Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

3. SPECIFICATION

2. INTRODUCTION

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

WARNING! Ensure all Health and Safety, local authority, and general workshop practice regulations and recommendations are

strictly adhered to when lifting or moving heavy loads. The lifting or movement of heavy loads may be dangerous if not undertaken

correctly.

Familiarise yourself with the application and limitations, as well as the specific potential hazards peculiar to the truck.

Maintain the truck in good condition (use an authorised service agent).

Replace or repair damaged parts. Use genuine parts only. Unauthorised parts may be dangerous and will invalidate the warranty.

Use a qualified person to lubricate and maintain the truck.

DO NOT

use brake fluid to top up hydraulic unit. Use Sealey hydraulic oil

only.

Keep the truck clean for best and safest performance. DO NOT use on Tarmacadam when fully laden as the wheels may sink in.

Locate truck in an adequate working area for its function, keep area clean and tidy and free from unrelated materials.

WARNING! Use truck on flat, level, solid ground, preferably concrete. Ensure the floor over which the truck will be transported is

swept clean and that there are no obstacles in the way.

Keep the work area clean, uncluttered and ensure there is adequate lighting.

Keep children and non essential persons away from the loading/unloading and transporting area.

Keep hands and body clear of the edge and underside of the platform when operating the truck.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

WARNING! Ensure load is placed level and centrally on truck platform and if necessary strap load in place before attempting to lift,

lower, or transport. When raised, check that the platform/load will not foul on the handle and/or your hand when lowering the load.

WARNING! Use the truck with diligence. DO NOT allow truck to knock into anything. Even when unladen, the truck is heavy and if

misused could cause serious damage and/or personal injury. Continually monitor transportation, lifting and lowering operations.

Take care to ensure you can view the way ahead when moving the truck. Take special care when approaching blind corners.

Before lifting check that there are no overhead obstructions.

Engage the wheel locks before attempting to raise or lower the platform.

DANGER! If a heavy load tips or leans STOP WHAT YOUR ARE DOING. MOVE QUICKLY TO A SAFE DISTANCE. DO NOT

TRY TO HOLD OR STEADY a heavy load. Failure to follow this instruction may cause serious personal injury.

Ensure the truck is fully lowered before attempting to transport a load.

Before lowering the platform, ensure there are no obstructions underneath the platform and that all persons are standing clear of

the truck.

The lowering speed is a fixed rate regardless of the load weight. Stop lowering by releasing the valve control lever on the handle.

WARNING! DO NOT exceed the rated capacity of the truck.

DO NOT use the truck if a part is missing or damaged.

DO NOT load the truck so that it is top heavy. Ensure loads are evenly placed on the truck platform.

DO NOT ride on the truck or allow any person to be transported on the truck.

DO NOT use the truck for any purpose other than lifting, lowering and transporting loads.

DO NOT allow truck to free wheel in transit. Always propel and control the truck by using the handle.

DO NOT use the truck on sloping surfaces.

DO NOT operate the truck when you are tired or under the influence of alcohol, drugs or intoxicating medication.

DO NOT allow children to operate the truck.

DO NOT adjust or tamper with the hydraulic safety valve.

DO NOT place any part of your body within or under the truck platform when raised.

When not in use, fully lower the platform and store in a safe, dry, childproof area.

WARNING! The warnings, cautions and instructions referred to in this manual cannot cover all possible conditions and

situations that may occur. It must be understood that common sense and caution are factors which cannot be built into this

product, but must be applied by the operator.

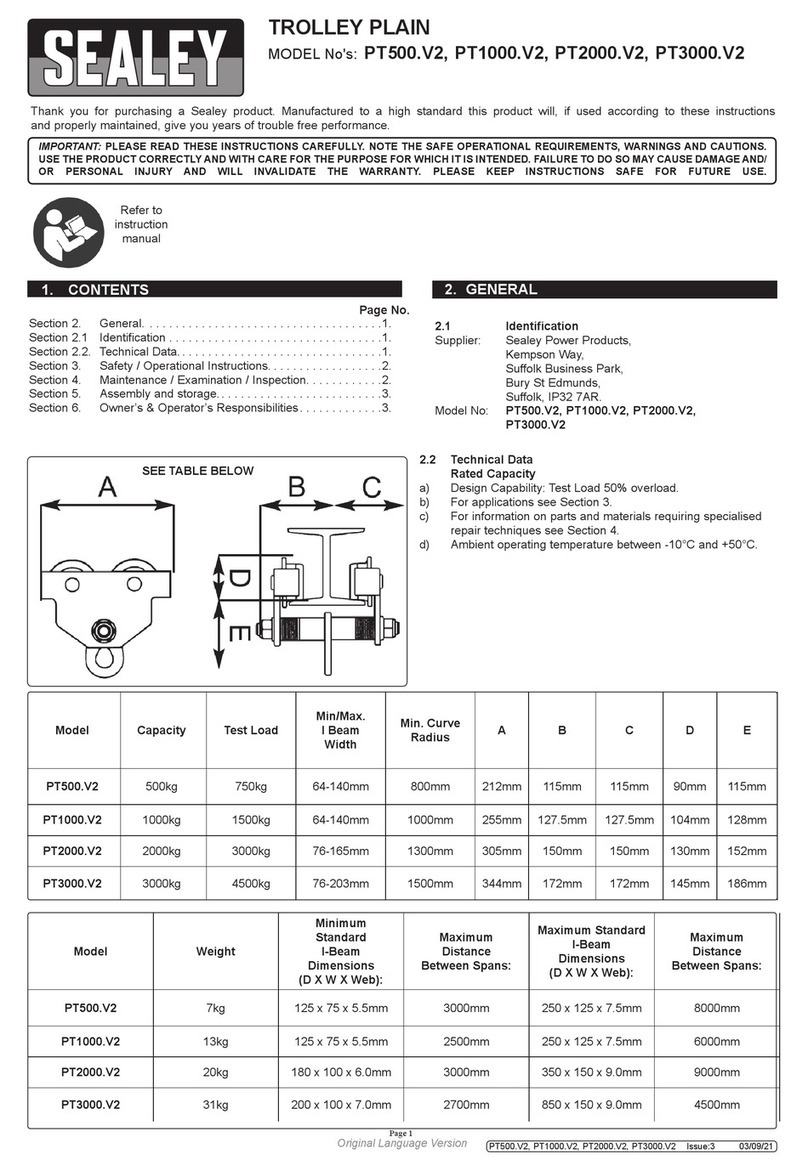

Model .....................HPT750.V2

Capacity. . . . . . . . . . . . . . . . . . . . . . . . 750kg

Min Platform Height..............280mm

Max Platform Height . . . . . . . . . . . . . 750mm

Platform Length ................820mm

Platform Width: . . . . . . . . . . . . . . . . . 520mm

Wheel Diameter . . . . . . . . . . . . . . . . 147mm

INSTRUCTIONS FOR:

hydraulic platform truck

MODEL No: HPT750.V2

Heavy-duty construction featuring two fixed wheels and two braked castors. One-piece hydraulic unit controlled by large, rear

mounted, foot pedal. Safety release mechanism positioned on handlebar for smooth, controlled descent. Suitable for numerous

garage, industrial and warehouse handling applications.

Original Language Version HPT750.V2 Issue: 2 - 15/10/09