WARNING! DO NOT use the wrench if damaged or thought to be faulty.

Ensure all workshop safety rules, regulations and conditions are complied with when using torque wrench.

Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

Keep children and unauthorised persons away from the working area.

After use clean with a soft dry cloth and store in a safe, dry, childproof location.

Keep the wrench away from magnets.

DO NOT subject the wrench to excessive force or shocks.

DO NOT drop or throw the wrench.

DO NOT use wrench unless you have been instructed in its use by a qualified person.

DO NOT leave the wrench in any place exposed to excessive heat, humidity or direct sunlight.

DO NOT use organic solvents such as alcohol or thinners to clean the wrench.

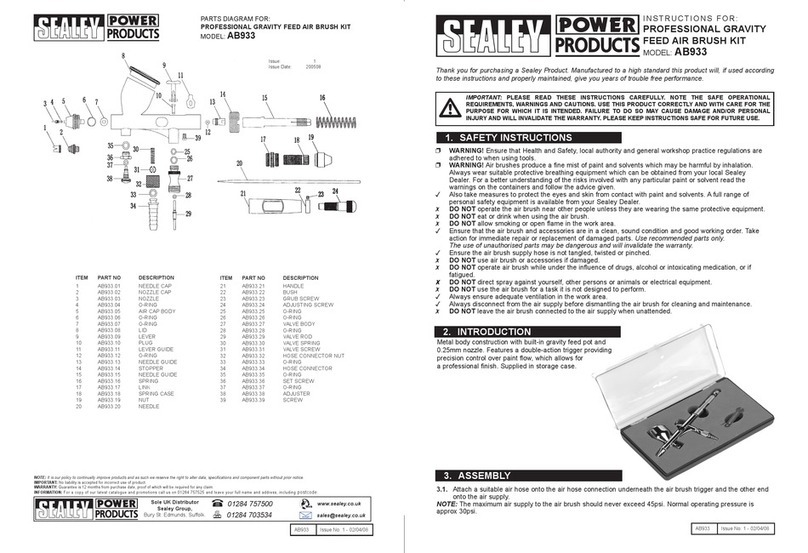

2.1. Introduction Rugged and resilient digital torque wrenchs suitable for workshop and factory use. LCD

readout with LED/audible alarm indicates achieved and target torque levels. Preset desired torque levels or

track peak and working torques using simple push-button menu. Stores up to 50 readings. Selectable

readout in lb.ft, lb.in or Nm. Reversible Chrome Vanadium ratchet allows torque reading in either direction.

Accurate to ±2% between 20% and 100% of wrench’s stated capacity. Tested in accordance with

EN ISO 6789. Supplied with certificate and storage case.

Thank you for purchasing a Sealey Product. Manufactured to a high standard this tool will, if

used according to these instructions and properly maintained, give years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THIS PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

DIGITAL TORQUE WRENCHES

INSTRUCTIONS FOR MODEL NOS:

STW300, STW301, STW302, STW303

1. SAFETY INSTRUCTIONS

2. INTRODUCTION & SPECIFICATION

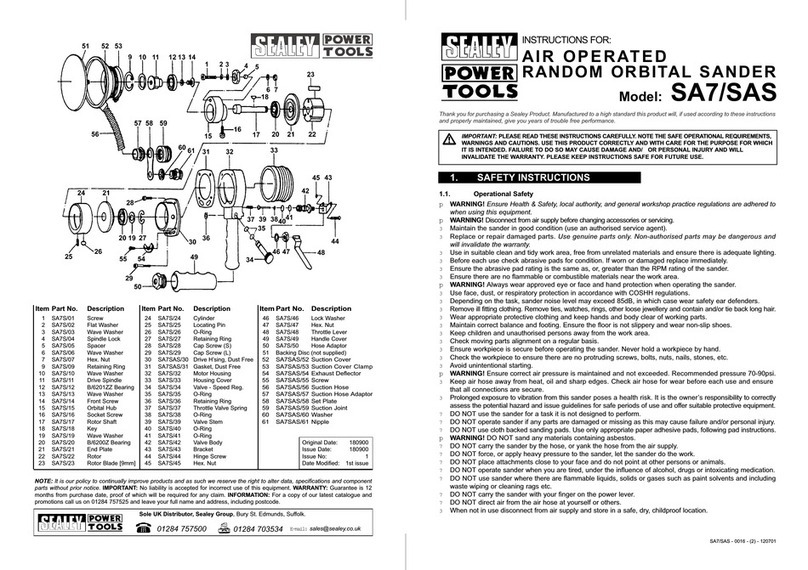

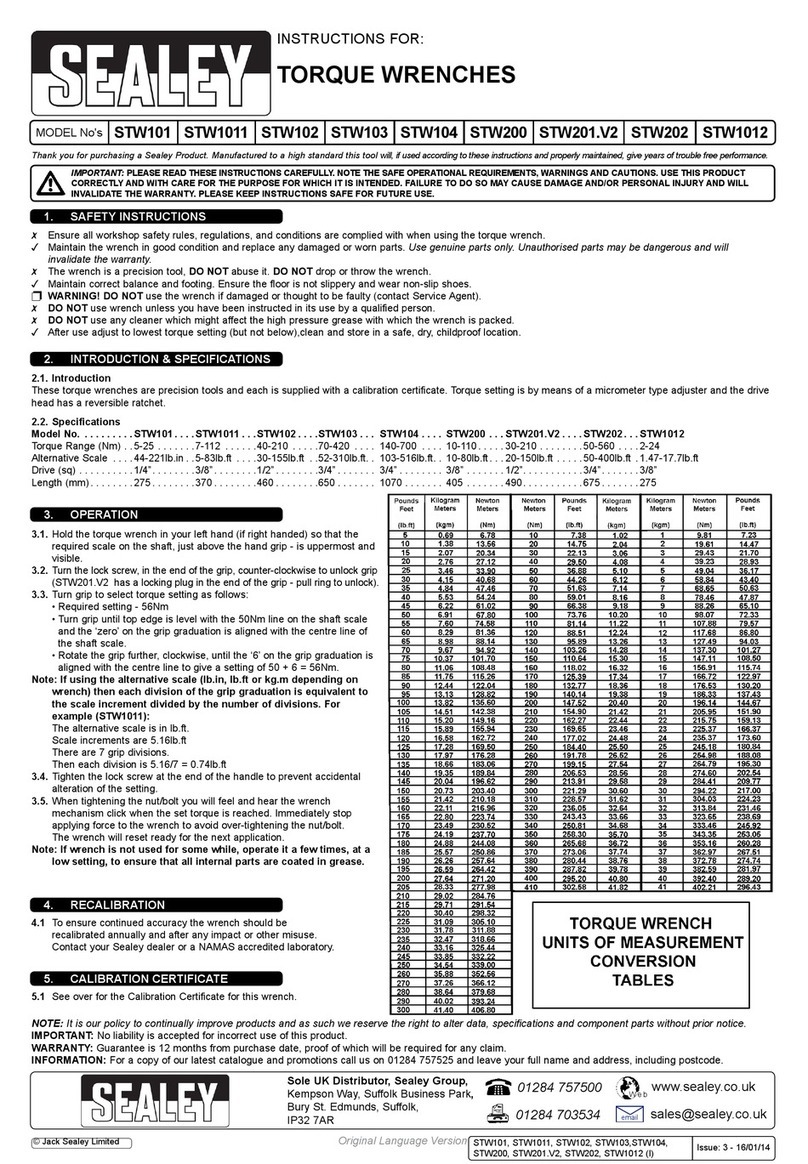

MODEL

NO.

STW300 STW301 STW302 STW303

DRIVE 1/4" 3/8" 1/2" 1/2"

LENGHT 390mm 415mm 530mm 650mm

Range

accurate to

±2%

Stated

capacity

Range

accurate to

±2%

Stated

capacity

Range

accurate to

±2%

Stated

capacity

Range

accurate to

±2%

Stated

capacity

TORQUE

(Nm)

6 - 30 1.5 - 30 27 - 135 6.8 - 135 40 - 200 10 - 200 68 - 340 17 - 340

TORQUE

(lb.ft)

4.42 -

22.12

1.11 -

22.12

19.9 -

99.5

5 -

99.5

29.5 -

147.5

7.4 -

147.5

50.1 -

250.7

12.5 -

250.7

TORQUE

(lb.in)

53.1 -

265.5

13.3 -

265.5

239 -

1195

60 -

1195

354 -

1770

88.0 -

1700

602 -

3009

150 -

3009

5. RE-CALIBRATION

5.1 In order to ensure continued accuracy the

wrench should be re-calibrated annually and

after any impact or other misuse. Contact your

local Sealey dealer.

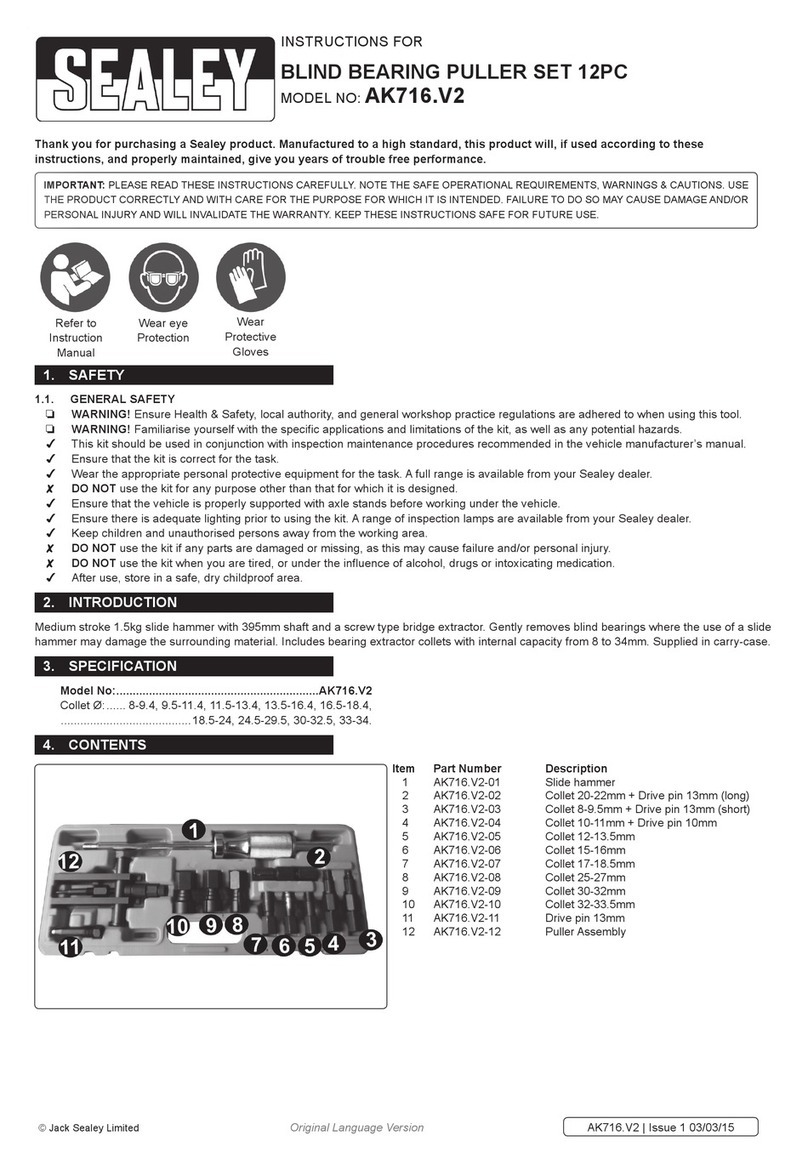

4. BATTERIES

4.1 Changing / loading batteries. Use a coin to

unlock the battery compartment by turning the

cap anti-clockwise and removing it. Insert two

new AA size batteries (positive end first) into the

compartment. Line up the small arrow on the

battery cap with the arrow above the

compartment aperture. Using a coin push the cap

flush with the end of the wrench and turn it to the

locked position.

4.2 Low voltage protection. If the battery serial

voltage falls below 2.3 volts the wrench will show

a battery symbol in the top left hand corner of the

display for a short while then cut off.

01284 757500

01284 703534

Sole UK Distributor

Sealey Group,

Bury St. Edmunds, Suffolk.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and

component parts without prior notice. IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim. INFORMATION: For

a copy of our catalogue and latest promotions call us on 01284 757525 and leave your full name, address and postcode.

www.sealey.co.uk

Web

email

STW300, STW301, STW302, STW303, ISSUE No:2 19/01/09