensure that the crane jib is in the lowest possible position, that there are no obstacles which may snag the load

whilst it is being lifted and that the area above the jib is clear.

7DO NOT apply any sideways pressure to the crane during lifting or suspension of load.

3To avoid injury, be fully aware of your own and other persons locations in relation to the lifting and lowering of the load.

3Keep a sound footing and balance, and ensure that the floor is not slippery. Wear non-slip shoes.

3Ensure the centre of gravity of the load always remains inside the crane base.

7DO NOT attempt to lift the load at an angle, and do not allow the load to swing during lifting.

7DO NOT allow the load to drop suddenly. Lower load with care and ensure that you are fully aware of the condition of the surface onto

which the load is to be lowered.

7DO NOT operate the hydraulic power unit beyond its maximum stroke, as indicated on the label.

7DO NOT load beyond rated capacity for each specified jib position as indicated in Section 2. The capacity of crane reduces as the jib is extended.

7DO NOT position any part of your body beneath the load, and do not climb on the crane.

7DO NOT use the crane to move or transport a load around the workshop. The crane is a lifting device only.

7DO NOT attempt to adjust the safety valve, as this has been set and sealed by the manufacturer.

7DO NOT use the crane for a task it has not been designed to do.

7DO NOT use whilst under the influence of drugs, alcohol or intoxicating medication.

3When not in use, store the crane in a safe, dry, childproof, area.

p

p

WARNING: Failure to heed safety and warning instructions may result in damage and/or personal injury and will invalidate the warranty.

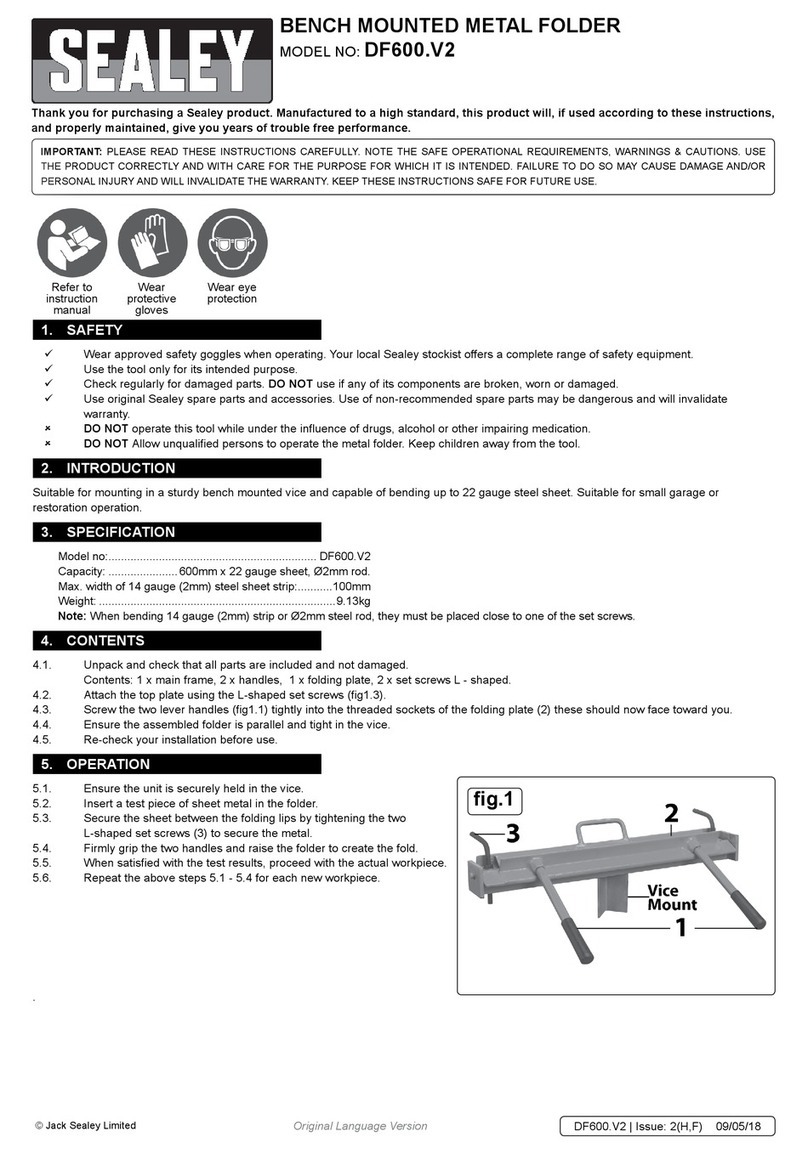

3. ASSEMBLY INSTRUCTIONS

2. SPECIFICATIONS

MODEL 500KCA 750VA WF10

Lifting capacity, Position 1: kg . . . . . .550 . . .750 . .1100

Lifting capacity, Position 2: kg . . . . . .500 . . .700 . .1000

Lifting capacity, Position 3: kg . . . . . .450 . . .650 . . .900

Lifting capacity, Position 4: kg . . . . . .400 . . .600 . . .800

Lifting capacity, Position 5: kg . . . . . .350 . . .550 . . .700

Length of jib, Position 1: mm . . . . . . .955 . . .955 . . .955

Length of jib, Position 2: mm . . . . . .1060 . .1060 . .1060

Length of jib, Position 3: mm . . . . . .1165 . .1165 . .1165

Length of jib, Position 4: mm . . . . . .1270 . .1270 . .1270

Length of jib, Position 5: mm . . . . . .1375 . .1375 . .1375

MODEL 500KCA 750VA WF10

Max. lift @ min. jib extension: mm . . . . . .2020 . . .2020 . . .2020

Max. lift @ max. jib extension: mm . . . . . .2340 . . .2340 . . .2340

Height (max) of frame: mm . . . . . . . . . . . . . . . . . .125 . . . . .125 . . . . .125

Length (max) of frame: mm . . . . . . . . . . . . . . . . .1420 . . . .1420 . . . .1420

Width (max) of frame: mm . . . . . . . . . . . . . .1090 . . .1130 . . .1130

Overall height: mm . . . . . . . . . . . . . . . . . .1520 . . .1520 . . .1520

Width inside frame (max): mm . . . . . . . . . .950 . . . .970 . . . .970

Distance between rear wheel centres: mm . . . . 300 . . . .300 . . . .300

Weight: kg . . . . . . . . . . . . . . . . . . . . . . . . . 73 . . . . .90 . . . . .98

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

4. OPERATING INSTRUCTIONS

p

p

WARNING! Ensure that you read, understand and apply Section 1 safety instructions, and that parts 3.3 and 3.4 have been

successfully performed before using the crane.

4.1. Pump the handle to raise the jib to the appropriate height at which the load may be secured.

4.2. Connect the crane hook to the load using a suitable certified sling or support beam. Ensure that you are aware of the load weight

and check that it is within the capacity of the crane at the jib extension you are using. When removing engines ensure that you know

the engine weight. Use only lifting points recommended by the vehicle manufacturer.

4.3. Lift only from directly above the load. p WARNING! DO NOT LIFT THE LOAD AT AN ANGLE!

500KCA/750VA/WF10 - 3 - 181202