SenseAir eSENSE User manual

EM eSENSE_all_housings_May'08.doc

1 of 10

Installation Manual for All Housings

eSENSE

eSENSEeSENSE

eSENSE™

(-D)

CO

2

transmitter

eSENSE™

eSENSE™eSENSE™

eSENSE™-

--

- D

D D

D

eSENSE™

eSENSE™eSENSE™

eSENSE™-

--

- K

K K

K

and

eSENSE™

eSENSE™ eSENSE™

eSENSE™-

--

- Ip54

Ip54 Ip54

Ip54

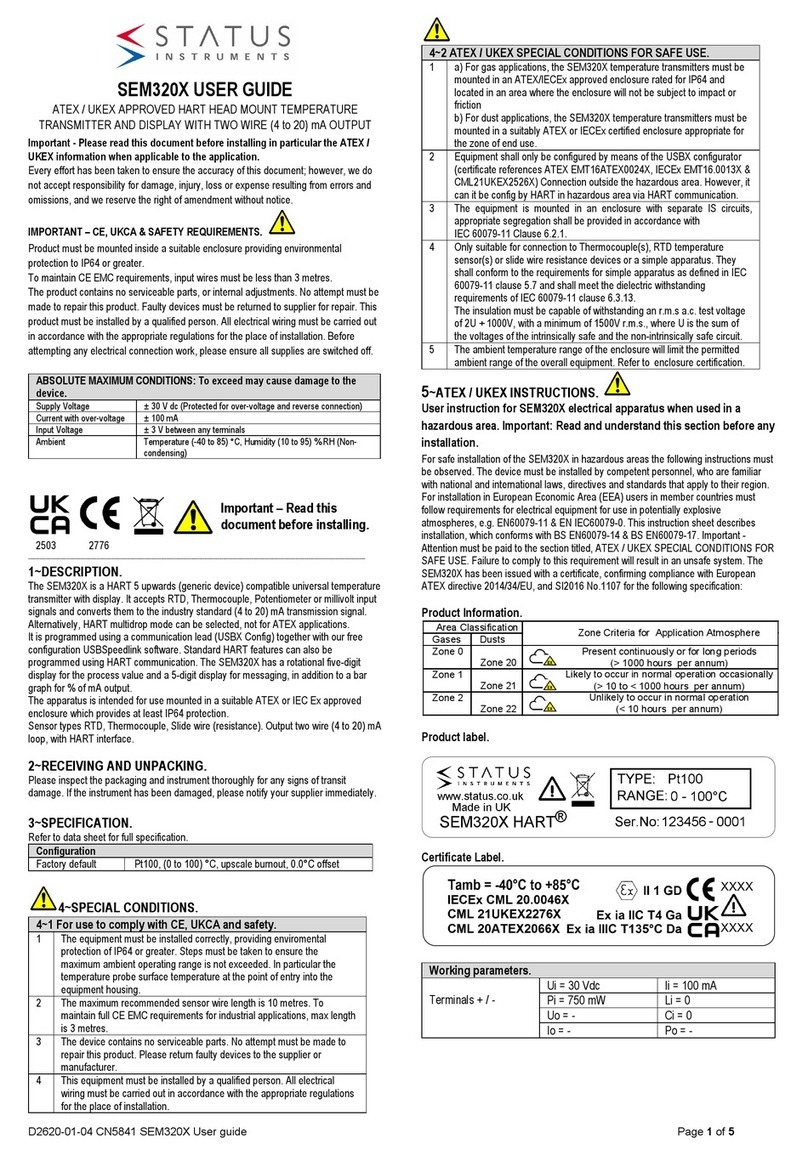

General

The IAQ-sensor product

e

ee

eSENSE

(sensor for wall mounting) is designed to measure carbon

dioxide (CO

2

) in rooms. Option

- Tr

is prepared for temperature measurements by the

resistive temperature probe mounted by the user. The temperature probe is potential free

(floating). Option

- D

displays the measured CO

2

value in ppm (parts-per-million) on the

LCD.

The units are designed for connecting to Direct Digital Control (DDC) with 0-10V or

2-10V signal inputs. The two parallel signal outputs OUT1 (0-10V) and OUT2 (2-10V or 4-

20 mA) give linear signal voltages or currents corresponding to the measuring range.

The output OUT2 also indicates the status by setting the output voltage to 1V or the output

current to 2 mA when the sensor self-diagnostics detects any error.

EM eSENSE_all_housings_May'08.doc

2 of 10

eSENSE

eSENSEeSENSE

eSENSE™

(-D)

CO

2

transmitter for wall mounting

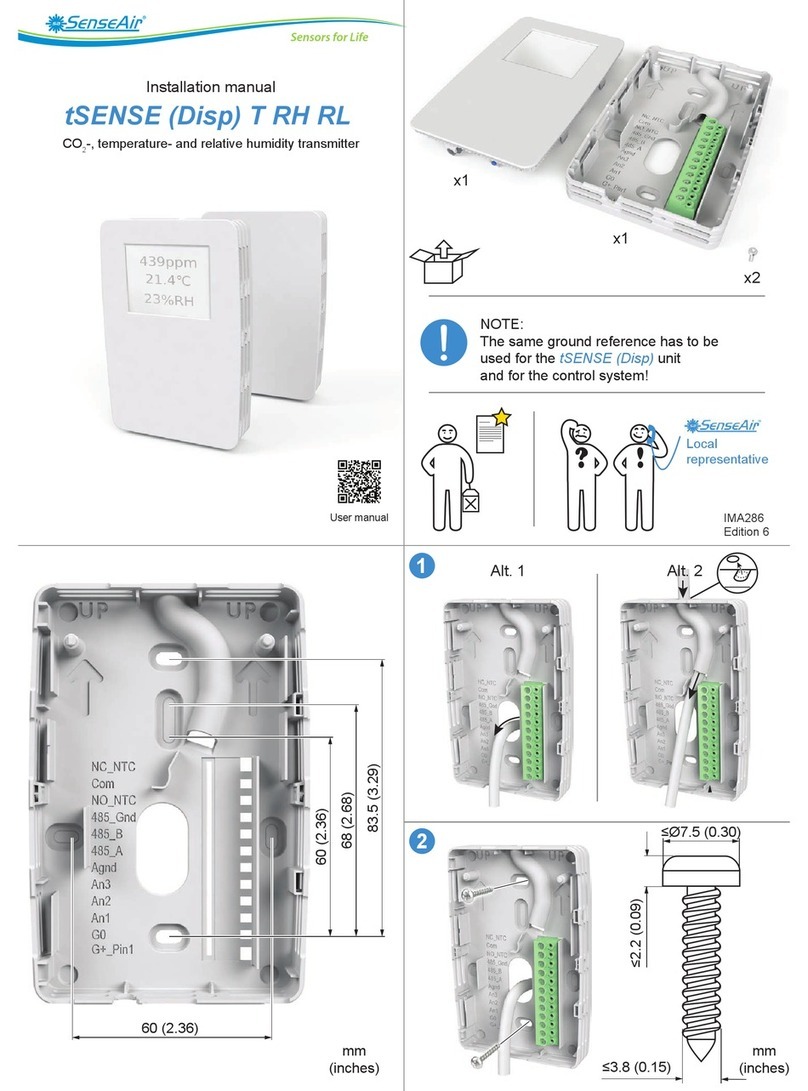

To open the wall mounted housing

Closed housing seen from above. Pressing

a screwdriver on the locking hook opens

the housing. The locking hook is then

released.

Dimensions and holes

80(3,15)

28(1,10)

30(1,18)

60(2,36)

4(0,16) 4(0,16)

30(1,18)

100(3,94)

The dimensions of the sensor in mm and (inches)

Press here to open.

EM eSENSE_all_housings_May'08.doc

3 of 10

eSENSE

eSENSEeSENSE

eSENSE™

(-D) -K

CO

2

transmitter for mounting in ventilation ducts

1

2

1

2

3

4

5

6

7

9

8

1 Sampling probe 6 O-ring 29,2x3,53 (Factory supplied mounted in box)

2 Sealing gasket 7 PCB (Factory supplied mounted in box)

3 Largest locking knob 8 Snap-in lid

4 2 washers BRB 5,3x10x1 9 PG9 cable entry bushing

5 2 screws RXS 4,8x16

Parts of the

e

ee

eSENSE

for duct mounting

EM eSENSE_all_housings_May'08.doc

4 of 10

Mounting of

e

ee

eSENSE

on to the duct.

10

10 Hole with 25 mm diameter

11 Temperature sensor with 110 mm cable mounted in the sampling probe

Figure 3. Mounting of the sensor to the ventilation duct

Mounting Instruction

Since there might be a substantial pressure difference in duct mounting applications, it is

essential to avoid ambient air from suction into the duct-mounting box. For correct function it

is indispensable that the sealing of the box cover, the cable entry bushings, the cable feed

through and the duct entrance are absolutely tight. The duct entrance may need extra sealing

paste in order to prevent leakage. The PCB must be handed carefully and protected from

electrostatic discharge.

1) Electrical cable entry: The box has a factory mounted cable entry bushing in dimension

PG9. Never feed more than one cable through each cable entry bushing, or else gas might

leak through!

2) Mounting the tube: Drill a hole (10) with 25 mm diameter (or 1 inch) for the sampling

probe and two holes with 4 mm diameter for the screws (5) into the air duct and mount

the tube (1) with the gasket (2). The sampling probe should be mounted with the largest

locking knob on top. The unit can be mounted with the air coming from the left or right.

3) Attaching the sensor box is made to the sampling probe by a snap-in bayonet fitting.

Orient the box onto the sampling probe so that the box upside is on the same side as the

largest locking knob (3). When the probe is fitted into the notches of the box, then turn

the box clockwise until stop (see Figure 1). Position 1 indicates open where the box can

be removed from the sampling probe. In position 2 the box is locked to the probe

.

EM eSENSE_all_housings_May'08.doc

5 of 10

Dimensions

42(1,65)

46(1,81)

84(3,31)

141,8(5,56)

151,3(5,96)

204(8,03)

The dimensions of the sensor in mm and (inches)

The dimensions of the sampling probe in mm and (inches)

66(2,6)

55(2,16)

56(2,2)

6(0,24)

EM eSENSE_all_housings_May'08.doc

6 of 10

eSENSE

eSENSE eSENSE

eSENSE™

(-D) –IP54

CO

2

transmitter mounted in industrial housing

4

5

3

2

1

6

1 Wall plate

2 CB (Factory supplied mounted in box)

3 Hole for wall plate hooks

4 Snap-in lid

5 Locking screw of the lid (not shown)

6 Air holes

EM eSENSE_all_housings_May'08.doc

7 of 10

7

10 8910

38,5 (1,5) 10 (0,39)

85 (3,35)

141,8 (5,58)

9,5 (0,37)

7 Lid locking screw

8 Wall plate

9 Screw to hold the wall plate

10 Drill marking for cable entry bushings

Dismounting the wall plate

The sensor is delivered with the wall plate

mounted. The wall plate has to be

removed before the sensor is mounted

onto the wall. Unscrew the screw on the

side of the box.

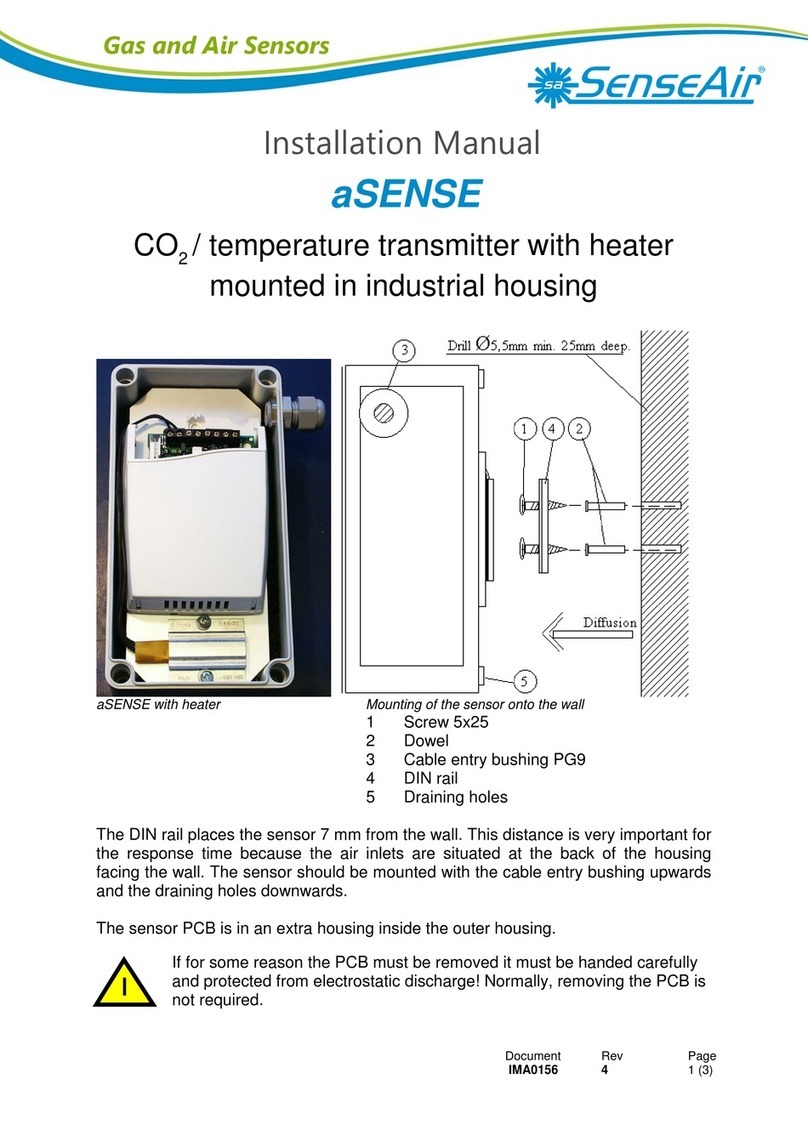

Wall Mounting Instruction

1) Electrical cable entry: The box has a factory mounted cable entry bushing in

dimension PG9. Never feed more than one cable through each cable entry bushing, or

else gas might leak through!

2) Screw the wall plate onto the wall: The wall plate has holes for three screws. Drill

holes for 3,5mm screws and put dowel into them. Dowels and screws 3,5 x 25mm are

included in a plastic bag

3) Attaching the sensor box to the wall plate is done by a snap-in fitting. The wall plate

has three hooks that fit in holes in the sensor box. Fasten the screw on the side of the

box.

4) The lid can be locked with the screw at the bottom of the sensor box.

If for some reason the PCB must be removed it must be handed carefully and

protected from electrostatic discharge! Normally, removing the PCB is not

required.

82(3,23)

66(2,60)

41(1,61)

17,5(0,69)

40,5(1,59)

63(2,48)

Ø5(0,20)

Ø5(0,20)

Ø5(0,20)

42(1,65)

39,9(1,57)

EM eSENSE_all_housings_May'08.doc

8 of 10

Electrical connections

The power supply has to be connected to

+~

and . is considered as system ground.

The same ground reference has to be used for the

e

ee

eSENSE

unit and for the DDC/signal

receiver.

PLEASE NOTE!

The same ground reference has to be used for the

e

ee

eSENSE

unit

and for the control system!

Terminal

Function Electrical data Remarks

Standard settings Remarks

Settings of this

sensor

+~

Power (+)

Power ground (-)

24 VAC/DC+

(+-20%), 2W

24 VAC/DC-

System voltage

reference

OUT1

OUT2

Analogue output 1 (+)

Analogue output 2 (+)

0-10 VDC

2,0-10,0 VDC or

4,0-20,0 mA

0,9-1,6 VDC or

1.5-2,5 mA

0 VDC or 0mA

0-2000 ppm CO

2

0-2000 ppm CO

2

Status = ERROR

Status = NOT READY

Table I. Connections of the main terminal of

e

ee

eSENSE

Option display

+

~

Option display

+

~

PCB with jumper to configure OUT2

PCB with mounted resistor OUT2 is then

For current output 4-20mA or

configured for voltage output 2-10VDC

voltage output 2-10VDC

EM eSENSE_all_housings_May'08.doc

9 of 10

+

~

Enlarged picture of the PCB with the jumper set to current output (left position)

+

~

Enlarged picture of the PCB with the jumper set to voltage output (right position)

Self diagnostics

The system contains complete self-diagnostic procedures that are executed automatically

when the sensor is in operation. The yellow LED is lit if an error is found. Sensors with

display show a wrench if an error is found. The wrench is shown and the yellow LED is lit

during the first seconds after power up and if the measuring range exceeded. They are

automatically turned off when the sensor returns to normal operation. The output OUT2

indicates the same information by setting the output voltage to 1V or 2 mA.

Maintenance

The

eSense K50

eSense K50eSense K50

eSense K50

is basically maintenance free in normal environments thanks to the built-in

self-correcting ABC algorithm. Discuss your application with SenseAir in order to get advice

for a proper calibration strategy.

PLEASE NOTE!

The sensor accuracy is defined at continuous operation (at least 3 weeks after

installation)

PLEASE NOTE! Electronic products should be disposed of via a suitable recycling

centre.

EM eSENSE_all_housings_May'08.doc

10 of 10

WARRANTY AND LIMITATION OF LIABILITY

1. SenseAir warrants that for a period of twentyfour (24) months following receipt by Buyer

the Product supplied by SenseAir to Buyer will be, under normal use and care, free from

defects in workmanship or material and to be in material conformity with SenseAir's

specifications. Units returned to SenseAir for warranty repairs shall be shipped to SenseAir, at

Buyer’s expense, according to SenseAir's instruction. Within ninety (90) days of the receipt of

product, SenseAir shall replace or repair such units and shall ship them to Buyer’s designated

return destination freight pre paid.

2. Warranty Limitations. This warranty does not extend to any unit that has been subject to

misuse, neglect or accident; that has been damaged by causes external to the unit; that has

been used in violation of SenseAir's instructions; that has been affixed to any non-standard

Accessory attachment; or that has been modified, disassembled, or reassembled by anyone

other than SenseAir.

3. The retailer is not responsible for any consequential loss or damages, which may occur by

reason of purchase and use of this product. The warranty is, in any event, strictly limited to

the replacement/repair of the product

This product is in accordance with the EMC 2004/108/EC, 92/31/EEG including amendments

by the CE-marking Directive 93/68/EEC

The product fulfils the following demands: EN 61000-4-2 level 2,

EN 61000-4-3 level 2, EN 61000-4-4 level 4, EN 61000-4-6, EN 61000-4-8 level 4,

EN 55022 class B

Other manuals for eSENSE

2

This manual suits for next models

3

Table of contents

Other SenseAir Transmitter manuals

SenseAir

SenseAir aSENSE User manual

SenseAir

SenseAir aSENSE User manual

SenseAir

SenseAir aSENSE GH (Disp) RL User manual

SenseAir

SenseAir tSENSE VAV Disp User manual

SenseAir

SenseAir aSENSE User manual

SenseAir

SenseAir aSENSE User manual

SenseAir

SenseAir tSense User manual

SenseAir

SenseAir aSENSE User manual

SenseAir

SenseAir eSENSE Ind User manual

SenseAir

SenseAir aSENSE User manual