Ram diameter..................................................................48mm

Lateral ram travel ..........................................................403mm

Max height - ram to table.............................................1018mm

Min height - ram to table..................................................58mm

Work table aperture.......................................................100mm

Work table depth ...........................................................206mm

Work table width............................................................630mm

Overall height ..............................................................1796mm

Weight ...............................................................................93kg

Gauge included ...................................................................Yes

Air consumption.................................................................4cfm

Working pressure ....................................................108-120psi

4. ASSEMBLY

REFER TO PARTS LIST DIAGRAM

4.1. Unpack the product and check the contents. Should there be any damaged or missing parts, contact your supplier immediately. Take

care to ensure safety when removing main frame from its packing, as the unit is very heavy.

4.2. Use the parts diagram as your guide to assembly. Lay all parts and assemblies out before beginning assembly. The following

procedure is recommended.

4.3. Attach one base section (21) to left frame post (20) and lower cross member (26) using bolts (25), washers (22), lock washers (23) and

nuts (24). Attach two diagonal supports (60) between the post and base section using bolts (25), washers (22), lock washers (23) and

nuts (24).

4.4. Attach the other base section (21) and the right frame post (20) to the lower cross member (26). Attach two diagonal supports (60)

between the right post and base section using bolts (25), washers (22), lock washers (23) and nuts (24).

4.5. Put the press frame in an upright position, attach one upper crossbeam (10) to left and right posts (20) using bolts (9), washers (13),

lock washers (12) and nuts (11).

4.6. Hook the under plate (7) onto the first cross beam and slide the other cross beam sideways through the other hooks until it is in

position in front of the posts. Attach to the posts with bolts (9), washers (13), lock washers (12) and nuts (11).

4.7. Screw the upper round nut (6) onto the ram (3), insert the ram into the hole in the under plate (7), then screw the lower round nut (8)

onto the ram and attach the serrated saddle (5) to the ram.

4.8. Place the two halves of the press bed frame (18) back to back. Move them apart until the space between them is the same as the

length of the four spacers (28). Align each spacer with the holes in the bed halves and insert a bolt (27) through both frames and the

spacer. Secure the four bolts by using the washers (14), lock washers (15) and nuts (16).

4.9. Insert bed frame pins (19) into the holes in the posts at the same level. Hold the assembled bed frame diagonally between the posts.

Turn it horizontal so that the ends are in contact with the posts and lower it onto the pins.

4.10. Attach the pump and air motor assemblies to the right post using bolts (29) and washers (14). Ensure that the air motor is below the

pump. Insert the pumping handle (48) into the handle bracket (38).

4.11. Connect the hydraulic hose fitting (57) to the connection nut (58) and assemble the pressure gauge (1) to the pressure gauge

connection nut and nylon ring (59) (2) which is on the top of the ram (3).

4.12. Tighten all nuts, bolts and screws.

5. INSTALLATION

▲DANGER! The press is top heavy. If it requires moving after assembly or for relocation, use suitable slings around the top

crossbeam, or lift direct with a forklift with the forks located under the top crossbeam. DO NOT use a pallet truck.

5.1. Securely attach the press to a flat, firm, level surface, taking into account any clearance required for workpieces.

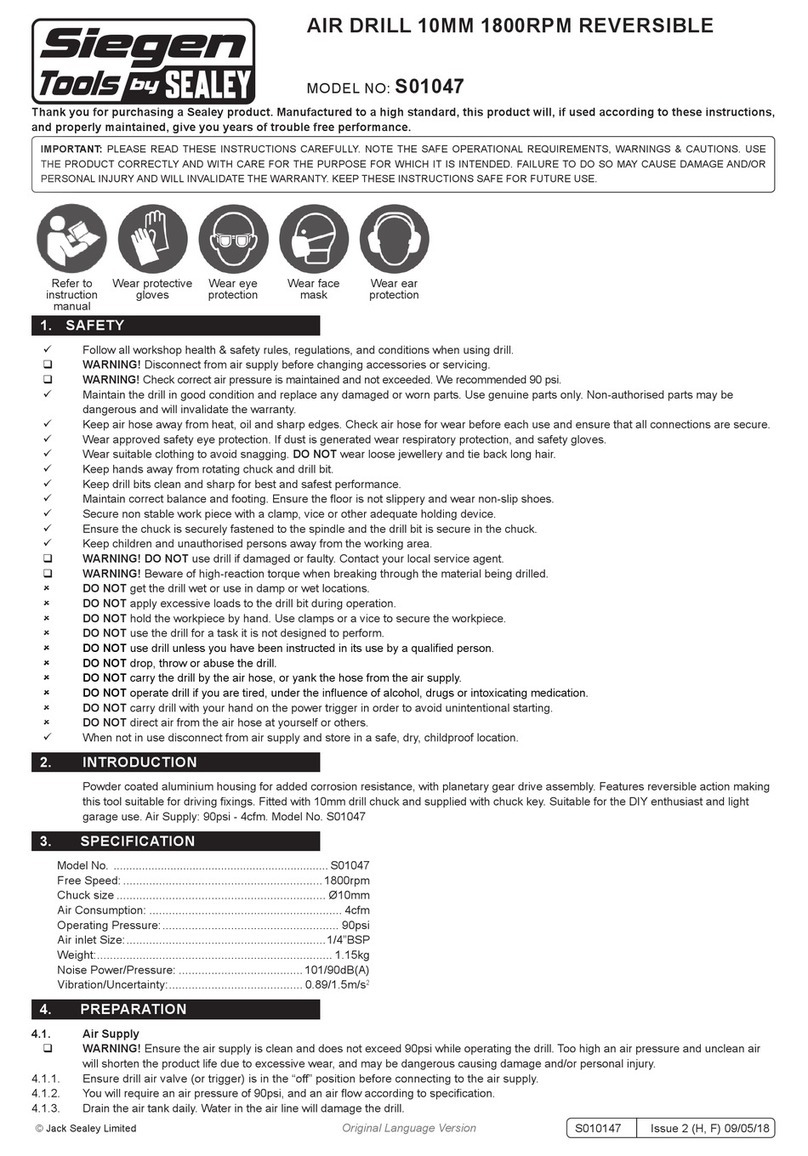

5.2. Connect to an air supply as recommended in fig.1. The air supply must be capable of 108 to 120psi and 4cfm.

5.3. Purge hydraulic system. Before operating the press, the hydraulic system may require purging in order to eliminate any air that may have

built up during transit.

5.4. Manual operation: open the release valve (41) by turning it counter-clockwise. Pump several full strokes to eliminate any air in

the system.

5.5. Air operating system: open the release valve (41) by turning it counter-clockwise. Connect the air inlet fitting (39) into the air supply

hose lock fitting, then turn on the air valve (40) letting the pump work for several times to eliminate any air in the system.

5.6.

5.7.

5.8.

5.9.

5.10.

5.11.

5.12.

5.13.

5.14.

5.15.

5.16.

6. OPERATION

▲DANGER! This model is purpose designed to withstand greater loads than the hydraulic units can develop. For safety reasons, always

ensure the workpiece and press tools are secured on the table and will not flex or suddenly “give way” causing danger to operator or the

component.

6.1. Place the arbor plate (17) on press bed frame/table (18), then place the workpiece onto the arbor plate and align beneath the ram as

required. NOTE: care must be taken to ensure an arbor does not fall from the press work table. If necessary hold the configuration in

position with clamps.

Original Language Version

© Jack Sealey Limited

fig.1

YK20FAH.V2Issue2(H,F,4,5,6)30/11/18