Servomex 700B User manual

700B

Oxygen Analyser

Instruction Manual

Ref :00700 / 001B / 9

Order as part No. 00700 001B

NOTES

I

GENERAL SAFETY INFORMATION

Servomex oxygen analysers are sophisticated devices intended for use by qualified personnel

only. It is necessary that this manual be read and understood by those who will install, use and

maintain this equipment.

USE OF WARNING, CAUTION AND NOTE

This publication includes WARNING, CAUTIONand NOTE information where

appropriate to point out safety related or other important information.

WARNING - Hazards which may result in personalinjury ordeath.

CAUTION - Hazards which may result in equipment or property damage.

NOTE - Alerts to pertinent facts and conditions.

ELECTRICAL SAFETY WARNING

1. THE ELECTRICAL POWER USED IN THIS EQUIPMENT IS AT A VOLTAGE

HIGH ENOUGH TO ENDANGER LIFE.

2. BEFORE CARRYING OUT MAINTENANCE OR REPAIR, PERSONS

CONCERNED MUST ENSURE THAT THE EQUIPMENT IS DISCONNECTED

FROM THE ELECTRICAL SUPPLY AND TESTS MADE TO VERIFY THAT THE

UNIT IS DISCONNECTED.

3. WHEN THE SUPPLY CANNOT BE DISCONNECTED, FUNCTIONAL TESTING,

MAINTENANCE AND REPAIR OF THE ELECTRICAL UNITS IS TO BE

UNDERTAKEN ONLY BY PERSONS FULLY AWARE OF THE DANGER

INVOLVED AND WHO HAVE TAKEN ADEQUATE PRECAUTIONS.

WARNING

This 700B analyser is not suitable for use in hazardous areas without a suitable purge.

II

CAUTION

To maintain the analyser's performance only spares of suitable quality should be

used to repair this analyser. These should be obtained from either Servomex, its

associated companies or local agents.

NOTICE

Informationinthismanualisintendedonlytoassistourcustomersintheefficientoperationofour

equipment. Useofthismanualforanyotherpurposeisspecificallyprohibitedanditscontentsare

not to be reproduced in full or part without prior approval of Group Marketing Department,

Servomex plc, Crowborough, Sussex, England TN6 3DU.

RETAIN THIS MANUAL FOR FUTURE REFERENCE

The 00700B Oxygen and Combustibles Analyser complies with the European Community

“Electromagnetic Compatibility Directive”89/336/EEC by the application of the following:

A Technical Construction File No. 00700-P-004-1 dated 20.11.95 and

Test Reports No. 5044/9Y7 and 5044/9N8 issued by:

ERA Technology Ltd, Cleeve Road, Leatherhead, Surrey, KT22 7SA

The 00700B complies with the European Community “LowVoltage Directive” 73/23/EECand the “CE

Marking Directive”93/68/EEC and are rated in accordance with:

IEC664 for “Installation Category II”which is characterised as being local level (i.e. not

distribution level), appliances and portable equipment with over-voltage

impulse withstand up to 2500V.

The 00700B is CE marked (when fitted with external mains filter)for the European Community

“Electromagnetic Compatibility Directive”89/336/EEC only. It also complies with the transitional

arrangements of the European Community “ATEX Directive”94/9/EC.

III

700B OXYGEN ANALYSER

INSTRUCTION MANUAL CONTENTS

SECTION

1 INTRODUCTION

2 ANALYSER DESCRIPTION

3 INSTALLATION

4 OPERATION

5 MAINTENANCE

6 FUNCTIONAL DESCRIPTION AND SPECIFICATION

7 RECOMMENDED SPARES AND PARTS LIST

APPENDICES

APPENDIX

1 INTERCONNECTIONS - OXYGEN ONLY

2 INTERCONNECTIONS - OXYGEN AND COMBUSTIBLES

3 CABLE SCHEDULES

4 PURGE DETAILS

IV

NOTES

1.1

SECTION 1 : INTRODUCTION

LIST OF CONTENTS

SECTION PAGE

1.1 INTRODUCTION TO 700B ..................................................1.3

1.2 ANALYSER OVERVIEW ....................................................1.3

1.2.1 Product Identification ................................................1.3

1.3 HAZARDOUS AREA USE ..................................................1.4

1.4 OPTIONS ...............................................................1.4

1.2

NOTES

1.3

SECTION 1 INTRODUCTION

1.1 INTRODUCTION TO 700B

This manual provides descriptive information, installation and maintenance instructions for the

Servomex 700B combustion gas analysers.

It is divided into the following sections covering :

Section 1 Introduction to the 700B

Section 2 Description of the analyser, its operating principle and options

Section 3 Installation of the analyserand user connections

Section 4 Operating instructions

Section 5 Maintenance, fault diagnosis and repairs

Section 6 Functional description and specification

Section 7 Recommended spares and parts lists

1.2 ANALYSER OVERVIEW

TheServomex700BZirconiaOxygenanalysermeasurescombustionandsimilargasestoprovide

ananalysisofoxygenconcentration. Wheretherelevantoptionisfitted, indicationofthelevelof

unburned combustibles is given.

The system comprises two units, a sensor head and a control unit with display and keypad.

Acomprehensiverangeofsampleprobesandfiltersisavailabletoenabletheanalysertobeused

inawiderangeofapplicationsandprocessconditions,includingsamplegas temperaturesofup

to 1800OC (3200OF). It can be adjusted to operate on all common supply voltages and

frequencies.

1.2.1 Product Identification

The individual units of the analyser (sensor headand control unit)all have serial numbers. The

serialnumber of the sensorheadwill befoundin thecentreof thesensorhead cover. It is in the

form714/XYZ/NNNwhere714isthemodelnumberofthesensorhead,XYZisthemodelvariant

and NNN is the serial number.

1.4

The serial number of the control unit will be found on a label attached to the inside of the door.

Itisoftheform722/NNNwhere722isthemodelnumberofthecontrolunitandNNNistheserial

number.

A label identifying the analyser as a whole is also fixed to the control unit. This label has the

following information:

Identification number e.g. 807387

Software e.g. 722/652/2

Date tested

Picture code

When ordering spare parts it will assist if the identification number and the serial number of the

relevant unit are quoted.

1.3 HAZARDOUS AREA USE

The standard unpurged 700B is suitable only for use in safe areas.

The 700B control unit and sensor head for installation in hazardous areas may also be purged.

1.4 OPTIONS

Optionsavailableincludeisolatedanalogueoutputandalarms,adatalink,facilitiesforcalculating

anddisplayingfluegastemperatureandcombustionefficiency(usinganexternalthermocouple).

Theanalyserrequiresasupplyofcompressedairtoaspiratethesample. Arangeofairregulator

sets are available.

2.1

SECTION 2 : ANALYSER DESCRIPTION

LIST OF CONTENTS

SECTION PAGE

2.1 INTRODUCTION ..........................................................2.3

2.2 CONTROL UNIT DESCRIPTION .............................................2.3

2.2.1 Keypad...........................................................2.3

2.2.2 Display ...........................................................2.3

2.2.3 ControlUnitFunctions ...............................................2.4

2.3 SENSOR HEAD DESCRIPTION ..............................................2.5

2.4 AIR REGULATOR UNITS ...................................................2.7

2.4.1 Oxygen Analyser ...................................................2.7

2.4.2 Oxygen and Combustibles Analyser .....................................2.7

2.4.3 Oxygen and Combustibles Analyser with Auxiliary Air and Calibration ..........2.7

2.5 MOUNTING FLANGE ......................................................2.8

2.5.1 Welded Flange .....................................................2.8

2.5.2 Bolt-On Flange .....................................................2.8

2.6 PROBE TUBES ...........................................................2.9

2.7 OUTPUTS AND ALARMS ...................................................2.9

2.7.1 Standard Outputs ...................................................2.9

2.7.2 Isolated Oxygen and Combustibles Output Card ...........................2.9

2.7.3 Isolated Oxygen Output and AlarmCard .................................2.9

2.7.4 DataLink ........................................................2.10

2.7.5 Temperature and Efficiency Card ......................................2.10

LIST OF ILLUSTRATIONS

FIGURE PAGE

2.1 AnalyserBlockSchematic...................................................2.4

2.2 Sensor Head Flow Schematic ................................................2.6

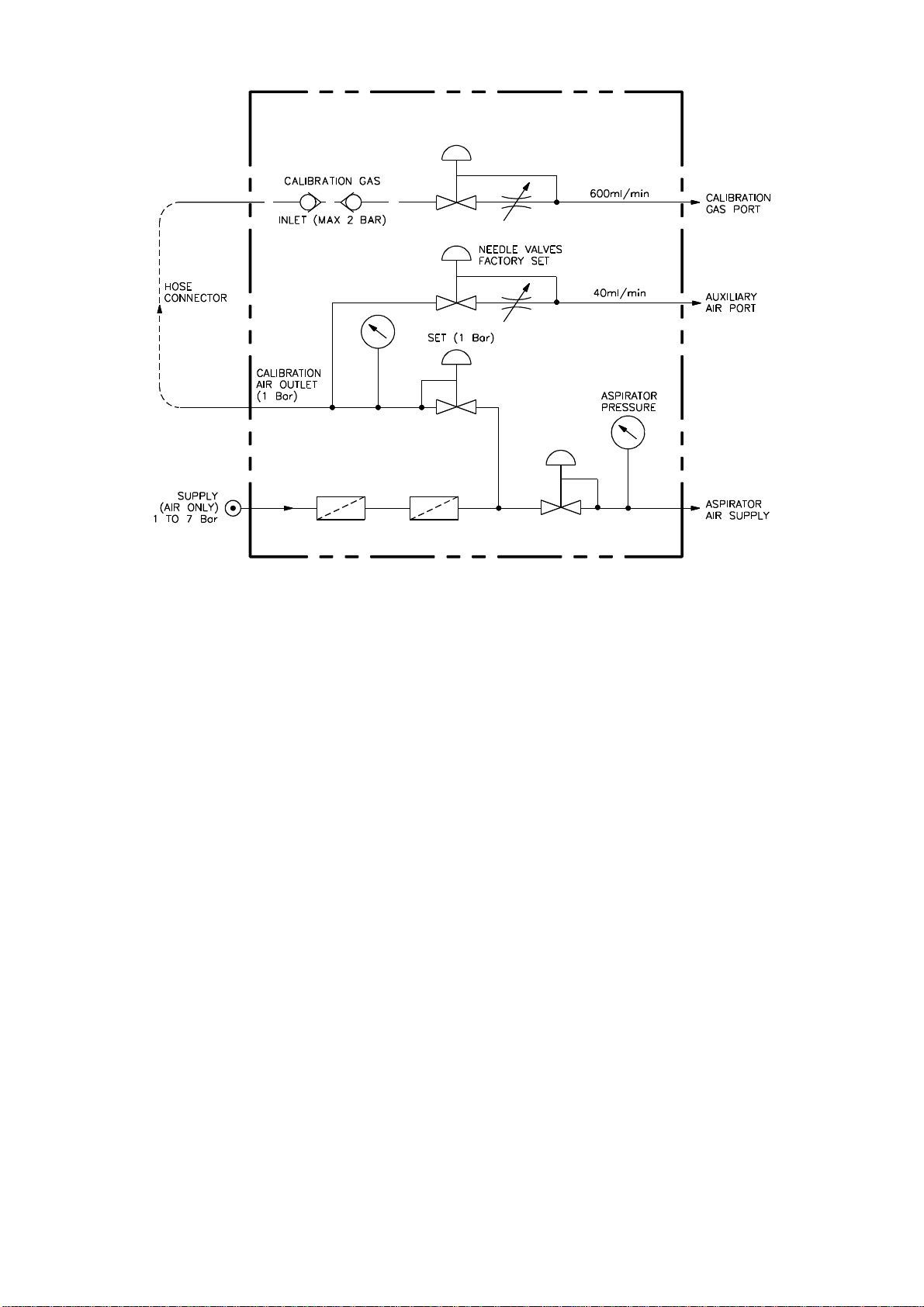

2.3 Flow Schematic - AirSupply and Calibration Unit .................................2.8

2.2

NOTES

2.3

SECTION 2 ANALYSER DESCRIPTION

2.1. INTRODUCTION

The analyser comprises two separate units, thesensor head and the control unit, which may be

mounted up to 300m apart. Refer to Appendix 3.

Thesensorheadmountsdirectlyonto the fluewitha probetubewhich projectsthrough the duct

wallintotheprocessgastodrawoutasampleforanalysis. Itcontainsazirconiacellto measure

theoxygencontentofthefluegasesandaflowsensortomonitortheflowofthesamplegas. An

optional combustibles sensormay also be fitted. The power forthe sensor head is derived from

the control unit.

The control unit, which is remote from the sensor head, provides powersupplies to the sensors

and heaters. It also processes the outputsignals fromthe measuring cellsto provide the output

indications, and houses the option cards to provide additionalfeatures.

2.2 CONTROL UNIT DESCRIPTION

The control unit houses the power supplies, microprocessor, membrane keypad,display, option

cards, output circuits for the system and the combustibles electronics, when specified. The unit

is designed for surface mounting.

The basic control unit contains two circuit boards. The first is mounted on the door and carries

the membrane keypad and the display with associated electronics.

The second board is the main motherboard and is mounted on a chassis in the rear of the

enclosure. It carries the analogue input and output circuits and, at the right hand, the power

supply for the electronics and the low voltage ac powerfor the zirconia cell heater.

Thesupplyvoltageismonitoredby themicroprocessor. Ifthevoltagefallstoalevelat whichthe

electronicscannotoperate,theinstrumentputs itselfinasafe conditionandthenceasesnormal

operation. When possible, in this condition a 'POWER FAIL' message is displayed. Normal

operation is automaticallyresumed when sufficient voltage is restored.

2.2.1 Keypad

The keypad is used to control the display and operating parameters of the system. Certain

functions,whichaffecttheoutputandcontrolsignalsfromtheunit,areaccessibleonlybyentering

a password.

2.2.2 Display

The unit has a 12 character alphanumeric display. Normally this displays the oxygen and/or

combustiblecontent of the sample; but, when the instrumentis being calibratedor the operating

parametersarebeingadjusted,itdisplayspromptmessagestoensurethatthecorrectsequence

of operations is carried out. It will display messages which permit diagnosis of faults and

2.4

interrogation of alarms which may arise within the analyser. If the temperature and efficiency

option is fitted, flue gas temperature and combustion efficiency can be displayed.

2.2.3 Control Unit Functions

The main board of the control unit inputs the analogue signals from the sensors via a 12bit A to

D converter. The microprocessor processes the signals, provides temperature control of the

zirconia cell and the sample block and generates outputs to the display, alarms and analogue

outputs.

Data is stored in a permanent memory (EEPROM)which does not require battery back-up.

The programme run by the microprocessor is monitored by a Watchdog. In the event of a

malfunction a microprocessor reset is automatically performed by the Watchdog.

Ifeitherthe zirconiacellorsampleblocktemperaturegoes outof limitsformorethan 30minutes

the control unit shuts down and generates a 'SYS. FAIL' message to protect the analyser and

indicate a fault.

Figure 2.1 Analyser Block Schematic

2.5

An interface adaptor card, to which option cards may be plugged, is fitted when options are

specified. Up to 6 cards may be fitted to the interface adaptor card. See Figure 2.1.

Whentheoptionalcombustiblessensorisfitted,itstemperatureiscontrolledindependentlybythe

combustibles card which occupies two positions on the interface adaptor card.

2.3 SENSOR HEAD DESCRIPTION

The sensor head is designed for industrial use in process plants. It is designed to IP55 (NEMA

4) to withstand dust concentration and spray water.

Parts containing sample gas within the sensor head are maintained at 200oC (392oF) to avoid

sample condensation.

The oxygen and optional combustible sensors are mounted external to the flue. Sample gas is

drawn through the sensors by means of an air driven aspirator.

The oxygen content of the sample is measured with the well-proven Servomex zirconia cell.

TheoptionalcombustiblessensorisaConstantTemperatureCatalytic(CTC)sensorandisused

to determine the level of combustible gases (expressed as carbon monoxide) in the sample

stream.

Theoxygenandcombustiblessensorsareindependentlytemperaturecontrolled. Theoperating

principles of the sensors are described in Section 6.

In order to provide a reading of combustible gases in the sample under reducing conditions,

Servomex has adopted a parallel arrangement of the sensors. In this arrangement an optional

supplementaryairbleedtothecombustiblessensorcanbeprovidedtoensurecompleteoxidation

of the combustible gases when the oxygen content of the sample gas is low.

Itisrecommendedthatexhaustgasesarereturnedtotheprocess. Someprobeoptionsdoallow

venting to atmosphere.

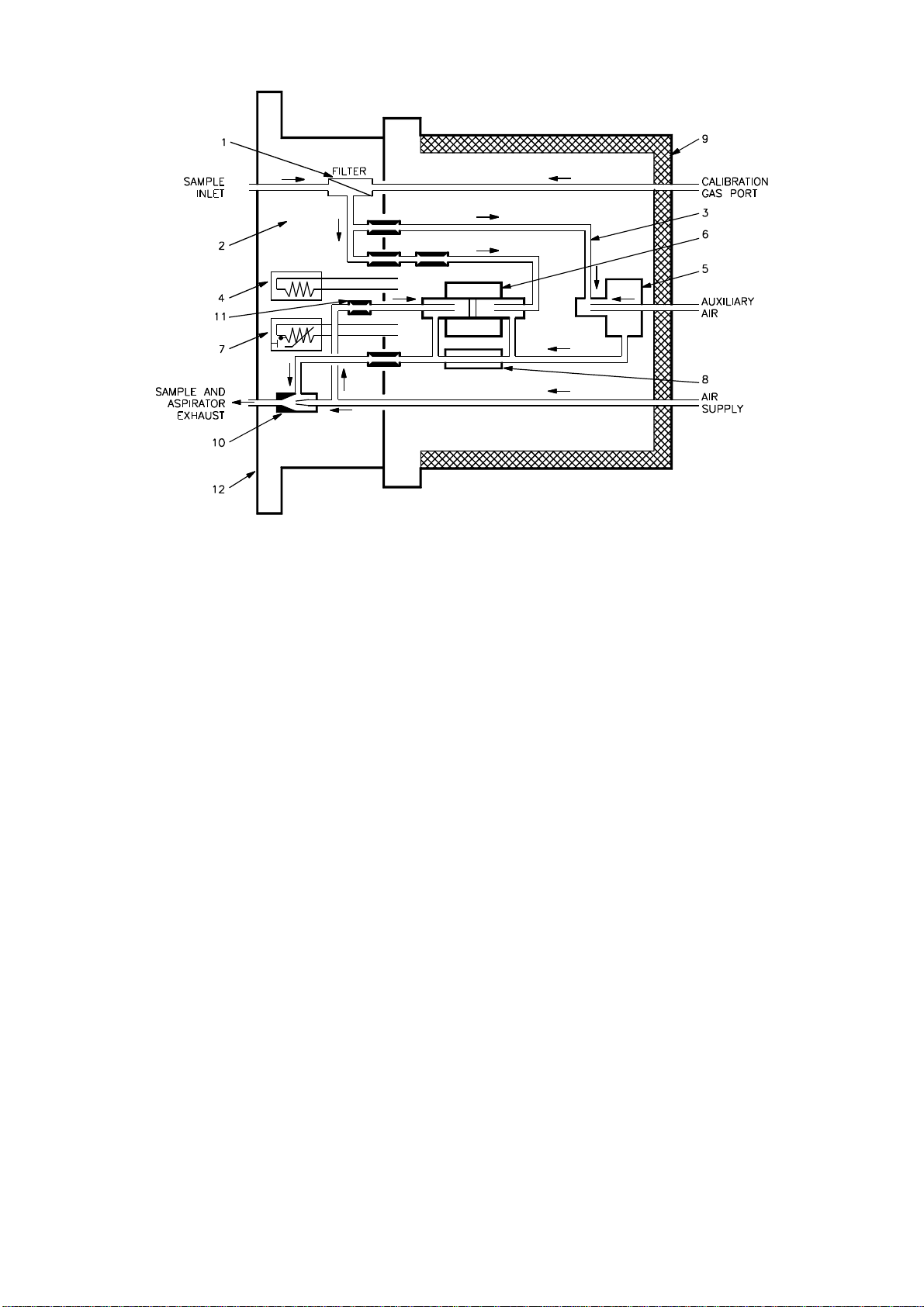

Referring to Figure 2.2, the following description assumes that the combustibles option is fitted.

Theaspirator(10),operatedbycompressedair,drawssamplegasfromtheflueataflowofabout

300ml/min through the filter (1). The flow isdivided inthe ratio2:1 by the restrictors (3). These

restrictors and the one down stream of the oxygen measuring cell (6) also act as flame trapsto

isolate the hotcell from the process. This prevents the possibility of an explosion should a high

concentration of flammable gases be present in the sample at high oxygen levels.

2.6

Figure 2.2 Sensor Head Flow Schematic

A small portion of the aspirator air supply is tapped via the capillary restrictor/flame trap (11) to

provide a reference oxygen level in the reference side of the oxygen measuring cell (6).

Thetotalsamplegasflowismonitoredbytheflowsensor(8)whichinitiatesanalarmifthesample

flow drops below a preset level.

Sensor (5) is fitted to measure the combustibles content of the sample. Should there be

insufficient air in the sample to ensure complete combustion of the gases an auxiliary air supply

can be fitted. The auxiliary air flow rate, which has to be strictly controlled, is mixed thoroughly

with the sample gasbefore being presented to the combustibles sensor in orderto obtain a true

reading.

If combustibles analysis is not required, the sensor is replaced by a bypass tube to maintain the

same sample flow rate.

The sample block (2)is heated by the cartridge heater(4). The block temperature is monitored

by the temperature sensor(7).

The sensor head is mounted onto the flue by the flange (12).

The insulated cover (9)reduces the heat loss fromthe sensor head.

Calibration gases are introducedvia the calibration gasport at apressure abovethat in the flue.

Thecalibrationgas port,filterandprobetubeare arrangedin-lineso that the probe tube may be

tested without the need to demount the sensorhead from the process.

2.7

Theterminalblockonthesensorheadcontainsvoltageselectorlinkstoadapttheunittothelocal

supply voltage.

2.4 AIR REGULATOR UNITS

Threetypesofairregulatorunitare availablewhicharedesignedfordifferentapplications. Inall

cases inlet air pressure should be in the range 0.6 - 6 barg (10 - 100 psig).

2.4.1 Oxygen Only Analysers

This is a simple air pressure regulator which controls the airpressure applied to the aspirator in

the sensor head to within ± 70mbarg (±1psig).

2.4.2 Oxygen and Combustibles Analysers

When the combustibles content of a sample is being measured, the output of the combustibles

sensorisproportionaltothequantityofcombustiblegasflowingthroughthesensor. Thisdepends

on two factors:

a) The absolute concentration of combustible components in the sample.

b) The flow rate of the sample.

Therefore, to obtain a stable measurement, it is necessaryto control the flow rate of the sample

accurately. Thisisachievedbycontrollingtheaspiratorsupplypressurecloselyusingaprecision

regulator which maintains thispressure to within ±7mbarg (±0.1psig)

2.4.3 Oxygen and Combustibles Analyser with Auxiliary Air and Calibration Unit

In those cases where the concentrationof combustiblegases meansthat there isan insufficient

quantity of oxygen available in the sample stream to perform the combustibles analysis, an

auxiliaryairsupplyisnecessarytoobtainatruemeasurement. Thisenablesmeasurementofup

to 5% carbon monoxide in the absence of oxygen in the process.

Astheoutputofthecombustiblesdetectordependsuponrateofairflowthisunitregulatestheair

flow to tight tolerances. It also includes facilities for introducing calibration gases.

2.8

Figure 2.3 Flow Schematic - Air Supply and Calibration Unit

2.5 MOUNTING FLANGE

The flue has to be fitted with a flange for attachment of the sensor head.

The standard flanges are suitable for a skin temperature up to 350oC (662oF). Flanges with a

stand-off are used for skin temperatures of 350 -500oC (662 - 932oF).

Two mounting flange options are available for both standard and stand-off flanges.

2.5.1 Welded Flange

This flange maybe either welded directly on tothe surface ofthe flue when itis flat,or to ashort

length of 4 inch O.D. tube when the flue surface is curved.

2.5.2 Bolt-On Flange

This flange isfor bolting to the flue wall when welding is impracticable.

2.9

2.6 PROBE TUBES

A wide range of probe tubes, with or without filters, is available. Servomex can advise on the

choice of probe for a specific application. Standard probes include:

a) Unsupported filter probes up to 1 metre long for a maximum flue gas temperature of

500oC (932oF).

b) Supportedfilterprobesupto3metreslongforamaximumfluegastemperatureof500oC

(932oF).

c) High temperature alloy probes up to 1m length for a maximum flue gas temperature of

1000oC (1832oF). Longer probes can be used at temperatures below1000oC, 1.5m up

to 800oC, 2m up to 750oC. External filters can be fitted to these probes to suit dusty

applications.

d) Ceramic probes up to 1.5 metres long for maximum flue gas temperatures of 1600oC

(2912oF).

e) Ceramic probes up to 1.5 metres long for maximum flue gas temperature of 1800oC

(3272oF).

2.7 OUTPUTS AND ALARMS (See Section 6 for specifications)

The standard analyser hasnon-isolated analogue output available from themain board. Option

boards can be fitted to give isolated outputs and alarms for gas concentration and analyser

status/fault.

2.7.1 Standard Outputs

Thestandardoutputsforoxygen,andcombustiblesiffitted,arenon-isolatedandcanbeselected

via the keypad as 0-20 mA or 4-20mA and 0-10V or 2-10V for oxygen ranges of 2.5, 5, 10 and

25% and combustibles ranges of 0.25, 0.5, 1 and 5%

2.7.2 Isolated Oxygen and Combustibles Output Card 00722921

Thisoptioncardprovidesisolatedcurrentoutputsfortheoxygenandcombustiblesignals.These

outputs can be selected via the keypad as 0-20 mA or4-20 mA. See Section 6.

2.7.3 Isolated Oxygen Output and Alarm Card 00722911

Thisoption card providesan isolated currentand voltage output for oxygen level and a volt free,

normallyclosed contact, to open onalarm, foroxygen level or analyser fault. The output can be

selected via the keypad as 0-20mA or 4-20 mA and 0-10V or2-10V. See Section 6.

2.10

The analyser fault alarm will warn of the following:

Low sample flow

Sensor head under or over temperature

Oxygen cell under or over temperature

Oxygen cell output out of limits

In addition to the volt-free contact alarmthere are three non-isolated alarms for:

Oxygen high

Oxygen low

Analyser fault (alarms as above)

2.7.4 Data Link 00722913

The data link card option enables full duplex communication between the control unit and a

computer or dumb terminalvia isolated RS232, RS423 or 20mA current loop. The Baud rate is

userselectablebetween300and9600Bauddependentontheinterfaceandcabledistance. Data

display modes are selectable. Section 6 gives fulldetails of data protocol.

2.7.5 Temperature and Efficiency Card 00722914

This option card provides non-isolated outputs for both combustion efficiency and flue gas

temperature (requires the installation of thermocouple in the flue), or when requested from the

keyboard, a display of the air inlet temperature (requires a secondthermocouple to monitor the

air inlet temperature). No electrical output is available for air inlet temperature. Where no inlet

temperature thermocouple is fitted an assumed value of ambient temperature may be entered

manually. This is necessary for the analyser to performthe efficiency calculation.

The outputs can be selected via the keypad as 0-20mA or 4-20 mA and 0-10V or2-10V.

Calculation of the efficiency is according to the Siegert equation (BS 845.1972). See Section 6.

Also provided is a non-isolated output forflue gas temperature high alarm.

This manual suits for next models

1

Table of contents

Other Servomex Analytical Instrument manuals

Servomex

Servomex 2700 User manual

Servomex

Servomex DF-310E User manual

Servomex

Servomex xendos 1800 Series User manual

Servomex

Servomex DF-150E User manual

Servomex

Servomex SERVOPRO k2001 User manual

Servomex

Servomex SERVOTOUGH SpectraExact 2500 Instruction manual

Servomex

Servomex SERVOPRO 4900 User manual

Servomex

Servomex NanoTrace DF-760E User manual

Servomex

Servomex SERVOPRO Chroma User manual