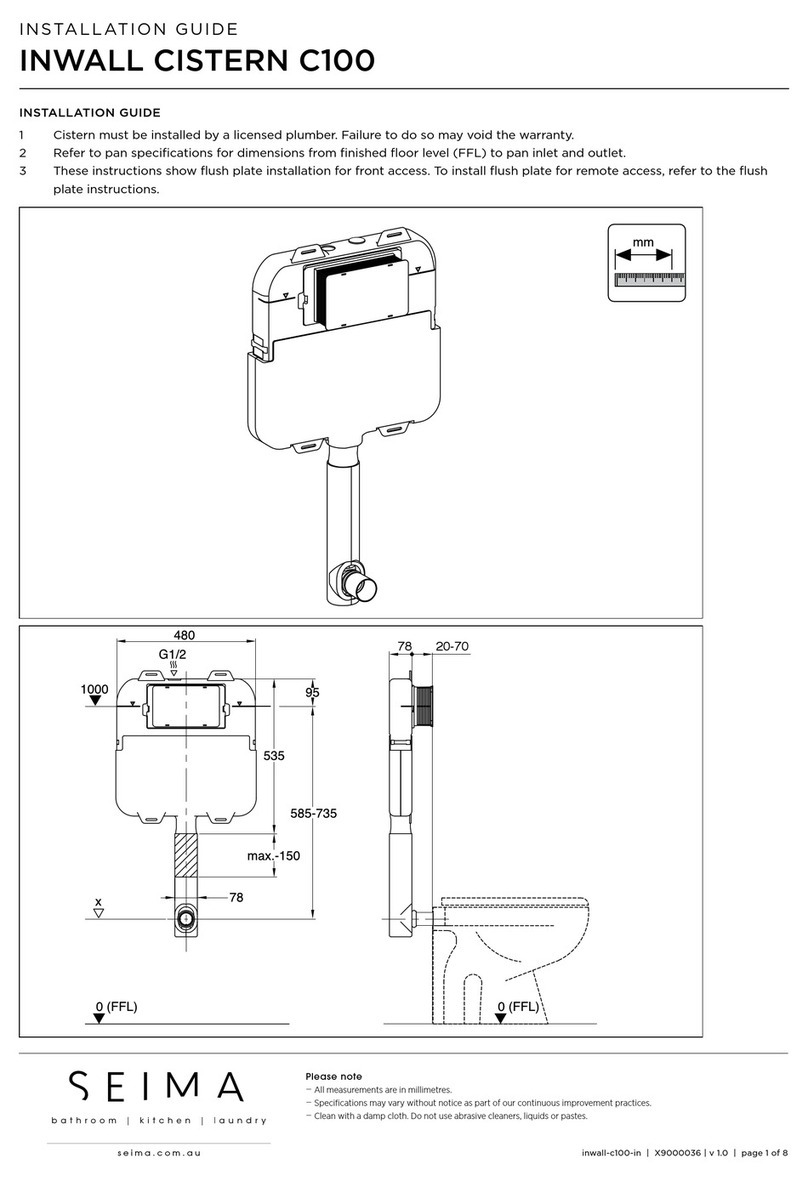

Seima Modia STO-20 User manual

Modia / STO-20 Ceramic Wall Faced Toilet Suite

Installation Instructions .com.au

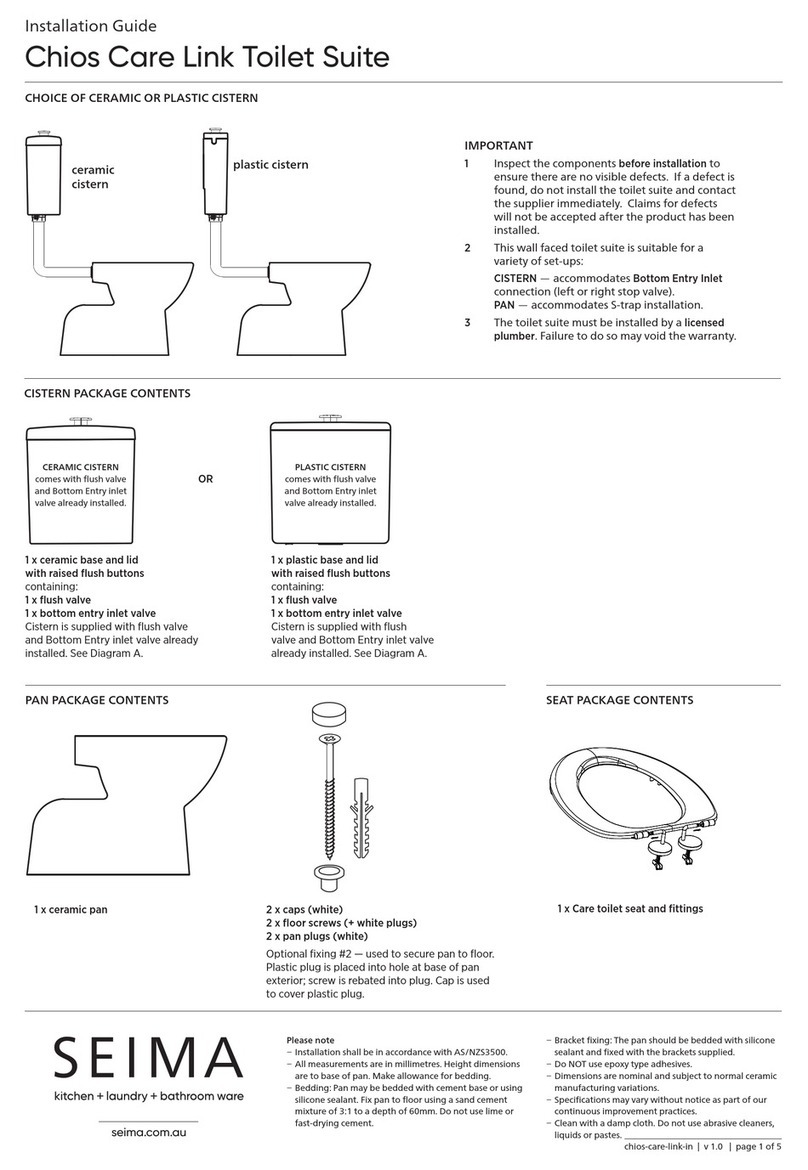

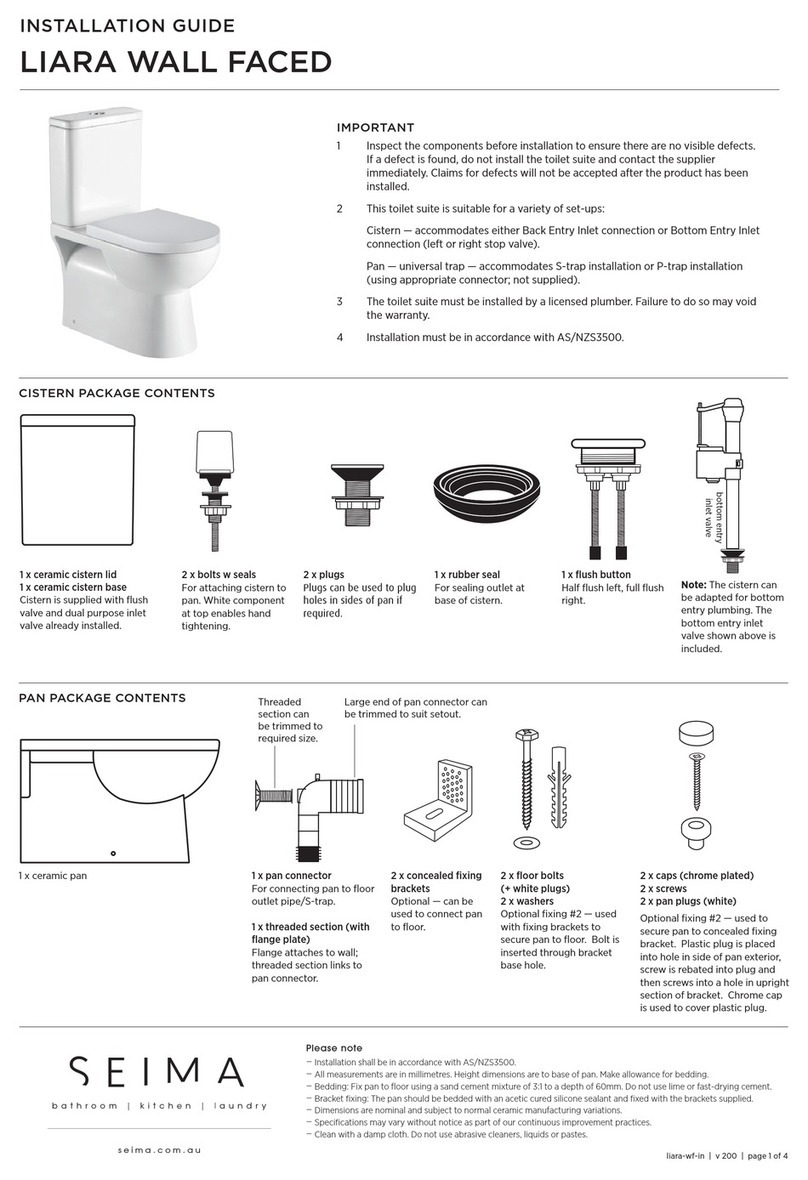

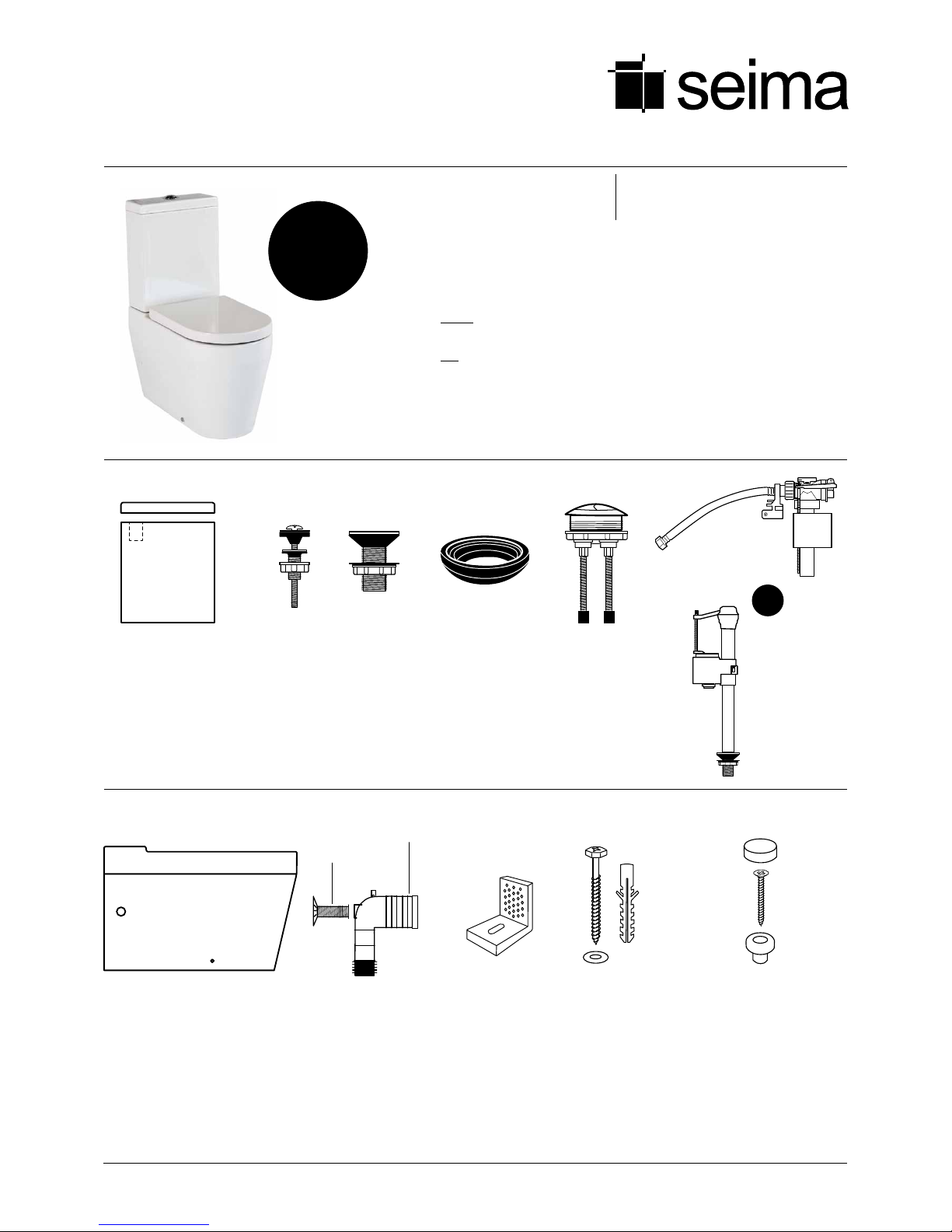

Cistern package contents

Important

1Inspect the components before installation to ensure there are no visible defects.

If a defect is found, do not install the toilet suite and contact the supplier immediately.

Claims for defects will not be accepted after the product has been installed.

2This toilet suite is suitable for a variety of set-ups:

nCistern — accommodates either Bottom Entry Inlet connection

(left or right stop valve) or Back Entry Inlet connection.

nPan — universal trap — accommodates S-trap installation or

P-trap installation (using appropriate connector; not supplied).

3The toilet suite must be installed by a licensed plumber. Failure to do so may void

the warranty.

4Installation must be in accordance with AS/NZS3500.

IN-Modia_STO-20 | v2.0X9000009 | page 1 of 4

Modia

STO -2 0

Order codes

STO-20-BE Back Entry inlet plumbing

STO-20 Bottom Entry inlet plumbing

OR

bottom entry

inlet valve

1 x back entry

inlet valve

Supplied with

STO-20BE.

1 x ceramic cistern lid

1 x ceramic cistern base

Cistern is supplied with flush

valve and bottom entry inlet

valve already installed.

2 x bolts

with seals

For attaching

cistern to pan.

3 x plugs

One required

if installing

back entry (BE)

version; others

can be used to

plug holes in

sides of pan if

required.

1 x rubber seal

For sealing outlet at

base of cistern.

1 x flush button

Half flush left, full

flush right.

Large end of pan connector

can be trimmed to suit setout.

Threaded

section can be

trimmed to

required size.

Pan package contents

1 x ceramic pan 1 x pan connector

For connecting pan to

floor outlet pipe/S-trap.

1 x threaded section

(with flange plate)

Flange attaches to wall;

threaded section links to

pan connector.

2 x concealed

fixing brackets

Optional — can be

used to connect pan

to floor.

2 x floor bolts

(+ white plugs)

2 x washers

Optional fixing #2 —

used with fixing brackets

to secure pan to floor.

Bolt is inserted through

bracket base hole.

2 x caps (chrome plated)

2 x screws

2 x pan plugs (white)

Optional fixing #2 — used

to secure pan to concealed

fixing bracket. Plastic plug

is placed into hole in side of

pan exterior, screw is rebated

into plug and then screws

into a hole in upright section

of bracket. Chrome cap is

used to cover plastic plug.

1 x bottom entry

inlet valve

Supplied with

STO-20.

S-trap procedure — Securing the pan

connector in place

1.1 Determine the centre of the pan and mark the centre line on the

floor and wall.

1.2 Work out the setout required. The recommended setout is

150mm (setout range is 90-190mm).

1.3 You may need to trim the large end of the plastic pan connector

to fit the required setout. To trim, first remove the plastic ring

and rubber seal, then cut pipe to size. Refit rubber seal and

plastic ring securely, ensuring a good fit.

1.4 Position the pan connector into the floor outlet pipe (S-trap).

The height measurement from the floor to the centre of the pan

connector is 185mm.

1.5 Slot the threaded section (with flange plate) onto the pan

connector, ensuring that the flange plate is touching the wall.

You may need to trim the threaded section so that it fits properly.

1.6 Mark and drill the flange plate holes and secure the plate to the

wall with fixing screws. The pan connector is now installed.

Positioning the pan

2.1 Use the centre line marked on the wall and floor to position the

pan (see Step 1.1). Push the pan into the installed plastic pan

connector.It is recommended that wedges are used to support

the foot of the pan during positioning.

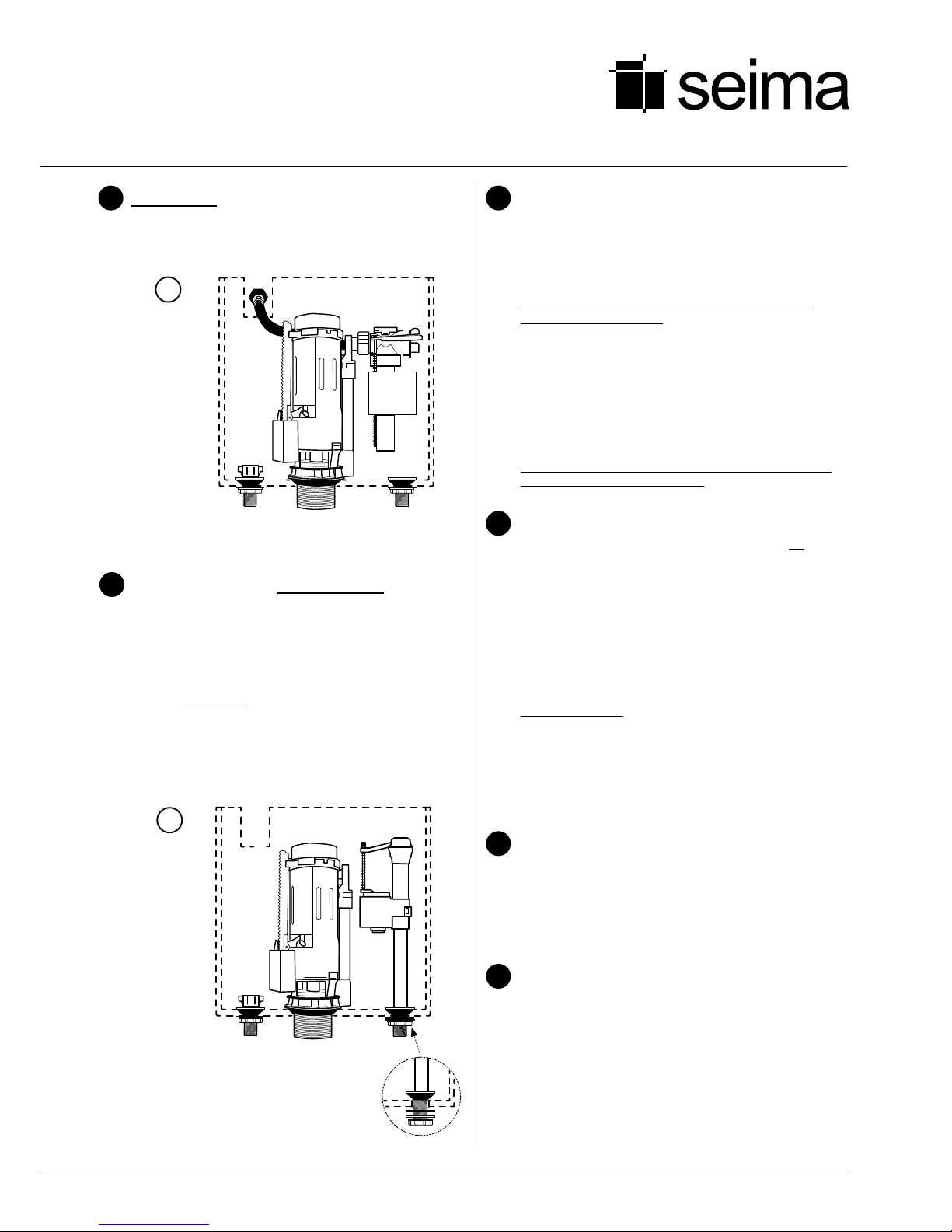

Cistern — set-up for Back Entry

inlet plumbing

Diagram A shows the cistern as supplied for Back Entry plumbing, with

the inlet valve and flush valve already installed. The flexible hose is

ready for Back Entry inlet plumbing (see Diagram B).

For Bottom Entry Inlet plumbing, refer to Step 5 and Diagrams C and D.

Modia / STO -2 0

Installation Instructions

1

2

3

X9000009 | page 2 of 4

bottom entry inlet port

hole for flexible hose

(on both sides of pan)

bracket fixing holes

(both sides of pan)

bottom entry water

control holes

cistern/pan

attachment holes

seat connection holes

cistern outlet pipe hole

All measurements are in millimetres. Height dimensions are to base of pan. Make allowance for bedding.

Cistern setup for Back Entry

plumbing. The end of the

flexible hose is loose, ready

to be attached to the Back

Entry inlet nozzle (see

Diagram B).

A

inlet

valve

cistern

flush valve

DIAGRAM

plug

plug

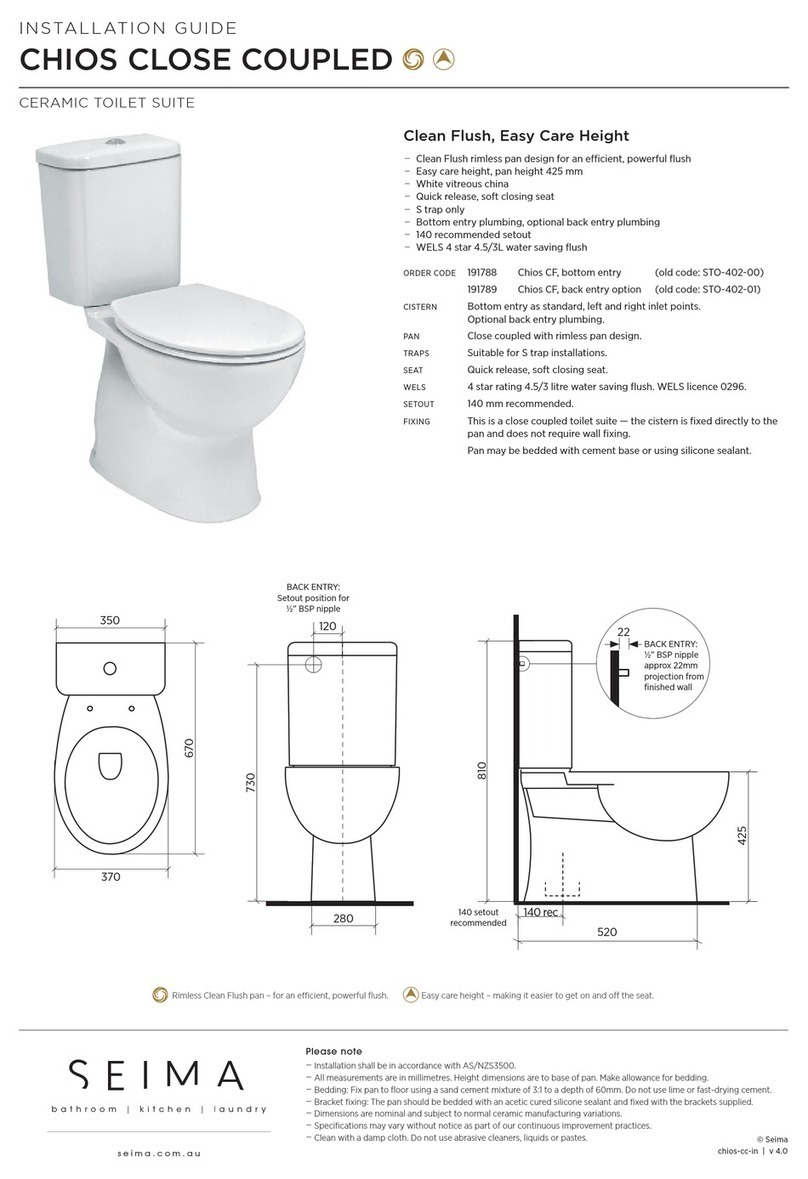

655

360

360

105

785

860

360

360

250

back entry inlet

setout position

for ½” BSP

nipple

22053

420

180

150 rec 150 setout

recommended

(range 90-190)

bottom entry inlet

port hole for

flexible hose

back entry inlet

½” BSP nipple

approx 22mm

projection from

finished wall

Securing the pan on the oor

6.1 Cement fixing (optional fixing #1)

If using cement bedding, level the pan while the cement

mixture is workable. Fix pan to floor using a sand cement

mixture of 3:1 to a depth of 60mm. Do not use lime or fast-

drying cement.

Important: Allow at least 24 hours for the cement mixture

to set before using the toilet.

6.2 Bracket fixing (optional fixing #2)

Bed the pan with acetic cured silicone sealant, ensuring that

the pan is level. Then position the concealed fixing brackets

in line with the bracket fixing holes. Screw the floor bolts in

place through the base of the brackets. Then secure the pan to

the brackets using the plastic pan plugs and rebated screws.

The chrome caps can be used to cover the plugs on each side

of the pan.

Important: Do not over-tighten the bolts or screws as this may

cause the ceramic to crack and break.

Fixing the cistern to the pan

(Note: The cistern fixes directly onto the pan and does not

require wall fixing.)

7.1 First check the alignment of the cistern and pan attachment

holes — place the cistern onto the pan and ensure that the

holes align. The back of the cistern and pan should line up so

that the assembled toilet suite will align with the wall. Now

remove the cistern.

7.2 Place the rubber seal onto the plastic pipe outlet at the base of

the cistern and ensure it is securely attached. Locate the cistern

outlet (with rubber seal) onto the pan, ensuring a good fit.

7.3 If using Bottom Entry inlet plumbing, refer to Step 5 and install

the back entry inlet valve.

7.4 Now secure the cistern to the pan using the two bolts with

seals in the cistern/pan attachment holes.

7.5 Flush the lines and connect the water supply and check the

operation of the cistern.

Fitting the cistern lid

8.1 Fit the flush button into the cistern lid, with the half flush on

the left and full flush on the right. Ensure that the rubber feet

of the flush button connect and line up correctly with the flush

valve inside the cistern.

8.2 Fit the cistern lid and push the buttons to check operation.

Operation and maintenance

9.1 Press the left side half flush to save water and the full flush as

required.

9.2 Clean the toilet with liquid detergent and a damp cloth.

9.3 Do not place water additives inside the cistern as this may have

chemicals that damage the valves and impair the functionality

of the cistern.

6

7

8

9

X9000009 | page 3 of 4

Back Entry installation

Connect the flexible hose to the ½” BSP nipple in the wall outlet.

Run the flexible hose behind the flush valve, ensuring that the hose

does not obstruct the operation of the flush valve.

4

.com.au

Cistern set-up for Bottom Entry

inlet plumbing

5.1 Connect the flexible inlet hose to the stop valve and water

control inlet valve on the wall. Then run the flexible inlet hose

through a port hole in the side of the pan. Pull the flexible inlet

hose upwards, to allow it to pass through the water control hole

on the pan upper. Leave flexible inlet hose unsecured for now

— for the bottom entry inlet connection, the flexible inlet hose

will be connected to the cistern’s inlet valve in Step 7.3.

5.2 The bottom entry inlet valve is already installed on the right

side of the cistern. The position can be swapped to the left side

if required.

5

B

For Back Entry Inlet,

attach the loose end

of the flexible hose

to the ½” BSP nipple

water inlet in wall.

back entry

inlet

valve

cistern

flush valve

DIAGRAM

plug

plug

The bottom entry

inlet valve installed

in the cistern base.

C

DIAGRAM cistern

flush valve

bottom entry inlet valve

plug

.com.au

Modia / STO -2 0

Installation Instructions

X9000009 | page 4 of 4

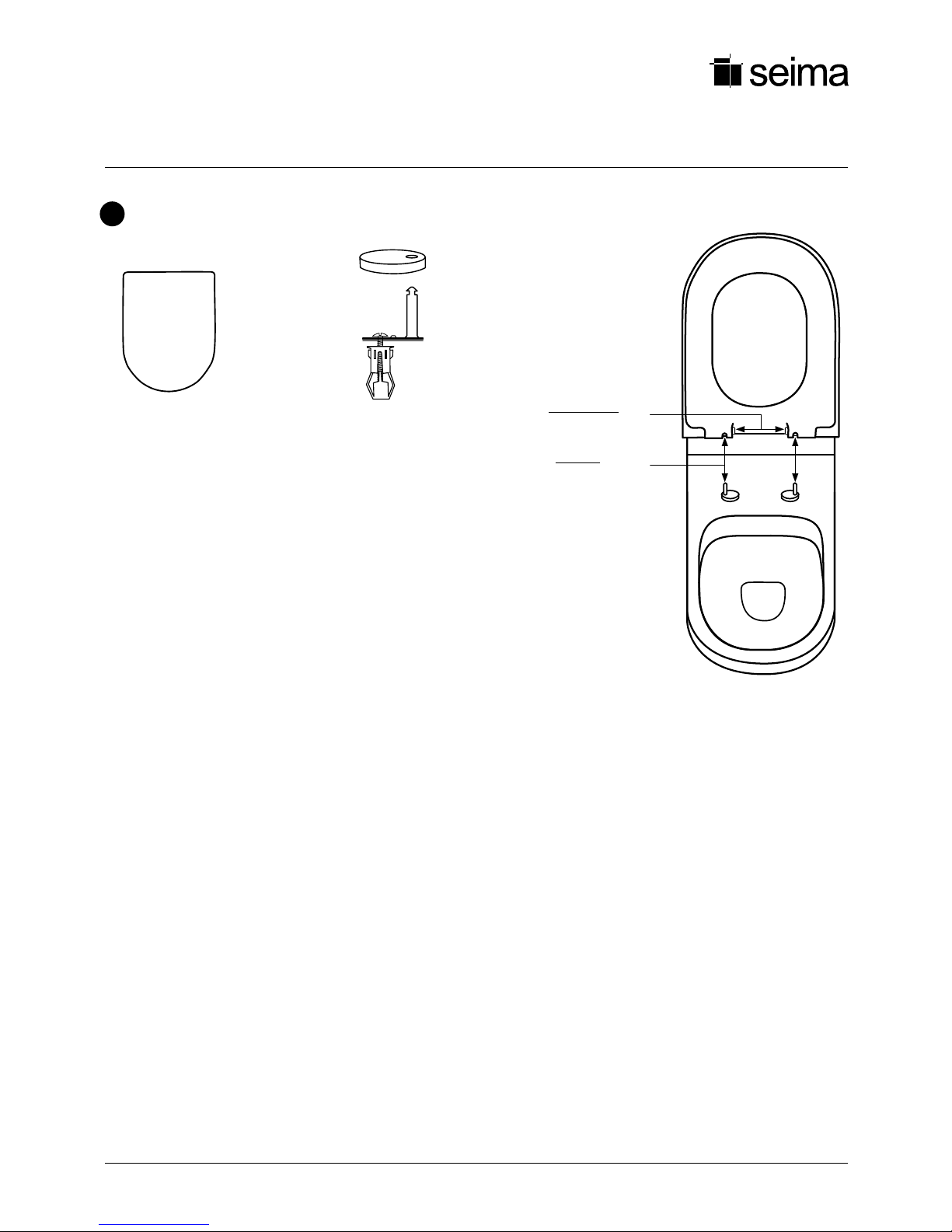

10.1 Secure the toggle bolts into the seat connection holes, ensuring that the

stainless steel pins line up with the receptor holes in the seat. Once correctly

placed, ensure that the bolts are properly tightened.

10.2 Slide the stainless steel caps onto the plates with pins.

10.3 To fit the seat, slide it onto the stainless steel pins. If you need to make

adjustments to position the seat correctly, go back to Step 9.1.

10.4 To remove the seat, put seat in upright position to expose the two chrome

seat release buttons at the base of the seat. To release, press both buttons

simultaneously and lift the seat upwards to remove it.

To fit seat, slide seat

down onto stainless

steel pins.

To remove seat, press

the two chrome buttons

at base of seat.

Seat package and installation

1 x solid construction seat

and lid — soft closing

Has receptor holes that slide onto

stainless steel pins.

2 x stainless steel caps

Used to cover stainless steel plate w pin.

2 x stainless steel plates with pin

Seat locates onto stainless steel pins.

2 x toggle bolts

Used for securing stainless steel plate

and pin to pan.

10

This manual suits for next models

1

Other Seima Toilet manuals

Popular Toilet manuals by other brands

Swiss Madison

Swiss Madison SM-WC424 installation instructions

Laufen

Laufen ILBAGNOALESSI One 8.2097.1 Installation

Separett

Separett Tiny installation manual

ECOWAY

ECOWAY KOMFY300 user manual

Cinderella

Cinderella TRAVEL installation manual

rba

rba RBA8847-100 Installation, operation and maintenance instructions

Woodbridge

Woodbridge B0970S installation manual

Kallista

Kallista P70080-00 installation guide

EcoLet

EcoLet 25e owner's manual

Laufen

Laufen ILBAGNOALESSI 82097.6 Installation instruction

Raritan

Raritan Crown Head CW912 Installation, operation and maintenance instructions

Ideal-Standard

Ideal-Standard Waverley Assembly and installation instructions