SEFRAM MW3105 User manual

MW3105

DIGITAL CLAMP MULTIMETER

2

M MW3105 A

01

3

INTRODUCTION

1.1 - Unpacking and inspection

Upon removing your newDigital Clamp Meter from its packing, you should have the following items:

1. Digital Clamp Meter.

2. Test lead set (one black, one red).

3. Carrying case.

4. Instruction manual.

5. Battery (installed).

1.2 - Meter Safety

Terms as marked on equipment:

ATTENTION - Refer to manual.

DOUBLE ISOLATION - (Protection Class II)

DANGER - Risk of electric shock.

4

Symbols in this manual

This symbol indicates where cautionaryor other information is found in the manual.

Battery

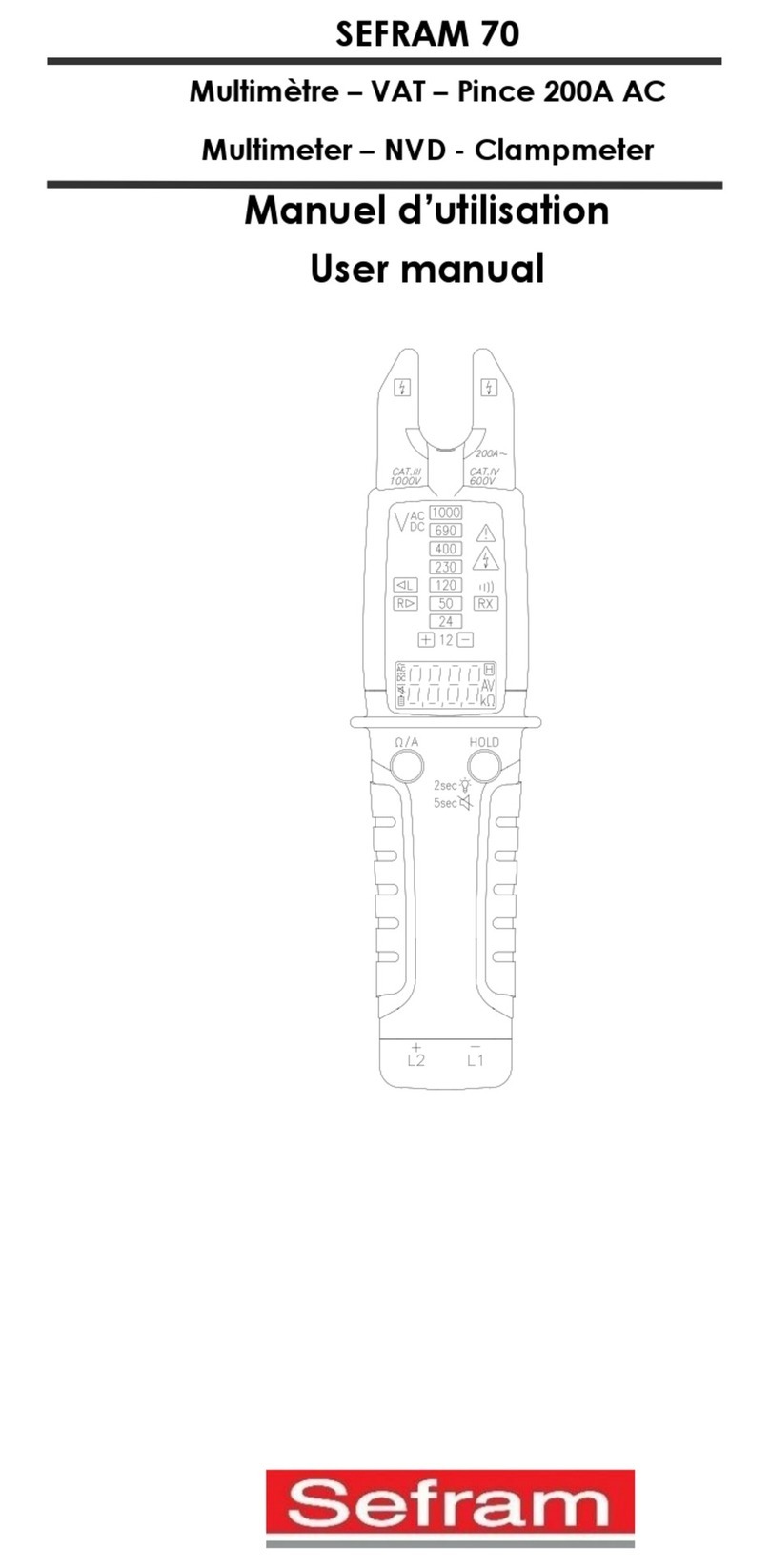

1.3 Front panel

Refer to figure 1 and the following steps to familiarize yourself with the instrument’s front panel, controls and connectors.

1. Hz F . Test lead input for frequency, resistance, capacitance, continuity and diode test measurements.

2. Volt Plug . Positive (or high) test lead input for voltage measurements.

3. COM Plug. Black (common neutral, ground), low side test lead input.

4. Current Clamp Jaws. Use for current measurements without disconnecting circuit. Simply open jaws and loop around

conductor.

5. Lever. Press to open, or release to dose jaws.

6. Power/Function/Range Selector. Rotary switch to turn power off or to select measurement range and function.

5

7. Display, LCD Readout . Indicates function selected, data reading selected (PEAK, HOLD, etc.) over-range, polarity(-), and

low batterystatus. Digit display: 3-3/4 digits with maximum reading 4000 for, with automatic placement of decimal point.

8. HOLD. Press to freeze present reading at displayand to display "HOLD" annunciator. Press again to exit.

9. MAX/MIN. Press to record and enable display of minimum and maximum input levels. Press this button to increment through

levels recorded and present input level. Display shows

HOLD MAX or MIN and active level.

10. PEAK. Push button store peak value of a varying input, PEAK displayed. Press to toggle in and out.

11. ZERO. Push button to obtain difference between a stored reference and present reading, ZERO displayed. Stored

reference is input level when ZEROdata mode is enabled. Press and hold button down for at least 2 seconds to exit.

12. RANGE. Button to selectmanual range mode and to increment present range; shown at display, in this mode, each

time button is pressed range increments by 0.1. Range starts from active autoranging level. To exit, press and hold down this

button for about 2 seconds.

13. Bargraph. Provides analog displayof magnitude and direction of change of input; 42 segments

6

Figure 1

7

SPECIFICATIONS

2.1 General specifications

Display: 3 ¾ digit LCD with a maximum reading of 3999

Polarity:Automatic polarity indicated. « - » shown, « + » assumed.

Measuring Rate : Nominal, 2 mes/sec.; Cap. & Freq., 1 mes/sec.

Overrange Indication: OL shown, all digits blank.

Low BatteryIndication: symbol shown at about 7.4 V, or less.

Power Requirement: Single 9 V battery (NEDA 1604A, 6F22).

BatteryLife : 100 hours typical (with alkaline)

Jaw opening : 57mm (2.24’’).

Position error : Add 1% to specified accuracy if conductor is not centered in jaws.

Dimensions (H x W x D) : 277 x 102 x49 mm (10.9" x 4" x 1.9").

Weight : 540 g (18.9 oz),includes battery.

Accessories supplied: battery, carrying case, test leads, instruction manual.

Temperature coefficient: 0.1 xspecified accuracy/°C(<18 °C or>28 °C)

Auto Power OFF : if not used, turns meter off after 30 minutes typical.

8

2.2 Environmental conditions

Indoor use only

Maximum altitude of use: 2000 meters.

Operating temperature : 0 °Cto 50 °C,<70% relative humidity.

Storage temperature : -20 °C to +60 °C, <80% relative humidity with battery removed.

Installation category: IEC1010 Cat III 600V.

Pollution degree : 2

9

2.3 Electrical Specifications

Accuracy is given as ±(% of reading + number of digits) from 18 °C to 28 °C, with relative humidity up to 70%.

Temperature coefficient: 0.1 x specified accuracy/°C (t <18 °C or t >28 °C).

DC Current - Manual ranging

Range

Resolution

Accuracy

Overload Protection

400A

100mA

( 1.5% + 5 dgt)

1000A

1A

0-600A ( 1.5% + 5 dgt)

600-800A ( 2.5% + 5 dgt)

800-1000A ( 3.5% + 5 dgt)

1200A for 60 s maximum

Specifications given from 5% to 100% of the range. Accuracy given after having performed auto-zero of the clamp.

AC Current - Manual ranging

Range

Resolution

Accuracy50-60Hz

Accuracy60-400Hz

Overload

Protection

400A

100mA

( 1.5% + 5 dgt)

( 3.0% + 5 dgt)

1000A

1A

0-600A ( 1.5% + 5 dgt)

600-1000A ( 2.0% + 5 dgt)

0-600A ( 3.0% + 5 dgt)

600-1000A ( 3.5% + 5 dgt)

1200A for 60 s

maximum

Specifications given from 5% to 100% of the range.

Crest factor : 3 max. Add 1% to accuracy for crest factor between 2 and 3. Conversion : TRUE RMS.

10

DC Voltage (using test leads, auto or manual ranging)

Range

Resolution

Accuracy

Input Impedance

400mV

100µV

> 1000M

4V

1mV

11M

40V

10mV

( 0.5% + 1 dgt)

10M

400V

100mV

10M

1000V

1V

10M

Overload protection : 1000V DC or 750 VAC RMS.

11

AC Voltage (using test leads, auto or manual ranging)

Range

Resolution

Accuracy

50Hz to 500Hz

Input Impedance

Overload protection

400mV*

100µV

> 1000M// 100pF

4V

1mV

11M// 100pF

1000V DC or

40V

10mV

( 1.5% + 4 dgt)

10M// 100pF

750V AC RMS

400V

100mV

10M// 100pF

1000V

1V

10M// 100pF

Specifications given from 5%to 100%of the range (except 400mV range, see *)

Conversion : TRUE RMS

Crest factor : 3 max. Add 1% to accuracy for crest factor between 2 and 3

* Input signal >40mV, bandwidth 50-100Hz for this range.

12

Resistance (using test leads, auto and manual ranging)

Range

Resolution

Accuracy

Open circuit voltage

Overload protection

400

0.1

( 1.2% + 4 dgt)

0.4V

4K

1

( 1.0% + 2 dgt)

0.4V

40K

10

( 1.0% + 2 dgt)

0.4V

500V DC or

400K

100

( 1.0% + 2 dgt)

0.4V

AC RMS

4M

1K

( 1.5% + 4 dgt)

0.4V

40M

10K

( 2.0% + 4 dgt)

0.4V

ContinuityTest (using test leads)

Range

Threshold

Response time

Test current

400

< 40

100ms typ.

<0.4mA

Overload Protection : 500V DC or AC RMS

13

Diode Test (using test leads)

Range/Resolution

Accuracy

Open circuit voltage

Test current

4V / 1mV

( 1.0% + 2 dgt)

3.2V

about 0.6mA

Overload Protection : 500V DC or AC RMS

Frequency (using test leads, auto or manual ranging)

Range

Resolution

Accuracy

Trigger level

Overload protection

100Hz

0.01Hz

( 0.1% + 10 dgt)

1kHz

0.1Hz

( 0.1% + 4 dgt)

500V DC

10kHz

1Hz

( 0.1% + 4 dgt)

2.5 V RMS

or AC RMS

100kHz

10Hz

( 0.1% + 8 dgt)

400kHz

100Hz

( 0.1% + 20 dgt)

NOTE: Frequencies <100Hz or >100khz, readings may tend to be unstable.

Minimum frequency: 1Hz

14

Capacitance (using test leads, auto and manual ranging)

Range

Resolution

Accuracy

Overload protection

4nF

1pF

( 1.5% + 40 dgt)*

40nF

10pF

( 1.5% + 4 dgt)*

400nF

100pF

( 1.5% + 4 dgt)

500V DC or

4µF

1nF

( 1.5% + 4 dgt)

AC RMS

40µF

10nF

( 1.5% + 4 dgt) for C<20µF

* Accuracy specified after zeroing in relative mode.

Display is indicative above 20µF (no accuracy specified)

15

OPERATION

This instrument has been designed and tested in accordance with IEC Publication 1010, SafetyRequirements for

Electronic Measuring Apparatus and has been supplied in a safe condition. This instruction manual contains some

information and warnings which have to be followed bythe user to ensure safe operation and to retain the instrument

in safe condition.

3.1 Precaution and preparations for measurements

1. Read, thoroughly understand and followthe SAFETY instructions given in this manual.

2. Examine yourtest leads. Make sure they are in good condition, free from cracks, etc.,and that theymake good contact with

the plugs of your meter. Do this for safe operation and to avoid false readings.

3. Before taking a measurement, review the related instructions in this manual.

4. Before taking a measurement, estimate its expected value. If you are considerably out of an expected range, carefullyreview

your circuit under test; it could be defective.

5. If value of measurement is unknown, start with the highest range.

6. Stay within the operating range of your meter. Never exceed the 750 V AC or 1000 V DC maximum limits and 500 V from

COM plug to earth ground or reference.

7. If an over-range is shown, immediately switch to a higher range.

CAUTION

Never switch between ranges while connected to high voltage. This prevents damage to the instrument.

16

8. When using the jaws to take a measurement,center a single conductor of a cable in the jaws and perpendicular to the jaws

to avoid false readings. When two or more conductors are in the jaws when an ACreading is taken, current flows in each

wire tend to cancel each other. Off center wires produce lower readings.

9. For reliable measurements, replace batterywhen the lowbattery symbol appears on display. See MAINTENANCE

instructions to replace battery.

10. Set function selector to OFF when not in use to conserve batterypower.

3.2 VOLTAGE MEASUREMENTS (Use these instructions for AC and DC measurements).

CAUTION

Never tryto measure voltages greater than 750V AC or 1000V DC.

1. Select AC or DC voltage and range. lf range is unknown, start with the highest range. Set function selector to V= for DC

measurements or to V ~ for AC measurements.

2. Plug red test lead to VOLTplug, black test lead to COM plug.

3. Connect black test lead to common of circuit, red lead to point being measured at this circuit.

4. Value at display is actual level being measured, + assumed, - (negative) shown. In AUTO mode only: decimal point is

correctly located for best resolution.

17

CAUTION

Never switch between ranges while connected to high voltage to avoid personal harm and/or damage to the meter.

6. Disconnect testleads from voltage source then switch meter to OFF to conserve power.

3.3 RESISTANCE / CONTINUITY MEASUREMENTS

CAUTION

Remove power from circuit under test before making resistance measurements.

1. Verifythat power is off and that any capacitors are discharged in circuit about to be tested.

2. For resistance measurements: In AUTO (default) mode, set function selector to Range is automatically selected for best

resolution. If the meteris operating in manual ranging mode, select range that closely matches actual resistance expected.

3. For continuity measurements:

Set function selector to position.

Plug black test lead into COM plug. Plug red test lead into HzF plug.

5. Connect test leads across desired measuring points.

18

6. Resistance measurements: Read resistance at display in , k, or Mas shown by annunciator symbol.

Continuity measurements: Audible tone sounds when resistance is less than about: 40 ohms.

7. Switch meter to OFF when readings are done to conserve battery power.

3.4 DIODE TESTS CAUTION

Remove power from circuit under test before making diode measurements.

1. Verifythat power is off and that any capacitors are discharged in circuit about to be tested.

2. Set function selector to position.

Continuity is the default symbol.

3. Plug black test lead into COM plug. Plug red lead into HzF plug.

4. Connect black test lead to cathode ofdiode, red test lead to its anode. Typical forward voltages should be about as follows:

Silicone diode: 0.7 V.

Germanium diode: 0.3 V.

5. Reverse test leads,black to anode,red to cathode. Voltage reading should be: 3.1V.

6. Note: Make sure that correct reading is obtained in forward and reverse positions. If diode is partiallyshorted,the same or

higher reading may be obtained in both positions. If diode is open, an overload OL may be shown in both positions.

7. Switch meter to OFF to conserve power when tests are done.

19

3.5 AC CURRENT MEASUREMENTS CAUTION

Never tryto measure currents where the maximum voltage between anyconductor and ground exceeds 500 V to avoid

personal harm and/or damage to the meter.

1. Remove test leads from meter.

2. Set function selector to A ~ for AC current measurements and choose range. Ifrange is unknown, start with the highest

range, 1000A.

3. Press trigger on left side of meter to open jaws. Now, damp around a single conductor so it's centered and perpendicular in

the jaws as shown in following illustration. Release trigger to damp jaws and make sure theyare fully dosed.

NOTE : Position jaws around only one conductor centered and perpendicular to jaws. If jaws are placed around two or more

current carrying conductors reading will be false. For example, if damped around the line cord of an AC appliance, currents

flowing through the cord tend to cancel each other giving a false reading.

4. Read current level at display. If needed for better resolution, select a lowerrange.

3.6 DC CURRENT MEASUREMENTS

1. Set function selector to A = for DC current measurements and select range. lf range is unknown, start with the highest range,

1000A.

2. There maybe a residual reading on the meter. Press the ZERO button to zero the meter.

3. Clamp jaws around the conductor and read current level from display.

20

4. For maximum accuracy, remove the jaws from around the conductor and press the ZERO button again the meter, Then

repeatthe measurement and use the second reading.

3.7 FREQUENCY MEASUREMENTS

1. Set function selector to Hz position. AUTO mode is on, range is automatically selected.

2. Plug black test lead into COMplug. Plug red test lead into HzF plug.

3. Connect test leads across desired measuring points. Make sure that peak of frequency signal does not exceed 500 V DC or

AC.

4. Switch meter to OFF to conserve power.

Table of contents

Other SEFRAM Multimeter manuals