VSE127H05 Issue No. 1 - 10/11/09

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

01284 757500

01284 703534

sales@sealey.co.uk

www.sealey.co.uk

Web

email

Original Language Version

Fig.3

Fig.4

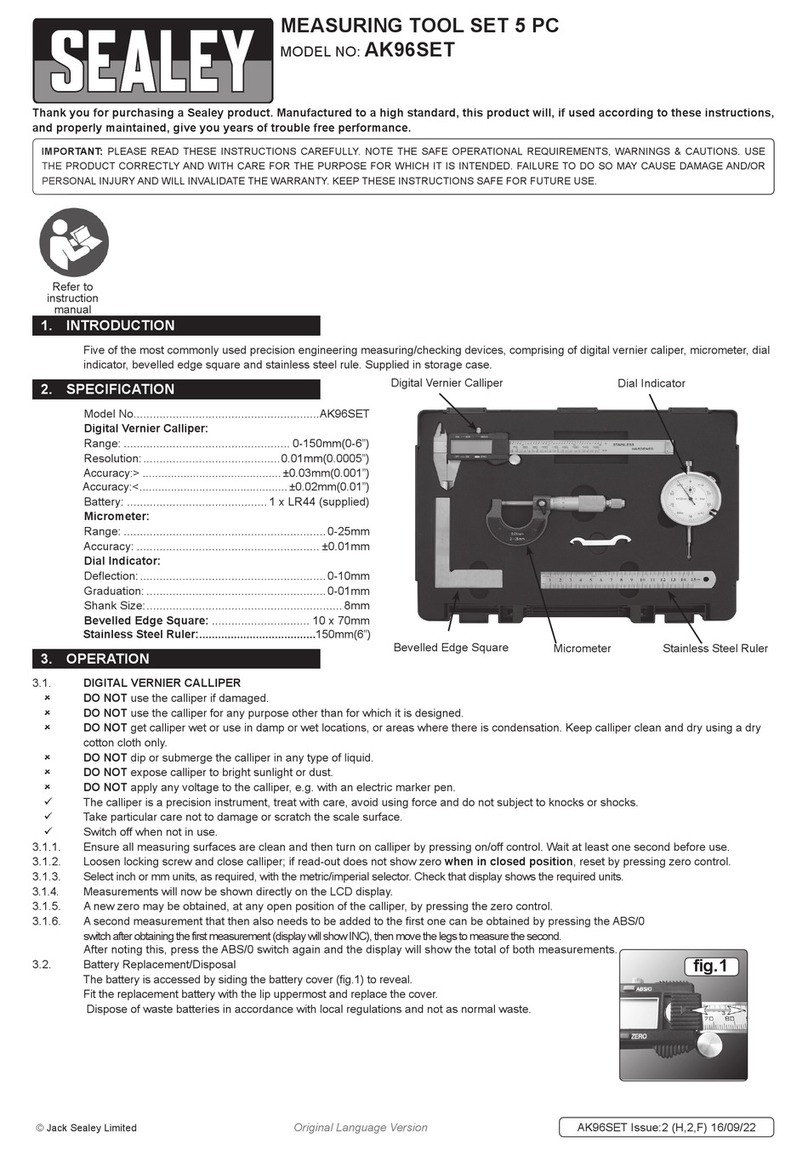

3.1 Ball Joint Removal. To remove the ball joint you will need to

use adaptors A & B in conjunction with Sealey Hydraulic Ball

Joint Remover/Installer Kit (Model No. VSE127H).

3.1.1 Referring to the vehicle manufacturers servicing information

disassemble the necessary suspension and steering

components to gain access to the ball joint for removal.

3.1.2 Rotate the hydraulic unit anticlockwise within the press frame

until the bottom of the unit is level with the underside of the top

bar. Ensure that the black ring is properly seated in the base of

the press (see fig.1-Z) and place adaptor (B) into the ring with

the narrower section upwards.

3.1.3 Holding the hydraulic unit, take the press to the exposed ball

joint and introduce it into adaptor (B). Lift the press so that

adaptor (B) bears directly onto the casting that holds the ball

joint. See ‘X’ inset in fig.3.

3.1.4 Slide adaptor (A) into position on the top of the ball joint itself

ensuring that the surface with the indent in it is uppermost. Turn

the handle on the hydraulic unit clockwise so that the ram

descends and the steel ball at the end of the ram enters the

indent. Continue turning the handle until the whole assembly is

firmly clamped onto the ball joint housing.

3.1.5 Before applying pressure to the ball joint ensure that the adaptors

are correctly seated as shown in the inset diagram in fig.3.

3.1.6 Continue to turn the ram handle slowly clockwise until the ball

joint is fully ejected. Be prepared for the sudden release of the

ball joint at which point the assembly will become unstable.

3.1.7 Turn the ram handle anticlockwise to back off the ram. Remove

adaptor (A) first, then remove the whole assembly from the ball

joint housing.

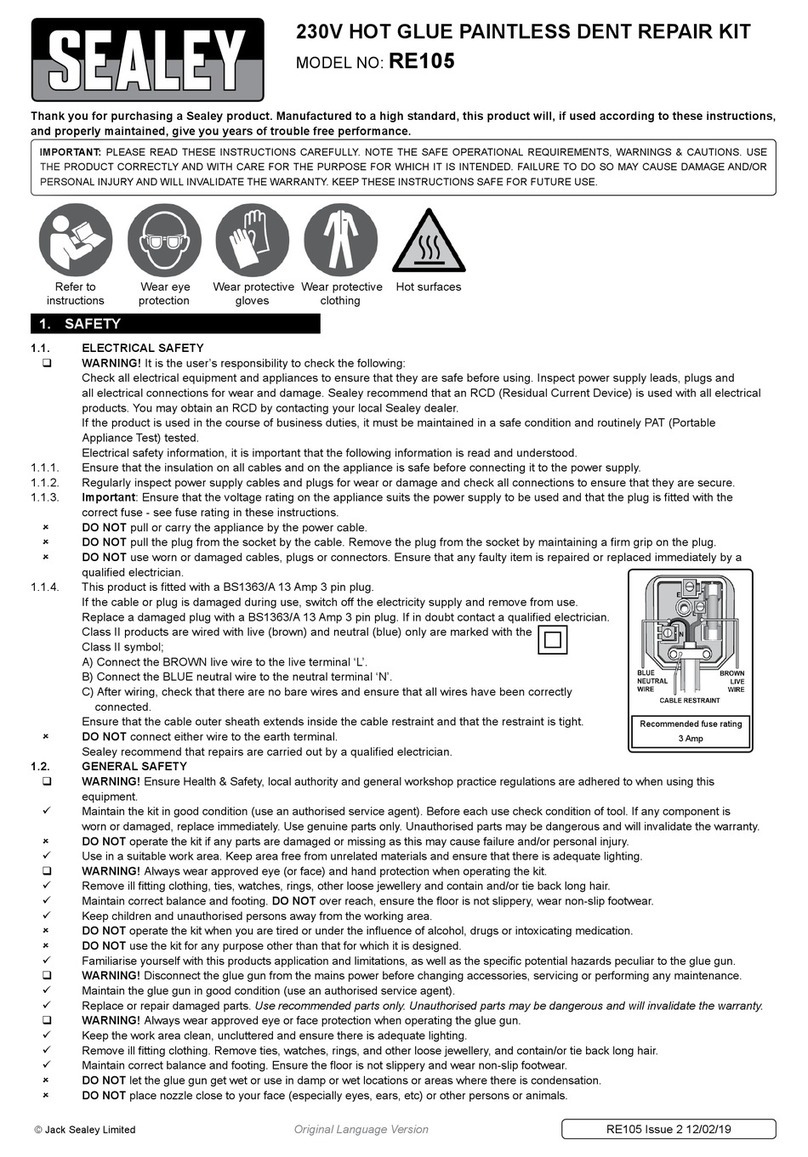

3.2 Ball Joint Installation. To install the ball joint you will need to

use adaptors C & D in conjunction with Sealey Hydraulic Ball

Joint Remover/Installer Kit (Model No. VSE127H).

3.2.1 Rotate the hydraulic unit anticlockwise within the press frame

until the bottom of the unit is level with the underside of the top

bar. Ensure that the black ring is properly seated in the base of

the press (see fig.1-Z) and place the closed end of adaptor (D)

into the ring. Place the threaded stub of the new ball joint (J) into

the open end of adaptor (D) so that the body of the ball joint sits

inside the flange in the top of the adaptor.

3.2.2 Holding the hydraulic unit, take the press to the exposed ball

joint housing. Lift the press so that the body of the ball joint (J) is

positioned ready to enter the ball joint housing.

3.2.3 Slide adaptor (C) into position on the top of the ball joint housing

ensuring that the surface with the indent in it is uppermost as

seen in the inset diagram in fig.4. Turn the handle on the

hydraulic unit clockwise so that the ram descends and the steel

ball at the end of the ram enters the indent. Continue turning the

handle until the whole assembly is firmly clamped onto the ball

joint housing.

3.2.4 Before applying pressure to insert the ball joint (J) ensure that the

ball joint is correctly aligned with the opening in the housing and

the adaptors are correctly seated as shown in the inset diagram

in fig.4.

3.2.5 Continue to turn the ram handle slowly clockwise until the ball

joint is fully inserted.

3.2.6 Turn the ram handle anticlockwise to back off the ram. Remove

adaptor (C) first, then remove the whole assembly from the ball

joint housing.