1.1. GENERAL SAFETY

3Visually and operationally inspect Jack before each use, ensure it is sound. Take action for immediate repair or replacement of

damaged parts. Use genuine parts only. The use of improper parts may be dangerous and will invalidate the warranty.

pWARNING! If any part of Jack fails to work properly, discontinue and have repaired. Never attempt to repair Jack while Jack is under load.

pWARNING! Ensure Jack to supported on suitable base so it will not slip or shift during operations and load is properly supported at lift

point to prevent shifting. If required, use appropriately rated clivis pins, chains, bolts, ropes etc, through beam holes to assist operation.

3Place complete lifting beak of jack under object to be lifted. You can pull lifting beak up to the point of lift (or strain) without pumping handle.

3Always lock and/or stabilise load to be lifted. The Jack will not act as a load stabiliser.

3Always keep firm grip on pumping handle and support beam.

3All persons shall be clear of load being raised, lowered or pulled. Never work under a raised load unless using additional supports

and insert 1/2 bolt (not included) through hole in steel beam immediately below lifting mechanism, (to act as a safety pin).

pWARNING! if you exceed rated capacity at the height of one foot, the shear pin will break and the handle will drop.

3Jack must have a 50kg load or more to activate the lowering step by step, otherwise lifting beak will drop.

3 Ensure there are no persons or obstructions beneath a load before lowering.

sDANGER! DO NOT use additional devices on handle to provide extra leverage. Use hand power only.

7 DO NOT operate the jack if damaged.

7 DO NOT exceed the rated capacity of the jack.

pWARNING! DO NOT place an excessive strain on load, equipment or supports when using jack for pulling or tensioning.

7 DO NOT push lifted load off Jack.

sDANGER! DO NOT use the jack for purpose other than for which it is designed.

3 Put handle in upright position before tripping the reversing latch to lower load.

3 KEEP JACK CLEAN AND OILED. Front and back of rail must be kept rust free. Store in a safe, dry childproof area.

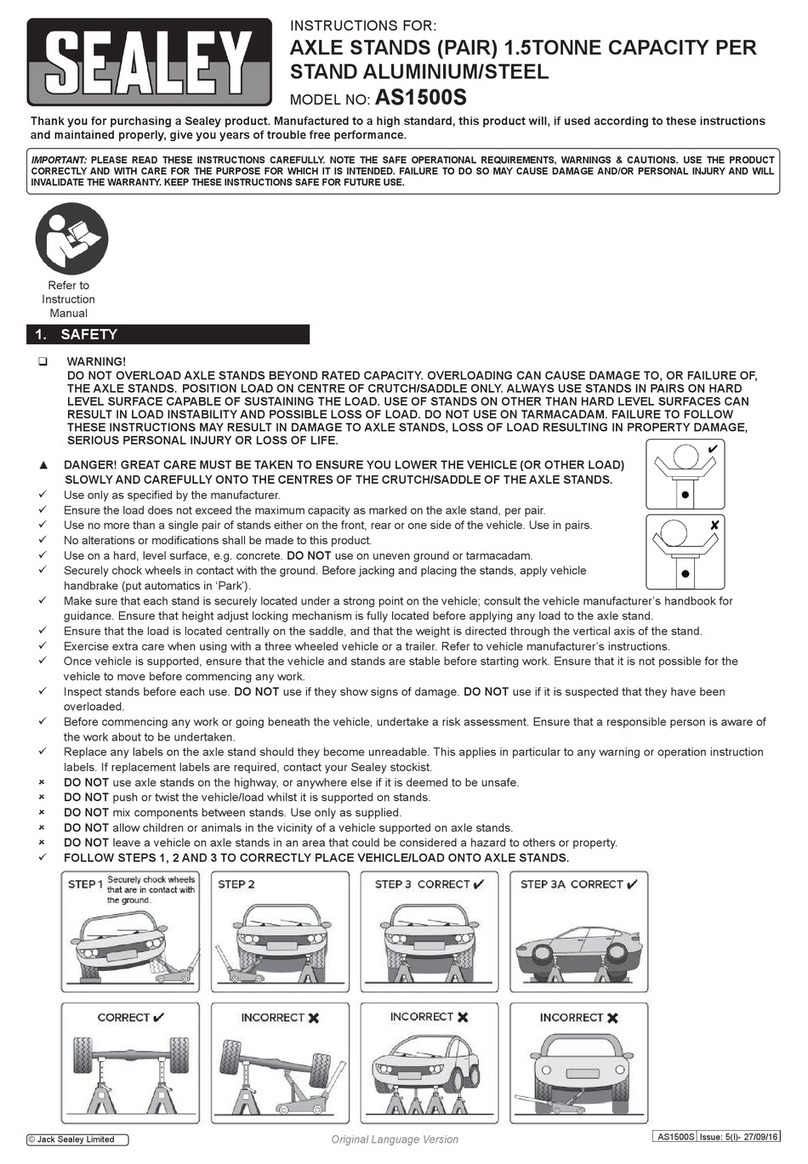

1.2. WHEN USED TO JACK A VEHICLE

OIMPORTANT:Apply appropriate safety features as mentioned in 1.1. above with the following additions or exceptions:

3Place wedges under wheels of vehicle.

3Ensure the vehicle handbrake is engaged, engine is switched off and transmission is in gear (or PARK if automatic).

3Ensure minimum distance of 0.5m between vehicle and static objects such as doors, walls, etc.,

to allow for vehicle tilting.

3Ensure there are no passengers in the vehicle.

3Only place jack under those lifting points recommended by vehicle manufacturer (see vehicle hand book).

3Check the lifting point is stable and correctly positioned on the lifting beak.

p DANGER: Use the jack for lifting only, NOT for supporting the lifted load.

3Use suitable capacity axle stands under the vehicle before proceeding with any task.

3 Ensure there are no persons or obstructions beneath the vehicle before lowering.

7 DO NOT jack vehicle if there is a risk of spillage of fuel, battery acid, or other dangerous substances.

7 DO NOT work under the vehicle until axle stands have been correctly positioned.

7 DO NOT allow the vehicle to move while supported by the jack, or use the jack to move the vehicle.

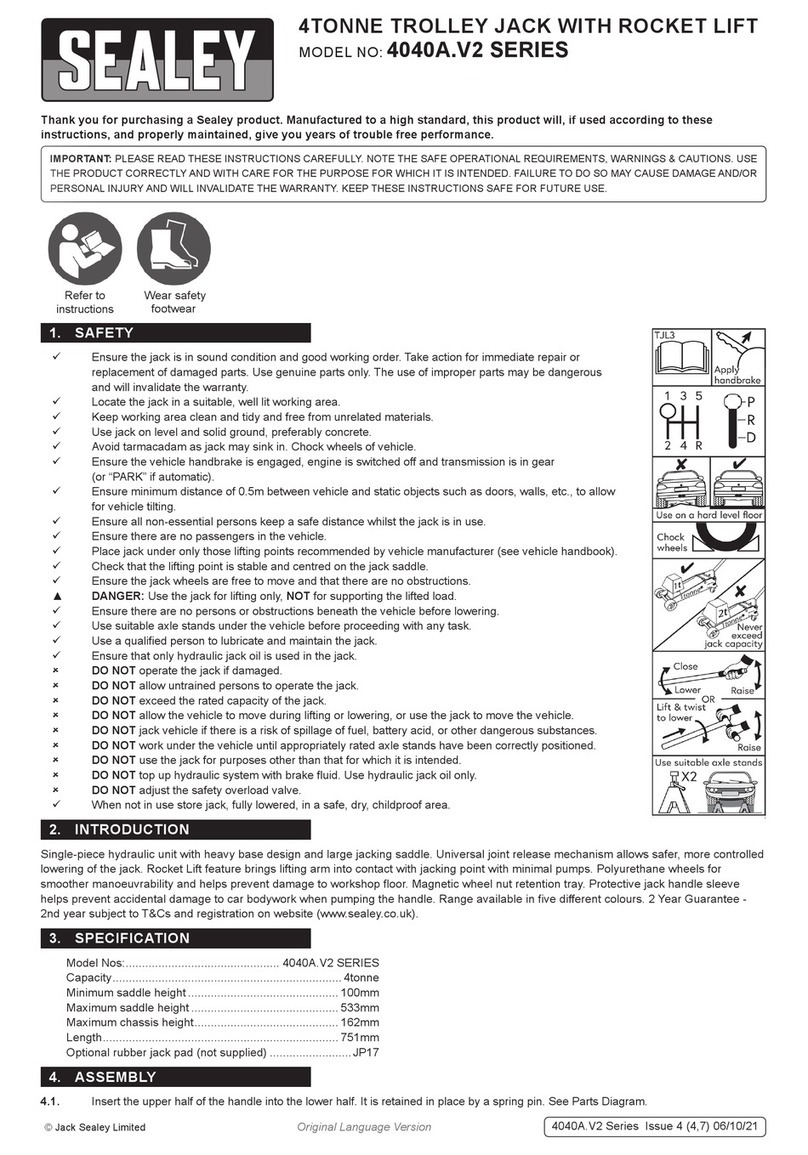

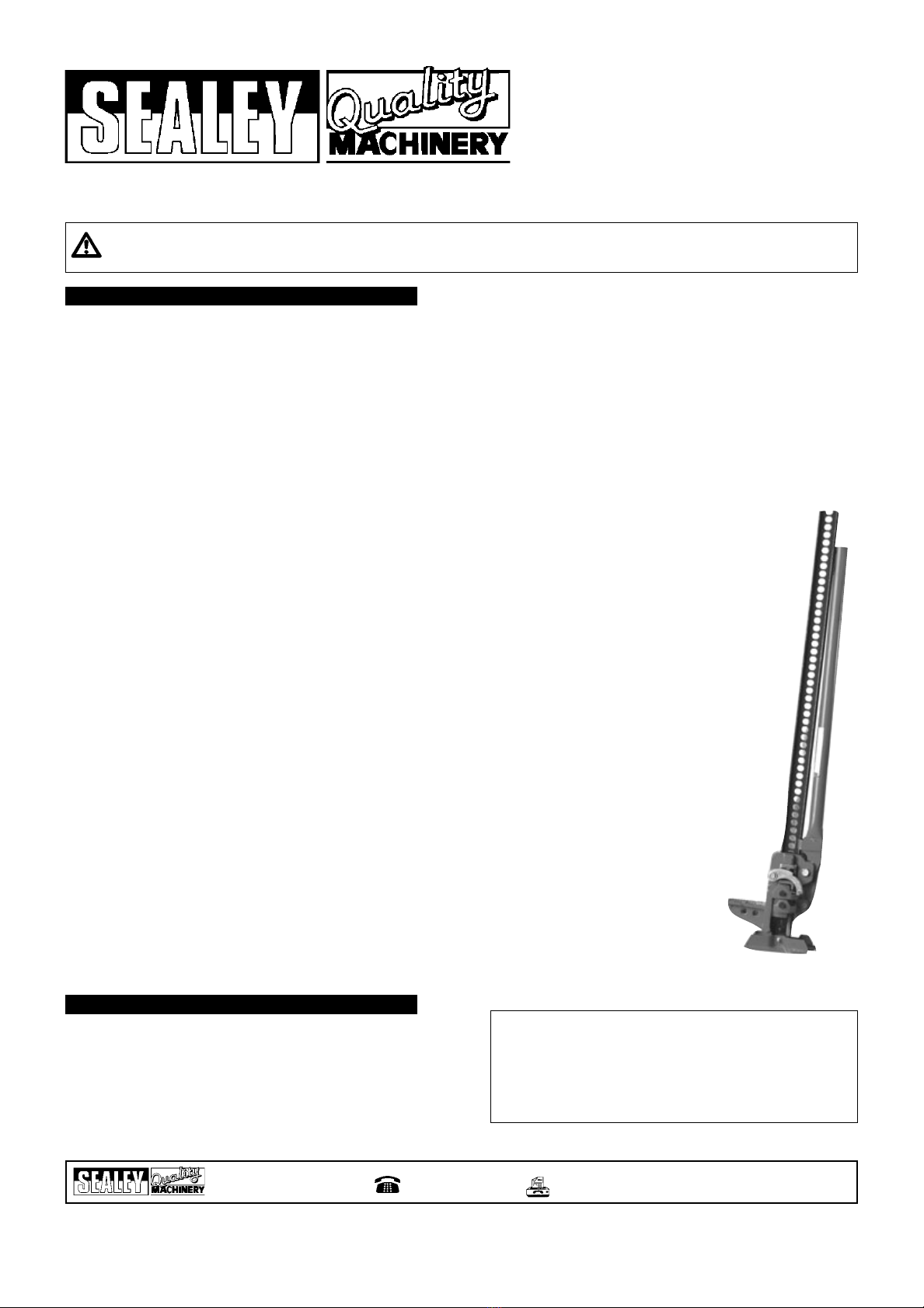

INSTRUCTIONS FOR:

FARM JACK

MODEL: FJ48

Your new Jack is produced and manufactured to a high standard of dependability and will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE

THIS JACK CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

1. SAFETY PRECAUTIONS

FJ48 - 0016 - (1) - 150600

Heavy-duty lever-ratchet operated jack with 48" beam. Reversible

ratchet mechanism enables jack to be used for lifting or lowering.

Versatile and lightweight unit suitable for pulling tree-stumps and

tensioning fences as well as a positioning aid for heavy machinery.

Many units sold to 4WD owners

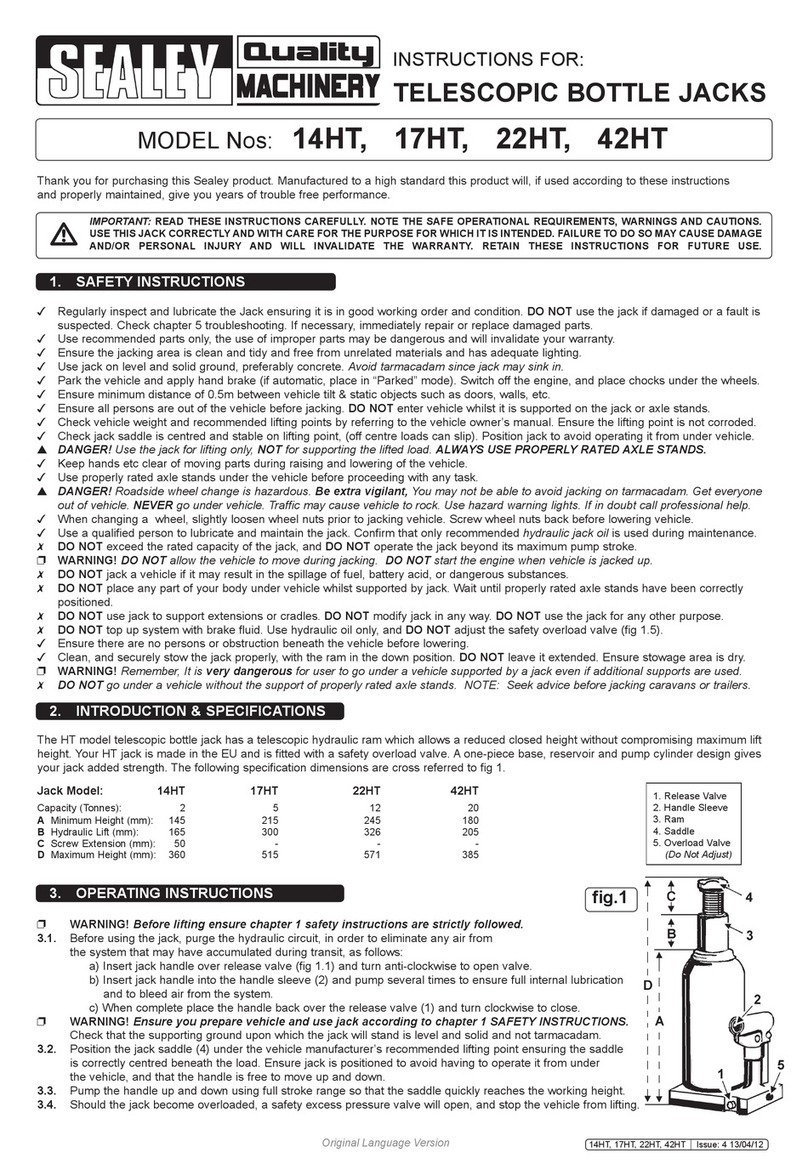

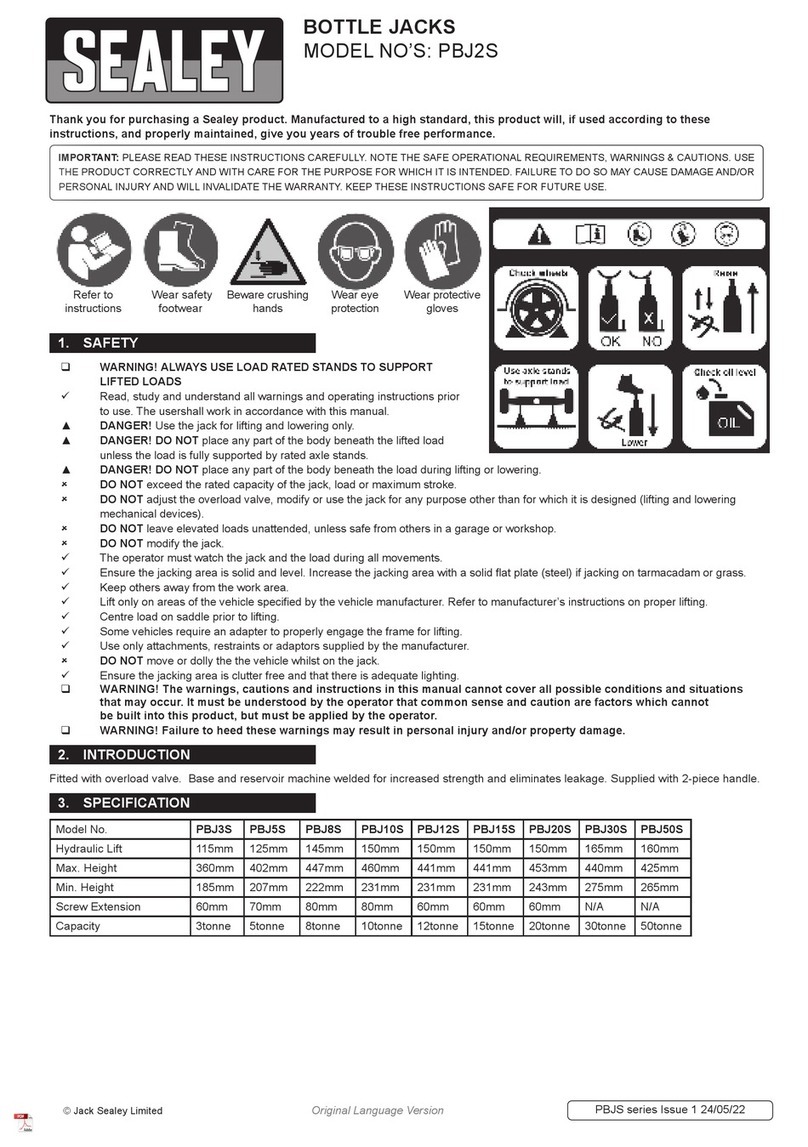

2. INTRODUCTION & SPECIFICATIONS

Specifications

Max Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1000kg

Min height . . . . . . . . . . . . . . . . . . . . . . . . . . . .150mm

Max. height . . . . . . . . . . . . . . . . . . . . . . . . . .1200mm

Min lowering load . . . . . . . . . . . . . . . . . . . . . . . . .50kg

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13.6kg

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk. 01284 757500 E-mail: sales@sealey.co.uk

01284 703534