Petrol is a highly flammable liquid and any spillage will evaporate to form a flammable, heavier than air vapour which is easily ignited.

Common ignition sources include, but are not limited to, smoking and light matches, welding and cutting equipment, heaters, all types of

electrical equipment unless specifically designed as suitable for use in flammable atmosphere. Even low voltage inspection lamps, if

damaged can ignite petrol vapour

Please take time to read the following safety information before commencing work with the TP95.

! Use the tool only for its intended purpose.

! Familiarise yourself with this product’s applications and limitations, as well as the specific potential hazards peculiar to this tool.

! Use original Sealey spare parts only. Non-recommended parts may be dangerous and will invalidate the warranty.

!We recommend that the TP95 is used outdoors or in a well ventilated area, and well away from pits or other openings in the ground

where vapour can collect.

!Disconnect the vehicle's battery before draining fuel.

!Keep a foam or dry powder fire extinguisher nearby.

!Ensure containers cannot easily be knocked over during filling.

!Ensure containers are large enough to hold the contents of the fuel tank you are draining.

! Ensure space required for use and maintenance of the tool is adequate, free from unrelated materials and has good lighting.

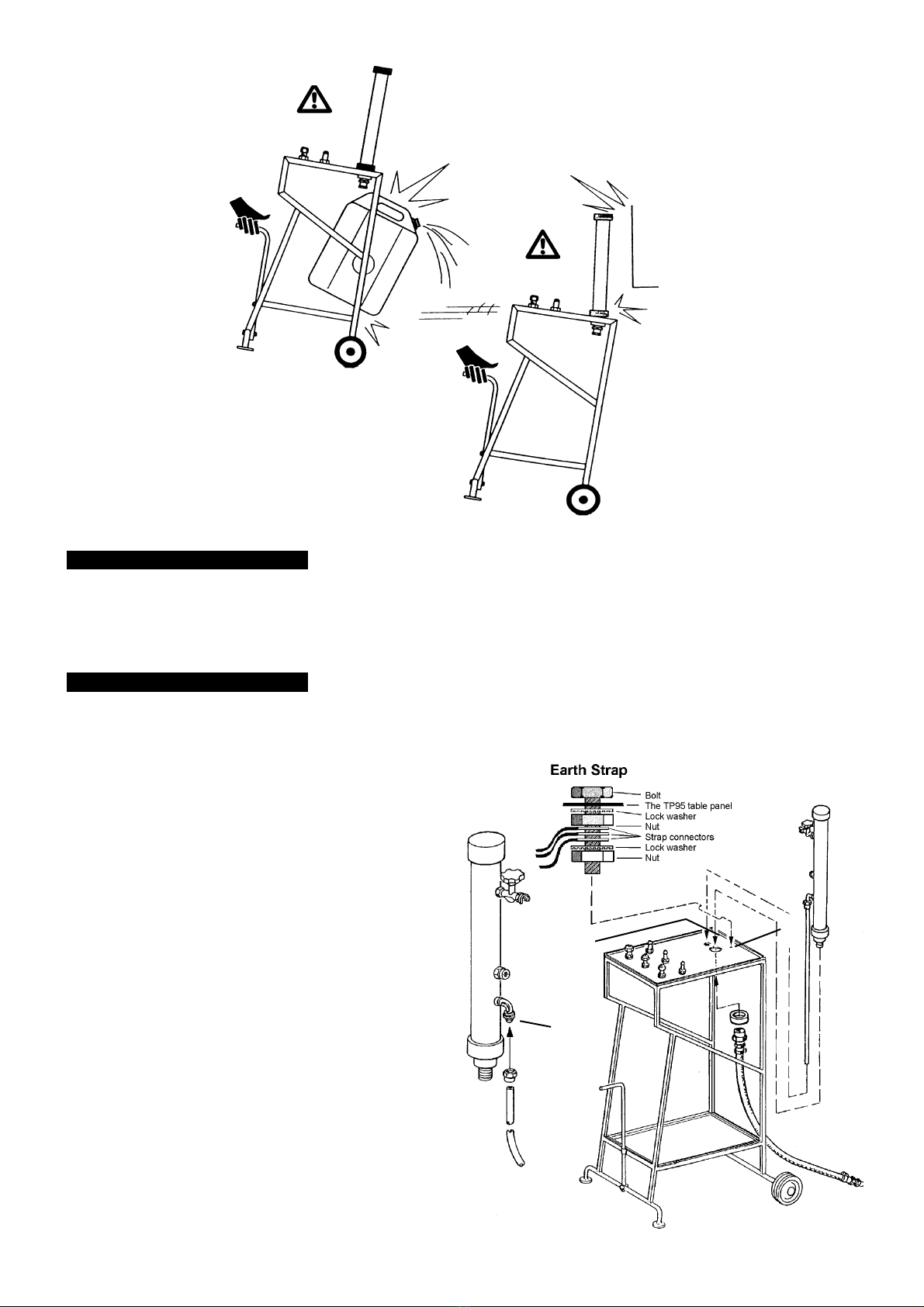

! Attach earth lead to the fuel container using the and crocodile clip supplied.

!Always use the earth bonding strap by connecting one end to the vehicle chassis away from any potential fuel vapour and the

other end to a suitable earthing point.

!Remove all combustible materials from the work area.

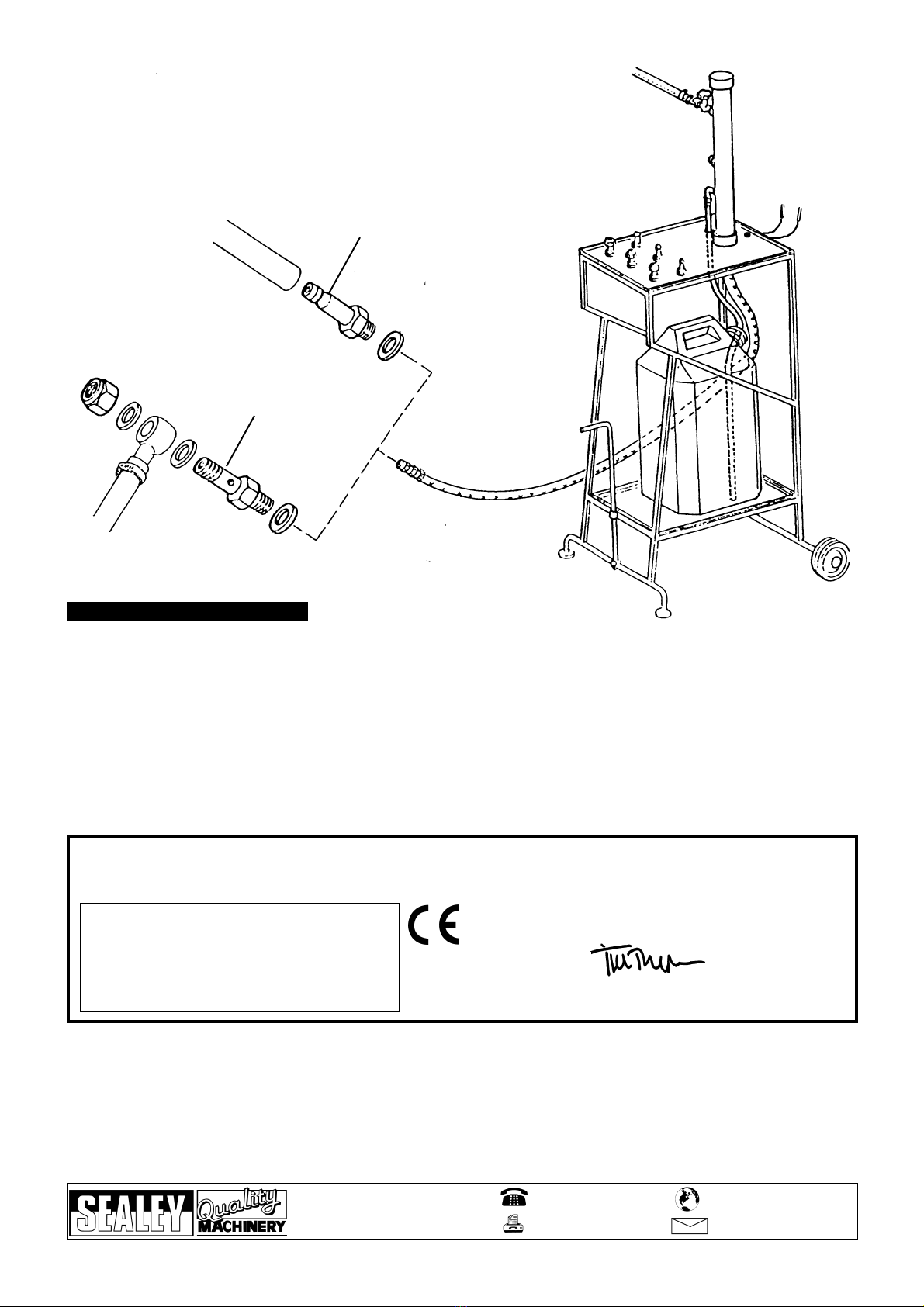

! Use only a container (not included) rated for the fuels used. Ensure that the container mouth is as narrow as possible and still

allow insertion of the drain hose.

!HSE guidance recommends use of metal containers with secure caps for holding drained fuel.

!Mark fuel containers with hazard labels to show their contents.

!Keep any fuel containers in a well ventilated, lockable store, preferably outside the working area.

!Soak up any spill immediately using absorbent granules or similar material.

! Keep children and unauthorised persons away from the working area, especially when the tool is in operation. Keep the work

area childproof by using padlocks and master switches.

! Maintain the tool in top condition. Keep it clean for best and safest performance.

!Follow the same precautions when transferring fuel from the retriever back into the vehicle or into any other container.

#Do not use this tool for anything other than its intended purpose. The TP95 is only to be used for pumping fuel from diesel or petrol

fed vehicles.

#Do not work on a fuel tank or remove a sender unit before draining the fuel.

#Do not use an open flame or smoke anywhere near the tool or around stored fuel.

#Do not drain fuel into open-topped containers such as buckets and watering cans.

#Do not drain fuel into dedicated workshop oil drain equipment.

#Do not drain fuel into plastic containers except for quantities less than 10 litres.

#Do not allow work which can produce a source of ignition, such as welding, electrical or other hot work, to be carried out

while draining petrol.

#Do not drain fuel over or close to a pit or drain because of the risk of flammable vapour accumulation.

#Do not use any electrical equipment on or near the vehicle while fuel draining is in progress. This includes the use of

inspection lights, cordless/mobile phones or pagers.

#Do not store drained or contaminated fuel in the workplace unless it is to be returned to the vehicle immediately.

#Do not add drained fuel to the waste oil tank.

#Do not wear clothing on which petrol has been spilt - stop work and change into uncontaminated clothing before continuing to work.

# Do not handle the unit with the collection tank on the lower table. The unit can become unstable and overturn.

# Do not use the drainer if the pump is damaged in any way.

# Do not stand on the frame.

# Do not leave pump running when unattended. Turn it OFF and do not leave area until it has come to a complete stop.

# Do not use whilst under the influence of drugs, alcohol or other intoxicating medication, or it you are fatigued.

# Do not force the tool to do a job it was not designed to do.

1. SAFETY INSTRUCTIONS

INSTRUCTIONS FOR:

PNEUMATIC FUEL TANK DRAINER

Model No: TP95

(The use of symbols in this document is to attract your attention to possible danger. The symbols and warnings themselves do not eliminate any danger, nor are they

substitutes for proper accident prevention measures).

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

IMPORTANT

BEFORE USING THIS PRODUCT, PLEASE READ THE INSTRUCTIONS CAREFULLY. MAKE CAREFUL NOTE OF SAFETY INSTRUCTIONS,

WARNINGS AND CAUTIONS. THIS PRODUCT SHOULD ONLY BE USED FOR ITS INTENDED PURPOSE. FAILURE TO DO SO MAY CAUSE

DAMAGE OR PERSONAL INJURY, AND WILL INVALIDATE THE WARRANTY. RETAIN THESE INSTRUCTIONS FOR FUTURE USE.

TP95 - 2 - 200307

Users/Businesses should perform their own hazard risk assessment based on their

specific environment and following the guidelines laid out above.