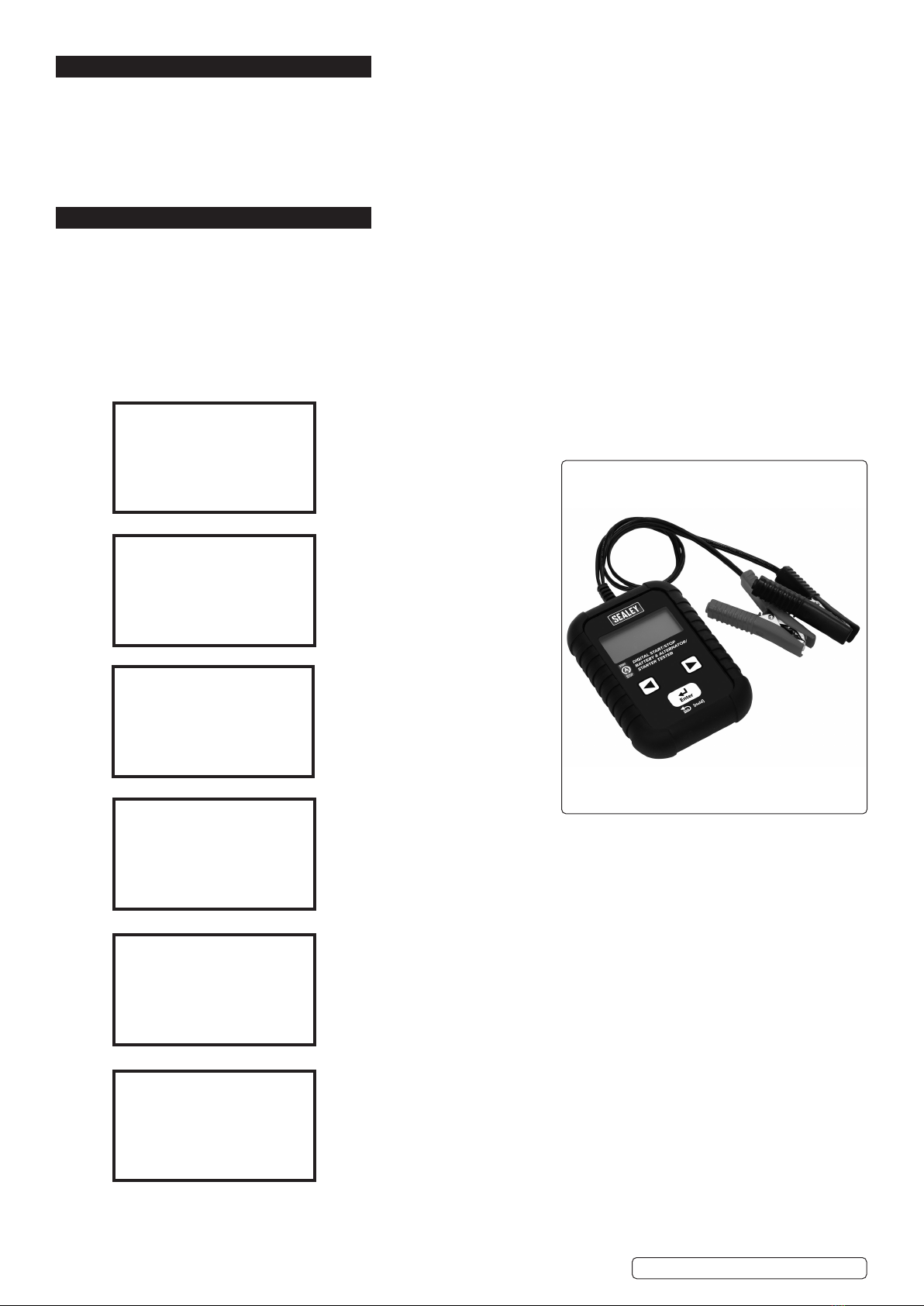

DIGITAL START/STOP BATTERY & ALTERNATOR/

STARTER TESTER

MODEL NO: BT2011

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETY

1.1. PERSONAL PRECAUTIONS

9Ensure that there is another person within hearing range and close enough to come to your aid, should a problem arise when working

near a lead-acid battery.

9Wear safety eye protection and protective clothing. Avoid touching eyes while working near battery.

9Have fresh water nearby in case battery acid contacts skin, clothing, or eyes.

9Rinse immediately with water if battery acid contacts skin or clothing. If acid enters eye, flush eye immediately with cool, clean

running water for at least 15 minutes and seek immediate medical attention.

9Remove personal metallic items such as rings, bracelets, necklaces and watches. A lead-acid battery can produce a short-circuit current

which is high enough to weld such items to the vehicle and cause severe burns.

9Ensure that hands, clothing (especially belts) are clear of fan blades and other moving or hot parts of engine. Remove ties and contain

long hair.

8DO NOT smoke or allow a spark or flame in the vicinity of the battery or engine.

1.2. GENERAL SAFETY INSTRUCTIONS

9Familiarise yourself with the application, limitations and potential hazards of the tester. Also refer to the vehicle manufacturer’s hand

book.

IF IN ANY DOUBT CONSULT A QUALIFIED ELECTRICIAN.

9Ensure that the tester is in good condition before use. If in any doubt DO NOT use the unit and contact a qualified electrician.

9Only use recommended attachments and parts. To use unapproved items may be dangerous and will invalidate your warranty.

9Keep tools and other items away from the engine and ensure that you can see the battery and working parts of the engine clearly.

9Determine the system voltage before using the tester.

9If the tester receives a sharp knock or blow the unit must be checked by a qualified service agent before using.

9If the battery terminals are corroded or dirty: clean them before using the tester.

9Keep children and unauthorised persons away from the work area.

8DO NOT dismantle the tester for any reason. The tester must only be checked by qualified service personnel.

WARNING! To prevent the risk of sparking, short circuit and possible explosion DO NOT drop metal tools in the battery area, or allow

them to touch the battery terminals.

8DO NOT cross-connect tester to battery. Ensure positive (RED) clamp is to positive terminal and negative (BLACK) clamp is to negative

terminal. If battery symbols cannot be distinguished: the negative terminal is the one directly connected to the vehicle bodywork.

8DO NOT use the tester outdoors, or in damp, or wet locations and DO NOT use in the vicinity of flammable liquids or gases.

8Ensure there is effective ventilation to prevent a build-up of explosive gases.

8DO NOT use the tester for a task for which it is not designed.

9When not in use, store the tester carefully in a safe, dry, childproof location.

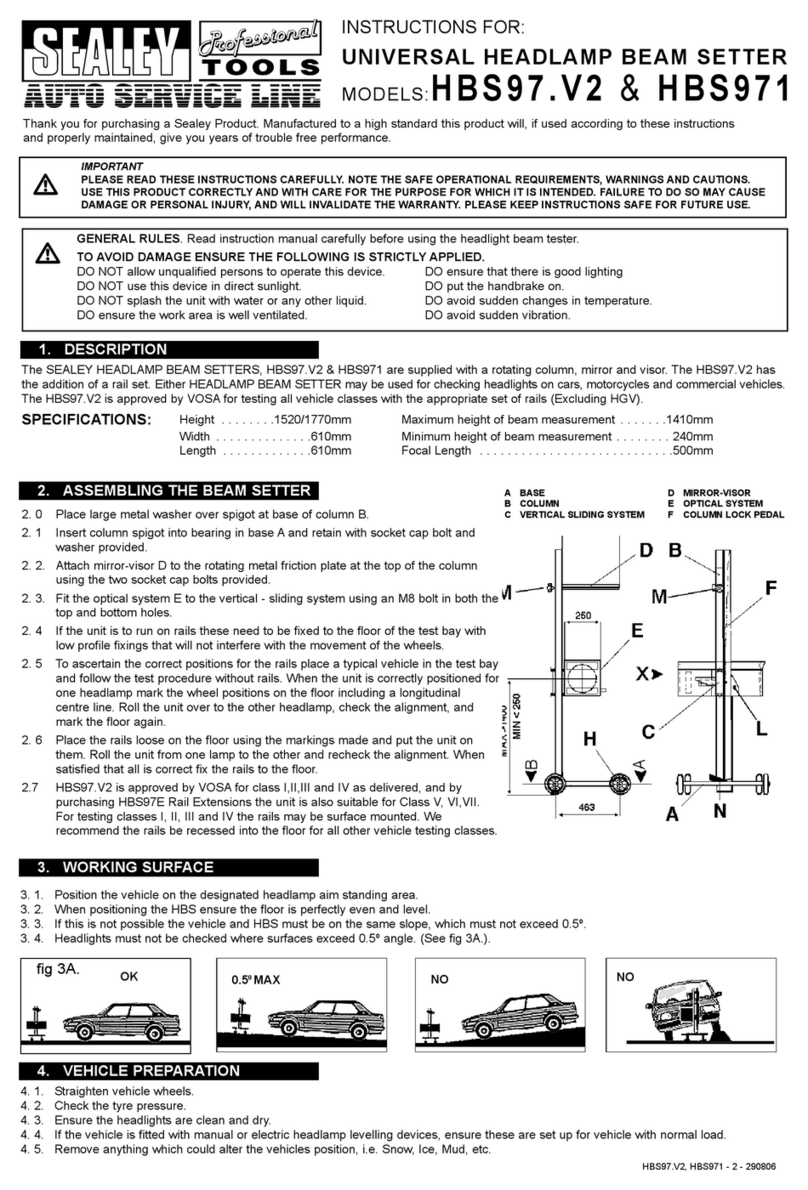

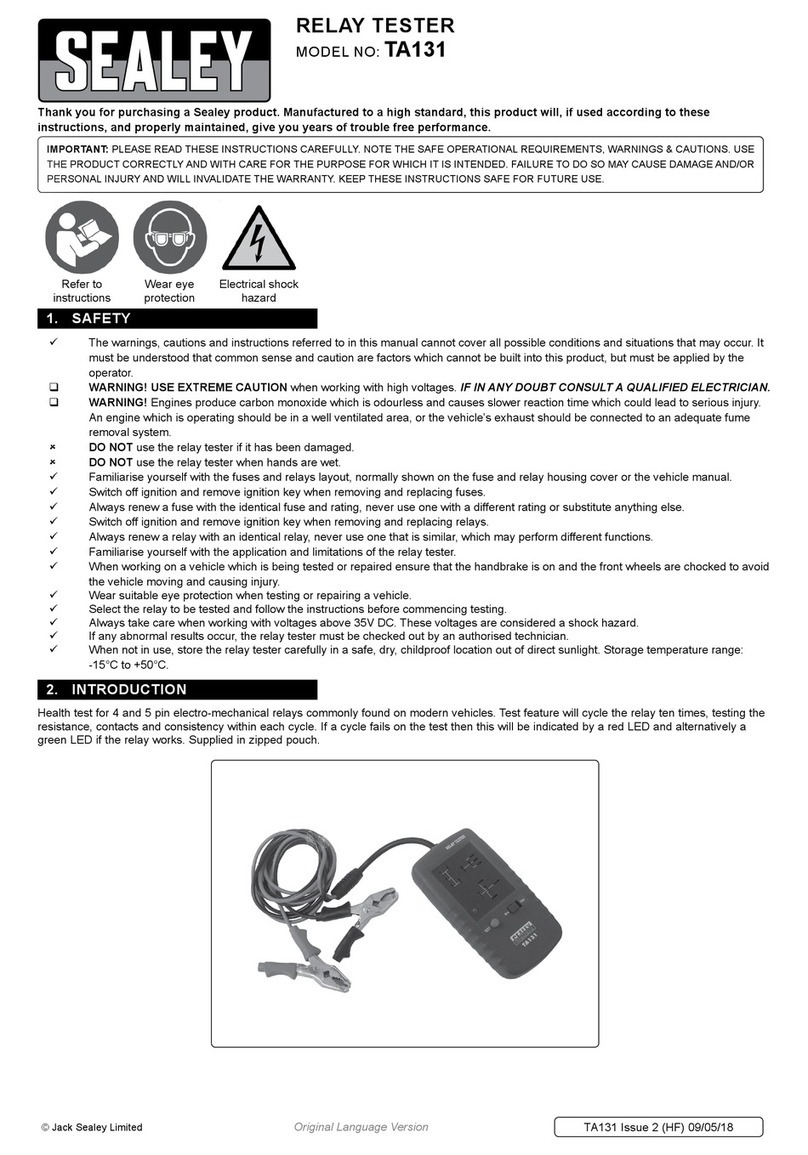

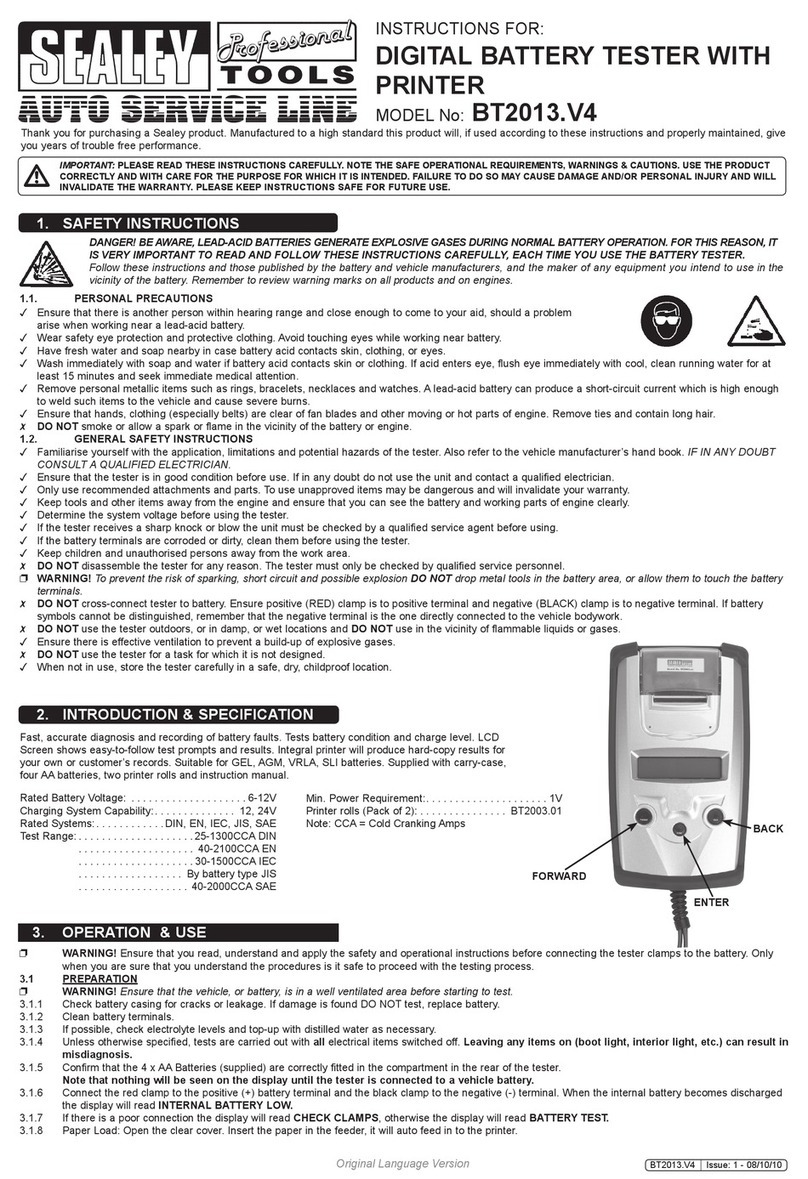

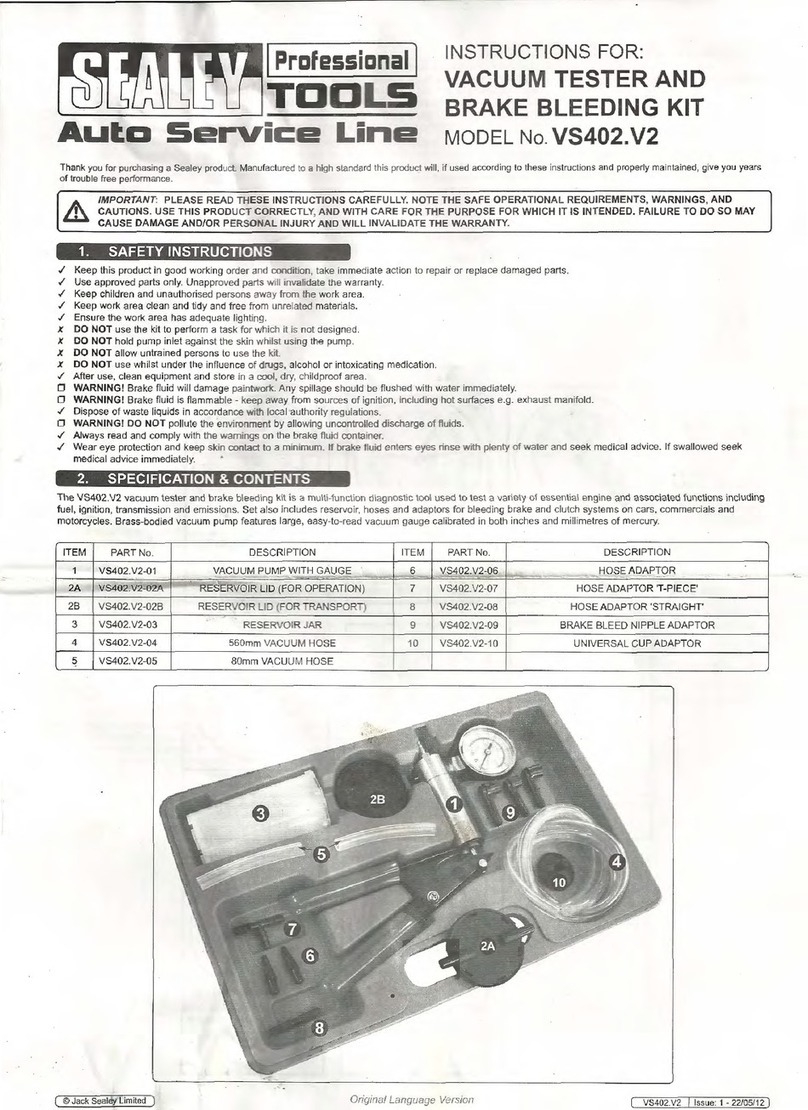

2. INTRODUCTION

Robust and simple-to-use design oers a full in-vehicle diagnosis of the vehicle battery, starter motor and alternator in seconds. Professional

tool supports all 12V batteries including standard Lead-Acid, VRLA, GEL plus AGM and EFB found on all Start/Stop vehicles. The in-vehicle test

mode allows diagnosis of battery health, state of charge, internal resistance, cranking voltage and a comprehensive charging system voltage at

rest and under load. No heat, no sparks and no misdiagnosis. Equipped with reverse polarity protection and a battery temperature compensation

feature. A 4-Line/16 character LCD display gives easy to follow prompts and accurate results. Fitted with a heavy-duty rubber protection cover.

3. SPECIFICATION

Model no. ...................................................................BT2011

Charging system capability .........................................12/24V

Languages

............................ English, French, Spanish, German, Italian,

......................... Portuguese, Dutch, Russian, Turkish, Czech

Rated battery voltage.......................................................12V

Rating systems ................EN, JIS, DIN, IEC, CA(MAC), SAE

Voltage range............................................................... 8-30V

Original Language Version

© Jack Sealey Limited

Refer to

instructions

Wear eye

protection

Warning

corrosive

substance

Wear protective

clothing

Wear protective

gloves

Warning!

BT2011 | Issue:1 02/03/20