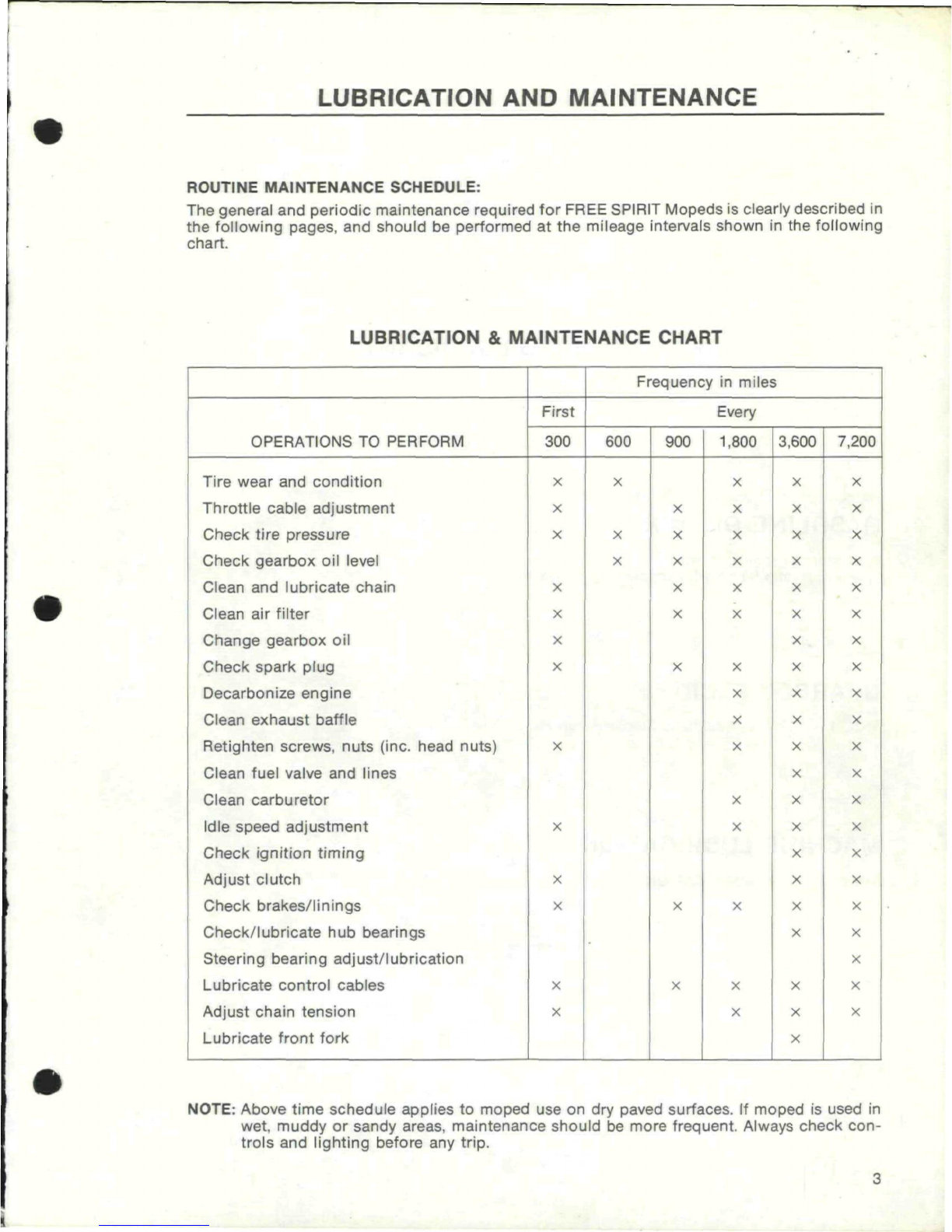

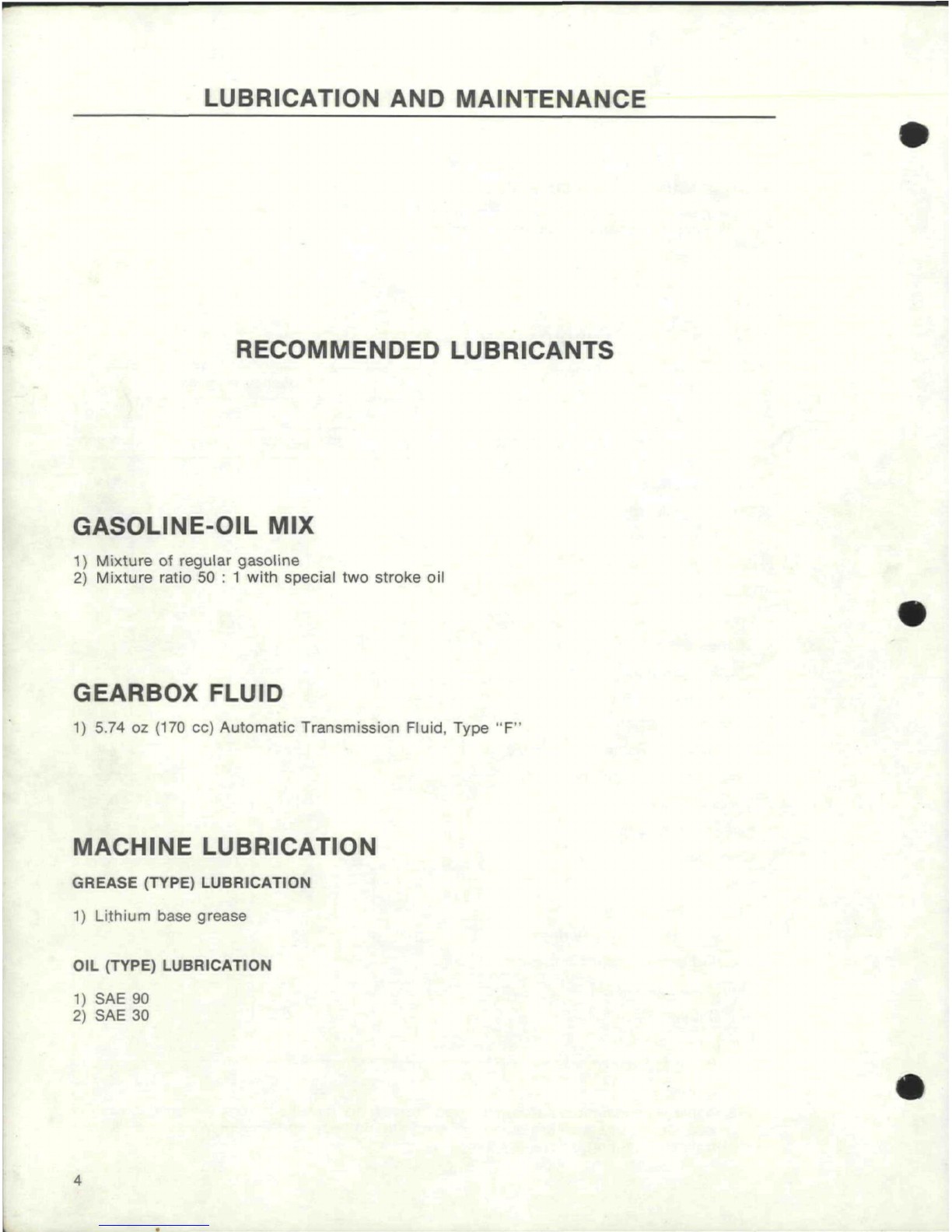

LUBRICATIONANDMAINTENANCE

Ji

Fig.

4

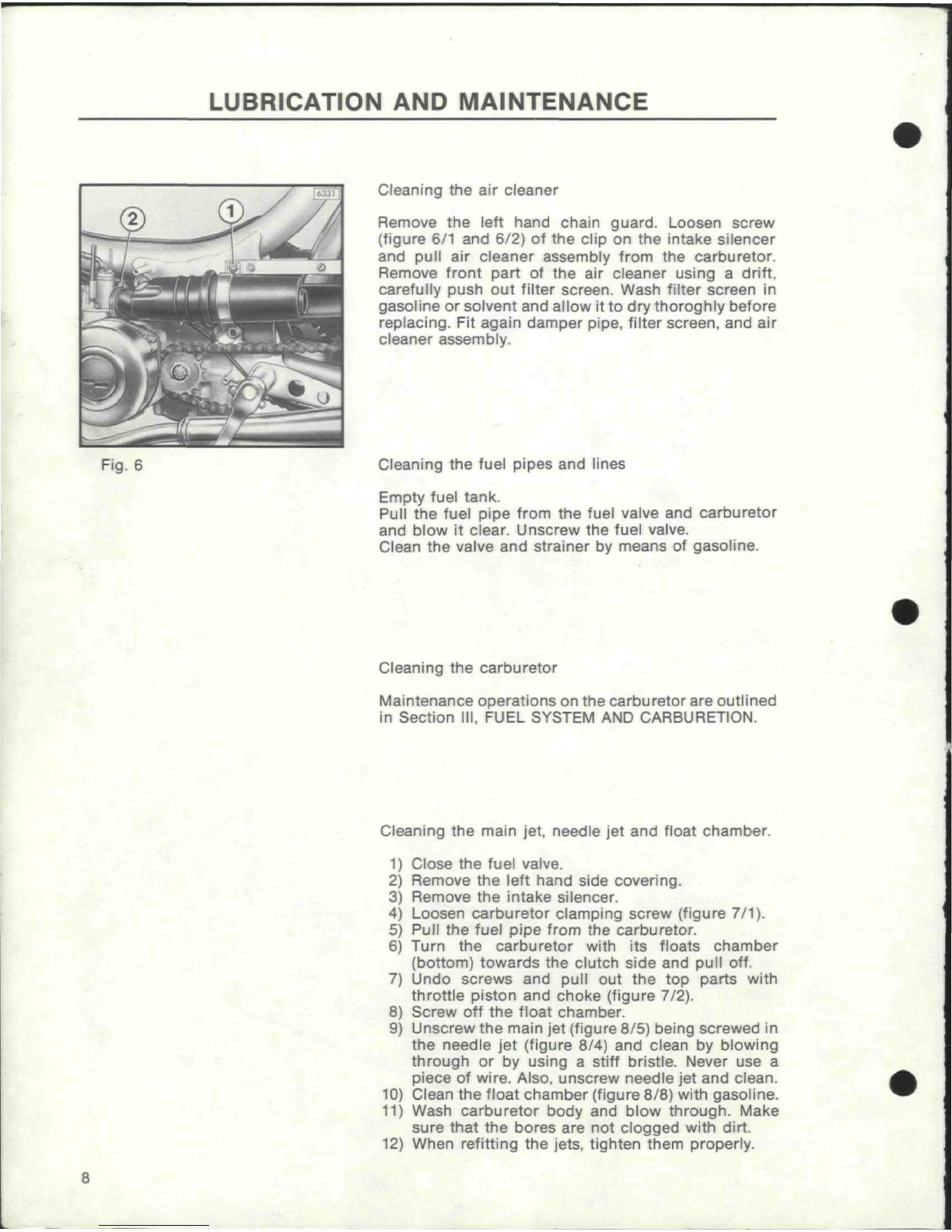

Bymeansofoil

1)Brakeadjustingscrewonfrontandrearwheel.

2)Adjustingscrewforstartingclutchcable.

3)Chaintensioningscrews.

4)Workingsurfacesofbothbrakelevers.

5)Bowdencables.

Lubricatingtheignitioncam:

Lubricatethegreasefelt.Thelubricantmustnotreach

thebreakerpointsasthiswouldcauseprematureand

excessivewear.

MAINTENANCE

PleasecontactanauthorizedSearsAutoCenterfor

workyoudonotwishtocarryoutyourself.Theagent

willbepleasedtoadviseandhelp.

Checkingsparkplugs

Unscrewspark

plug,

connecttohightensionleadand

placeplugbodytoearth,forinstanceonthecylinder

head.

A strongsparkmustbevisiblebetweenthespark

plugelectrodeswhenoperatingthestarter.Oiledup

plugsordirtyelectrodesdonotsparkandmustbe

cleanedfirstwitha pieceofwoodora steelwirebrush.

Fitonlyreplacementplugshavinga heatvaluein

accordancewiththeenclosedchart(page18).The

electrodegapshouldbefrom( .016-.020in)0.4to

0.5mm,iflarger,adjustbybendingtheearthelectrode.

Whenreplacingthesparkplugensurethreadmatches

properlyandtheplugcanbescrewedineasily.Never

applyforce.Screwinplugbyhandfor2 to3 turns

beforeusingthesparkplugspanner.

Appearanceoftheplugtipcantellyouhowyour

enginehasbeenrunning.

MAINTENANCE

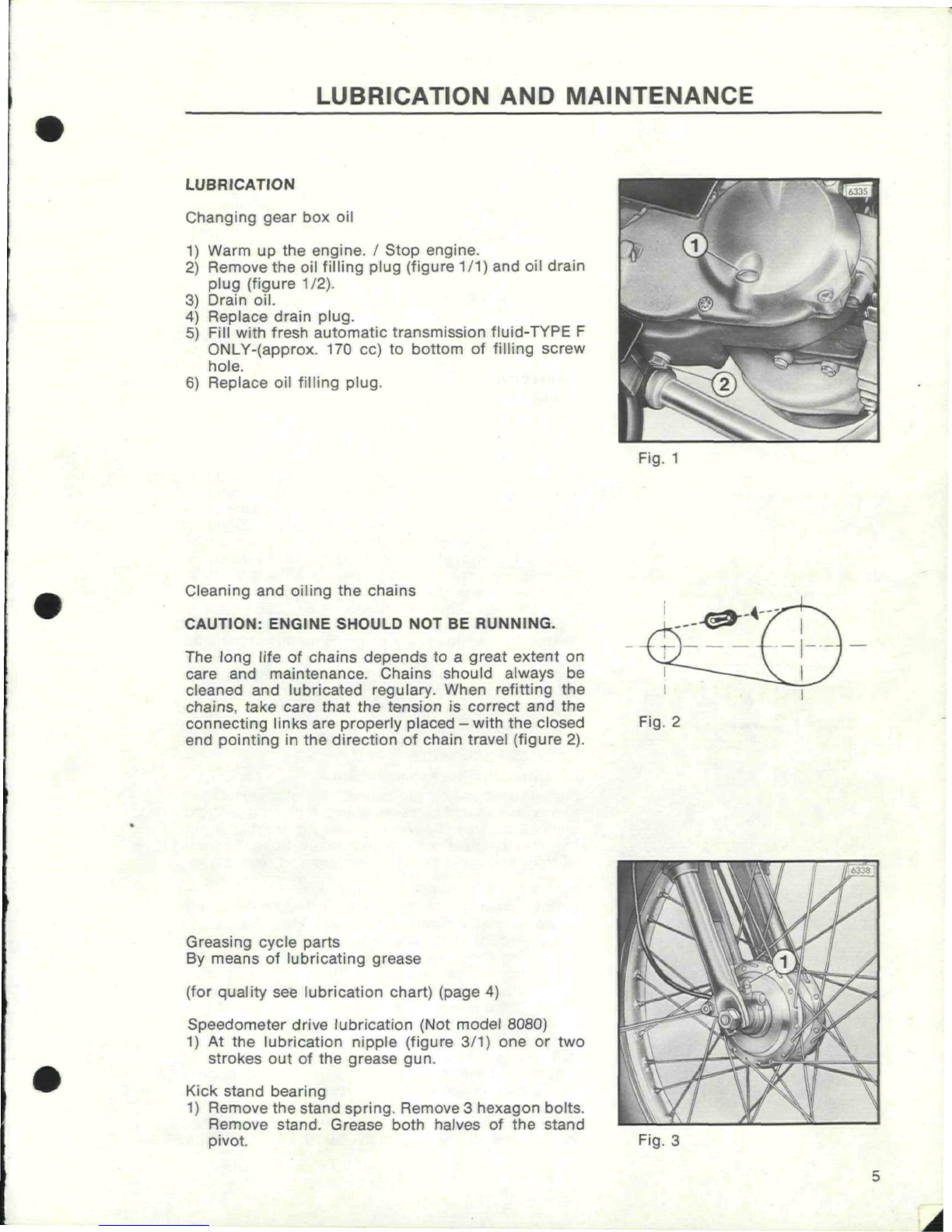

Decarbonizingtheengine(figure4)

Carbondepositsonthecylinderhead,pistoncrown

andintheexhaustportsarenormalwithalltwo-stroke

enginesandcaneventuallyleadtotroubleifnot

removedintime.Combustiondepositsfromoilaswell

asfromfuelmustthereforeberemovedregularly.

Cylinderheadandpistonhead

Carbondepositsonthecylinderheadandpiston

crownshouldberemovedonlywitha soft,bluntedged

instrumenttoavoiddamagetothelightalloycasting.

Scratchingshouldbeavoidedsinceeverynewscratch

willharbourmorecarboninfutureuse.

Onlyscallydepositsneedberemovedfromthepiston

crown,

thereisnoneedtodisturbthepistonifitis

coveredonlybya uniformlayerofoilcarbon.Before

refittingthecylinderhead,thoroughlyremoveall

carbondepositsandscrapingsfromthecylinderwall

witha nonfrayingsoftclothandsmearthesurface

lightlywithmotoroil.Beforeassembly,turnoverthe

enginea fewtimestomakesureitrunseasily.Then

cleanthejointingsurfaceswitha cleanrag.Tighten

thefourcylinderheadnutscrosswise(7ft/lb)(10

Nm).

L