Table of Contents Section-Page

Table of Contents LX25 12/21/22 3

SECTION 1 INTRODUCTION

1.1 About This Manual ............................................................................................. 1-1

1.2 Getting Service.................................................................................................... 1-1

1.3 Specifications ...................................................................................................... 1-1

1.4 Dimensions.......................................................................................................... 1-1

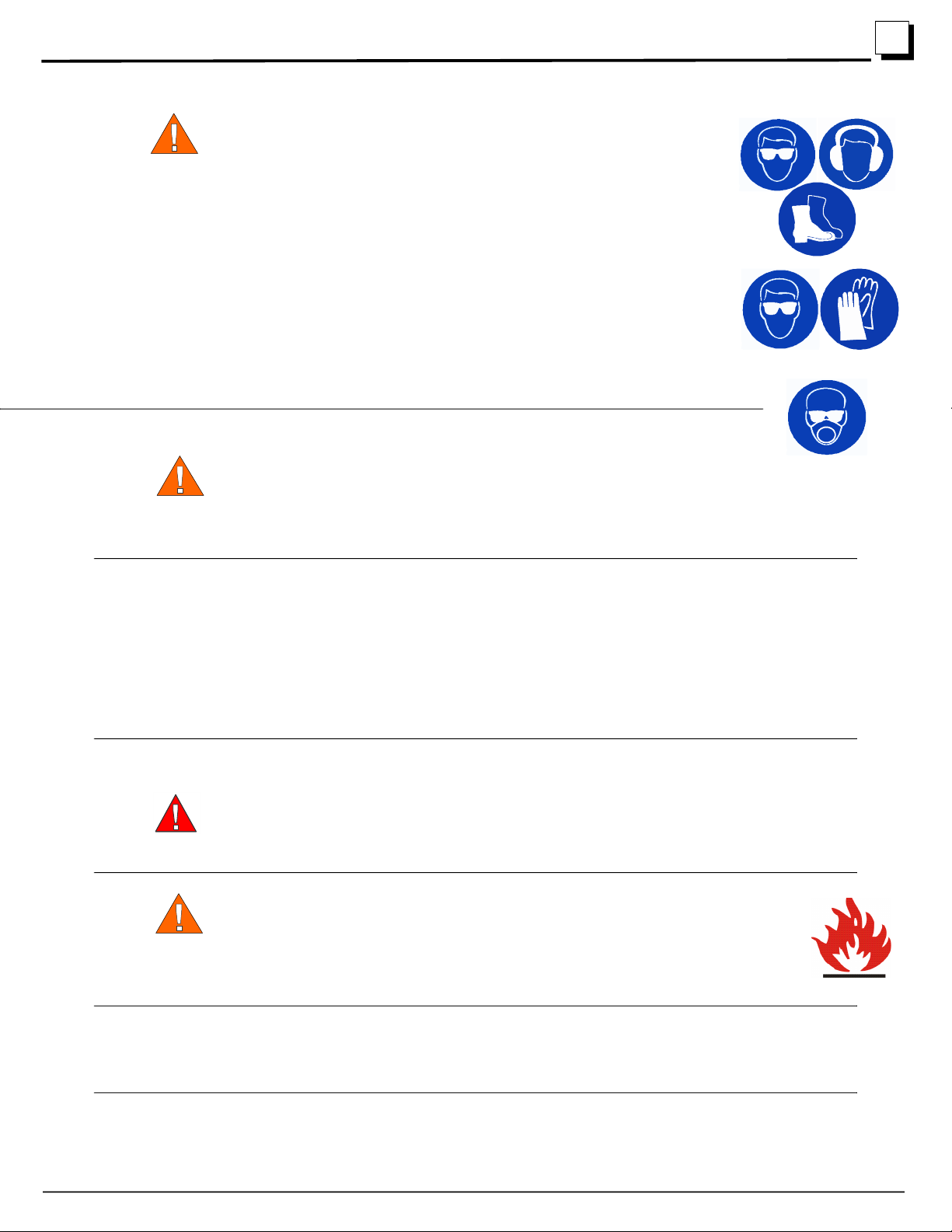

SECTION 2 SAFETY

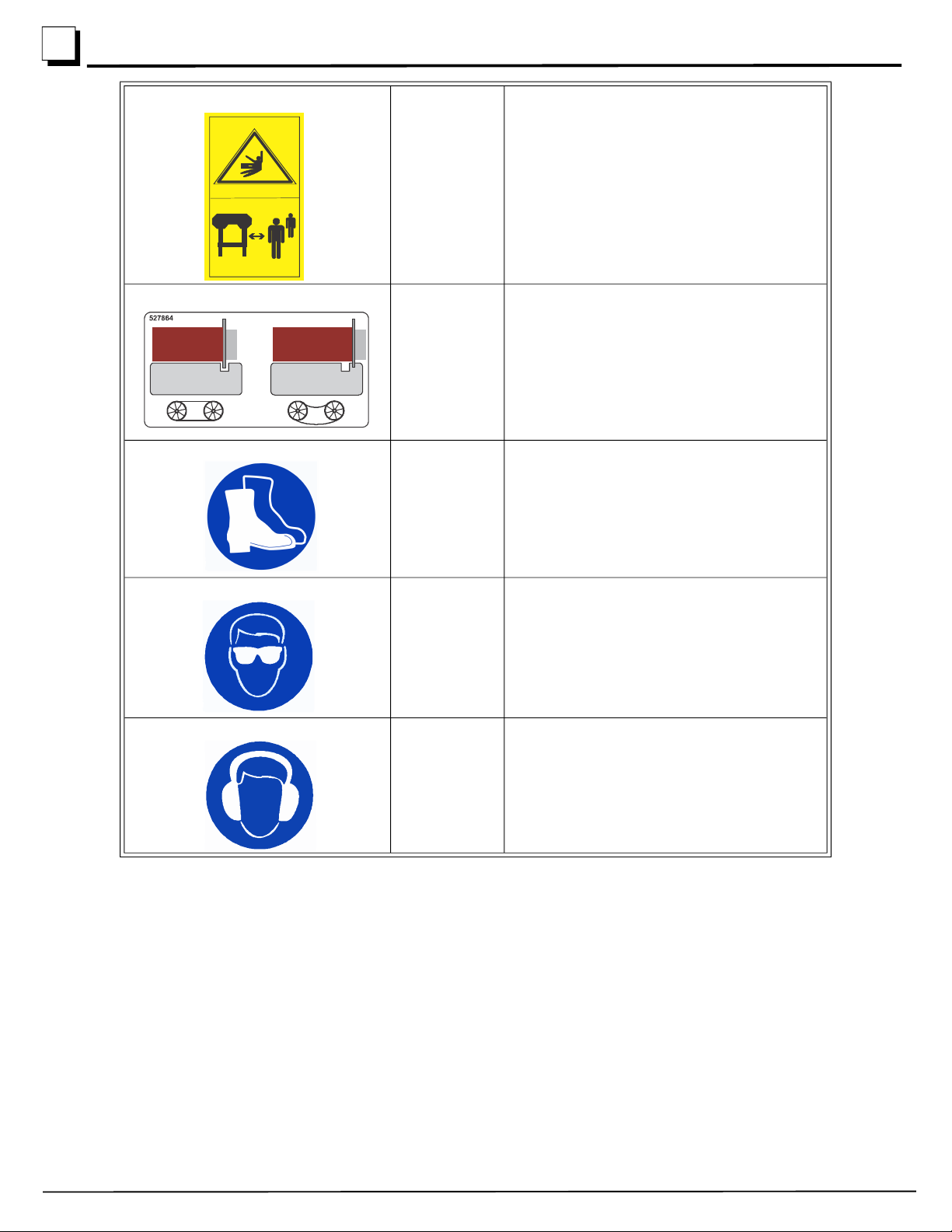

2.1 Safety Symbols ................................................................................................... 2-1

2.2 Safety Instructions............................................................................................... 2-1

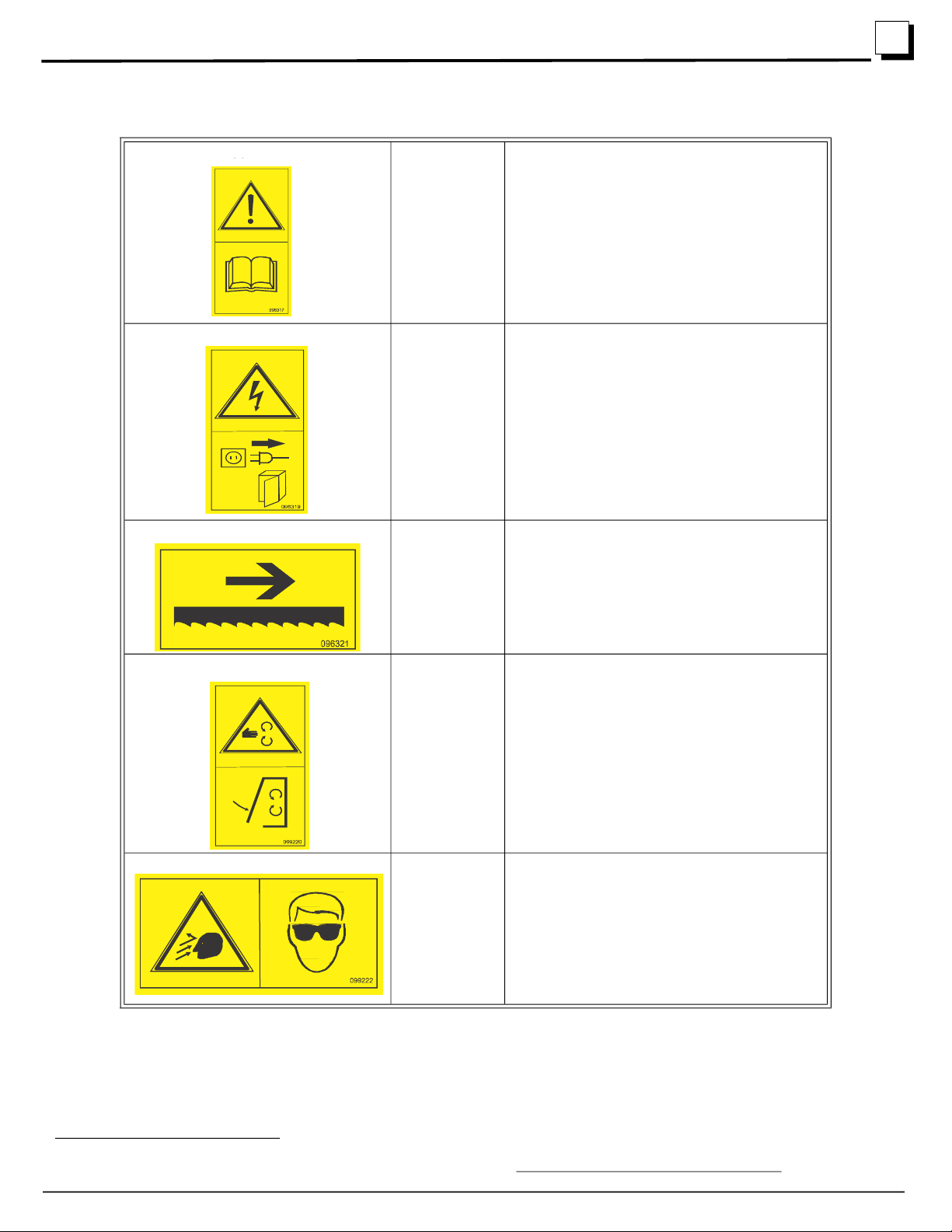

2.3 Safety Decals....................................................................................................... 2-4

SECTION 3 SETUP

3.1 Remove and inspect the parts boxes ................................................................... 3-1

3.2 Assemble the bed sections .................................................................................. 3-6

3.3 Level the bed....................................................................................................... 3-8

3.4 Install the mast .................................................................................................... 3-9

3.5 Install the sweepers and sawhead stops ............................................................ 3-11

3.6 Install the operator’s handle.............................................................................. 3-12

3.7 Install the Engine .............................................................................................. 3-12

3.8 Install the throttle cable..................................................................................... 3-14

3.9 Install the clutch cable ...................................................................................... 3-15

3.10 Assemble the up/down crank ............................................................................ 3-16

3.11 Install the scale.................................................................................................. 3-17

3.12 Install the dust chute ......................................................................................... 3-18

3.13 Install the Blade ................................................................................................ 3-18

3.14 Install the lube water tank ................................................................................. 3-20

SECTION 4 SAWMILL OPERATION

4.1 Sawmill adjustments ........................................................................................... 4-1

4.2 Starting the Engine/Motor................................................................................... 4-6

4.3 Loading, Turning, and Clamping Logs............................................................... 4-6

4.4 Level a Log ......................................................................................................... 4-7

4.5 Lift Operation...................................................................................................... 4-7

4.6 Engine Operation ................................................................................................ 4-7

4.7 Feed Operation.................................................................................................... 4-8

4.8 Cutting The Log.................................................................................................. 4-8

4.9 Edging ................................................................................................................. 4-9

4.10 Blade Height Scale.............................................................................................. 4-9

4.11 Water Lube Operation....................................................................................... 4-10

4.12 Transporting the Sawmill.................................................................................. 4-10

SECTION 5 MAINTENANCE

5.1 Continuous maintenance ..................................................................................... 5-1

5.2 General maintenance........................................................................................... 5-1

5.3 Engine maintenance ............................................................................................ 5-2

SECTION 6 SAWHEAD PARTS

6.1 Sliding Blade Guide Arm Assembly................................................................... 6-1