Servomex SERVOPRO 4900 User manual

Part Number: 04900001B

Revision: 4

Language: UK English

Installation and Operation

Manual

SERVOPRO 4900

Continuous Emissions Analyser

EMISSIONS ANALYSERS

This page intentionally blank

Xentra 4900

Continuous Emissions Analyser

Installation and Operation Manual

Ref:04900/001B/4

Order as part 04900 001B

i

The configuration of this xentra 4900 Continuous Emissions Analyser

Model and Issue: 0490_B1

Feature and option code number

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12 F13 F14 F15 F16

__________________

Serial number _ _ _ _ _

Instrument Configuration

Transducer I1

Type:

Serial No:

Transducer I2

Type:

Serial No:

Transducer I3

Type:

Serial No:

Transducer I4

Type:

Serial No:

Servomex Order Reference No:

Software Revision No:

Completed By: Date :

ii

iii

WARNINGS, CAUTIONS AND NOTES

This publication includes WARNINGS, CAUTIONS AND NOTES

which provide information relating to the following:

WARNINGS : Hazards which could result in personal injury or

death.

CAUTIONS : Hazards which could result in equipment or

property damage.

NOTES : Alert the user to pertinent facts and conditions.

NOTE

This manual covers installation, normal operation, routine maintenance

and fault diagnosis on the xentra models 4902B1 and 4904B1.

The following symbols are used on

the rear of the analyser:

iv

LIST OF CONTENTS

SECTION 1 INTRODUCTION ....................................... 1.1

1.1 Introduction ............................................... 1.1

1.2 Glossary .................................................. 1.1

1.3 General description ......................................... 1.1

1.4 Location of components ..................................... 1.4

1.5 Introduction to the xentra userinterface ........................ 1.4

1.5.1 The xentra measurement display ........................ 1.5

1.5.2 The xentra keypad..................................... 1.7

1.5.3 The xentra screenicons................................ 1.8

1.5.4 The xentra menudisplay ............................... 1.9

1.5.5 Numeric data input ................................... 1.10

1.5.6 Password protection .................................. 1.10

1.6 Transducersitenumberingsystem ........................... 1.11

1.7 Outputnumberingsystem................................... 1.11

1.8 Transducer full scale deflection .............................. 1.11

1.9 Technical assistance and spare parts ......................... 1.12

SECTION2 INSTALLATION ....................................... 2.1

2.1 Introduction ............................................... 2.1

2.2 Unpacking and Inspection .................................... 2.1

2.3 Panel mount installation ..................................... 2.3

2.4 Rack slide mounting installation .............................. 2.4

2.5 Electricalpower connection ................................. 2.6

2.6 Signalconnections ......................................... 2.8

2.7 Serialoutputconnection.................................... 2.14

2.8 Externalautocalibrationconnection .......................... 2.15

2.9 Samplestreamconnection .................................. 2.16

2.10 Sample gas condition ...................................... 2.20

2.11 Calibrationgassampleconnection ........................... 2.21

2.12 Readingflowmeters........................................ 2.23

2.13 Powerup ................................................ 2.23

SECTION3 INITIALCONFIGURATION............................... 3.1

3.1 Setting passwords .......................................... 3.1

3.2 Settingtimeanddate........................................ 3.2

v

SECTION4 CALIBRATION ........................................ 4.1

4.1 Introduction to calibration .................................... 4.1

4.2 Recommended calibration check periods ....................... 4.2

4.3 Settinglowandhighcalibrationtolerances ..................... 4.2

4.4 Paramagnetictransducerlowandhighmanualcalibration......... 4.3

4.5 Gfxgastransducerlowandhighmanualcalibration.............. 4.5

4.6 Manual cal check low and high ................................ 4.7

4.7 Autocalibrationoverview .................................... 4.9

4.8 Monitoring the progress of auto calibration .................... 4.11

4.9 Auto calibration and auto check setup ........................ 4.11

4.10 Initiating auto calibration or auto check from keypad ............ 4.14

4.11 Initiating auto calibration or auto check by external contact closure 4.14

4.12 Abortinganautocalibrationinprogress....................... 4.15

4.13 Disablingautocalibrationandautocheck ...................... 4.15

4.14 Restarting auto calibration or auto check after disabling ......... 4.15

4.15 Scaling ( calibration ) of the external analogue inputs ............ 4.16

SECTION5 MAINCONFIGURATION ................................ 5.1

5.1 Alarms.................................................... 5.1

5.2 Allocationofrelays ......................................... 5.3

5.3 Analogue outputs ........................................... 5.5

5.4 Component name definition .................................. 5.9

5.5 External analogue input configuration ......................... 5.10

5.6 Defining and selecting measurement displays .................. 5.11

5.7 Displayresolution ......................................... 5.12

5.8 Responsetime ............................................ 5.12

5.9 Displayunits.............................................. 5.12

5.10 Calculation of total nitrogen oxides (NOx)concentration.......... 5.13

5.11 Serialoutputcommunications ............................... 5.14

SECTION6 REVIEW ............................................. 6.1

6.1 Introduction to review section ................................ 6.1

6.2 Displaying alarms present .................................... 6.1

6.3 Displaying faults present ..................................... 6.1

6.4 Displayingrelayconfiguration ................................ 6.2

6.5 Displaying analogue output configuration ...................... 6.2

6.6 Displayingalarmsettings .................................... 6.4

6.7 Displayinganalyseridentity .................................. 6.5

6.8 Displayingalarmhistory ..................................... 6.5

6.9 Displayingfaulthistory ...................................... 6.6

6.10 Displayingcalibrationhistory................................. 6.6

6.11 Displaying diagnostics information ............................ 6.8

SECTION7 ROUTINEMAINTENANCE .............................. 7.1

7.1 Replacingfanfilterelement .................................. 7.1

7.2 Replacingsamplefilterelement ............................... 7.1

7.3 Cleaning .................................................. 7.1

vi

SECTION8 FAULTDIAGNOSIS .................................... 8.1

8.1 Introduction ............................................... 8.1

8.2 Fault diagnosis on the Pm1156 transducer ...................... 8.1

8.3 Fault diagnosis on the Gfx 1210 transducer ..................... 8.3

8.4 Fault diagnosis with a non-functioning display .................. 8.4

SECTION9 SPARES ............................................. 9.1

9.1 Orderingspares ............................................ 9.1

9.2 Sparepartslist............................................. 9.1

SECTION 10 APPENDICES & REVISION HISTORY

APPENDIX A

MENUMAP ..................................................... A.1

APPENDIX B

TECHNICAL DATA SHEET ......................................... B.1

APPENDIX C

CHARACTERSET ................................................ C.1

APPENDIX D

EFFECTSOFVARIATIONSINSAMPLECOMPOSITION ................ D.1

REVISION HISTORY

vii

LIST OF FIGURES

FIGURE PAGE

Figure1.1 Keyfeaturesofxentra.................................. 1.4

Figure 1.2 xentra measurement display ............................ 1.5

Figure 1.3 xentra process variable format .......................... 1.5

Figure1.4 Thexentrakeypad..................................... 1.7

Figure1.5 xentrastatusIcons .................................... 1.8

Figure2.1 Recommendedhandling................................ 2.2

Figure 2.2 Panel mounting detail. ................................. 2.4

Figure 2.3 Rack installation exploded view ......................... 2.5

Figure 2.4 Position of F2 in voltage selector for 170V to 264V operation . 2.7

Figure 2.5 Position of F2 in voltage selector for 85V to 132V operation . . 2.7

Figure2.6 Fuseholderspringclips................................ 2.7

Figure 2.7 Signal socket assembly ............................... 2.12

Figure 2.8 Sample gland plate without auto calibration .............. 2.17

Figure2.9 Sampleglandplatewithinternalautocalibration .......... 2.17

Figure2.10 Sampleglandplatewithexternalautocalibration.......... 2.18

Figure2.11 Typicalsinglestream,dualGfxconfiguration ............. 2.18

Figure2.12 Typicaldualstream,dualGfxconfiguration............... 2.19

Figure4.1 Typicalautocalibrationsequence ...................... 4.9

Figure4.2 Screeniconsindicatingautocalibrationprogress.......... 4.11

Figure5.1 Allocationofrelays .................................... 5.3

Figure5.2 Formatofserialoutputdataframe ...................... 5.15

Figure A.1 User interface menu map .............................. A.1

viii

LIST OF TABLES

TABLE PAGE

Table1.1 TransducerFSDvalues ............................... 1.12

Table 2.1 Rack mount installation kit parts list ..................... 2.5

Table 2.2 Loose socket parts ................................... 2.12

Table2.3 SignalterminallocationPL1toPL4 ..................... 2.13

Table2.4 SignalterminallocationPL5 ........................... 2.14

Table2.5 SerialoutputconnectionsPL6.......................... 2.14

Table2.6 Externalautocalibrationconnections .................... 2.15

Table2.7 Externalautocalibrationtruthtable...................... 2.15

Table2.8 Sampleports ........................................ 2.16

Table 2.9 Sample gas conditions ................................ 2.20

Table 2.10 Recommended calibration gases ....................... 2.22

Table 2.11 Recommended component concentrations ............... 2.22

Table 3.1 Changing the passwords .............................. 3.1

Table3.2 Settingtimeanddate ................................. 3.2

Table4.1 Recommendedcalibrationperiods ...................... 4.2

Table4.2 Settinglowandhighcalibrationtolerances............... 4.3

Table4.3 Paramagneticlowandhighcalibration................... 4.4

Table4.4 Gfxsensorlowandhighcalibration ..................... 4.6

Table4.5 Lowcalcheck ....................................... 4.8

Table4.6 Highcalcheck....................................... 4.8

Table4.7 Settingupautocalibrationandautocheck ............... 4.13

Table 4.8 Initiating auto cal or check from keypad .................. 4.14

Table4.9 Abortingautocalorautocheck......................... 4.15

Table 4.10 External analogue input scaling ........................ 4.16

Table5.1 Settingupalarms .................................... 5.2

Table5.2 Allocationofrelays ................................... 5.4

Table 5.3 Clearing of relay assignment ........................... 5.5

Table 5.4 Analogue output span limits ........................... 5.6

Table 5.5 Setting up analogue outputs ........................... 5.7

Table 5.6 Clearing an analogue output assignment ................. 5.8

Table 5.7 Component name definition ............................ 5.9

Table 5.8 External analogue input definition ...................... 5.10

Table 5.9 Defining and selecting measurement displays ............ 5.11

Table5.10 Settingresponsetimeandresolution.................... 5.12

Table 5.11 Setting the NOxconversionparameters .................. 5.14

Table5.12 Serialcommunicationsparameters...................... 5.15

Table5.13 Settingtheserialoutputframefrequency ................ 5.16

Table5.14 Settingtheserialoutputcommunicationsparameters ...... 5.17

Table 6.1 Displaying alarms present ............................. 6.1

Table 6.2 Displaying faults present .............................. 6.1

Table6.3 Displayingrelayconfiguration.......................... 6.2

Table 6.4 Displaying analogue output configuration ................ 6.3

Table6.5 Displayingalarmsettings.............................. 6.4

Table6.6 Displayinganalyseridentity............................ 6.5

ix

Table6.7 Displayingalarmhistory............................... 6.6

Table6.8 Displayingfaulthistory................................ 6.6

Table6.9 Displayingparamagneticgassensorcalibrationhistory .... 6.7

Table 6.10 Displaying diagnostic information ....................... 6.8

Table 8.1 Fault diagnosis on the Pm1156 transducer ............... 8.1

Table 8.2 Diagnostic signals for the Pm1156 transducer ............ 8.3

Table 8.3 Fault diagnosis on the Gfx1210 transducer ............... 8.3

Table 8.4 Diagnostic signals for the Gfx 1210 transducer ............ 8.4

Table 8.5 Fault finding with non functioning display ................ 8.5

x

NOTES

1.1

SECTION 1 INTRODUCTION

1.1 Introduction

This manual contains the essential information regarding installation, operation and

configurationoftheServomexxentra4902and4904 ContinuousEmissionsAnalysers.

Complete details of the xentra hardware and full instructions for servicing by qualified

personnel onlyare presented in the xentra 4900 Service Manual. The service manual

may be ordered from Servomex using part number 4900002A.

WARNING

The user should note that the xentra 4900 instrument contains no user

serviceable parts inside. The instrument enclosure protects the user

from electric shock and other hazards. All servicing should be referred

to qualified personnel.

1.2 Glossary

FSD Full scale deflection, the maximum range over which a

measurement may be made ( see section 1.8 ).

DV Dead volume.

Top level menu The first menu, this leads on to a succession of other menus.

VARS Variables for each sensor.

UDEF User-defined data.

I1....I4 Internal gas sensor modules 1...4.

E1,E2 External analogue inputs 1 and 2.

Gfx Gas filter correlation infra-red.

Pm Paramagnetic.

1.3 General description

The Servomex xentra chassis is a platform into which gas sensor modules may be

fitted to make precise measurements.

Up to three modular gas sensors, for a wide range of gases and concentration levels

selected according to the customer’s needs, reside in the xentra chassis. The xentra

chassisprovidespower,gasconnectionsandothersupportfunctionstothegassensor

modulesandreceivestheiroutputsfromwhichitcalculatessamplegasconcentrations.

The calculated gas concentrations then may be displayed on the LCD display screen,

directed to the analogue outputs and/or directed to the serial RS232 output.

1.2

The xentra chassis also supports two external analogue input signals. The data from

the external inputs may be displayed on the screen, output to the analogue outputs

and/or output via the serial RS232 output.

The xentra 4900 is designed for use in modern industrial and laboratoryenvironments.

The analyser is controlled using an on-board microprocessor which gives the flexibility

toconfiguretheanalysertosuita widerangeof applications.Thexentraisoperatedvia

simple keypad controls mounted on the front fascia of the analyser. Adjacent to the

keypad is a large, Liquid crystal display (LCD), on which are displayed measurement

values, alarms and other data.

A number of optional features are available for the xentra 4900. These include the

following:-

CFlow meters and needle valves to monitor and control sample gas flow

through the instrument.

CA sample filter to protect the gas sensor modules from particulate

contamination.

CA sample flow alarm to monitor the sample flow and alarm when the flow

falls below a defined level.

CAn Autocalibration manifold to allow the instrument to be calibrated

without user intervention.

CRelayouputcontactstoallowautocalibrationoftheanalyserviaexternally

located valves.

CAdditional signal output cards to extend the number of analogue outputs

and relay outputs available to the user.

Full technical specifications for this xentra model are presented in the Technical Data

Sheet in Appendix B of this manual.

1.3

Start up and commissioning of the xentra should be performed in the order presented

in this manual:-

Installation (section 2)

This section takes commissioning to the point where the xentra is powered and

operational. Theinstallerisadvisedtoreadthissectioncompletelybeforecommencing

installation.

Initial configuration (section 3)

This section serves as a tutorial for the user interface and ensures that the password

and clock are set before calibration. Setting the clock ensures that calibration activity

is correctly recorded in the calibration history file.

Calibration (section 4)

This section describes manual calibration, automatic calibration, manual calibration

check and automatic calibration check.

Main configuration (section 5)

This section describes setting up of alarm levels, analogue outputs, relays and other

parameters.

Review (section 6)

Thissectiondescribeshowtodisplayanalogueoutputsettings,relayallocation,alarms,

faults and analyser identity without changing the analyser settings.

1.4

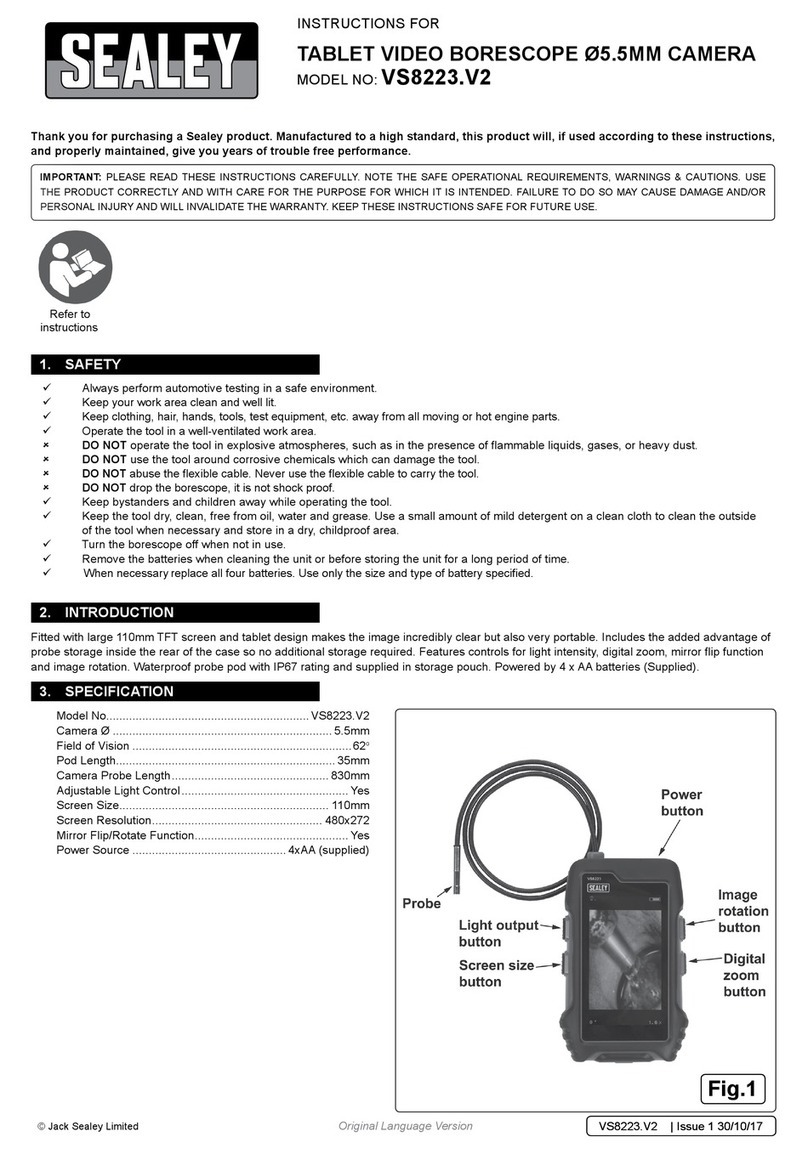

Figure 1.1 Key features of Xentra

1.4 Location of components

Figure 1.1 identifies the location of the key features of the xentra 4900 Continuous

Emissions Analyser.

1.5 Introduction to the xentra user interface

The xentra user interface consists of a keypad with nine keys and a large edge-lit LCD

display ( see Figure 1.1). During normal use of the instrument the LCD screen will

displayeither the default measurement displayor a menu based screen editor display.

Toggling between the measurement display and the menu based editor is via the

keypad. User input to the menu based screen editor is also via the keypad.

1.5

Figure 1.2 Xentra measurement display

Figure 1.3 Xentra process variable format

1.5.1 The xentra measurement display

The measurement display is the default display that is presented to the user of the

xentra 4900. The display can be user configured to show the gas concentrations

measured by the gas sensor modules fitted and/or the external analogue inputs. The

status of the instrument plus the occurence of an alarm or fault active are also

displayedon themeasurementdisplayviaiconspositionedatthebottomofthescreen.

The contents of the measurement display are shown in figure 1.2.

Each measured value on the display is known as a process variable and consists of

four fields as shown in figure 1.3.

1.6

1 A module location field ( 2 characters ).

2 A measurement value field ( 6 characters ).

3 An engineering units field ( 3 characters ).

4. A user defined message ( UDM ) field ( 6 characters ).

The module location field defines whether the process variable represents an internal

transducer or an external analogue input. The letter ’I’indicates an internalgas sensor

module. The letter ’E’ indicates an external analogue input. The letter is followed by

a number defining the gas sensor module site number.

The measurement field is a 6 character number representing the concentration

measured by an internal transducer or the scaled analogue input value. Should the

measured value for a transducer exceed 120% of the specified full scale deflection for

that transducer then the measurement field is replaced bythe word ‘OVER’to indicate

that the transducer is in over range condition.

The engineering units field is a user defined 3 character message identifying the units

of measurement. For Gfx transducers the user is offered a choice of the units to be

displayed. The options available are volume parts per million ( vpm ) ormg per normal

cubic meter. For paramagnetic oxygen transducers the displayed unit is fixed as

volume percent.

The user defined message ( UDM ) field represents the component name of the

process variable.

Thexentradisplaymaybereturnedtomeasurementdisplayatanytimebypressingthe

'MEASURE' key ( see figure 1.4 ). If no user key presses are input then the Xentra

returns to the measurement display after a one minute time out. This time-out is

extended to 20 minutes during the calibration options.

Whenfirst poweredup,the displaywillshowasequenceof powerup messages before

returning to the measurement display ( see section 2.12 ). If the user does not wish to

see the power up messages then these can be disabled by pressing the measure key

during the 'SYSTEM OK' message. The warming-up icon ( see figure 1.5 ) will also be

displayed until all gas sensor modules are at their respective operating temperature,

This may take up to 1 hour.

Iconslocatedatthebottomcentreofthemeasurementdisplayindicatethestatusofthe

instrument ( see figure 1.5 ). These icons show that the instrument is warming up or

being calibrated using the autocalibrate facility. Icons at the bottom of the display also

indicate the presence of alarms or faults. If the fault or alarm icons appear on the

measurement display the exact nature of the fault or alarm maybe determined via the

userinterface,(see6.2 'Displayingalarmspresent'and6.3'Displaying faultspresent').

This manual suits for next models

1

Table of contents

Other Servomex Analytical Instrument manuals

Servomex

Servomex DF-150E User manual

Servomex

Servomex NanoTrace DF-760E User manual

Servomex

Servomex DF-310E User manual

Servomex

Servomex 2700 User manual

Servomex

Servomex 700B User manual

Servomex

Servomex SERVOPRO k2001 User manual

Servomex

Servomex SERVOTOUGH SpectraExact 2500 Instruction manual

Servomex

Servomex xendos 1800 Series User manual

Servomex

Servomex SERVOPRO Chroma User manual