1

General information

About this documentation

Addendum to the Operating Instructions – CBG22A 3

1 General information

1.1 About this documentation

The documentation at hand is the original.

This documentation is an integral part of the product. The documentation is intended

for all employees who perform work on the product.

Make sure this documentation is accessible and legible. Ensure that persons respon-

sible for the systems and their operation as well as persons who work on the product

independently have read through the documentation carefully and understood it. If you

are unclear about any of the information in this documentation or if you require further

information, contact SEW‑EURODRIVE.

1.2 Other applicable documentation

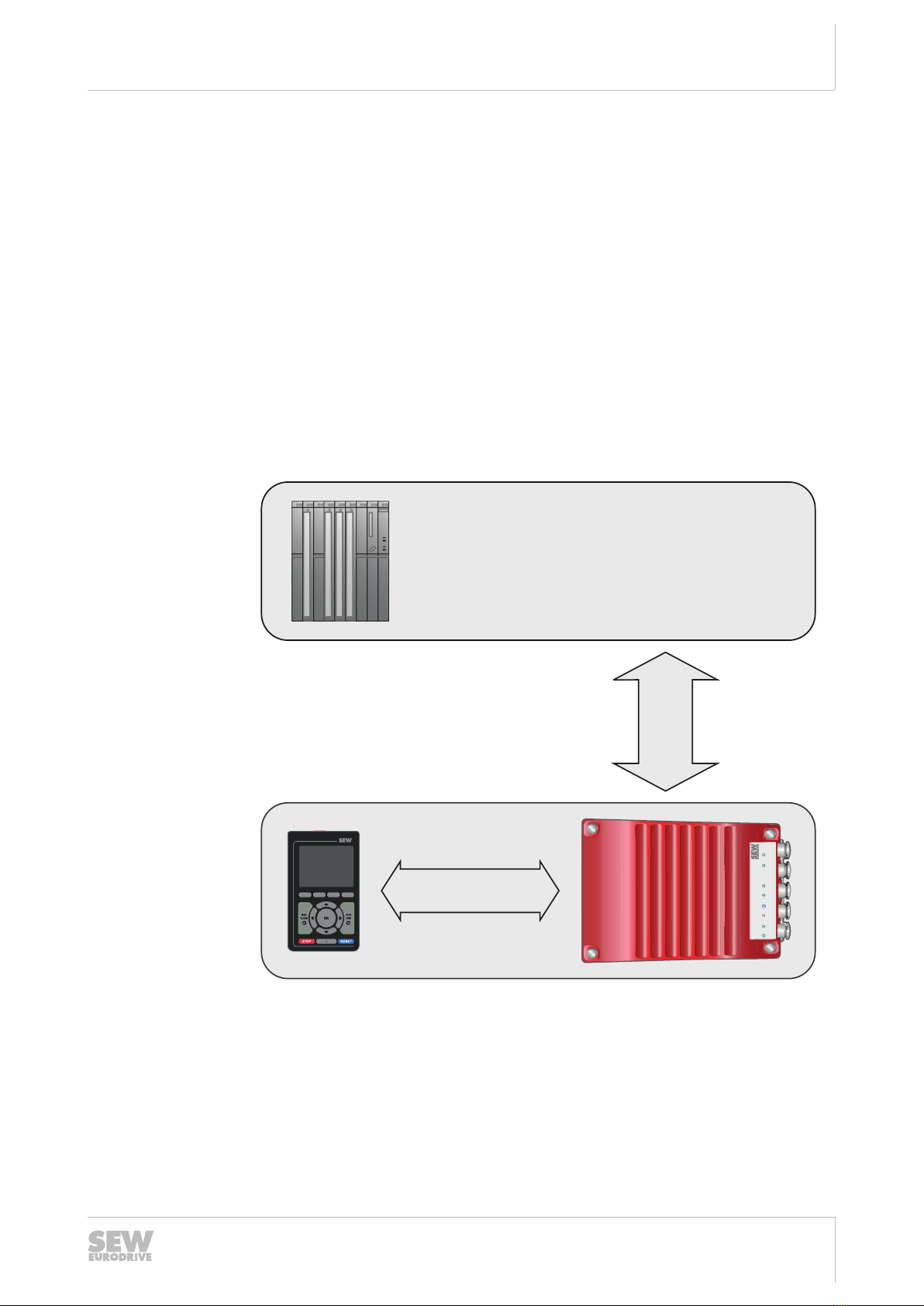

This documentation supplements the operating instructions of the associated product.

Use this document only in connection with the operating instructions.

Always use the latest edition of the documentation and the software.

The SEW‑EURODRIVE website (www.sew‑eurodrive.com) provides a wide selection

of documents for download in various languages. If required, you can also order prin-

ted and bound copies of the documentation from SEW‑EURODRIVE.

1.3 Structure of the safety notes

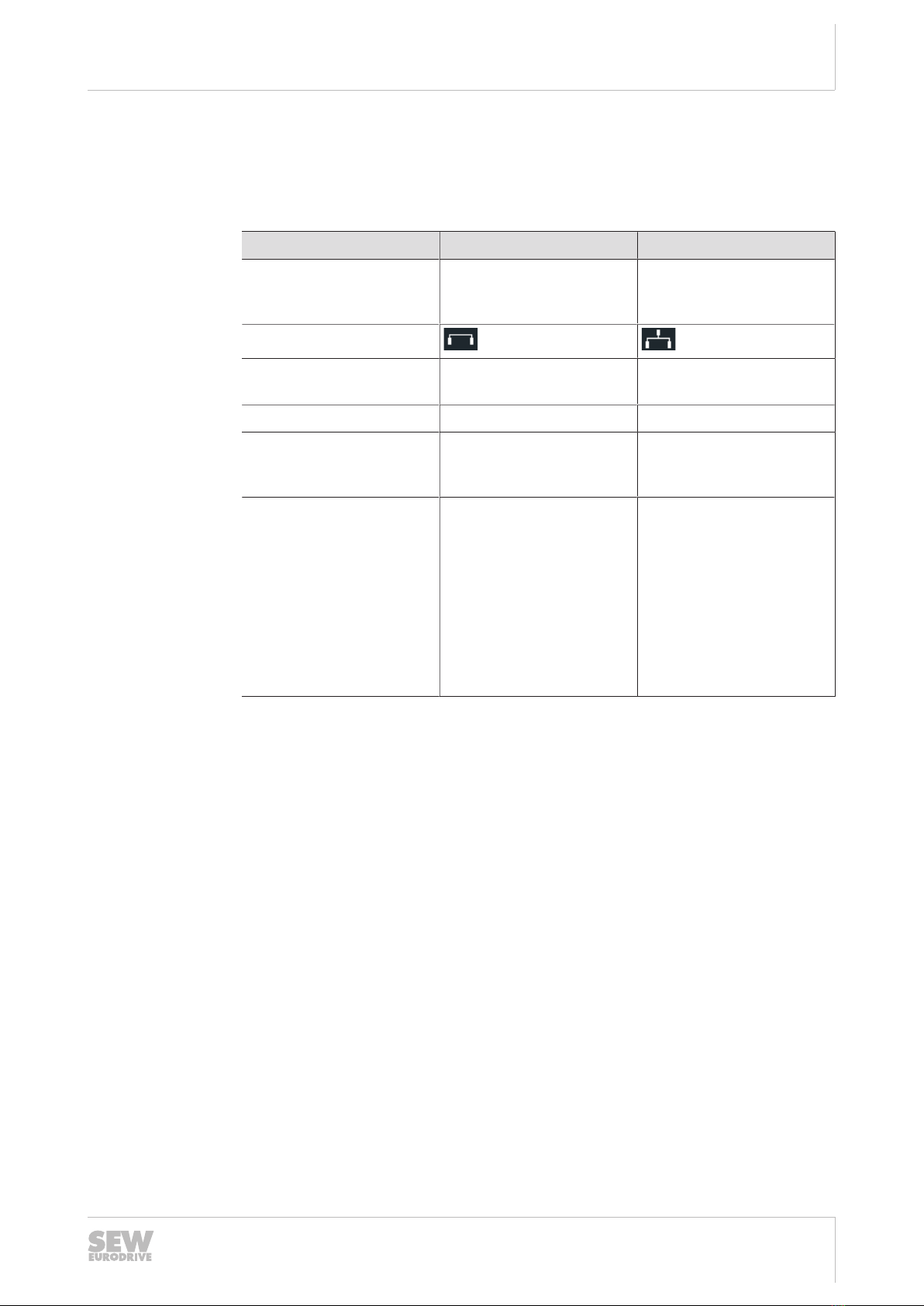

1.3.1 Meaning of signal words

The following table shows the grading and meaning of the signal words for safety

notes.

Signal word Meaning Consequences if disregarded

DANGER Imminent hazard Severe or fatal injuries

WARNING Possible dangerous situation Severe or fatal injuries

CAUTION Possible dangerous situation Minor injuries

NOTICE Possible damage to property Damage to the product or its envi-

ronment

INFORMATION Useful information or tip: Simplifies

handling of the product.

1.3.2 Structure of section-related safety notes

Section-related safety notes do not apply to a specific action but to several actions

pertaining to one subject. The hazard symbols used either indicate a general hazard

or a specific hazard.

26864967/EN – 03/2021