10/24

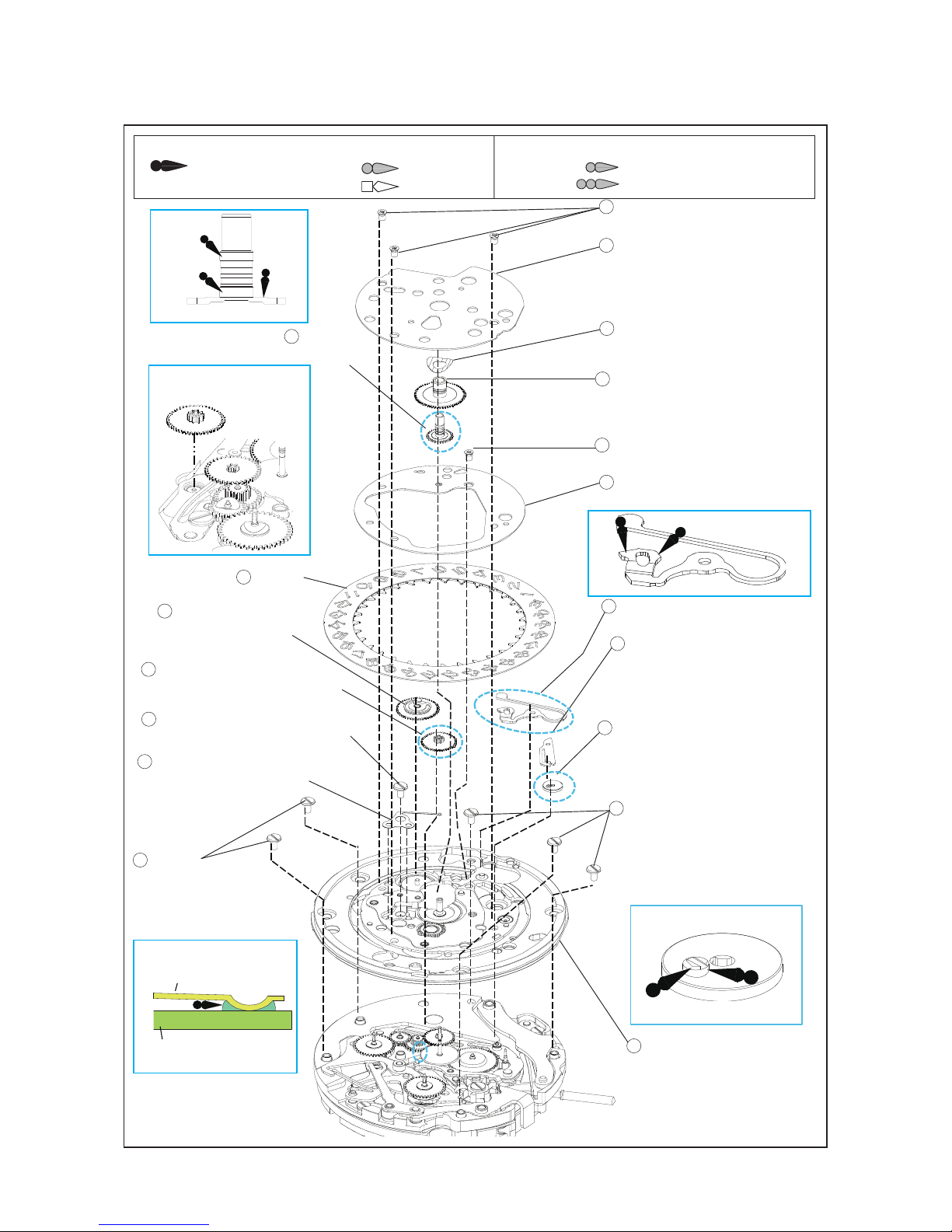

● List of screw

Parts code Parts name Parts code Parts name Parts code Parts name

0012 092 Second counting wheel

spring screw

0012 354 Unit intermediate

spacer screw

0012 420 Balance bridge

screw

Chronograph bridge

screw (x5)

Pallet bridge screw

(x2)

Barrel and train

wheel bridge

screw (x3)

Operation lever spring

screw Automatic train

bridge screw (x2)

0012 168

Yoke spring screw

(x2)

Operation cam jumper

screw

Lower plate for barrel

and train wheel bridge

screw

Chronograph coupling

lever spring screw

Center wheel bridge

screw

Main plate screw (x4) 0012 201

Operatig cam screw

0016 709 Hour wheel guard

screw (x3)

0012 919

Ratchet wheel screw

Date indicator

maintaining plate

screw

59

69

85

45

79

75

64

61

49

15

17

33

36

38

58

67

2

7

Date dial

9

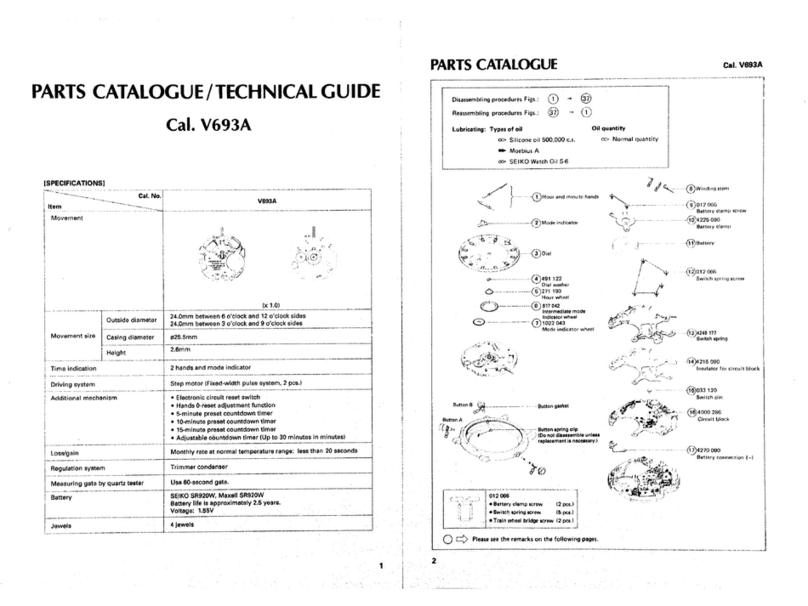

Parts code Position of crown Position of date

frame Color of numbers Color of background

0878 109 3H 3H Black Silver

(Plain metal)

0878 108 3H 3H White Black

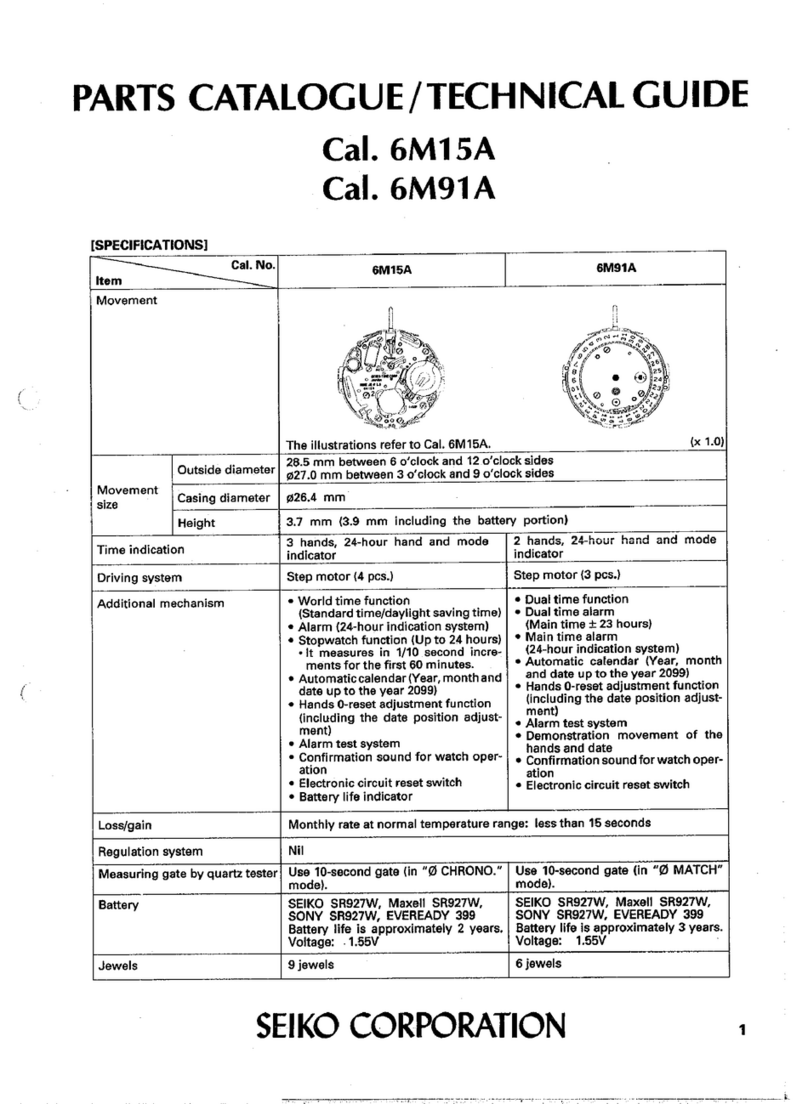

● How to find the correct parts, if not determined by 4 digit caliber number

*All parts code are subject to change without notice.

Following parts are determined based on the design of watches, such as hands height, dial color,

and design of cases. Please refer to the SEIKO WATCH PARTS CATALOGUE in order to choose

corresponding parts.

Oscillating weight with ball bearing 0509 *** • 1509 ***

DATE DISK 0878 ***

WINDING STEM 0351200

*For screw down crown models, the stem is assembled to the crown and is not available separately.

1

9

90

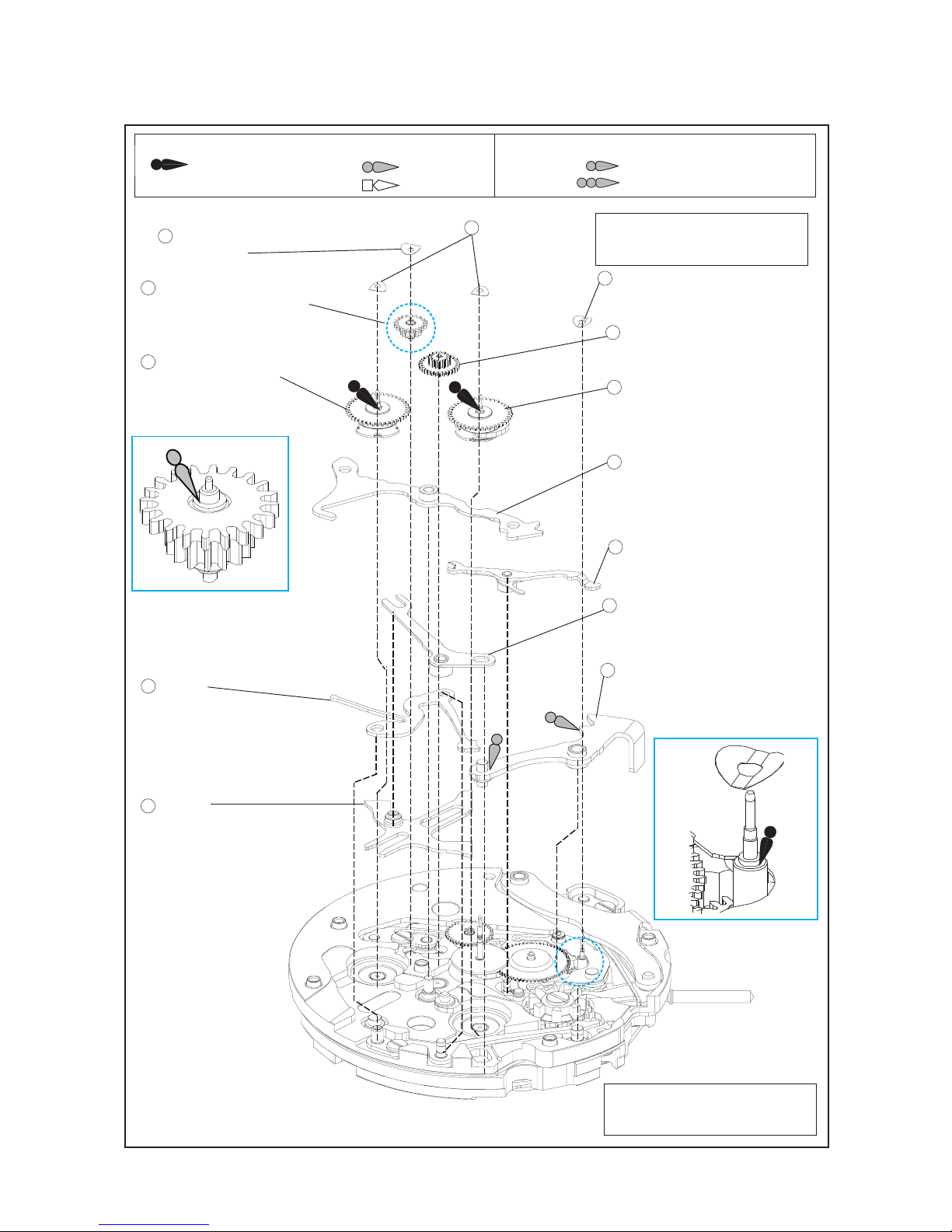

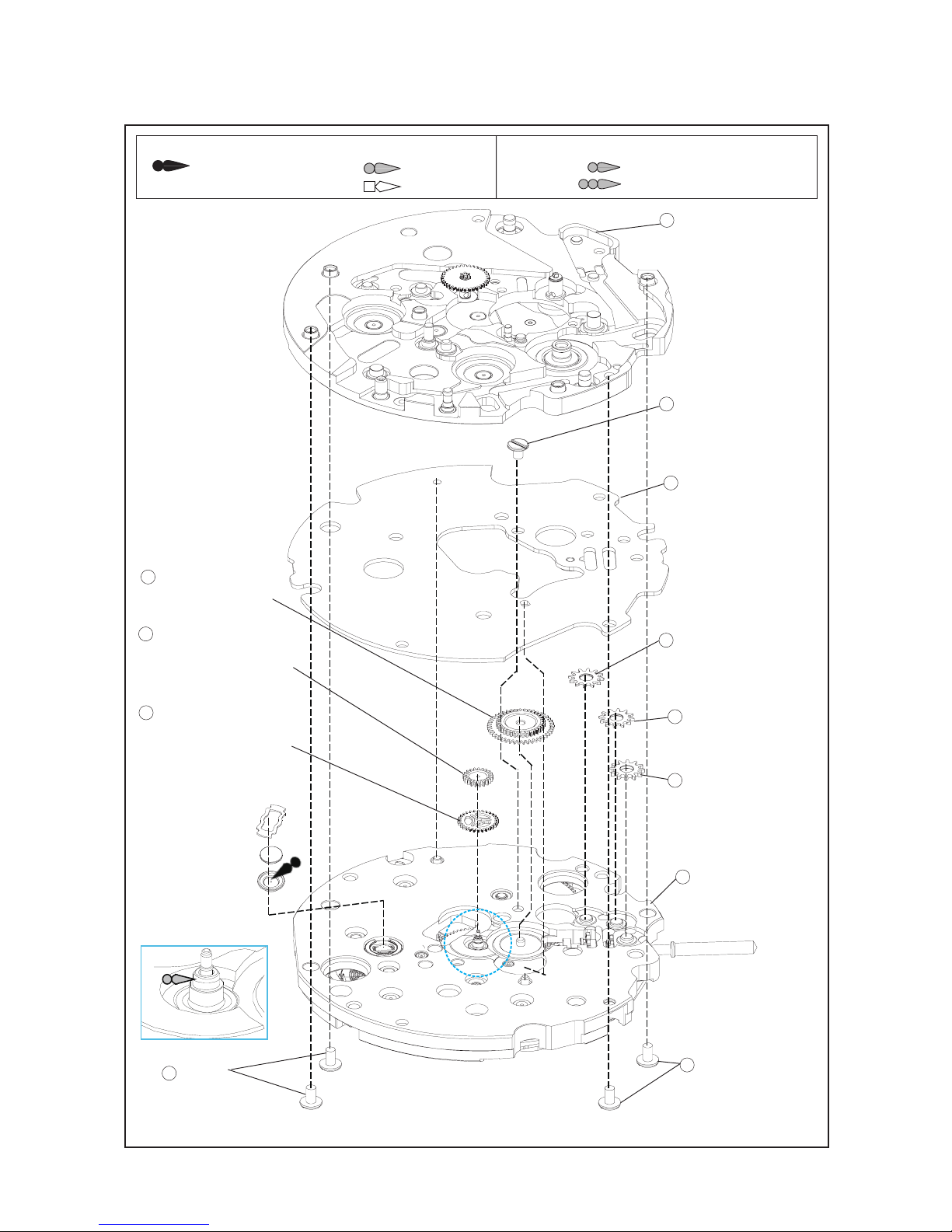

CAL Hand Height 18 Chronograph

bridge

19 Minute counting wheel

20 Hour counting wheel

44 Seconds

wheel

60-1 Balance

complete without

stud

8R48 3 (LONG) 0190192 0902184 0240178 0310055

4 (SPECIAL) 0190193 0902191 0240191

8R49 3 (LONG) 0190192 0902184 0240178 0310277

18

Chronograph bridge 0190 ***

24

Minute counting wheel 0902 ***

25

Hour counting wheel 0902 ***

44

Seconds wheel 0240 ***

60 -1 Balance complete without stud 0310 ***