INSTRUCTIONS FOR:

FOUR-WHEEL LASER WHEEL ALIGNER

MODEL No: GA70.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions

and properly maintained, give you years of trouble free performance.

1. SAFETY INSTRUCTIONS

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS.

USE THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE

DAMAGE AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

1.1 GENERAL SAFETY

WARNING! Ensure Health & Safety, local authority, and general

workshop practice regulations are adhered to when using this

equipment.

Maintain the wheel aligner in good condition (use an

authorised service agent).

Replace or repair damaged parts. Use genuine parts only.

Non-authorised parts may be dangerous and will invalidate

the warranty.

Locate wheel aligner in a suitable working area, keep

area clean and tidy and free from unrelated materials.

WARNING! Use aligner on vehicles that are parked on level

and solid ground.

Keep the gauge clean to ensure accurate performance.

DO NOT use outside in damp or wet weather conditions.

DO NOT allow untrained persons to operate the aligner.

DO NOT leave the aligner unattended.

WARNING! When setting front end alignment on commercial

vehicles never make adjustments to drop arms or

interconnecting links. Doing so could result in serious tyre,

wheel and steering problems.

WARNING! The warnings, cautions and instructions

contained within this document cannot cover all possible

conditions and situations that may occur. It must be

understood that common sense and caution are factors

which cannot be built into this product, but must be

applied by the operator.

Any alignment changes deemed necessary as a result of

using this equipment must be made strictly in accordance

with the vehicle manufacturer’s recommendations.

1.2 LASER SAFETY

The GA70 utilises a Class II laser that emits low levels

of visible radiation (i.e. wavelengths between 400 and

700 nanometres) which are safe for the skin but not

inherently safe for the eyes. The Class II emission limit is set at the

maximum level for which eye protection is normally afforded by

natural aversion responses to bright light. Accidental eye exposure

is therefore normally safe, although the natural aversion response

can be overridden by deliberately staring into the beam, and can

also be influenced by the use of alcohol or drugs.

WARNING!DO NOT look or stare into the laser beam as

permanent eye damage could result.

DO NOT direct the laser beam at any person’s (or animal’s)

eyes as eye damage could result. If the beam is obstructed by

a person during use, release the contact switch immediately.

DO NOT use the equipment while under the influence of

alcohol, drugs or whilst on medication.

Be aware that reflections of the laser beam from mirrors or

other shiny surfaces can be as hazardous as direct eye

exposure.

2. INTRODUCTION

Fast, simple and accurate alignment of both front and rear wheels.

Optimises vehicle performance and set up after installation or

modification of steering or suspension components. Simple and fast

to use, it is ideal for the busy professional workshop and has a fast

return on investment - potentially adding value to every steering or

suspension job. This fully portable kit is also ideal for track-day set

up for the enthusiast. Works on practically all cars and light

commercials with rim diameters between 320mm and 540mm.

Supplied with steering wheel clamp, wheel turn plates and wheeled

storage rack. Supplied with comprehensive operating instructions.

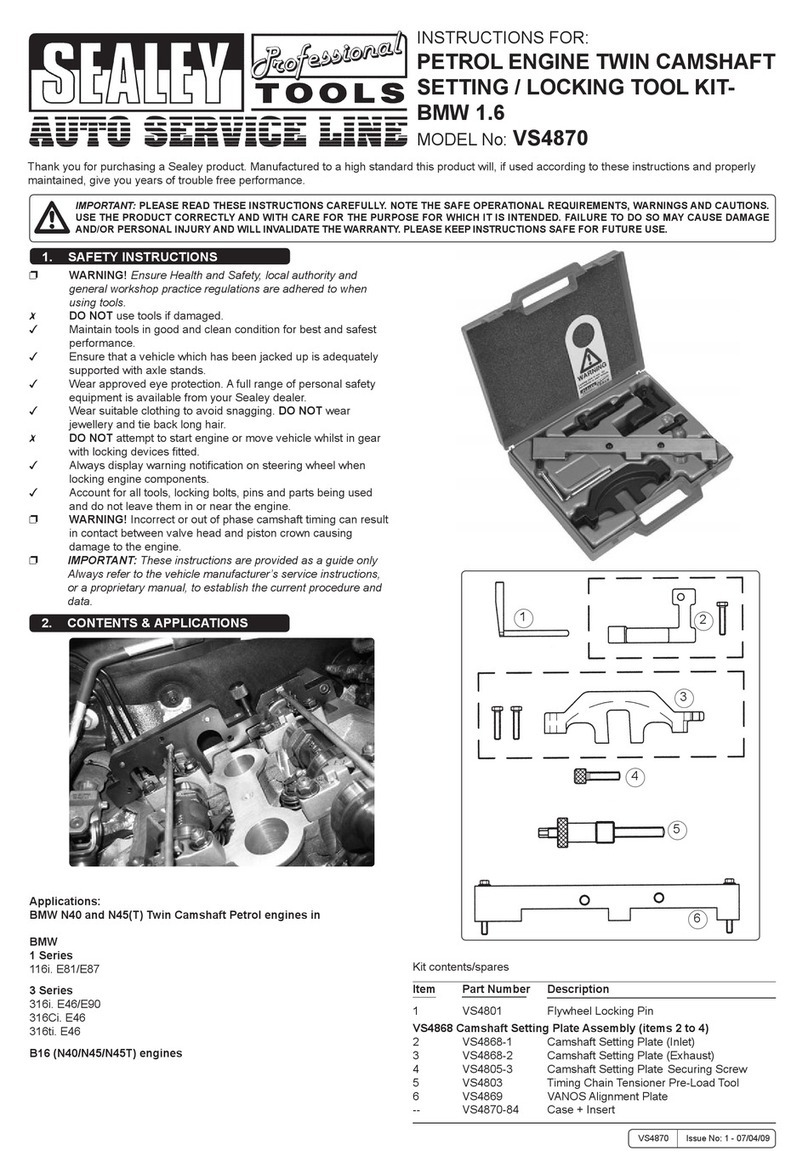

3. CONTENTS

The GA70 kit consists of: Mobile storage unit (see above)

1. Laser Measuring Head x 2 3. Steering Wheel Clamp

2. Alignment Assembly Flags x 2 4. Dished Turning Plate x 2

5. Extension Bobbins x 6 6. 13" Wheel Spacers

Original Language Version

Original Language Version GA70.V2 Issue: 1- 19/02/14

©Jack Sealey Limited