GAS SPRUNG MECHANIC’S SEAT

MODEL NO: SCR10.V2 and SCR15

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these

instructions, and properly maintained, give you years of trouble free performance.

PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGEAND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

WARNING! Ensure Health & Safety, local authority, and general workshop practice regulations are adhered to when using this seat.

9Locate seat in a suitable working area.

WARNING! Use the seat on level and solid ground, preferably concrete.

9Keep the seat clean and tidy in accordance with good workshop practice.

8DO NOT use the seat for any purpose other than that for which it is designed.

8DO NOT stand on the seat.

8DO NOT use the seat outdoors.

8DO NOT get the seat wet or use in damp or wet locations or areas where there is condensation.

8DO NOT clean the seat with any solvents which may damage the paint surface or the protective coating on the padded seat.

8DO NOT exceed maximum capacity of 136kg.

2. INTRODUCTION

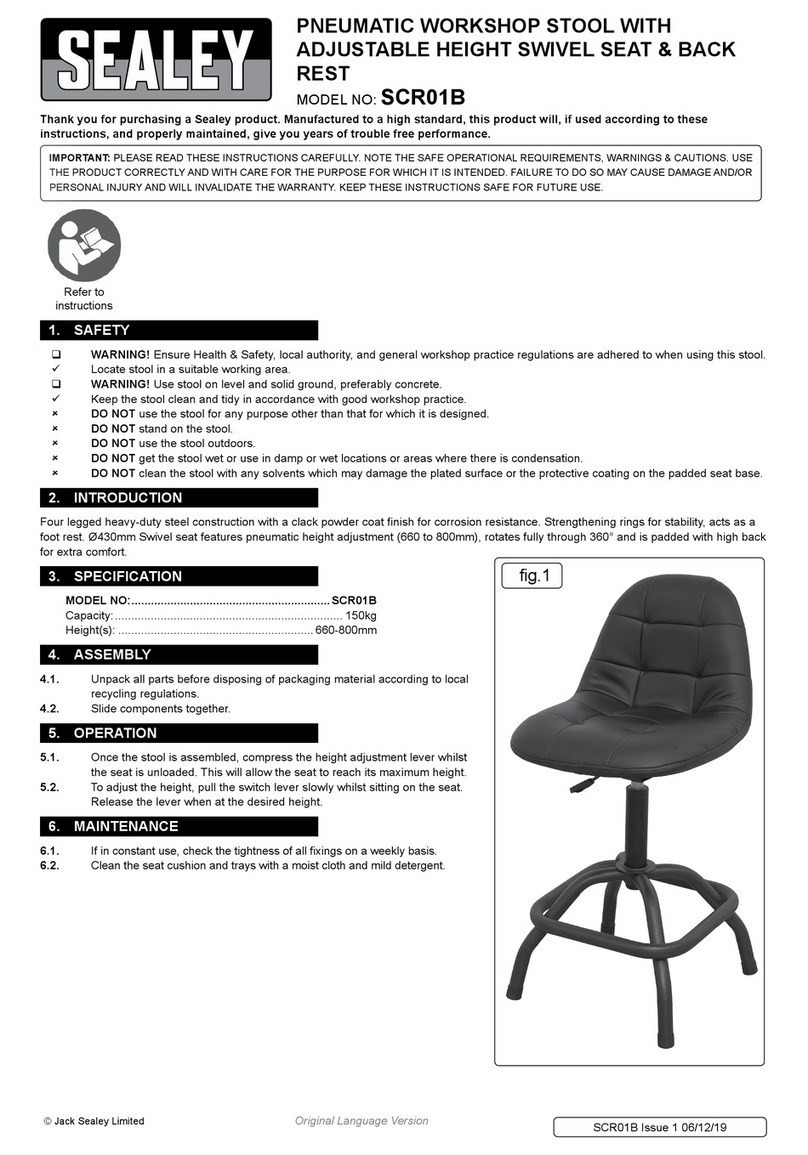

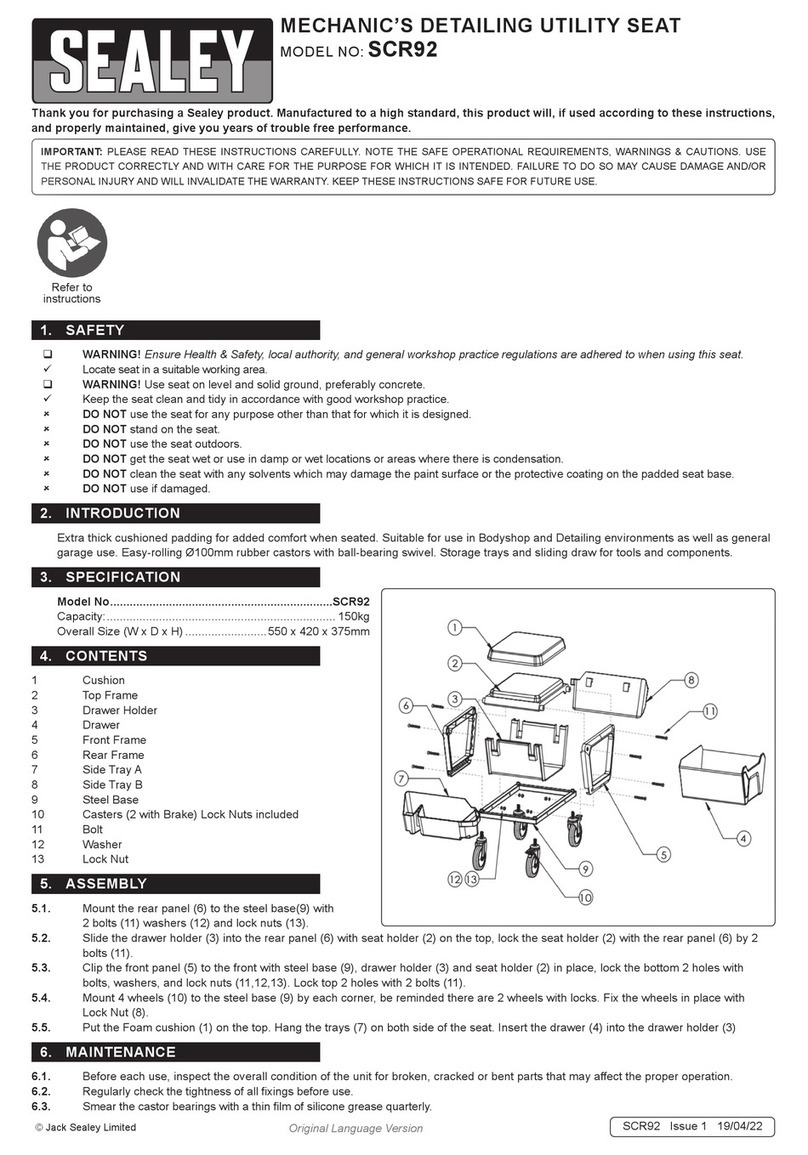

Swivel action seat with lever operated gas sprung height adjustment between 380mm and 500mm. Padded cushion for added comfort. Seat

glides across workshop oor on ve Ø60mm ball bearing castors. Base doubles as temporary tool and component storage tray.

3. SPECIFICATION

Model No:.............................................................. SCR10..................................... SCR15

Max. Capacity......................................................... 136kg.........................................136kg

Minimum Height: ................................................... 380mm.....................................380mm

Maximum Height:.................................................... 500mm.....................................500mm

Gas Strut Nitrogen approximate quantity............... 3g.....................................................3g

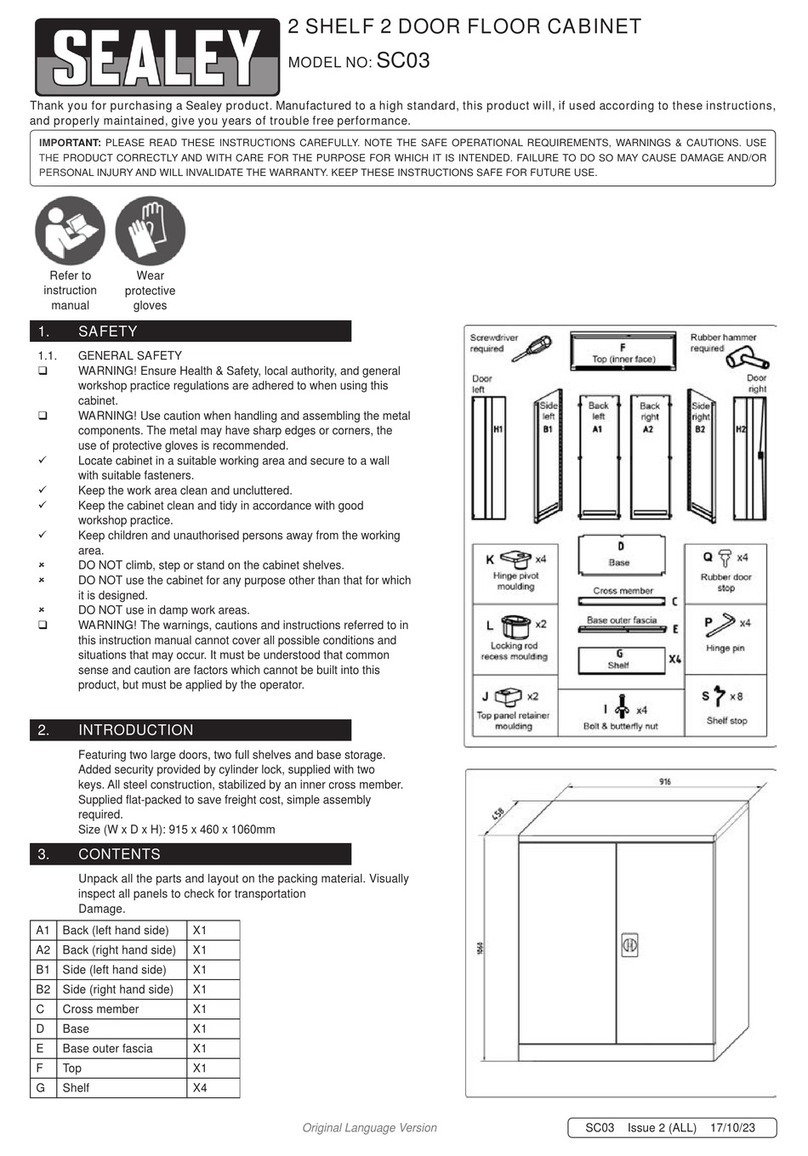

4. ASSEMBLY

4.1. If the 5 swivel castors, 5 domed head nuts and 5 plain washers are not fitted, invert the seat on to a non-scratch clean surface and fit

the five castors.

4.2. If the swivel castors are fitted, check the fixings for tightness and tighten if necessary.

5. OPERATION

5.1. To lower: sit lightly on the stool and lift the operating lever; the stool will lower until the lever is released.

5.2. To raise: remove weight from seat. Lifting the operating lever will allow the seat to raise.

6. MAINTENANCE

6.1. If in constant use, check the tightness of the domed head nuts on a quarterly basis.

6.2. Smear the castor bearings and the gas cylinder rod with a thin film of silicone grease annually.

6.3. The castor wheels are maintenance free; ensure they are able to rotate and swivel freely.

6.4. Clean the seat cushion and trays with a moist cloth and mild detergent.

SCR10.V2, SCR15 | Issue 1 20/03/18

Original Language Version

© Jack Sealey Limited

Refer to

instructions

SCR15

SCR10