8DO NOT pull or carry by cable, use cable as handle, close a door on the cable, or pull cable around sharp edges or corners.

9 Ifthesupplycordisdamaged,itmustbereplacedbythemanufacturer,aqualiedserviceagentorsimilarlyqualiedpersonsinorder

to avoid a hazard.

8DO NOT handle the plug or vacuum cleaner with wet hands.

9 Frequentlycheckthattheoatvalvepositionedunderneaththemotorisabletomovefreely.

8DO NOT usethisvacuumcleanerwithatornlterorwithoutthelterinstalled.

8DO NOT allow to be used as a toy. Close attention is necessary when used by or near children.

WARNING!Toreducetheriskofinjuryfromaccidentalstarting,unplugpowercordbeforechangingorcleaninglter.

WARNING! Unplug from power supply when not in use and before carrying out maintenance.

8DO NOT cover the ventilation openings. DO NOT vacuum with any ventilation openings blocked; keep free of dust, lint, hair or

anythingthatmayreduceairow.

9 Keephair,looseclothing,ngers,allpartsofbodyawayfromopeningsandmovingparts.

9This machine is not intended for use by persons (including children) with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge. Children shall not play with the appliance. Cleaning and user maintenance shall not be made by children

without supervision. For additional protection: It is recommended that this vacuum cleaner can be used in conjunction with residual

current device (RCD) with a rated residual current of 30mA or less.

9 Onlyusethesocketoutletonthemachineforpurposesspeciedintheinstructions.

9 Iffoamorliquidescapesfromthemachine,switchoimmediately.

9 Checktheoatvalveregularlytoensureitismovingfreelyandexamineitforsignsofdamage.

9Precautions should be taken when changing attachments.

9For user servicing, the machine must be dismantled, cleaned and serviced, as far as is reasonably practicable, without causing risk to

themaintenancestaandothers.Suitableprecautionsincludedecontaminationbeforedismantling.

9 Provisionmustbemadeforlocallteredexhaustventilationwherethemachineisdismantled,cleaningofthemaintenanceareaand

suitable personal protection must be worn whilst carrying out these tasks.

9 Performatechnicalinspectionatleastannually,consistingof,forexample,inspectionofltersfordamage,airtightnessofthe

machine and proper function of the control mechanism.

9Besides the operating instructions and the binding accident prevention regulations valid in the country of use, observe recognized

regulations for safety and proper use.

9When dust removers are used, the rate at which air is exchanged in the room must be adequate if the exhaust air from the vacuum

cleaner is blown into the room (please observe regulations valid in the country of use).

9 Beforestartingwork,theoperatingstamustbeinformedon:

- use of the vacuum cleaner

- risks associated with the material to be picked up

- safe disposal of the picked up material.

9Before transporting the collection tank, close all the locks.

8DO NOT tilt the cleaner if there is liquid in the collection tank.

8DO NOT use a crane hook to lift the cleaner.

9For class M machines, the outside of the machine should be decontaminated and wiped clean or treated with sealant before being

taken out of a hazardous area. All the machine parts shall be regarded as contaminated when removed from the hazardous area and

appropriate action taken to prevent dust dispersal.

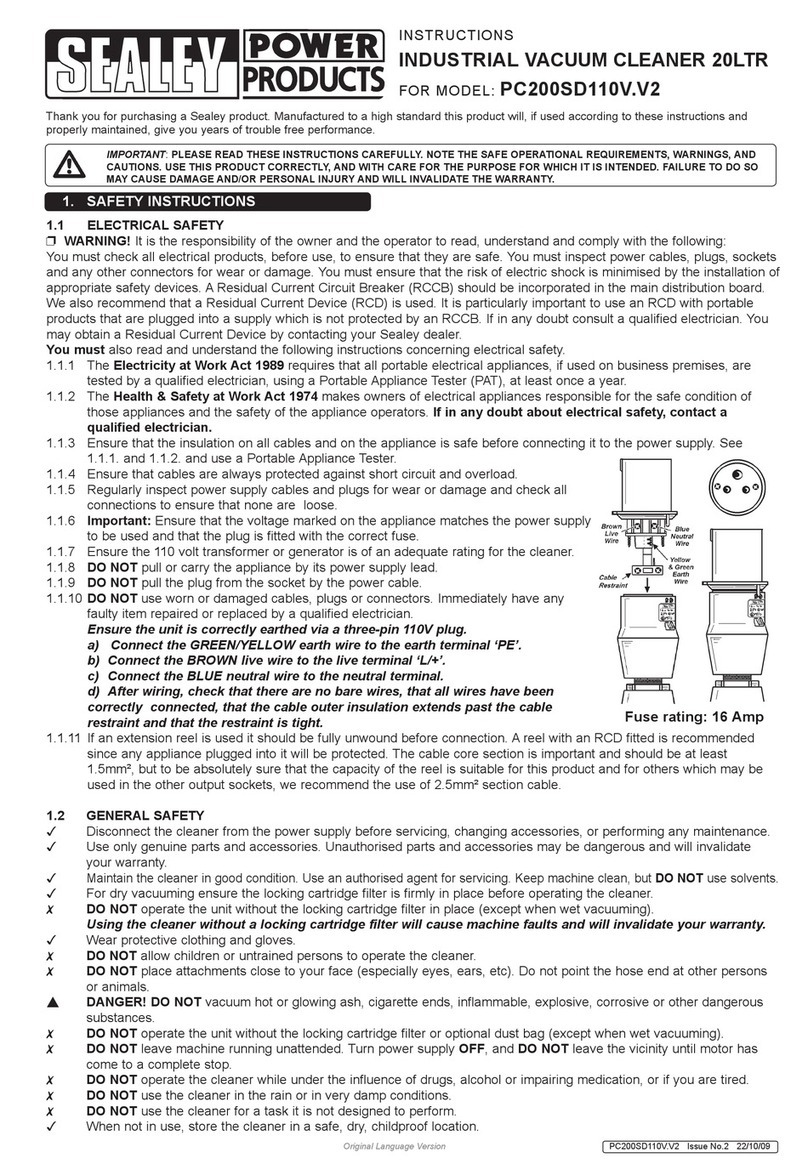

If an extension reel is used it should be fully unwound before connection. A reel with an RCD fitted is preferred since any appliance

plugged into it will be protected. The cable core section is important and should be at least 1.5mm², but to be absolutely sure that the

capacity of the reel is suitable for this product and for others which may be used in the other output sockets, we recommend the use

of 2.5mm² section cable. If an extension reel is to be used outdoors, ensure it is marked for outdoor use.

2. INTRODUCTION

110V M Class wet and dry vacuum cleaner with a 38 litre stainless steel drum. Removes 99.9% of hazardous dust with the exposure limit value

of >0.1mg/m³. When the air velocity starts to fall below 20 metres per second a visual LED warning light on the top of the unit will show. Built-in

pushcleansystemthatforcesairbackthroughthelterrestoringthesuctionpower.Usesacombinationofltersandliningbagstocreatea

2-stagecollectiontostopanyhazardousdustbeingleftinthetankorbecomingairborne,italsohastheoptionofusingafoamlterforwet

cleaningwhichisreusable(allconsumablesareincluded,5xTankliners,5xdustbagsand1xfoamlter).Includedaccessoriesareantistatic

crevicetool,antistaticroundbrush,multi-surfaceoornozzle12”andPowertooladaptor.

3. SPECIFICATION

Model no .......................................................... PC380M110V

Airow ...................................................................147.6m³/hr

Consumable parts

Foamlter(x3).....................................................PC380MFF

CartridgelterClassM ........................................PC380MCF

Tank liner Class M (x5) ...................................... PC380MTL,

Dust bag class M (x5) ........................................ PC380MDB

Drum size......................................................................... 38L

Max. vacuum pressure.................................................22Kpa

Motor power................................................................ 1100W

Power tool capacity............................................110V - 660W

Supply.....................................................................110V-16A

Vacuum accessories diameter ..................................... 35mm

Original Language Version

© Jack Sealey Limited PC380M110V Issue:1 08/04/21