7. FILTERS

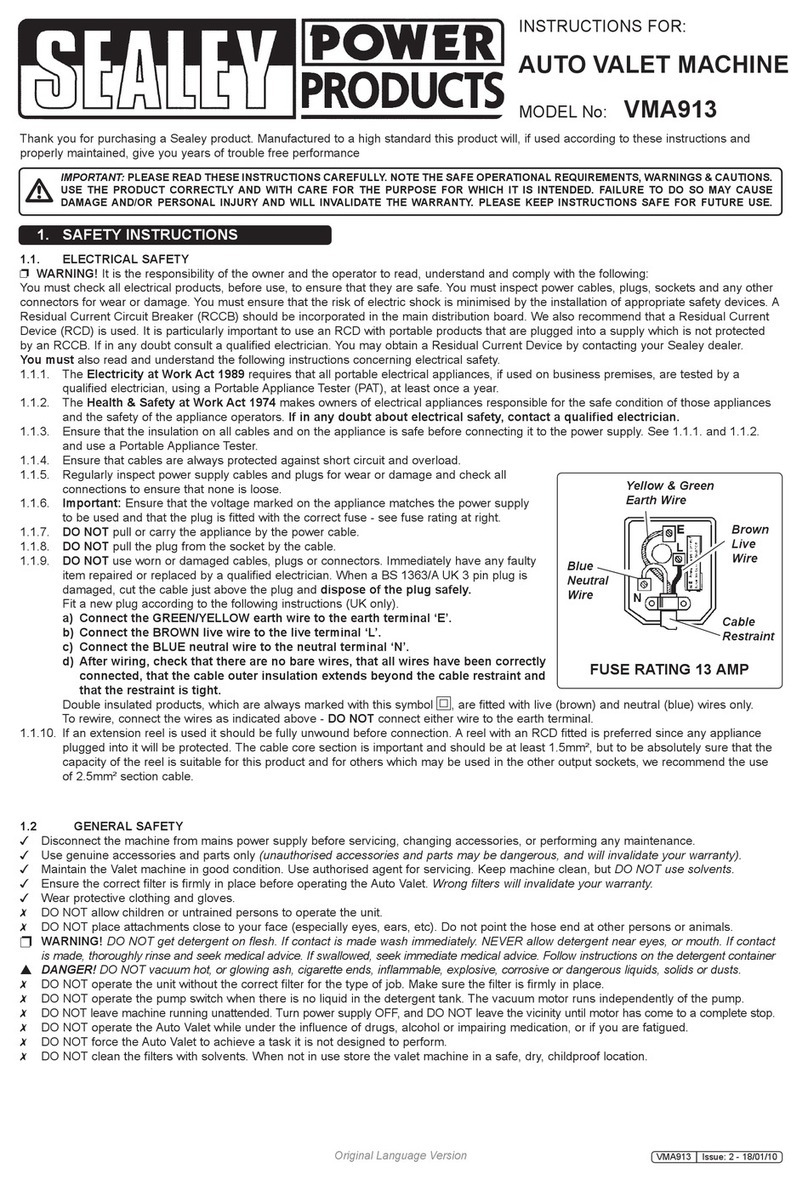

p WARNING! Disconnect the cleaner from the power supply before servicing, changing

accessories, or performing any maintenance.

7.1. Cartridge Filter - Fitting - Fig. 8

Note: Numbers in brackets refer to Fig. 8.

7.1.1. To fit the cartridge filter, remove the motor head by undoing the two side clips, Fig. 1, and

lifting off the head.

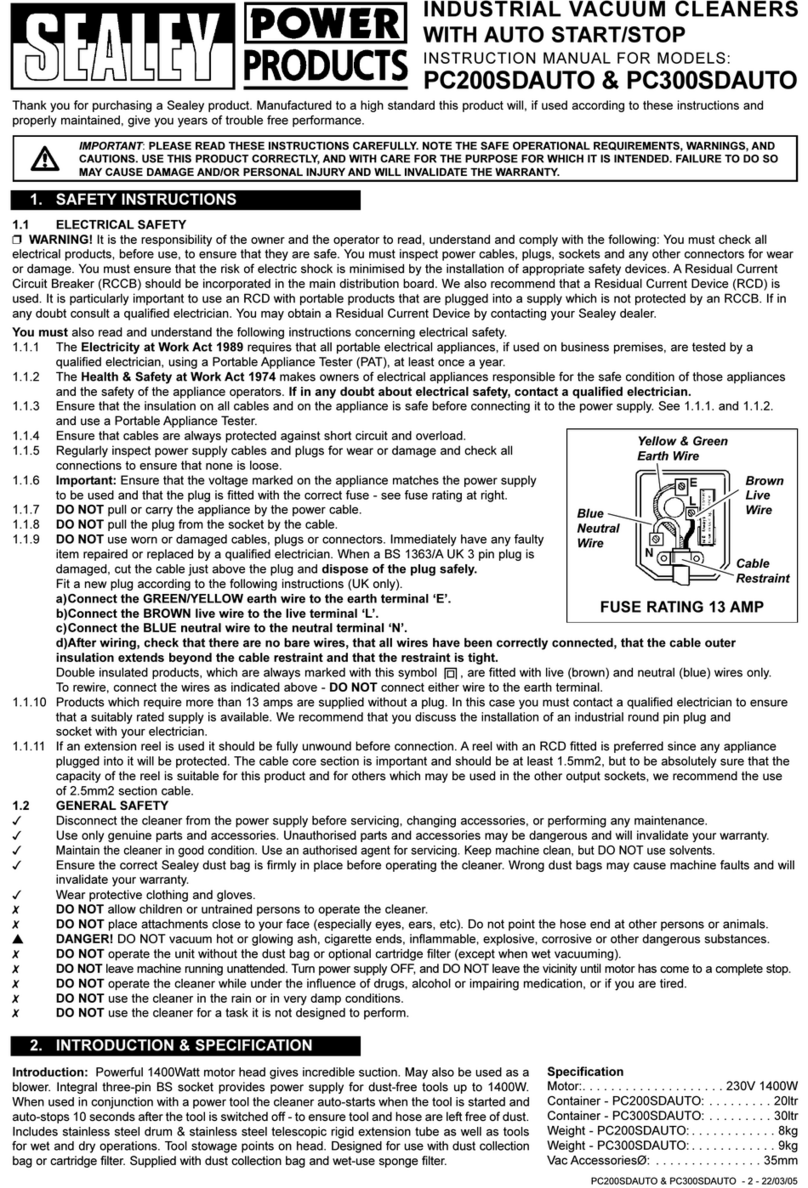

7.1.2. Position the filtering element (1) on the motor support (2), fit the adaptor disk (3) on the

filtering element (1) and secure both to the motor support by turning the adaptor

disc (3) in a clockwise direction.

7.1.3. Refit the motor head and secure using the two side clips, Fig. 1.

7.2. Cartridge Filter - Cleaning

7.2.1. To clean the cartridge filter, remove the motor head by undoing the two side

clips, Fig. 1, and lifting off the head.

7.2.2. Turn the adaptor disc, Fig. 8.3, in an anti-clockwise direction to unlock it.

7.2.3. Remove the adaptor disc and cartridge filter, Fig. 8.1.

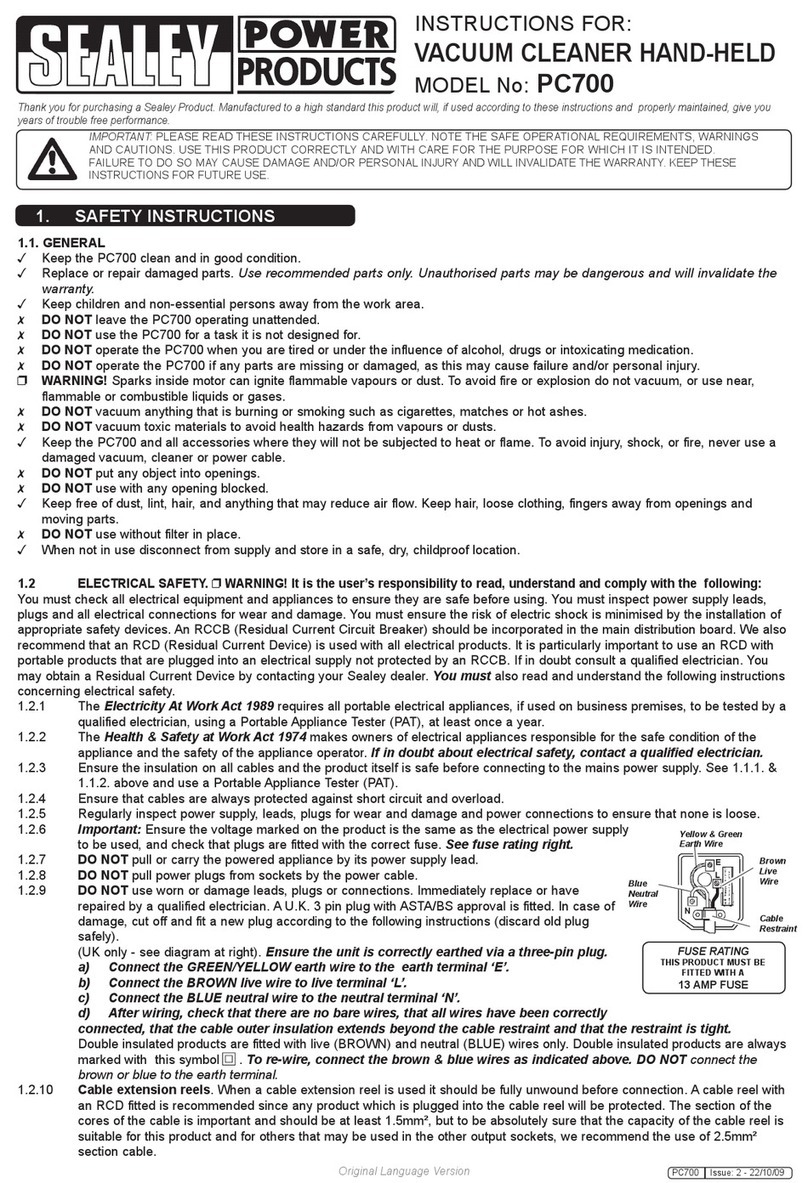

7.2.4. Clean the cartridge filter frequently using a soft bristle brush as shown in Fig. 9.

7.2.5. To clean the filter more thoroughly, use a shower fitting and direct the jet of water from the

inside towards the outside of the filter, Fig. 9.

Note: Handle with great care as the cartridge filter becomes extremely delicate when wet.

7.2.6. Ensure that the cartridge filter is completely dry before refitting.

7.2.7. The cartridge filter should be replaced if it becomes heavily contaminated or damaged.

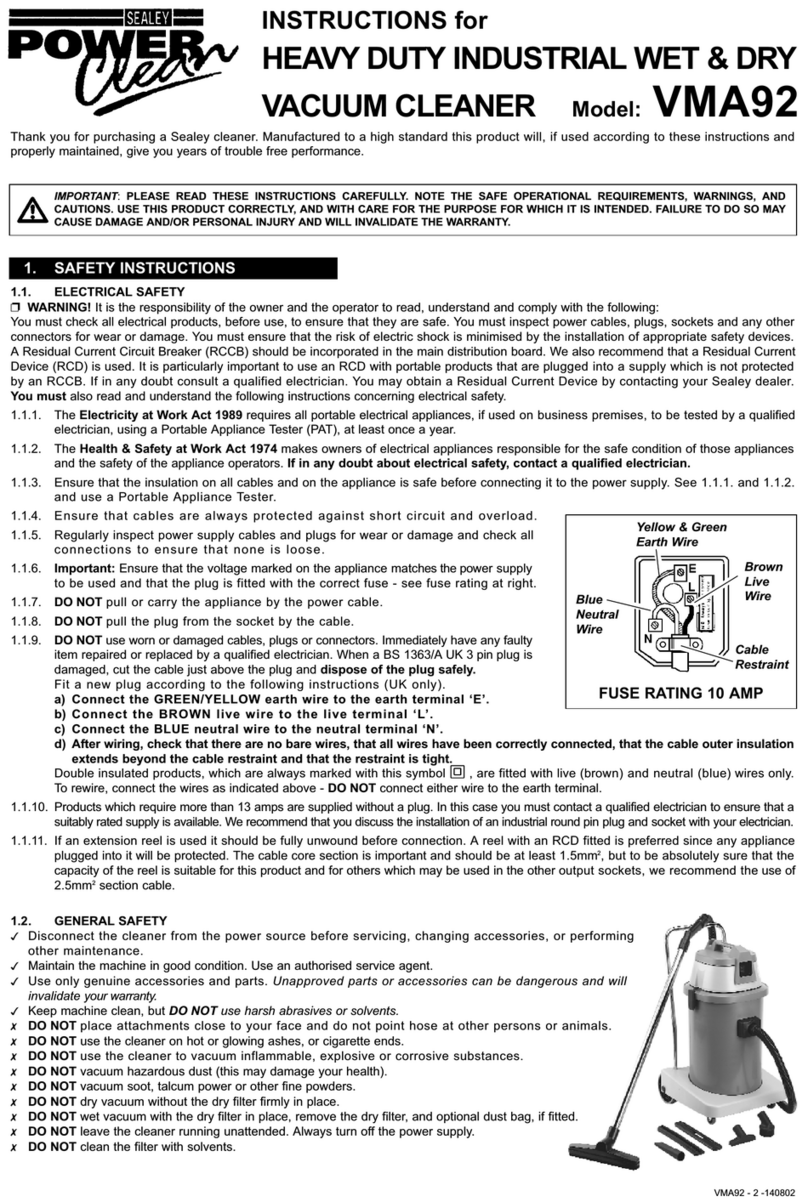

7.3. Basket Pre-Filter - Assembly and Fitting - Fig. 10

Note: Use this pre-filter only when the cartridge filter element is fitted.

7.3.1. To assemble the basket pre-filter, fit the filter onto the basket edge and secure in place using

the plastic snap ring provided.

Note: The plastic basket frame has six dovetail hooks underneath the upper rim. After fitting the

filter material, ensure that the plastic snap ring is secured by all six of the hooks.

7.3.2. To fit the assembled filter assembly, remove the motor head by undoing the two side clips,

Fig. 1, and lifting off the head.

7.3.3. Insert the pre-filter into the drum, Fig. 10, refit the motor head and secure using the two side

clips, Fig. 1.

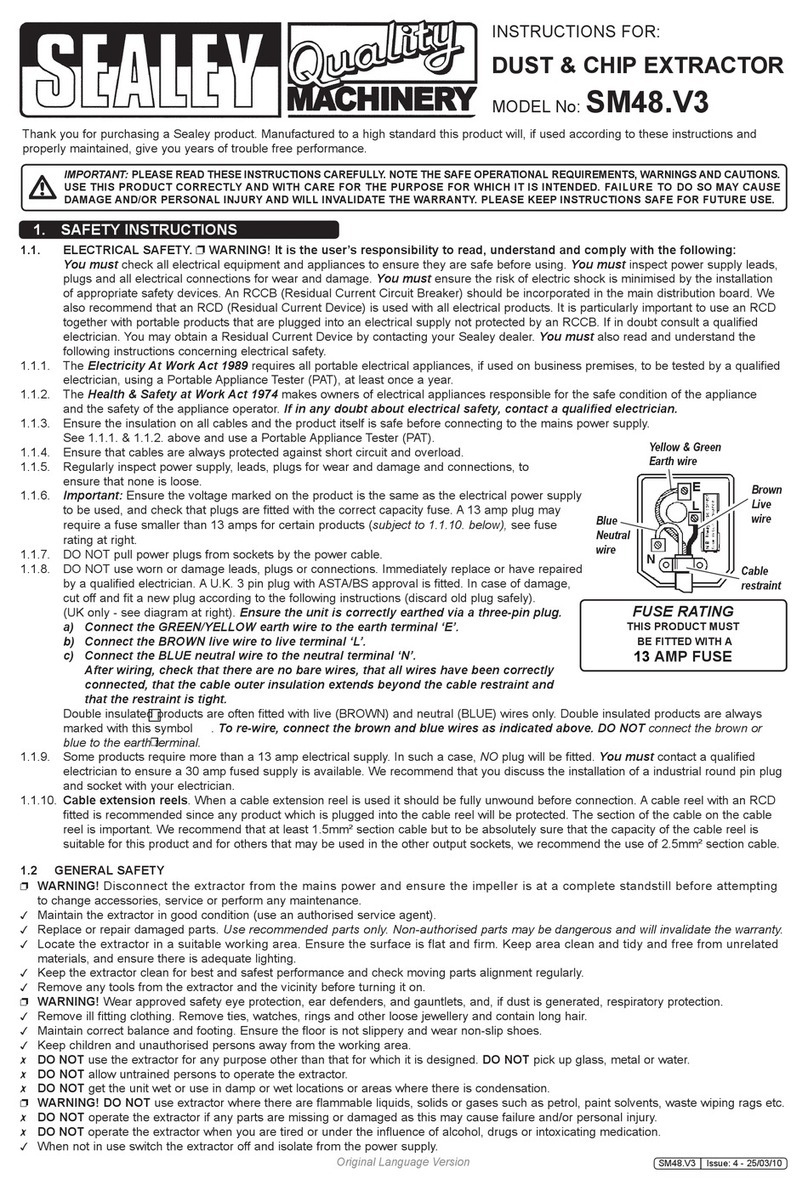

6. AUXILIARY POWER SUPPLY

Note: The maximum rating for an appliance operated from the auxiliary power supply is 800W.

6.1. To use the auxiliary power supply, Fig. 6, lift the cover plate and plug in the appliance. The On/Off switch is above the socket.

Fig. 8

Fig. 9

Fig. 11

PC80 & PC90P - 2- 271103

Fig. 6

5. WET VACUUM CLEANING

p

p

WARNING! Ensure that you read, understand and apply Section 1 Safety Instructions.

DO NOT vacuum solvents, explosives, inflammable and/or hazardous liquids such as petrol,

oil, spirits, paint, thinners, acids etc.

5.1. Wet Vacuum Cleaning - PC80 & PC90P

5.1.1. Ensure that the machine is unplugged from the power supply.

5.1.2. Remove the motor head by undoing the two side clips, Fig. 1, and lifting off the head.

5.1.3. Remove the filters and the disposable collecting bag.

5.1.4. Make sure the container is clean and free from dust and dirt.

5.1.5. Fit the sponge filter (para. 7.5), replace the motor head and secure using the side clips.

5.1.6. Attach the same flexible hose as used for dry cleaning and fit the appropriate nozzle.

5.1.7. Ensure the switches are in the O position, Fig. 4, and then plug the cleaner into the power supply.

5.1.8. To vacuum large quantities of liquid, from a sink or tank, etc., do not immerse tool completely in the liquid, leave a gap at the top of

the tool opening to allow an air inflow, Fig. 5.

5.1.9. The machine is fitted with a float valve which stops the suction action when the container has reached its maximum capacity or if the

cleaner is overturned. There will be an increase in motor speed. When this happens, turn the motors off and disconnect from power supply.

5.2. Emptying the container - PC80

Note: It is advisable to empty the container when it is less than half full.

The container is not designed to store water, please ensure the container is emptied

imediately after use.

5.2.1. Ensure the machine is unplugged from the power supply.

5.2.2. Remove the motor head by undoing the two side clips, Fig. 1, and lifting off the head.

5.2.3. Empty liquid into a suitable receptacle or drain.

5.2.4. To continue vacuuming, refit head and proceed.

5.2.5. On completion of wet vacuuming, empty the container and dry inside and out.

Remember! After wet vacuuming the cartridge filter element must be refitted before dry vacuuming again.

5.3. Emptying the container - PC90P

5.3.1. The PC90P is fitted with a pump which can be used to empty the container of liquids.

5.3.2. To operate the pump, turn the vacuum motors off and plug the pump into the auxiliary power socket

on the motor head, Fig. 6.

5.3.3. Remove the cap, Fig. 7, place the drain hose into a suitable receptacle or drain and start the pump.

5.3.4. As the liquid level drops, tilt the cleaner backwards in order to empty the container completely.

5.3.5. Switch off the pump as soon as liquid stops flowing from the drain hose.

Note: If liquid stops flowing from the drain hose and there is still sufficient liquid in the container to cover

the filter, the filter may be blocked. Switch off the pump immediately and clean the filter, para. 7.10.

5.3.6. Empty the bin and clean and dry the inside and outside before storage.

Remember! After wet vacuuming the cartridge filter element must be refitted before dry vacuuming again.

Fig. 5

Fig. 7

Fig. 10