5.6. Catalytic Converter

With the engine at normal operating temperature and running at 1000rpm the inlet of the catalytic converter should be cooler than the

outlet by >55OC (2-way converter) or >20OC (3-way converter).

1) If the outlet temperature is lower than the inlet then the converter is plugged and must be replace.

2) If the outlet temperature is the same as the inlet then the converter has reached the end of its service life (say 150,000 miles) or

the converter material has broken up due to damage or has become contaminated.

Always determine the cause of failure, and rectify if appropriate, before fitting a replacement.

5.7. Brakes

The thermometer can be used to check comparative brake performance. The brakes should be

brought up to operating temperature, by braking the vehicle from 30mph to a halt five times in

quick succession, and the brake disc/drum temperatures then measured immediately. Brakes on

the same axle should not differ by more than 3OC and front brakes should be hotter than rear

brakes by about 30OC. In the case of temperatures not meeting these criteria further investigation

will be required - noting that it is normally the cooler brake which is faulty (seized, contaminated, etc.).

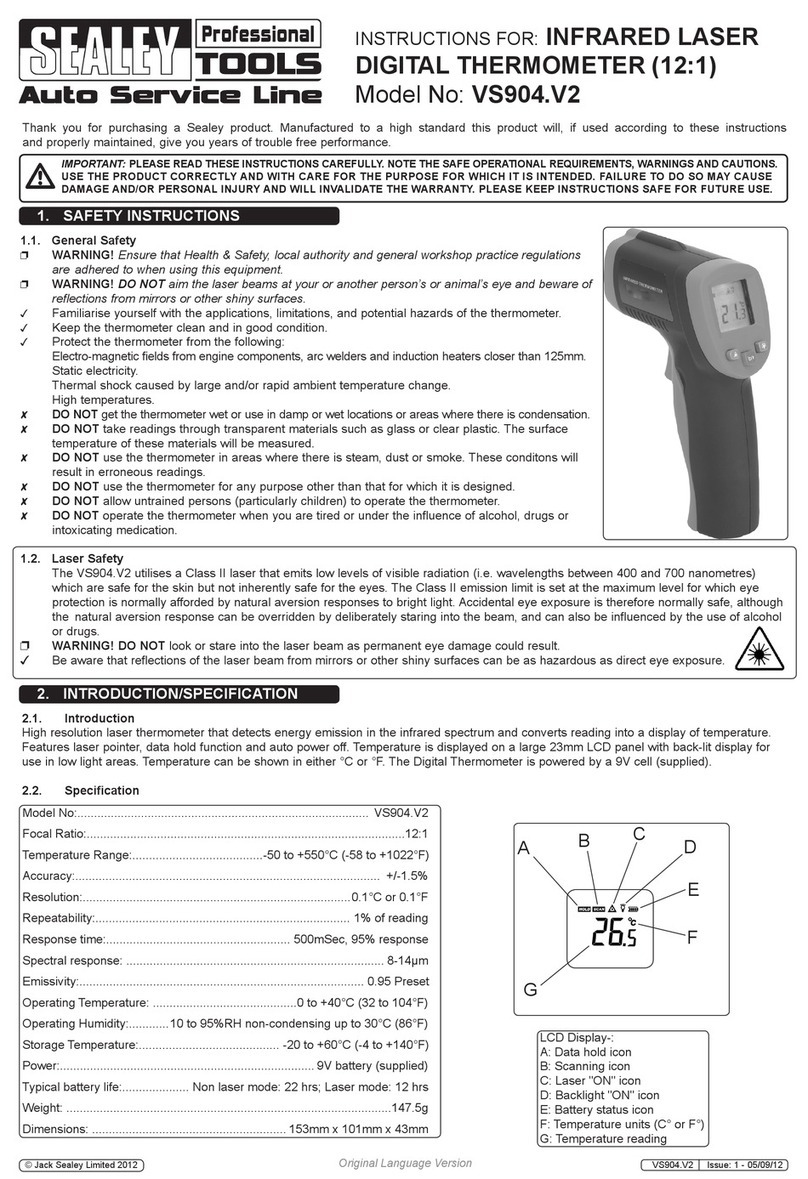

5.8. Tyres

A correctly inflated tyre will have the same temperature across the tread, within 10OC. To check,

drive the car for a few miles and then measure the tread in three places as shown in fig. 5.

If the readings from the sides of the tread are higher than that from the centre the tyre is probably

under-inflated.conversely over-inflation causes the centre to be hotter than the edges. In either case, adjust the tyre pressure in 2psi

steps until even temperatures are achieved. If the resulting pressure is significantly different from that recommended by the

vehicle/tyre manufacturer look for another cause of the temperature difference (worn, damaged or misaligned suspension). Note that

edge-of-tread temperatures which are significantly different from each other indicate a suspension fault.

fig. 5

Declaration of Conformity We, the sole importer into the UK, declare that the product listed here

is in conformity with the following standards and directives.

The construction file for this product is held by the Manufacturer and may be inspected, by a national

authority, upon request to Jack Sealey Ltd.

For Jack Sealey Ltd. Sole importer into the UK of Sealey Professional Tools.

10th March 2004

INFRARED LASER THERMOMETER

Model: VS900.V2

EN 60825-1 Laser safety

93/68/EEC CE Marking Directive Signed by Mark Sweetman

6. DECLARATION OF CONFORMITY

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

VS900.V2 - 2 - 090304

Sole UK Distributor,

Sealey Group,

Bury St. Edmunds, Suffolk.

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

e-mail Web

5.3. Radiator

When the engine is running at normal operating temperature, there should be an even temperature drop between the radiator inlet and

outlet. Check the whole radiator surface for any cold spots which would indicate a blockage.

5.4. Thermostat

Under normal operation the thermostat will will open as the engine reaches operating temperature, releasing hot coolant into the hose

linking the thermostat housing to the radiator.

Use the thermometer to monitor the hose temperature, adjacent to the thermostat housing, as the engine warms up to

operating temperature (85-105OC).

1) If the hose temperature abruptly and quickly increases the thermostat is functioning correctly.

2) If the temperature increases gradually and does not reach operating level the thermostat

has failed in the open condition (or is missing).

3) If the temperature does not rise at all the thermostat as failed in the closed condition

or coolant is not flowing for some other reason (air lock, pump failure etc.) and

further investigation is required.

4) A fluctuating temperature indicates a weak thermostat spring or air in the system.

5.5. Misfiring Cylinder

A misfiring cylinder (petrol or diesel) can be located by taking temperature readings

of each branch of the exhaust manifold (fig. 4). The cool branch will indicate the misfiring

cylinder. The temperature difference will be most marked before the engine has

warmed up and heat transfer has warmed the cool branch. One exhaust branch

hotter than the rest (petrol) suggests weak mixture to that cylinder, which should

be investigated (faulty injector, inlet manifold gasket leak, etc.).

fig. 4