Servomex SERVOTOUGH SpectraExact 2500 Instruction manual

Part Number: 02500003E

Revision: 0

Language: UK English

SERVOTOUGH SpectraExact 2500

QUICK START MANUAL

Servomex 2500 Quick Start Manual

2 2500 Series - Configuration and Operation 02500/003E/0

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 3

Servomex 2500 Quick Start Manual

4 2500 Series - Configuration and Operation 02500/003E/0

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 5

1INTRODUCTION ........................................................................................................6

1.1 Warnings, Cautions and Notes................................................................................ 6

1.2 About this manual ................................................................................................... 6

1.3 Introduction to the user interface ............................................................................. 8

2INITIAL CONFIGURATION.........................................................................................9

2.1 Power up procedure................................................................................................ 9

2.2 General access to analyser functions...................................................................... 9

2.3 Setting passwords................................................................................................. 10

2.4 Setting time and date ............................................................................................ 11

3MAIN CONFIGURATION..........................................................................................12

3.1 Alarms................................................................................................................... 12

3.2 Allocation of relays ................................................................................................ 13

3.3 Analogue outputs .................................................................................................. 15

3.4 Defining and selecting measurement display screen............................................. 16

3.5 Communication Options ........................................................................................ 17

3.6 Communication Setup ........................................................................................... 18

3.7 RS232................................................................................................................... 18

3.8 MODBUS ASCII .................................................................................................... 20

3.9 MODBUS RTU ...................................................................................................... 20

3.10 ETHERNET........................................................................................................... 20

3.11 Functions .............................................................................................................. 21

3.12 Associate .............................................................................................................. 23

4CALIBRATION..........................................................................................................24

4.1 Introduction to calibration ...................................................................................... 24

4.2 Setting low and high calibration tolerances............................................................ 24

4.3 Manual calibration and checking ........................................................................... 25

4.4 Auto calibration and autocheck setup.................................................................... 26

4.5 Calibration when learnt cross interference is enabled............................................ 29

5VIEWING CONFIGURATION AND HISTORY FILES................................................ 30

5.1 Displaying ‘current’ alarms and faults .................................................................... 30

5.2 Displaying alarm settings ...................................................................................... 31

5.3 Displaying output configuration ............................................................................. 31

5.4 Displaying analyser histories ................................................................................. 32

5.5 Displaying analyser identity and diagnostics ......................................................... 33

Servomex 2500 Quick Start Manual

6 2500 Series - Configuration and Operation 02500/003E/0

1 INTRODUCTION

1.1 Warnings, Cautions and Notes

This publication includes WARNINGS, CAUTIONS and NOTE which provide

information relating to the following:

WARNINGS

Hazards which could result in personal injury or death.

CAUTIONS

Hazards which could result in equipment or property damage.

NOTES

Alert the user to pertinent facts and conditions.

1.2 About this manual

This manual covers software configuration and operation for the 2500, 2520 and 2550

range of analysers. Further copies of this manual may be ordered (part number

02500/003E).

Addresses for technical assistance and spares are given on the back cover.

An installation manual is supplied with the analyser which includes the technical

specification, routine maintenance and spares information.

A service manual is available for use by qualified personnel.

Some variants may be supplied with a certification manual.KEY TO FIGURES

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 7

KEY TO FIGURES

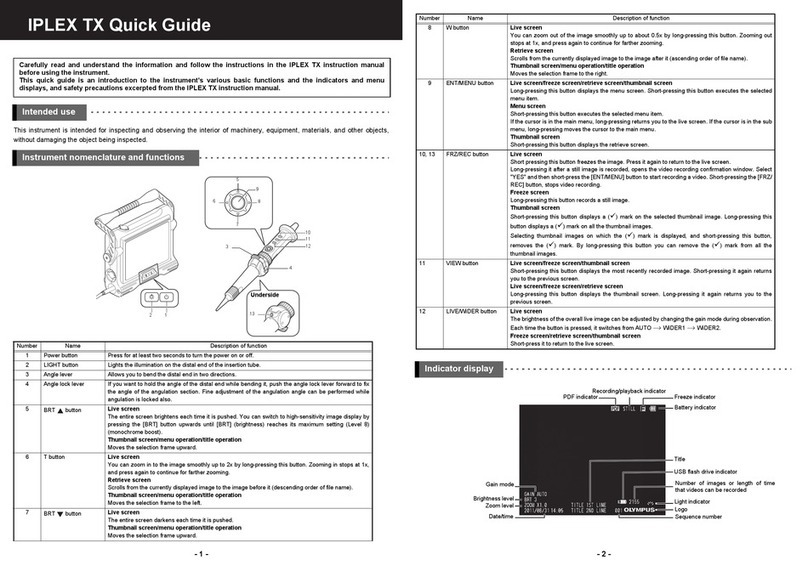

Figure A Analyser Front View

1. 16 Character 2 line VF Display

2. Hard key to select Measurement Display

3. Hard key to select Menu Display

4. Hard key to exit to the previous menu level

5. Fault warning LED

6. Alarm warning LED

7. Hard key to enter data or accept highlighted option within Menu

8. Up/Down/Left/Right Cursor keys to select Menu options and increase/decrease

numerical values

Figure B Analyser Menu Map

Figure C Auto calibration Examples Schematic

1. Autozero

2. Autozero and Span

Servomex 2500 Quick Start Manual

8 2500 Series - Configuration and Operation 02500/003E/0

1.3 Introduction to the user interface

See Figure A.

The keypad and display used on the 2500 series analysers have been designed to be

easy to operate and have a minimum number of keys. There are only 4 single-function

(‘hard’) keys: MEASURE; MENU; ENTER; EXIT. There are also 4 cursor (directional)

keys: Up; Down; Left; Right; these are arrow-head shapes. All keys require only a

modest pressure to operate them, and give tactile feedback.

Information is displayed on a 2-line, 16-character vacuum fluorescent display which

ensures good visibility under all conditions. Items on the display which require user-

selection are highlighted, i.e. appear flashing.

Also fitted to the keypad are red warning LEDs, one for ‘FAULT’ and one for ‘ALARM’.

These are normally only illuminated when a fault or a concentration alarm is being

signalled.

The 2500 series is controlled by the user via a ‘menu-driven’ interface; in other words,

at each level of operation the user is offered a selection, or menu, of items on the

display and he/she selects the appropriate one by highlighting it with the cursor keys

and then pressing the ENTER key. Where required, data is also entered by using the

cursor keys to increase/decrease values displayed.

Certain operations require the use of a password. There are two passwords, an

operator password and a supervisor password. These are factory set to 2000, but may

be changed if required (see Section 2.3).

Under normal operating conditions, the actual measurement result is continuously

displayed. This measurement display is the ‘default’ display. To perform any user

operations on the 2500, the user must first obtain the top-level menu display by

pressing the MENU key.

NOTE

During any operations within the menu, the fundamental measurement of the sample is

still being made by the 2500 and all relevant outputs, alarms and diagnostics remain

fully active and functioning.

To return to the (measurement) default display at any time and from any part of the

2500 user menu, simply press the MEASURE key.

NOTE

The display will also revert automatically to measurement if no key is pressed for one

minute.

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 9

2 INITIAL CONFIGURATION

2.1 Power up procedure

WARNING

Ensure that the instrument variant is properly installed before proceeding.

Confirm that all electrical and plumbing connections have been correctly made as

described in the installation manual.

Follow the Power up procedure as detailed in the installation manual.

The normal measurement display will then appear and the 2500 will be operational.

NOTE

•The measurement will not be valid at this point since process sample is not yet

flowing.

•If a heated cell is fitted, it will not yet be up to temperature and the intermittent

‘warming-up’ message will be displayed. Depending on set point and/or

environment, this may take several hours to reach temperature and for the

message to cease.

•The 2500 chopper box assembly will take up to 2 hours to reach specified

temperature and the ‘warming-up’ message will also be displayed until this is

accomplished.

While the analyser is warming up, the software configuration to suit the user's particular

requirements may now be accomplished. Proceed to Section 3: Configuration. Note

that during the ‘warming-up’ period, all outputs and alarms are live and fully

operational. All diagnostics are also operational, EXCEPT cell temperature and

chopper box temperature. These last two diagnostics only become operational once

the temperature set points have been reached or after 2 hours (for chopper box) or 10

hours (for cell) have elapsed from power up.

WARNING

Check for no leaks of sample at full operating pressure and temperature before

proceeding. This is especially important for toxic/flammable samples.

At this point, process sample may be turned on and allowed to flow through the 2500

sampling system.

Where the 3rd (sample/inert) solenoid valve is in use (see installation manual), the inert

medium will automatically be supplied to the analyser until the cell reaches correct

temperature.

2.2 General access to analyser functions

It is recommended that the user refers to the menu map (see Figure B) and locates the

function required. Then, using the keypad and display, follow the route as mapped. It

Servomex 2500 Quick Start Manual

10 2500 Series - Configuration and Operation 02500/003E/0

will often be necessary to enter the password.

NOTE

The factory-default password for the 2500 series is ‘2000’ - this must be entered.

Alternatively, if a keyswitch has been fitted this should now be closed. Failure to close

the keyswitch is interpreted as an invalid password, and this should prompt the user to

operate the keyswitch at this point.

NOTE

The ‘up arrow’ (↑) appears at the lower right of the display. This arrow is used

throughout the 2500 software to indicate that more information, or further items for

selection, are available and can be viewed by pressing the ▲ key. A ‘down arrow’ (↓)

means further information in the ▼ direction, and a ‘double headed’ arrow (↕) indicates

more information in either direction.

2.3 Setting passwords

NOTE

If the keyswitch facility is to be used, ignore this section.

Several sections of the 2500 menu are password-protected against unauthorised

changes by a 2-level password system. A lower-level OPERATOR password protects

basic calibration functions, and a high-level SUPERVISOR password protects the

essential configuration functions. The factory default password is ‘2000’ in both cases.

At this stage, new passwords may be selected.

NOTE

•Be sure to record the chosen passwords in a safe place.

•Three consecutive failed attempts at entering a password will cause a fault to be

signalled.

•The numbers can be scrolled round completely using the cursor keys, and the

decimal point (.) and minus sign (-) are included in the character set.

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 11

Go via MENU/SET UP/UTILITY/UTILITY 1 to NEW PASS - Press ENTER

At display screen Operation

SUPERVISOR

OPERATOR

Select required password and press ‘ENTER’

NEW SUPERVISOR

PASS 00 0 0

Use the cursor keys to set the new password,

then press ‘ENTER’

NEW PASS IS NNNN

ACCEPT YES/NO

To confirm new password, press ‘ENTER’

SUPERVISOR

OPERATOR

Select required password and press ‘ENTER’, or

press ‘EXIT’ to finish

2.4 Setting time and date

The 2500 is equipped with a real-time clock and this is capacitor-backed to retain the

time setting for up to 2 days without power. At this stage, it should be set to the correct

local time and date, and the preferred day/month format, in order that all future-timed

operations and historical logs reflect correct local times.

Go via MENU/SET UP/UTILITY/UTILITY 1 to CLOCK - Press ENTER

At display screen

Operation

TIME = 16:15

DATE = 07/03/00

This display will change after 4 seconds to:

CHANGE DATE/TIME

YES/NO Select ‘YES’ or ‘NO’ and press ‘ENTER’

SET CLOCK

SET YEAR 0 0 0 0

Use the cursor keys to set the correct value, then

press ‘ENTER’

SET MONTH 0 0

As above

SET DAY 0 0

As above

SET HOUR 0 0

As above

SET MINUTE 0 0 As above

SELECT FORMAT

DDMMYY/MMDDYY Select format required, then press ‘ENTER’

NOTE

Illegal times/dates outside the range of the clock are not accepted.

Servomex 2500 Quick Start Manual

12 2500 Series - Configuration and Operation 02500/003E/0

3 MAIN CONFIGURATION

3.1 Alarms

There are 4 concentration alarms for each measured component on the 2500 series,

and these are called ‘AL1’, ‘AL2’, ‘AL3’ and ‘AL4’. These must now be set up to suit the

measurement and control needs of the particular installation. Factory default settings

are 70%, 80%, 90% and 100% fsd respectively, and HIGH activation.

Each enabled alarm has four parameters which need to be set up:

i) FREEZE to prevent alarms during calibration, or FOLLOW so that alarms may be

activated by calibration gases.

ii) HIGH concentration alarm or LOW concentration alarm.

iii) The concentration LEVEL at which the alarm is to occur.

iv) The HYSTERESIS (dead band) of the alarm; this may be used to avoid ‘chatter’

if the typical sample concentration is close to the alarm level.

Go via MENU/SET UP to SET ALARM - Press ENTER

At display screen Operation

SELECT COMPONENT

CO2vpm f

(if more than 1

component)

select required component using cursor keys, then press

‘ENTER’

[Measurement]

SELECT AL 1/2/3/4

select required alarm using cursor keys, then press ‘ENTER’

[Measurement] AL1

ENABLE / DISABLE

select required state, then press ‘ENTER’

[Measurement] AL1

FREEZE / FOLLOW

select required state, then press ‘ENTER’

[Measurement] AL1

HIGH / LOW ALARM select required state, then press ‘ENTER’

[Measurement] AL1

LEVEL = 00000 [units] select required value, then press ‘ENTER’

[Measurement] AL1

HYST = 0.0% FSD

select required value, then press ‘ENTER’

[Measurement]

SELECT AL1/2/3/4

select next required alarm using cursor keys, then press

‘ENTER’, or press ‘EXIT’ to set up another component

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 13

3.2 Allocation of relays

Each standard 2500 series analyser has 3 relay outputs, which can now be assigned to

various functions. These relay outputs are given software identity numbers which relate

physically to the particular PCB from which they are provided. The hardware locations

and terminal strip identifiers are given in the installation manual.

Each relay output may be assigned to any combination of the following functions:

i) Any of the concentration alarms for any of the measured components, in any

combination.

ii) Calibration in Progress.

iii) Fault.

Any existing relay allocation may be edited or cleared. When cleared, the relays will

remain non-functional.

NOTES

•The Calibration in Progress function is active whenever a Manual Calibration or

Check, or an Auto calibration or Autocheck routine, is in progress.

•The Fault alarm is active whenever any Fault condition (i.e. parameter out of

tolerance) is detected, except for cell or chopper box temperature during warmup.

•Serious Faults (Shutdown/Measurement withdrawn) will also drive all analogue

outputs HIGH (or LOW, depending on user setting).

•Factory default settings are:

- All concentration alarms

- Calibration in Progress

- Faults

Servomex 2500 Quick Start Manual

14 2500 Series - Configuration and Operation 02500/003E/0

Go via MENU/SET UP/ASSIGN to RELAYS - Press ENTER

At display screen

Operation

SELECT RELAY

1.3 ASSIGNED ↑ or

1.3 UNASSIGNED ↑

Select required relay using cursor keys, then press 'ENTER'

RELAY ASSIGNMENT

1.3 EDIT / CLEAR or

1.3 ASSIGn? Y/N

Select 'EDIT' to edit allocation, or re-assign a cleared relay or

select 'CLEAR' to clear the relay, then press 'ENTER'

1.3 [Measurement] AL1

HI 10.0 % Y/N

Select 'Y' to assign this function to this relay or 'N' to clear the

function, then press 'ENTER'

1.3 [Measurement] AL2

HI 0.0 % Y/N

Select 'Y' to assign this function to this relay or 'N' to clear the

function, then press 'ENTER'

{Cycle through all the

available assignment

options, selecting with 'Y'

or 'N' as required}

Select 'Y' to assign this function to this relay or 'N' to clear the

function, then press 'ENTER'

SELECT RELAY

1.3 ASSIGNED ↑ or

1.3 UNASSIGNED ↑

Select next relay using cursor keys, then press 'ENTER'

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 15

3.3 Analogue outputs

Each standard 2500 series analyser has 2 analogue outputs, which can now be

assigned to the measurement being made. These analogue outputs are given software

identity numbers which relate physically to the particular PCB from which they are

provided. The hardware locations and terminal strip identifiers are given in the

installation manual for each analogue output.

Each analogue output is supplied configured as current but may be set to voltage. This

selection is made as described in the installation manual.

Each analogue output has 2 sets of parameters, one for ‘Range 1’ (normal state) and

one for ‘Range 2’ (engaged when external ‘Range 2’ contact is closed, as specified in

the installation manual).

Each analogue output can be scaled across the whole measurement range of a

component (e.g 0-100% fsd corresponds to 4-20 mA), or a smaller or larger proportion

of the calibrated range. Minimum recommended analogue output range is 5% fsd,

maximum is 200% fsd (i.e. 2x over-range). Factory default is 0-100% fsd for all outputs.

NOTE

•Above 100% fsd, linearity performance may be degraded.

•At minimum (5% fsd) output scaling, i.e. maximum expansion of output, increased

noise may require adjustment of Time Constant (see Section 3.11).

•Upper and lower limits of measurement for each output are entered in actual

concentration units. The lower limit can be non-zero, but cannot be higher than the

upper limit (i.e. reversed outputs not permitted).

The parameters which can be adjusted on the analogue outputs are:

i) LOWER and UPPER range of the output in the units of the measurement

(component).

ii) TRUE or LIVE zero. TRUE zero = 0 to 20 mA and LIVE zero = 4 to 20 mA.

iii) FREEZE to prevent alarms during calibration or FOLLOW so that alarms may be

activated by calibration gases.

Each of these parameters can also be independently set for range 2, if required.

LOWER and UPPER example:

2500 First Component Calibrated 0-20% CO2

Default analogue output range:

(4-20 mA) corresponds to (0-20% CO2)

Minimum output range:

(4-20 mA) corresponds to (0-1% CO2)

Maximum output range:

(4-20 mA) corresponds to (0-40% CO2*)

(* = approx)

Servomex 2500 Quick Start Manual

16 2500 Series - Configuration and Operation 02500/003E/0

The analogue identity (in this case ‘1.1’) appears lower left, and the current status

(ASSIGNED OR UNASSIGNED) next to it. All are initially ASSIGNED in the factory to

the measurements in logical order, one analogue per measurement.

Go via MENU/SET UP/ASSIGN to ANALOGUE - Press ENTER

At display screen

Operation

SELECT ANALOGUE

1.1 ASSIGNED ↑ OR

1.1 UNASSIGNED ↑

Select required analogue output using cursor keys, then press

‘ENTER’

ANALOGUE

ASSIGNMENT 1.3 EDIT /

CLEAR OR

1.3 ASSIGN? Y/N

Select ‘EDIT’ to edit allocation, or re-assign a cleared relay

OR select ‘CLEAR’ to clear the relay, then press ‘ENTER’

SELECT COMPONENT

CO2vpm t

(if more than 1

component)

Select component to be assigned to this analogue output

using cursor keys, then press ‘ENTER’

1.1 [Measurement] R1

L=00.0 U=20.0

Select Lower and Upper limits for the output and press

‘ENTER’

1.1 [Measurement] R1

TRUE 0 / LIVE 0

Select required state, then press ‘ENTER’

1.1 [Measurement] R1

FREEZE / FOLLOW

Select required state, then press ‘ENTER’

1.1 [Measurement] R2

L= 00.0 U=20.0

Repeat above process for range R2

SELECT ANALOGUE

1.1 ASSIGNED ↑ OR

1.1 UNASSIGNED ↑

Select another analogue output using cursor keys, then press

‘ENTER’

3.4 Defining and selecting measurement display screen

The window menu enables the user to display the measurement value and measured

component in the preferred format for the (default) measurement display.

Go via MENU/SET UP/UTILITY/UTILITY 1 to WINDOW - Press ENTER

At display screen

Operation

SELECT SCRN /

UDEF DEFINE SCRN

/ VARS

Select required function using cursor keys, then press ‘ENTER’

SELECT SCRN is used to display the required measured components on the display.

AUTOSCROLL is used on multi component analysers only, and is used to show all

measured components in a continuous circular scroll.

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 17

If SINGLE display is selected, the name of a chosen measured component appears on

the top line and the measurement value on the bottom line.

The SPLIT display is used on multi component analysers only, and is used to show two

measured components at a time.

UDEF is used to select the required displayed chemical name, chemical formula and

engineering unit, e.g. carbon dioxide, CO2, vpm.

DEFINE SCREEN is used on multi component analysers only, and is used to specify

the sequence order in which the measured components are displayed.

VARS is used to set the number of displayed digits (DECIMAL POINTS) appearing

after the decimal point in the measurement value. This is adjustable between values of

0 to 3.

3.5 Communication Options

A standard 2500 provides RS232 serial communications. If specified, the analyser may

be fitted with additional hardware to allow digital communications using either Modbus

over RS485 or Modbus TCP over Ethernet. If either option is fitted the RS232 output is

no longer available.

The 2500 menu system displays all communication options but for correct operation

the selection must match the analyser hardware. The following table lists the options.

Go via COMMS to SET COMMS MODE - Press ENTER

At display

screen

Operation

Analyser Option

NONE

OR

Select required

option using cursor

keys, then press

‘ENTER’

Any

RS232

OR

Standard

MODBUS

OR

ASCII

02500912 Communications Board RS485

MODBUS

OR

RTU

02500912 Communications Board RS485

ETHERNET

02500913 Communications Board Ethernet

NONE disables all digital communications.

RS232 enables the serial output and print functions. See section 3.7 for further details.

Modbus ASCII enables this protocol using the RS485 interface on the 02500912

Communication Board (if fitted).

Modbus RTU enables this protocol using the RS485 interface on the 02500912

Communication Board (if fitted).

Servomex 2500 Quick Start Manual

18 2500 Series - Configuration and Operation 02500/003E/0

Ethernet enables Modbus TCP communication using Ethernet interface on the

02500913 Communication Board (if fitted)

WARNING

Do not use an uncertified DCS, dilatator, printer or other external equipment in a

Hazardous Area.

3.6 Communication Setup

When the communication mode has been selected as described in section 3.5, it may

be configured using the SET COMMS PARMS menu. Note that this menu is only

displayed if the communication mode is not NONE.

The configuration options displayed are specific to the selected communication mode

and are described in the following sections.

3.7 RS232

The RS232 option uses the following fixed configuration.

BAUD rate: 2400

PARITY: EVEN

STOP BITS: 1

DATA BITS: 8

HANDSHAKE: HARDWARE

Any device intended for connection to the 2500 must be capable of serial RS232

communication and be configured with these settings.

Entering the RS232 menu displays further options.

SERIAL

This option configures the analyser to transmit serial data frames at user configurable

time intervals. For connection details and signal interpretation, refer to the installation

manual.

Go via MENU/COMMS/SET COMMS PARMS to SERIAL - Press ENTER

At display screen

Operation

FRAME PERIOD =

00s

Select required value using cursor keys, then press ‘ENTER’. A

zero value will disable transmission.

PRINT

The PRINT MENU is only displayed if the FRAME PERIOD under the SERIAL menu is

set to zero. It is provided to enable the user to download hard copy records of the

2500’s Identity (ID), current history logs (Alarm, Fault and calibration histories) and

complete SET-UP information. Any printer must have at least 80 column width.

Go via MENU/COMMS/SET COMMS PARMS to PRINT - Press ENTER

Servomex 2500 Quick Start Manual

2500 Series - Configuration and Operation 02500/003E/0 19

At display screen

Operation

SYSTEM SET-UP OR

IDENTITY OR

HISTORY

Select required value then press ‘ENTER’

Servomex 2500 Quick Start Manual

20 2500 Series - Configuration and Operation 02500/003E/0

3.8 MODBUS ASCII

This section details the analyser configuration that is displayed when the

communications mode is set to MODBUS ASCII. This should be adjusted as necessary

to match the requirements of the Modbus network to which the analyser is connected.

Go via MENU/COMMS to SET COMMS PARMS - Press ENTER

At display screen

Operation

MODBUS ADDRESS =

247

Select required value from 1 to 247 and press ‘ENTER’

SELECT STOP 1 / 1.5 /

2

Select required value and press ‘ENTER’

SELECT DATA BITS 8 /

7

Select required value and press ‘ENTER’

SELECT PARITY EVEN

/ ODD / NONE

Select required value and press ‘ENTER’

SELECT BAUD RATE

9K6 / 4K8 / 2K4 / 19K2 Select required value and press ‘ENTER’

3.9 MODBUS RTU

This section details the analyser configuration that is displayed when the

communications mode is set to MODBUS RTU. This should be adjusted as necessary

to match the requirements of the Modbus network to which the analyser is connected.

3.10 ETHERNET

This section details the analyser configuration that is displayed when the

communications mode is set to ETHERNET. This should be adjusted as necessary to

match the requirements of the network to which the analyser is connected.

Go via MENU/COMMS to SET COMMS PARMS - Press ENTER

At display screen

Operation

IP ADDRESS =

000.000.000.000

Select required value and press ‘ENTER’

SUBNET MASK =

000.000.000.000

Select required value and press ‘ENTER’

GATEWAY ADDRESS =

000.000.000.000

Select required value and press ‘ENTER’

Note that the SUBNET MASK value is automatically set to the appropriate default

value whenever an IP address is entered that falls into a different class. This may be

altered as required.

This manual suits for next models

1

Table of contents

Other Servomex Analytical Instrument manuals

Servomex

Servomex DF-150E User manual

Servomex

Servomex NanoTrace DF-760E User manual

Servomex

Servomex DF-310E User manual

Servomex

Servomex 2700 User manual

Servomex

Servomex SERVOPRO k2001 User manual

Servomex

Servomex SERVOPRO Chroma User manual

Servomex

Servomex xendos 1800 Series User manual

Servomex

Servomex SERVOPRO 4900 User manual

Servomex

Servomex 700B User manual