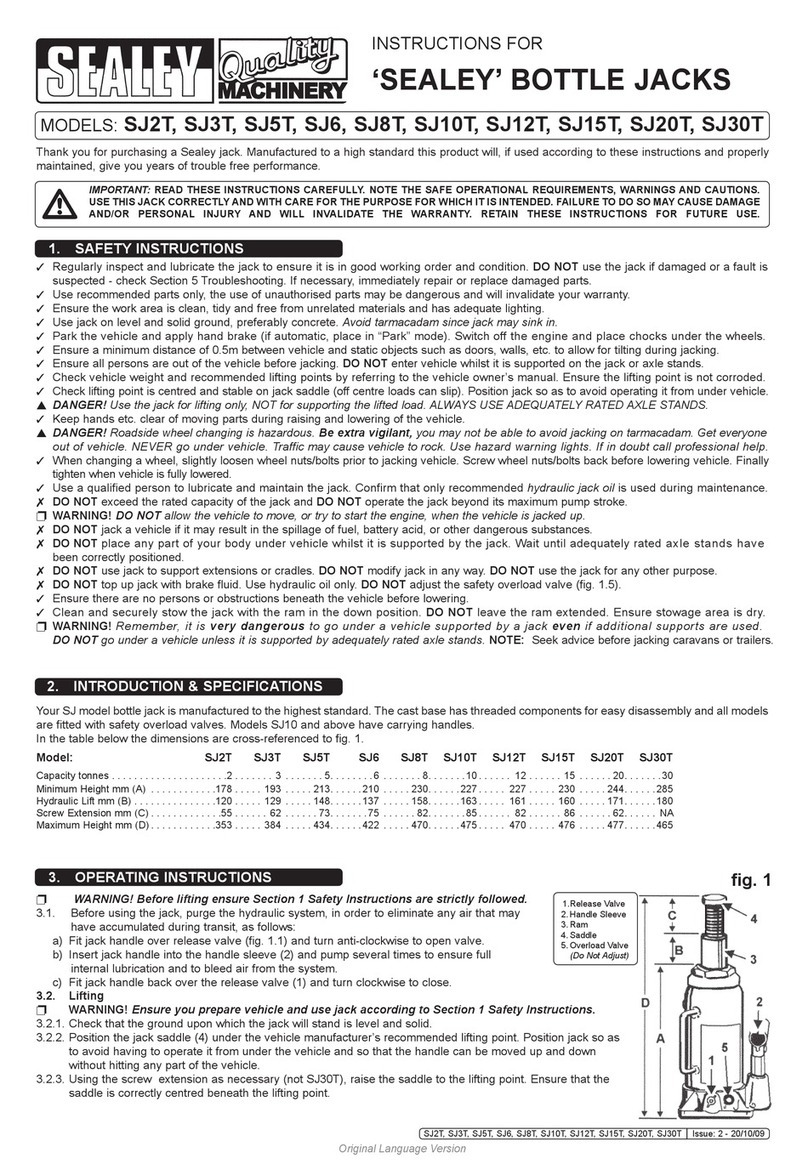

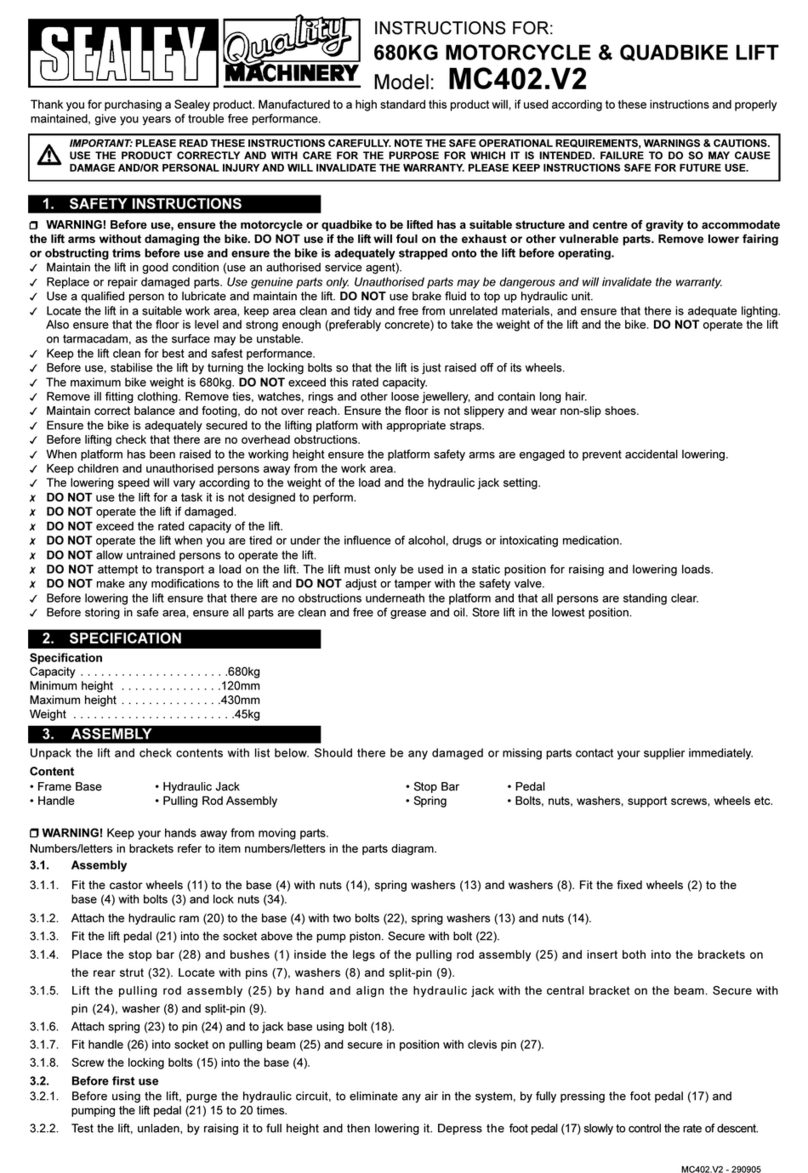

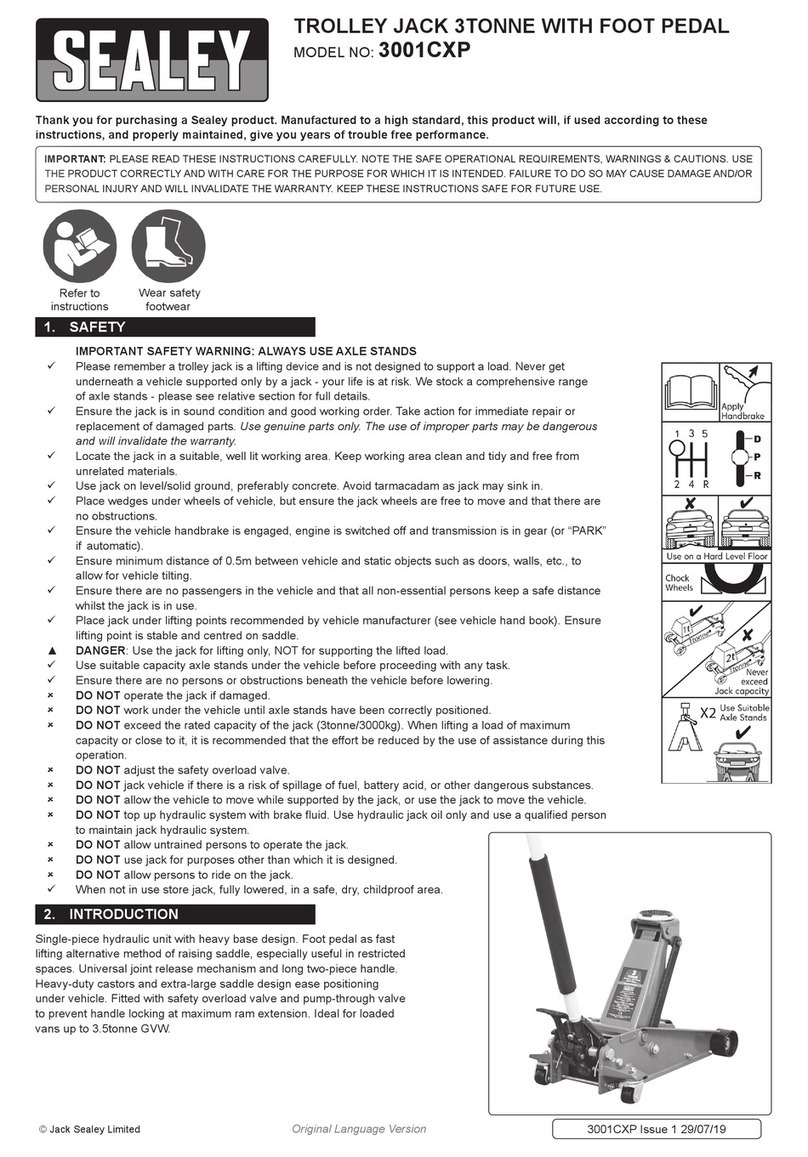

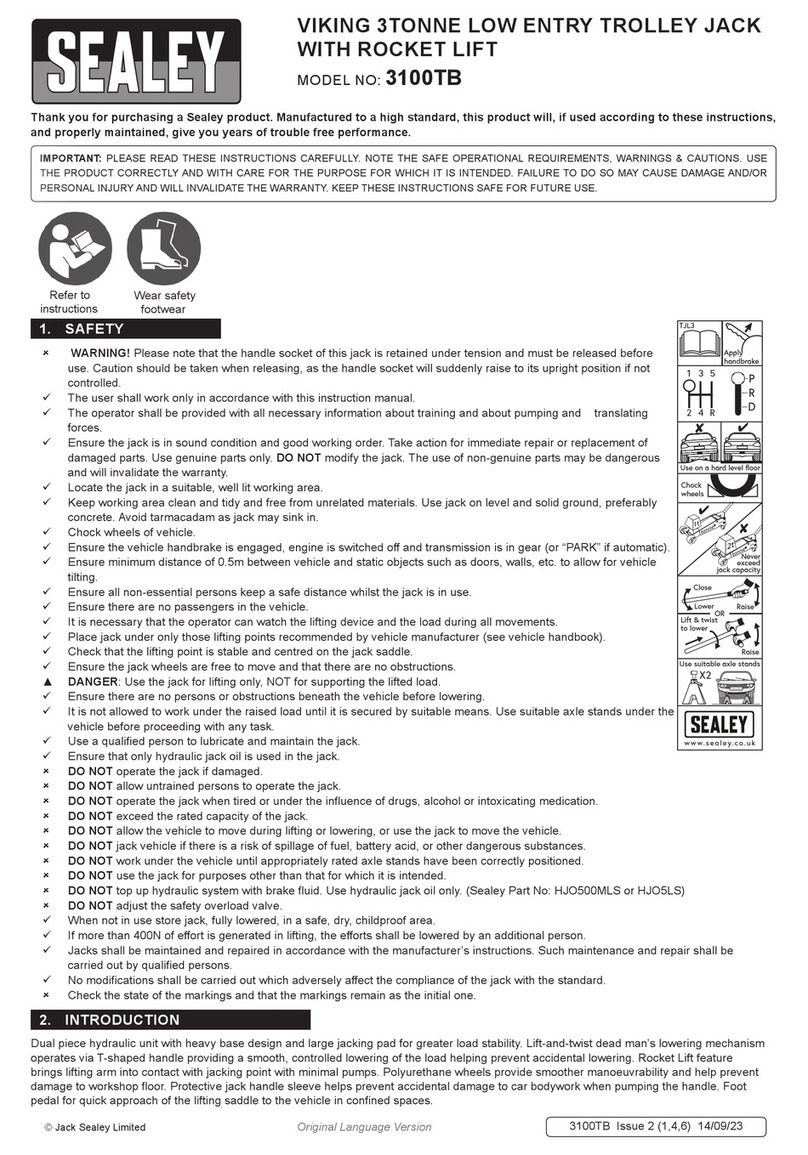

2.1. INTRODUCTION

Your jack has been designed for industrial use but must only be used on hard, flat, even surfaces. All

models have a safety lock and overload device built into the unit and a T-handle twist lock safety

release feature. A foot pedal is fitted for raising the saddle rapidly to the jacking point. Normal use of

pumping handle then lifts the load.

pWARNING! The load must not exceed the maximum capacity of each model (see model specifications).

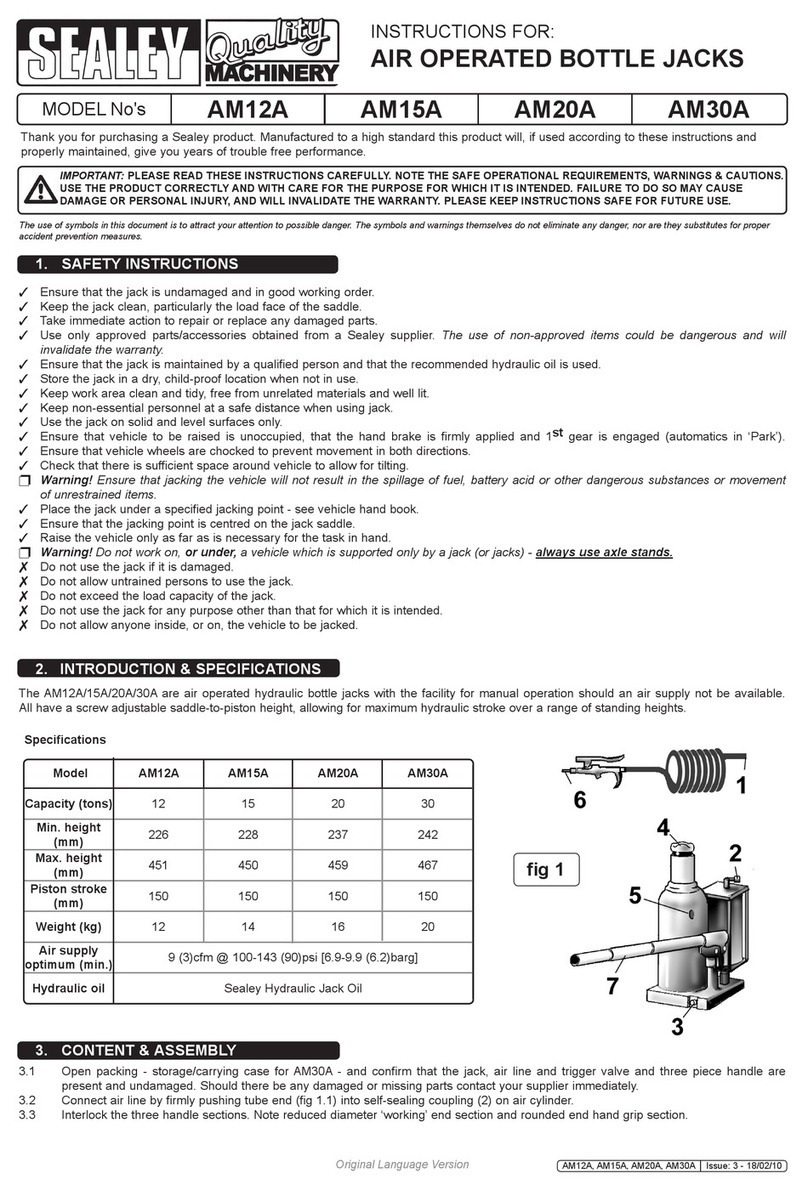

2.2. ASSEMBLY

Insert the handle into the socket whilst simultaneously pressing together the spring clip. Ensure that

the clip engages in the slot on the handle (see right).

sCAUTION! The spring is an important safety feature which will automatically stop the jack from lowering

if the handle is released (known as the Deadman principle). It is, therefore, very important to ensure that the

handle and spring are correctly fitted.

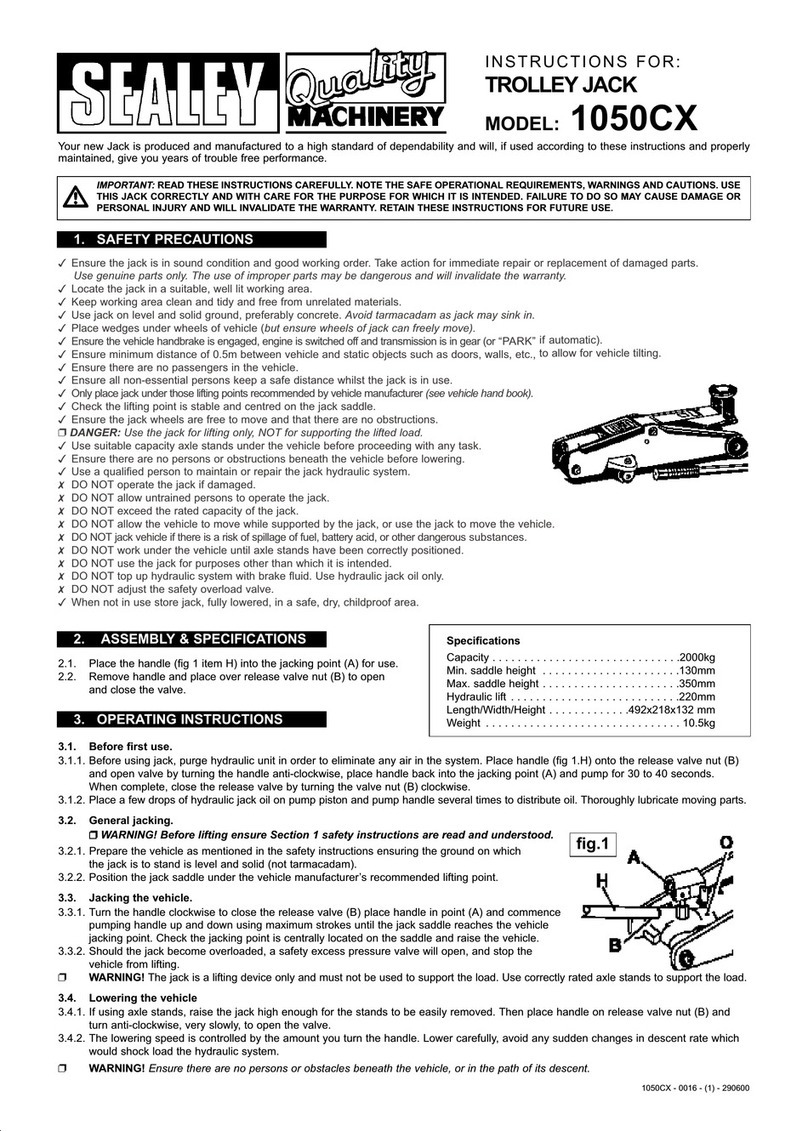

INSTRUCTIONS FOR:

TROLLEY JACKS

Models: TJ3, TJ5.V2, TJ10.V2, TJ15

Your new jack is produced and manufactured to a high standard of dependability and will, if correctly cared for, give you years

of trouble free performance.

1. SAFETY INSTRUCTIONS

2. INTRODUCTION & ASSEMBLY

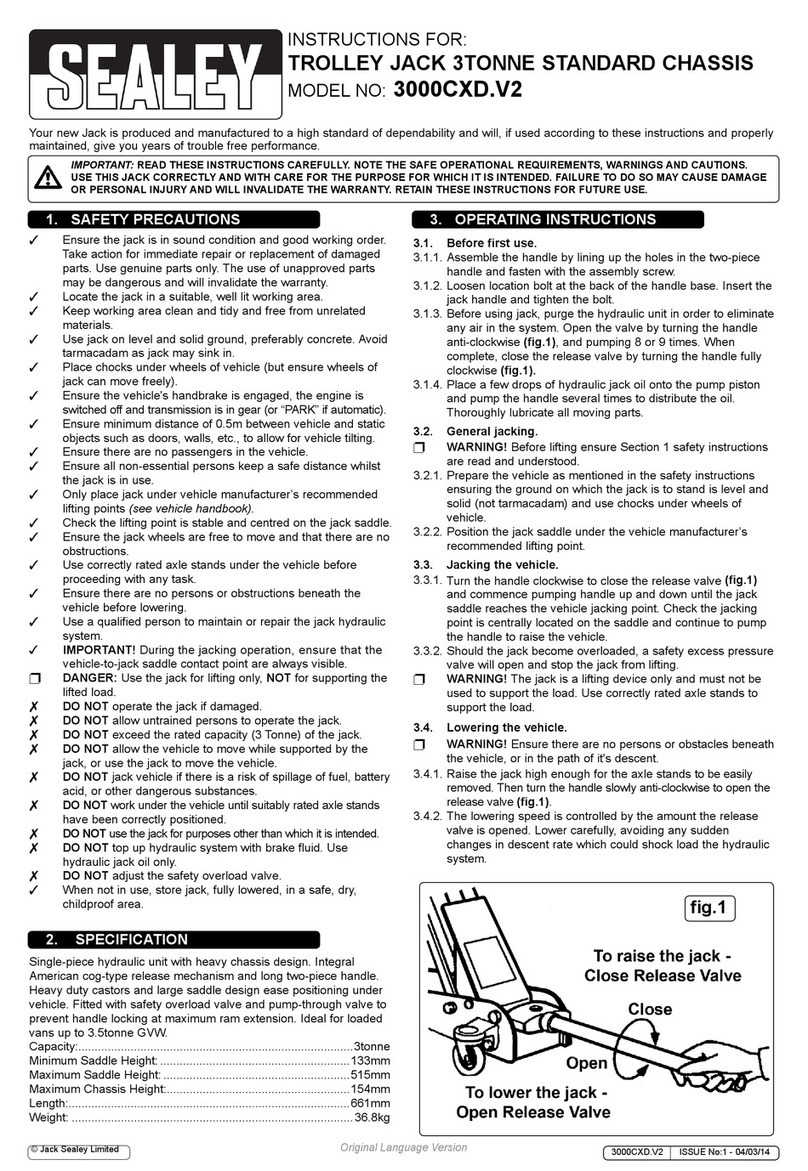

3.1. PREPARATION

3.1.1. Before using the jack, purge hydraulic circuit in order to eliminate any air that may have entered the system during transit.

a) Open the release valve by turning the handle clockwise against the spring and hold the handle in that position.

b) Pump using full strokes for approximately one minute to ensure complete internal lubrication and to bleed any air from the system.

c) Release the handle and the spring will automatically return the handle to the normal pumping position.

d) Place a few drops of hydraulic jack oil on the pump piston and pump the handle several times to distribute the oil.

e) Thoroughly lubricate all moving parts.

3.1.2. Prepare the vehicle for jacking according to Section 1 safety instructions.

3.2. JACKING

p

p

DANGER! Use the jack for lifting only, NOT for supporting the lifted load. Read, understand and apply Section 1 safety instructions.

3.2.1. Depress the foot pedal to raise the saddle to the jacking point.

3. OPERATING INSTRUCTIONS

TJ3, TJ5.V2, TJ10.V2, TJ15 - 1 - 250603

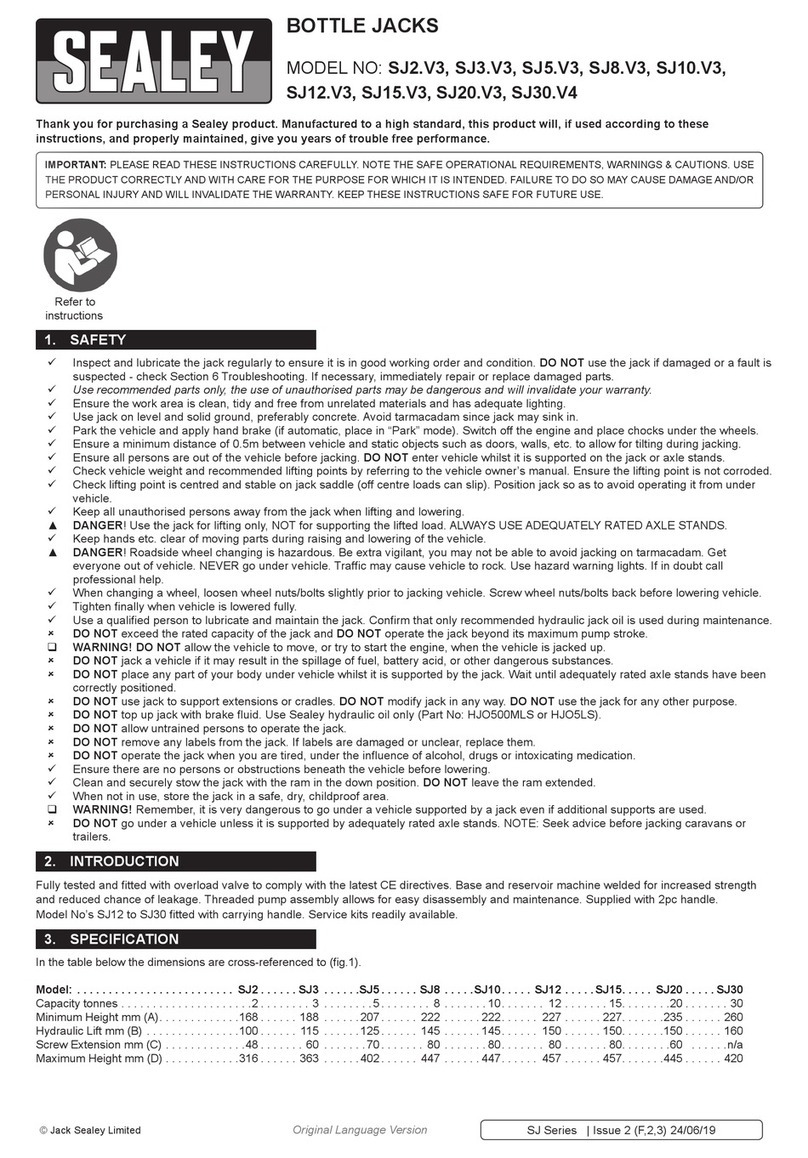

Model TJ3 Specification

Capacity . . . . . . . . . . . . . . . . .3 tons

Min. saddle height . . . . . . . .145mm

Max. saddle height . . . . . . . .525mm

Max. chassis height . . . . . . .190mm

Length . . . . . . . . . . . . . . . .1220mm

Weight . . . . . . . . . . . . . . . . . . .52kg

Oil capacity . . . . . . . . . . . . . .0.37ltr

Model TJ5.V2 Specification

Capacity . . . . . . . . . . . . . . . . .5 tons

Min. saddle height . . . . . . . .195mm

Max. saddle height . . . . . . . .575mm

Max. chassis height . . . . . . .220mm

Length . . . . . . . . . . . . . . . .1300mm

Weight . . . . . . . . . . . . . . . . . . .82kg

Oil capacity . . . . . . . . . . . . . .0.75ltr

Model TJ10.V2 Specification

Capacity . . . . . . . . . . . . . . . .10 tons

Min. saddle height . . . . . . . .195mm

Max. saddle height . . . . . . . .575mm

Max. chassis height . . . . . . .260mm

Length . . . . . . . . . . . . . . . .1600mm

Weight . . . . . . . . . . . . . . . . . .112kg

Oil capacity . . . . . . . . . . . . . .1.15ltr

Model TJ15 Specification

Capacity . . . . . . . . . . . . . . . .15 tons

Min. saddle height . . . . . . . .180mm

Max. saddle height . . . . . . . .575mm

Max. chassis height . . . . . . .255mm

Length . . . . . . . . . . . . . . . .1845mm

Weight . . . . . . . . . . . . . . . . . .160kg

Oil capacity . . . . . . . . . . . . . .1.25ltr

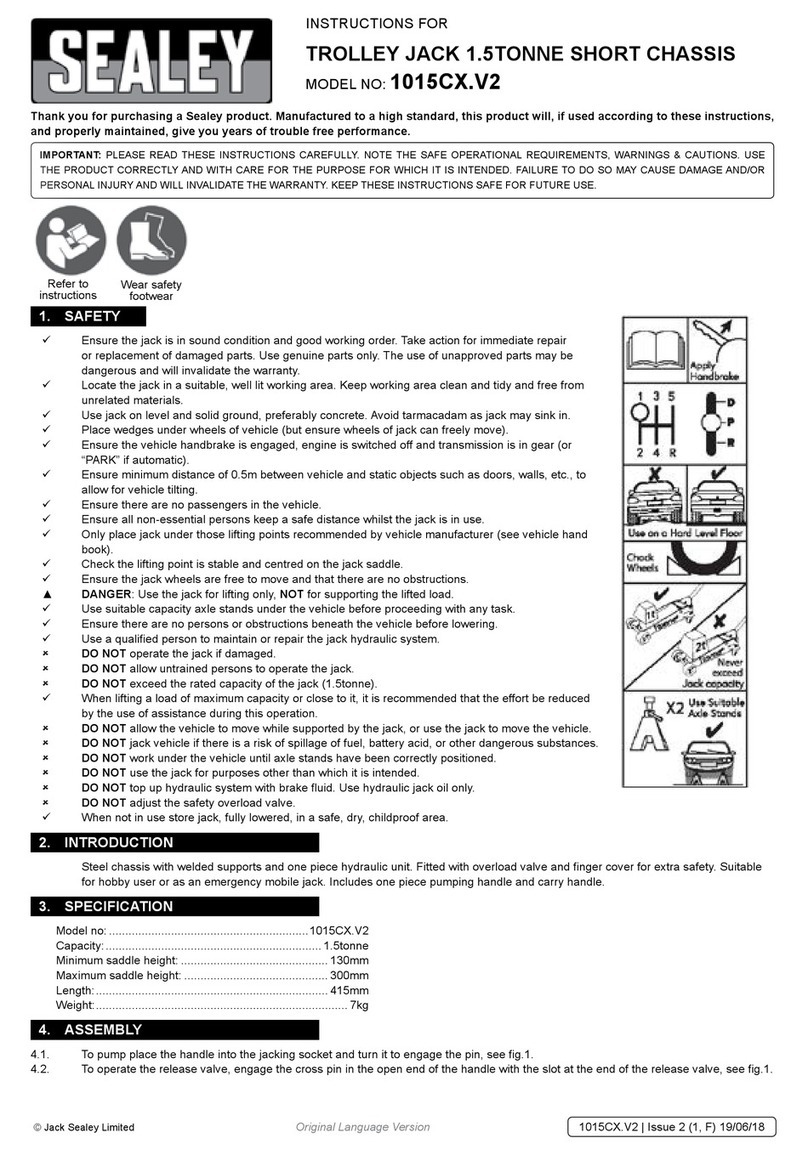

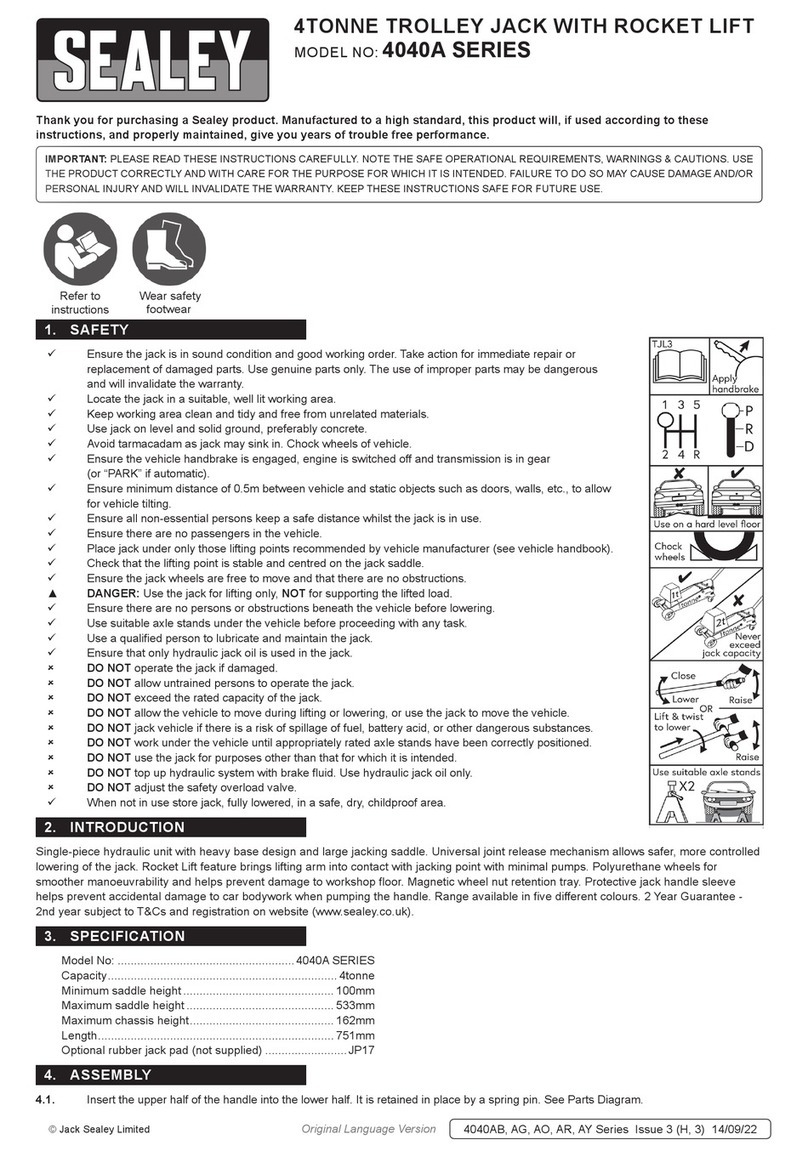

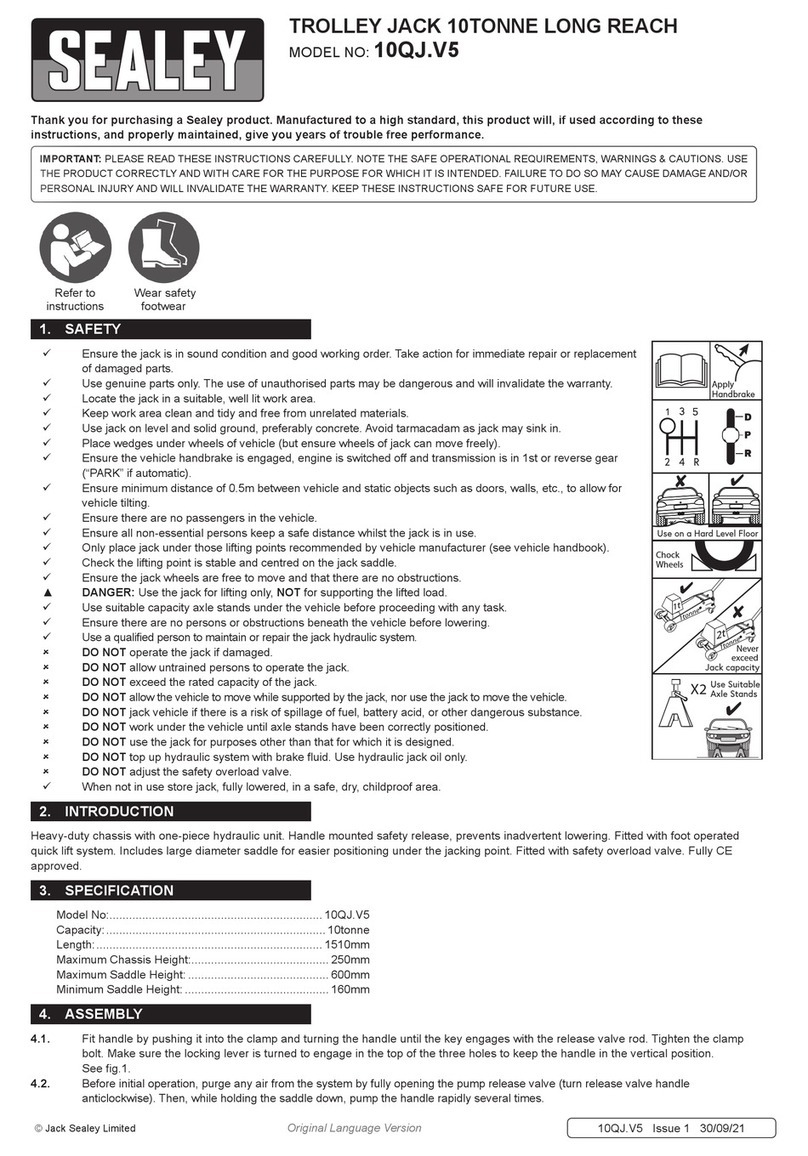

3Ensure jack is in sound condition and good working order. Take action for immediate repair or

replacement of damaged parts. Use genuine parts only, the use of unauthorised parts may be

dangerous and will invalidate the warranty. Repairs to be undertaken by qualified personnel only.

3Locate the jack in a suitable, well lit work area.

3Keep work area clean and tidy and free from unrelated materials.

3Use jack on level and solid ground, preferably concrete. Avoid tarmacadam as jack may sink in.

3Ensure that the vehicle handbrake is engaged, the engine is switched off, the transmission is in

gear (or in Park if automatic) and the wheels are chocked.

3Ensure at least 0.5m between vehicle and objects such as doors, walls, etc. to allow for tilt during jacking.

3Ensure there are no passengers in the vehicle at any time during jacking or whilst jacked up.

3Ensure all non-essential persons keep a safe distance whilst the jack is in use.

3Place jack under vehicle manufacturers recommended lifting points (see vehicle handbook).

3Check that the lifting point is not corroded and that it is centred and stable on the jack saddle.

3Ensure the jack wheels are free to move and that there are no obstructions.

pDANGER! Use the jack for lifting only, NOT for supporting the lifted load.

3Place adequately rated axle stands under the vehicle before proceeding with any task.

3Keep hands etc. clear of moving parts during the raising and lowering of the vehicle.

3Ensure that there are no persons or obstructions beneath the vehicle before lowering.

3Use a qualified person to lubricate and maintain the jack.

3Use only recommended hydraulic jack oil.

7DO NOT operate the jack if it is damaged.

7DO NOT exceed the rated capacity of the jack. Check vehicle weight in vehicle users manual.

7DO NOT allow the vehicle to move during jacking, and DO NOT start the engine.

7DO NOT place any part of your body under vehicle whilst it is supported by jack. Always use axle stands.

7DO NOT use the jack to move vehicle.

7DO NOT jack vehicle which may result in spillage of fuel, battery acid, or other dangerous substances.

7DO NOT top up hydraulic unit with brake fluid. Use recommended hydraulic oil only.

7DO NOT adjust safety overload valve or modify jack. Use for lifting vehicles only.

3When not in use ensure arm is in the down position and store in a safe, dry, childproof area.

pWARNING! It is very dangerous to go under a vehicle which is supported by a jack even if

additional supports are used. DO NOT go under vehicle unless it is supported by adequately rated axle stands.

sIMPORTANT! Make sure that you can see the saddle and jacking point throughout the

jacking operation in case there is any relative movement.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS. USE

THIS JACK CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.