INSTRUCTIONS FOR :

AIR OPERATED JACK 30tonne -

SINGLE STAGE/HIGH LIFT

MODEL No: YAJ30H

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS JACK CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

Thank you for purchasing a Sealey jack. Manufactured to a high standard this product will, if used according to these instructions and properly

maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

2. SPECIFICATION

Disconnect jack from air supply before changing parts, servicing or performing any maintenance.

WARNING! Ensure correct air pressure is maintained and not exceeded. Recommended pressure: 116-174psi Required air flow: 11.5cfm

Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use, and ensure that all connections are secure.

Ensure jack is kept clean and in good working order. Repair or replace damaged parts immediately

Use recommended parts only. Incorrect parts may be dangerous and will invalidate the warranty.

Use a qualified person to lubricate and maintain the jack.

DO NOT use brake fluid to top up system. Use Sealey hydraulic oil only.

Locate jack in a suitable, well lit work area. Keep area clean and tidy and free from unrelated materials.

Use jack on level & solid ground, preferably concrete. Avoid tarmacadam since jack may sink in.

Place chocks under wheels of vehicle.

Ensure the vehicle handbrake is engaged (or in “PARK” mode), and switch the engine off.

Ensure minimum distance of 0.5m between vehicle as it tilts & static objects such as doors, walls, etc.

Ensure all non essential persons keep a safe distance and that there are no passengers in the vehicle to be jacked up.

Place jack under vehicle manufacturer’s recommended jacking points (see vehicle handbook).

Check that the jacking point is stable and centred on the jack saddle and is free from grease or oil.

DANGER: Use jack for lifting only, NOT for supporting the raised load. Use correctly rated axle stands under vehicle before proceeding

with task.

DO NOT apply your body weight to the handle during jacking. The handle is only for moving the jack to and from the lifting location.

DO NOT operate the jack if parts are missing or damaged.

DO NOT exceed the rated capacity of the jack.

DO NOT allow the vehicle to move during lifting.

DO NOT jack a vehicle which may result in the spillage of fuel, battery acid, or dangerous substances.

DO NOT work under the vehicle until axle stands have been positioned correctly.

DO NOT use the jack for purposes other that those for which it is designed.

DO NOT adjust the safety overload valve.

DO NOT snatch the hose from the air supply, and DO NOT direct air from the air hose at yourself or others.

Ensure there are no persons or obstructions beneath the vehicle before lowering.

When not in use disconnect jack from the air supply, and store in the lowered position in a safe, dry, childproof area.

WARNING! Turn off air supply and de-pressurise the control nozzle before removing the pump unit from any installation or mobile system.

Failure to comply with this instruction may damage the unit and will invalidate your warranty.

Original Language Version

3. INTRODUCTION

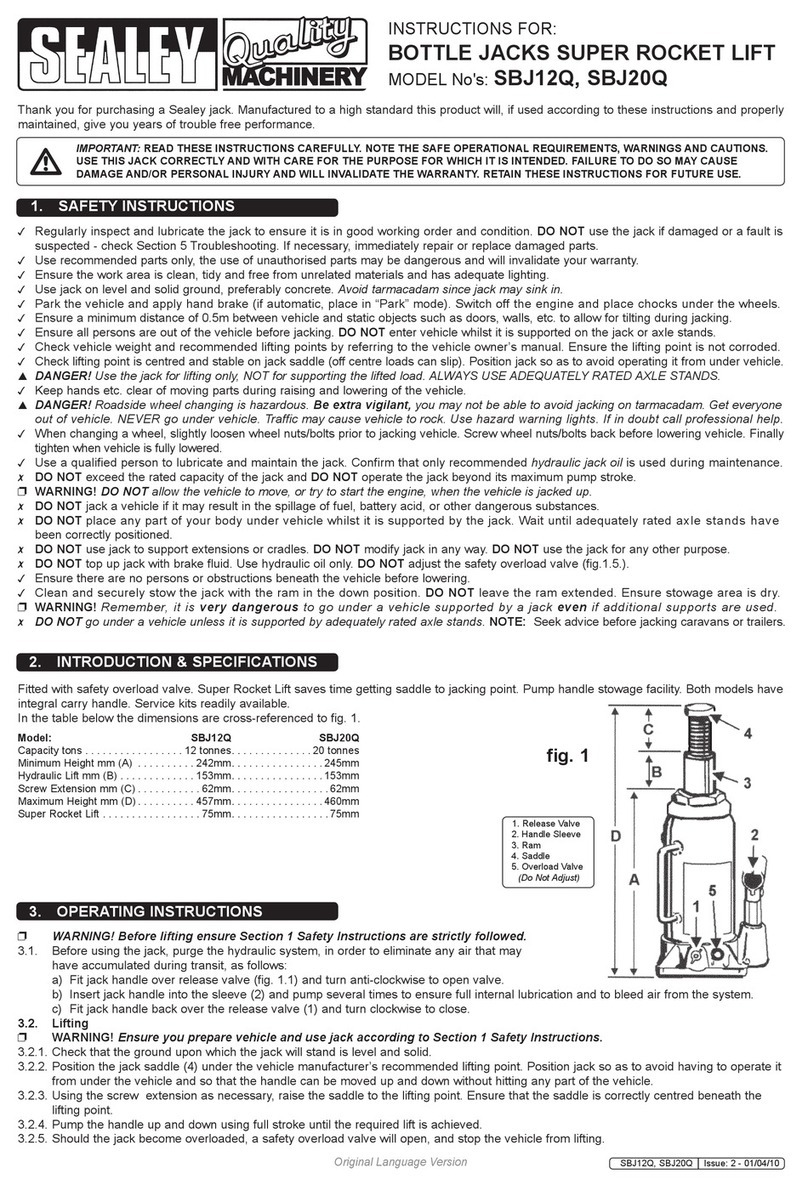

Ideal for workshop or roadside use, this jack takes the effort out of lifting heavy plant, tractors and commercial vehicles. For extra safety,

features a dead man’s handle which also aids controlled lowering speed. All models supplied with extensions that close the gap between the

saddle of the jack and the jacking point.

© Jack Sealey Limited

Model No: ......................................................YAJ30H

Maximum Capacity: ............................................... 30tonne

Minimum Height:...................................................360mm

Maximum Height (inc. Extensions) .....................................750mm

Stage 1 (mm/tonne): ................................................ 627/30

Piston Stroke: .....................................................267mm

Extensions: ..................................................... 45/75mm

Chassis Length: ...................................................842mm

Length inc. Handle:................................................2222mm

Width without Wheels: ..............................................195mm

Overall Width: .....................................................295mm

Air consumption: ...................................................11.5cfm

Working Pressure: ..............................................116-174psi

Weight: ...........................................................126kg

YAJ30H Issue:1 - 04/09/13