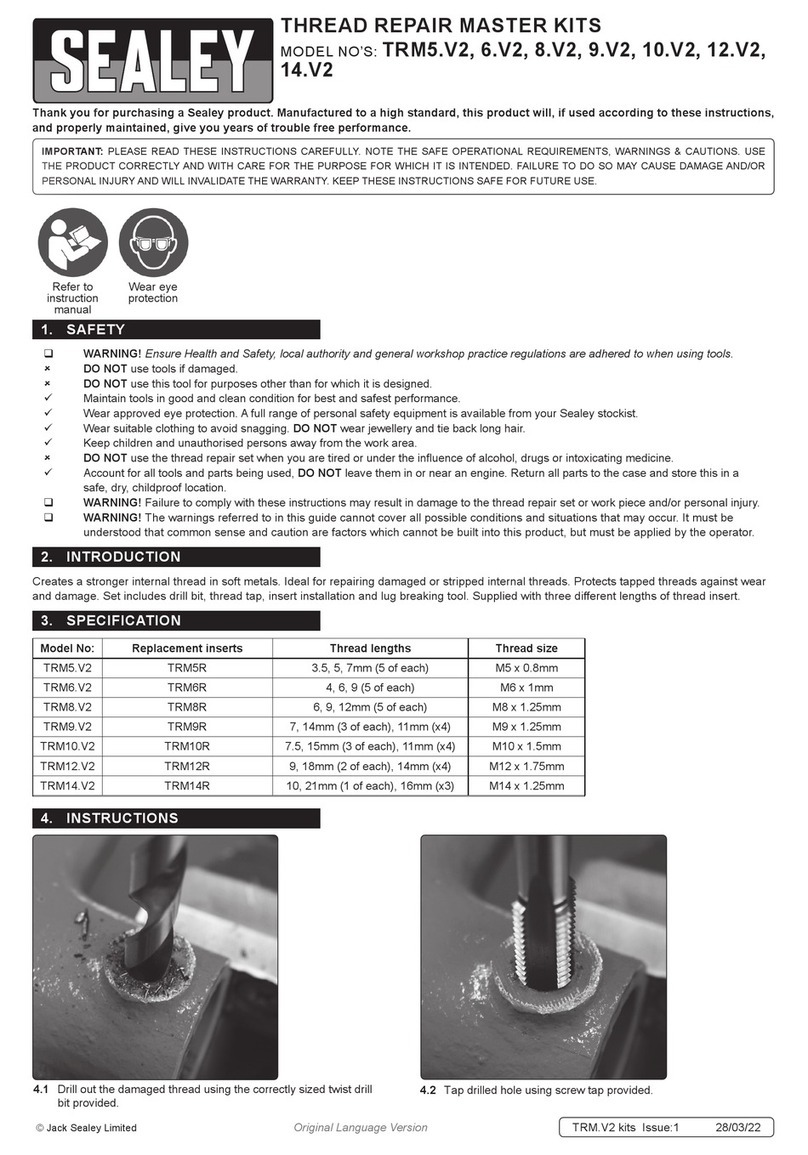

4.9.8 Fit VS4987 to the VVT Unit and rotate the Unit anti-clockwise

to the fully retarded position.ThentVS4984HoldingToolto

the EXHAUST camshaft gear and apply force in an anti-

clockwise direction in order to ensure slack on the secondary

chain on the tensioner plunger side.

4.9.9 Whilst continuing to apply this force, tighten the INLET camshaft

gear bolt.

4.9.10 Repeat this procedure on the left-hand bank.

IMPORTANT: Remove all tools.

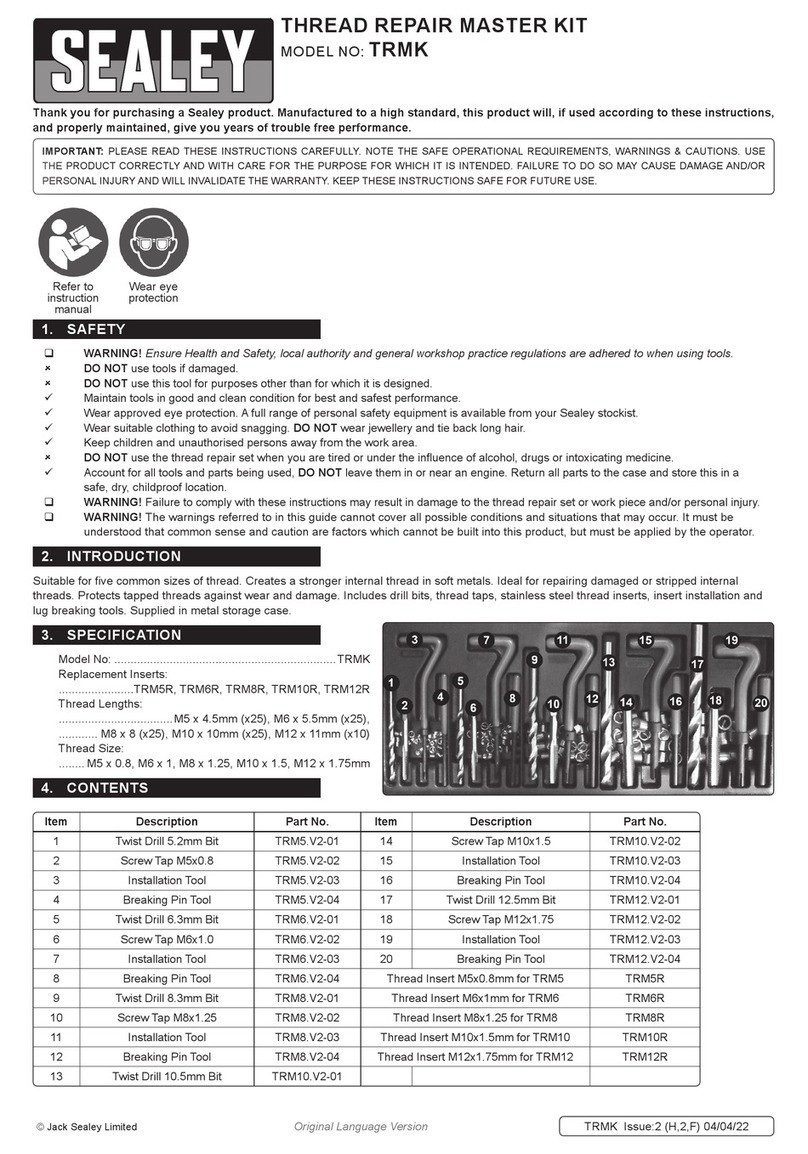

4.10 LATER ENGINES

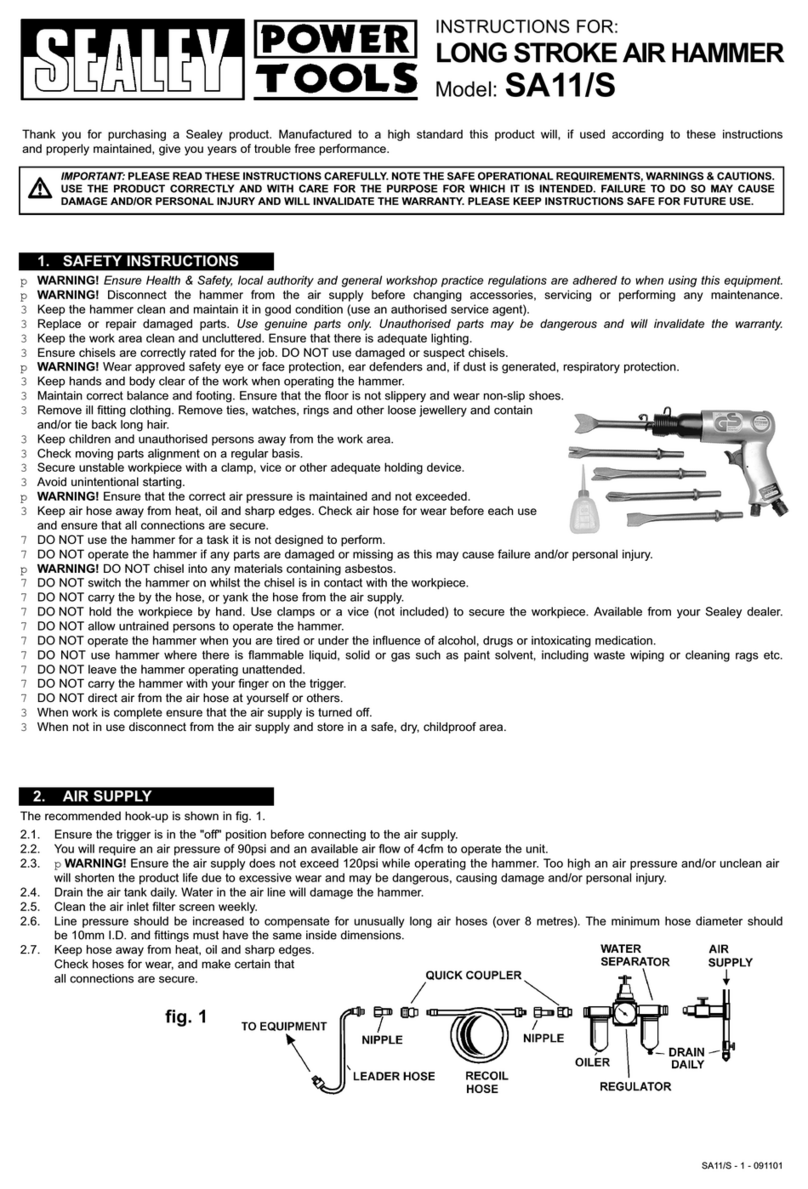

Primary chain tensioners

These primary chain tensioners have a ratchet system on the

tensioner plunger.

WARNING: When compressing the plunger DO NOT release

the ratchet until the plunger has fully retracted into its bore

or damage to the ratchet system will result.

The plunger is compressed using a vice, and retained in this

position using VS4975T8 Locking Pin, from Kit VS4980.

4.10.1 Slowly compress the tensioner plunger using minimal force, and

insert VS4975T8 Locking Pin to retain the retracted plunger

position.

4.10.2 Fit the tensioner to the engine.

4.10.3 Pull out VS4975T8 Pin to actuate the plunger onto the chain rail.

Tightening camshaft gear bolts:-

4.10.4 Work on the right-hand bank.

IMPORTANT: On later engines, Jaguar and Land Rover

instruct that the INLET camshaft gear bolt is tightened rst,

followed by the EXHAUST gear bolt.

WARNING: On these engines the INLET camshaft gear bolt

MUST BE tightened before the EXHAUST camshaft gear

bolt. Failure to tighten the INLET camshaft gear bolts rst,

will result in engine damage.

4.10.5 Fit VS4984 to the EXHAUST camshaft gear and apply force, in

an anti-clockwise direction, to tension the primary chain on its

drive side, allowing the tensioner plunger to fully extend

outwards.

4.10.6 Whilst applying force with VS4984 Holding Tool, tighten the

INLETgearboltrst,andthentightenEXHAUSTgearbolt

4.10.7 Repeat procedure on the left-hand bank.

01284 757500

sales@sealey.co.uk

www.sealey.co.uk

01284 703534

Web

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this equipment.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

.

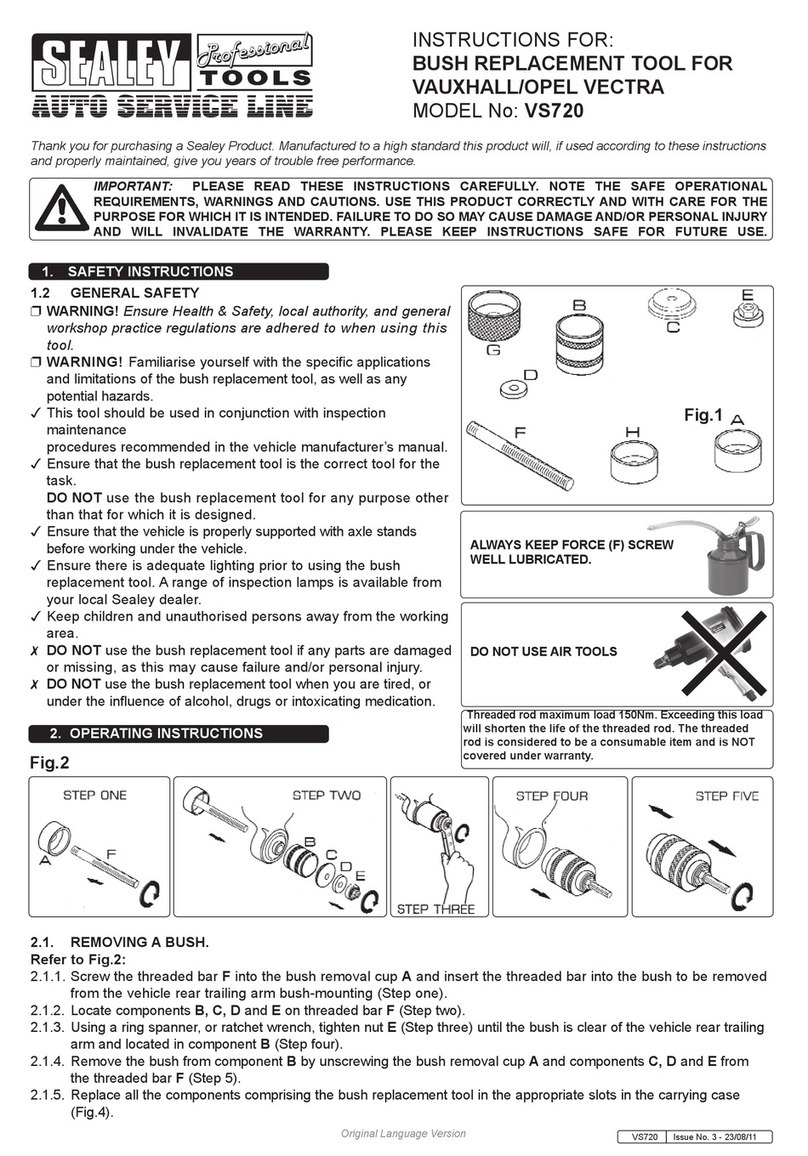

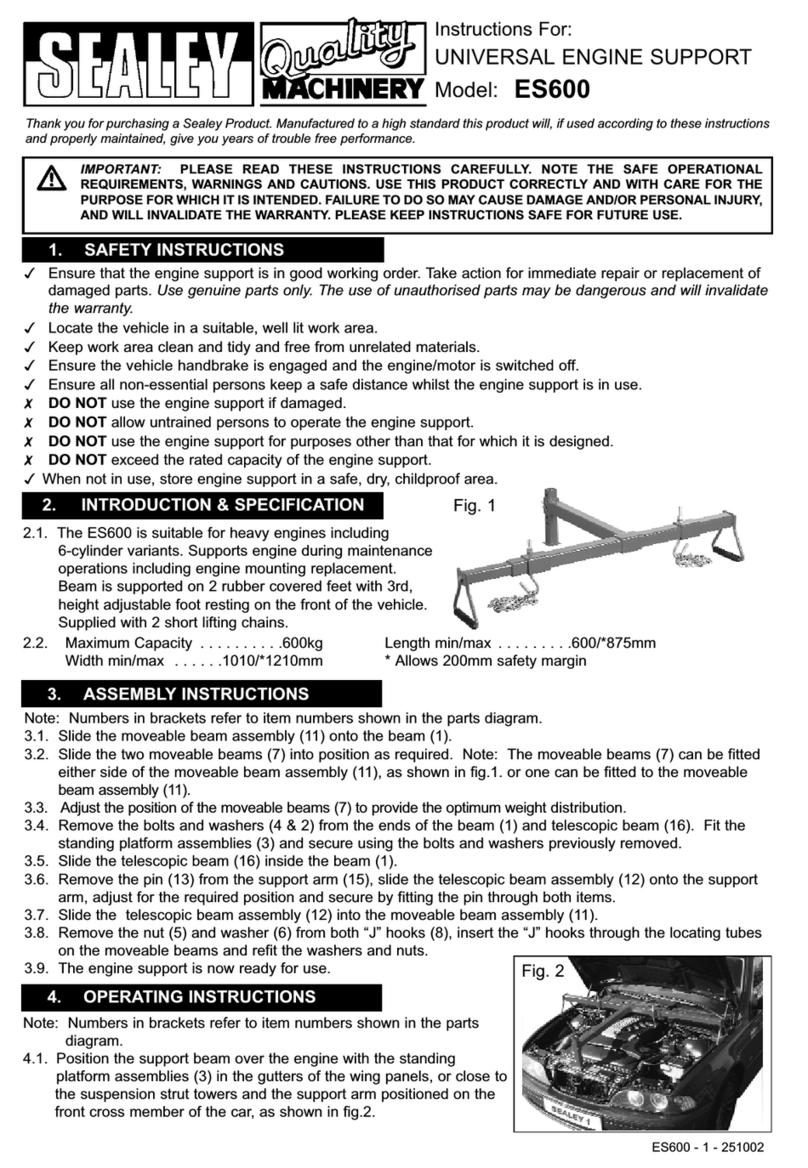

4.9.4 TightentheEXHAUSTcamshaftgearbolt(g.44).

4.9.5 Fit VS4984 Holding Tool to the EXHAUST gear and apply force

to the Tool, in an anti-clockwise direction, in order to ensure

slack on the secondary chain on the tensioner plunger side.

4.9.6 Whilst applying this force, tighten the EXHAUST camshaft gear

bolt.

4.9.7 If engine does not have VVT, continue to apply force with

VS4984andtightentheINLETcamshaftgearbolt(g.45).

VS4987 VVT Setting Tool

Someearlyengines,arettedwithVTT,anditisnecessaryto

use VS4987 Setting Tool before tightening the INLET camshaft

gear bolt.

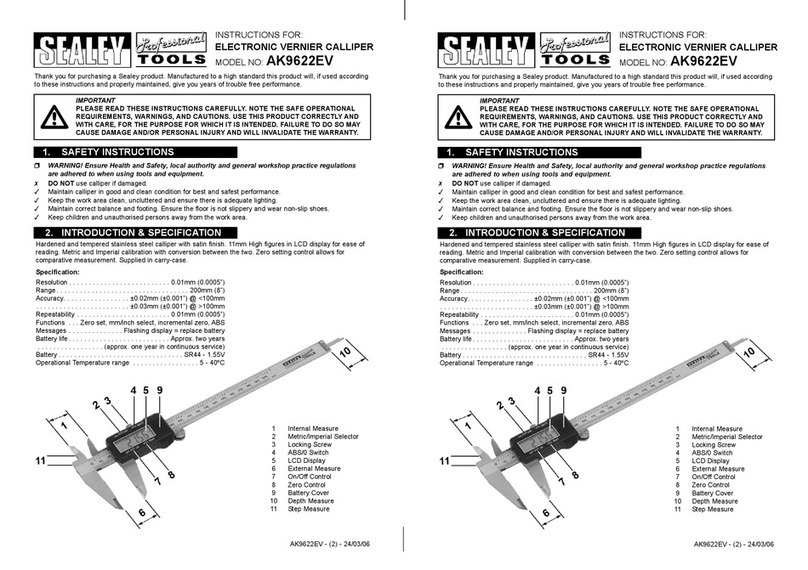

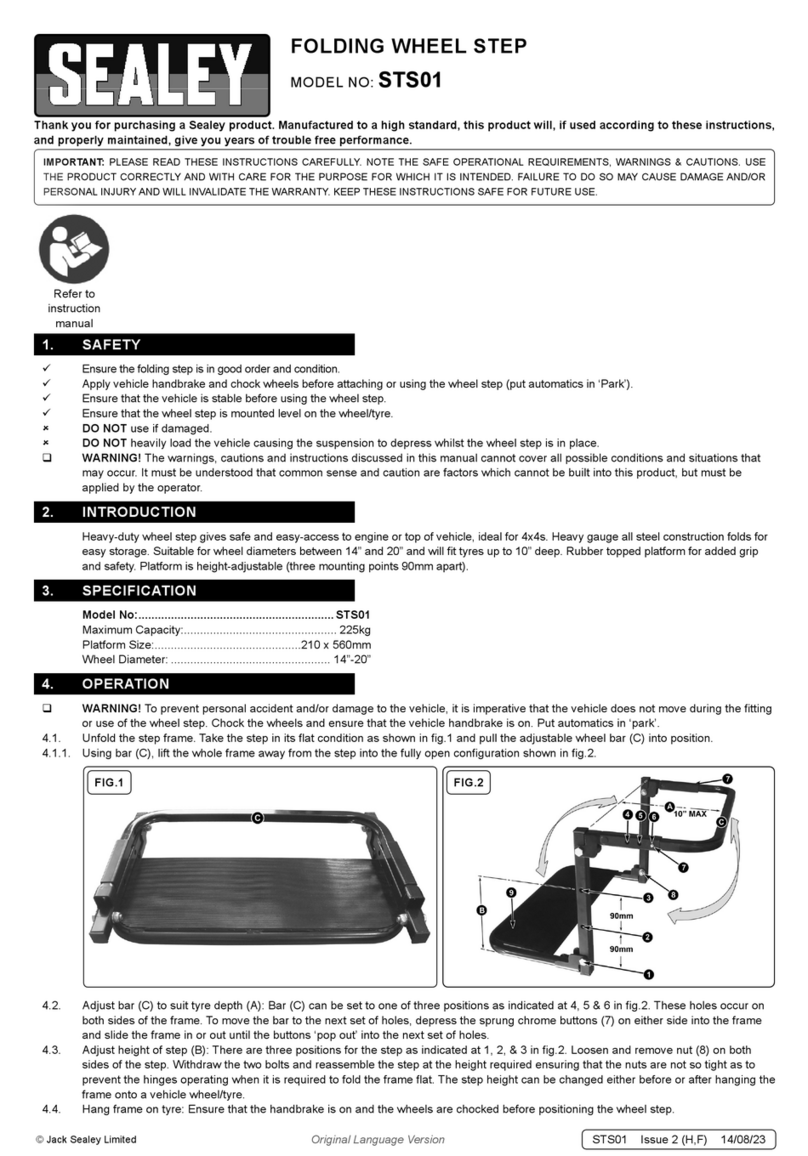

4.9.2 Fitthebackplateandtensionerunittotheengine(g.42).

VS4986 Tensioner Wedge Set

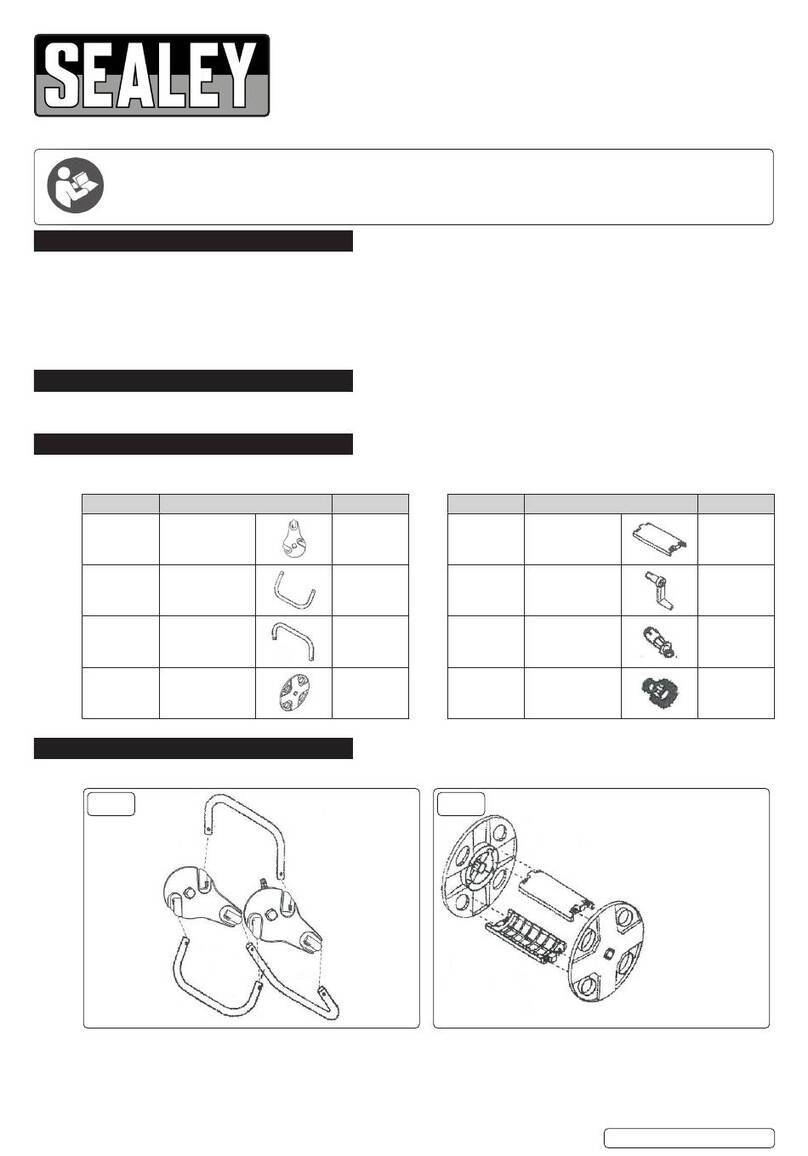

4.9.3 Fit the VS4986 Wedge between the tensioner plunger and the

chainrailtollanygap,removingslackfromthechain(g.43).

NOTE: VS4986 is a pair of Tensioner Wedges and can be used

as a single Wedge or in a combination of two Wedges,

dependant upon the gap between plunger and rail.

g.42

g.43

g.44 g.45

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

Original Language Version

© Jack Sealey Limited VS4980 Issue No: 3 (SP) 08/07/15

Tightening camshaft gear bolts:-

IMPORTANT: On early engines, Jaguar instruct that the

EXHAUST camshaft gear bolt is tightened rst, followed by

the INLET gear bolt.

Environmental Protection

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to a recycling centre

and disposed of in a manner which is compatible with the environment. When the product becomes completely unserviceable dispose of it according to

local regulations.