Try to restart sensor by power OFF/ON.

Check detailed settings and configuration

with UIP software version 5 and higher.

Contact local distributor.

Table 4 Error codes

Note 1.Any probe is out of range. It occurs, for instance, during over exposure of CO2sensor, in

which case the error code will automatically reset when the measurement values return to normal. It

could also indicate the need of zero point calibration. If the CO2readings are normal, and still the error

code remains, the temperature sensor can be defect or the connections to it are broken.

Remark:If several errors are detected at the same time the different error code numbers will be

added together into one single error code!

PLEASE NOTE! The sensor accuracy is defined at continuous operation (at least three (3) ABC

periods after installation)

Maintenance

aSENSE is basically maintenance free. An internal self-adjusting calibration function takes care of

normal long term drift associated to the CO2sensor. To secure the highest accuracy, a time interval of

five years is recommended between CO2calibrations, unless some special situations have occurred.

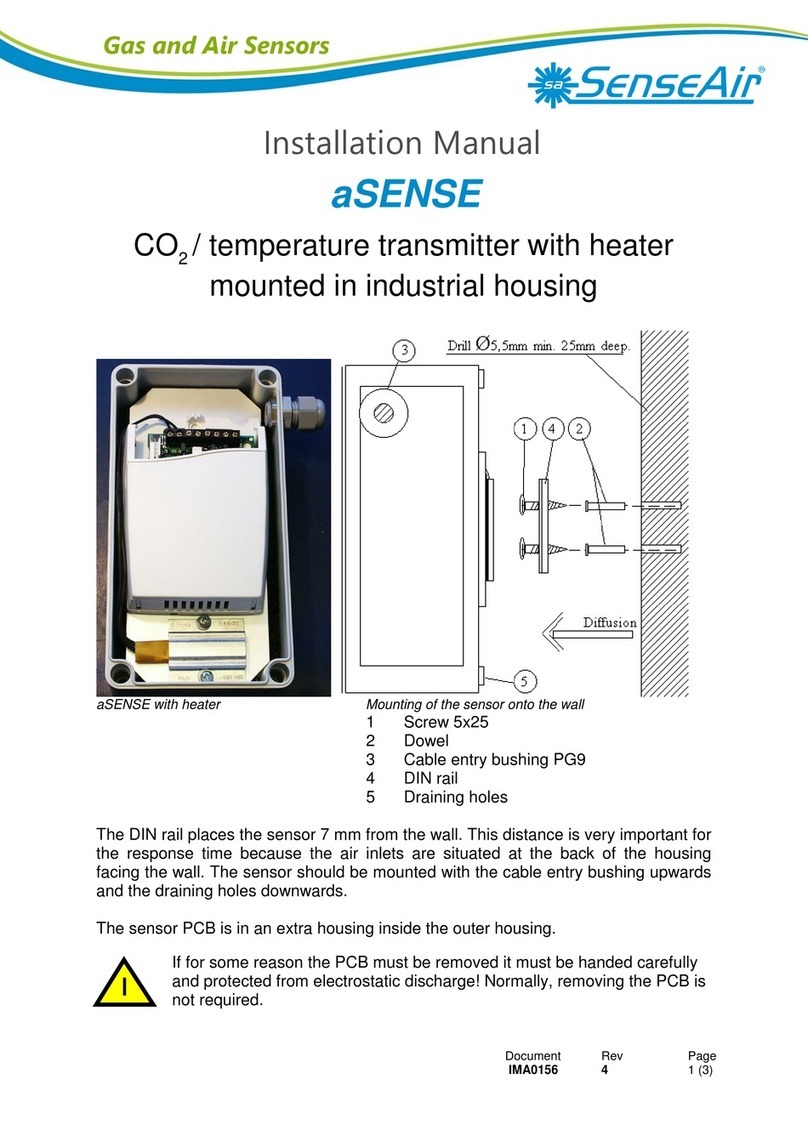

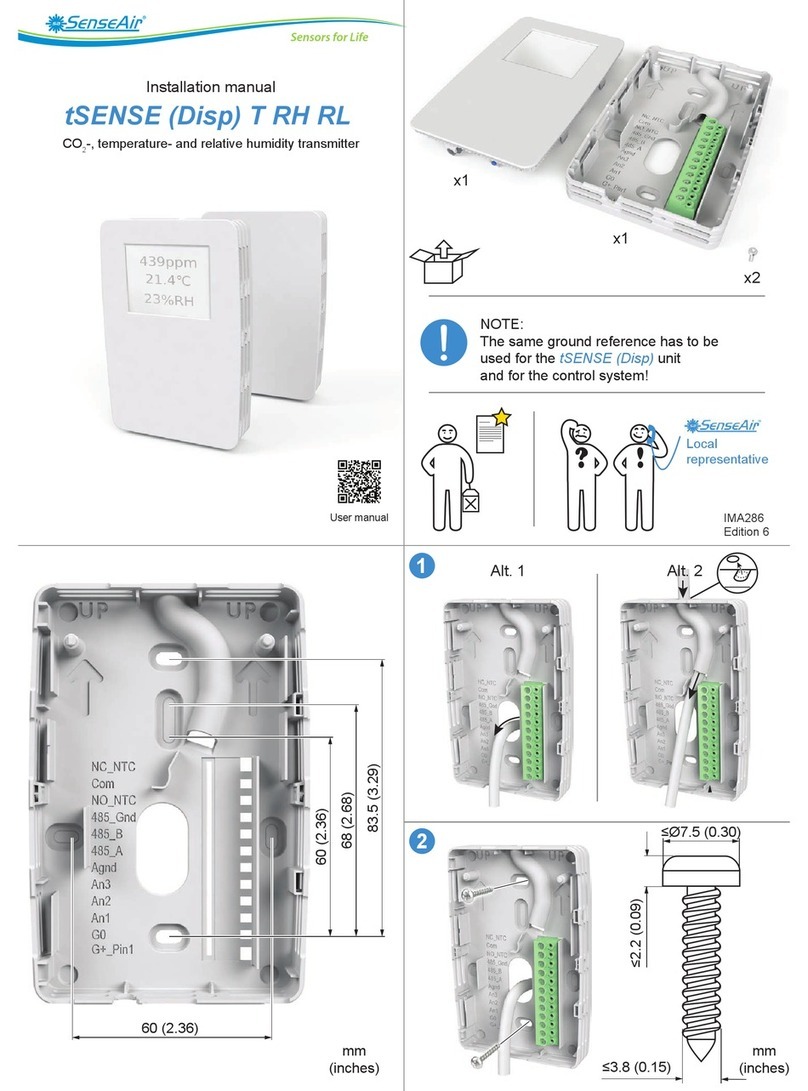

A zero calibration can be performed by use of pure nitrogen or air that has passed through a chemical

absorber and a PC together with the UIP software version 5 (or higher) or by shortening of holes

marked in figure 2 for at least 10 seconds. The sensor needs stable gas flow for at least 3 minutes

before zero calibration. The Zero Calibration bag can be used to produce carbon dioxide free air. The

software can be free downloaded from www.senseair.com. The RS232-cable and the zero calibration

bag can be ordered from SenseAir. The cable is to be connected to the UART port slide connector

(see Fig. 5). For change of control parameters and re-calibration of temperature this PC tool has to be

used. Zero calibration can be done with PC and UIP software version 5 or by shorting marked holes in

figure 2. The check can be done on site without interfering with the ventilation system.