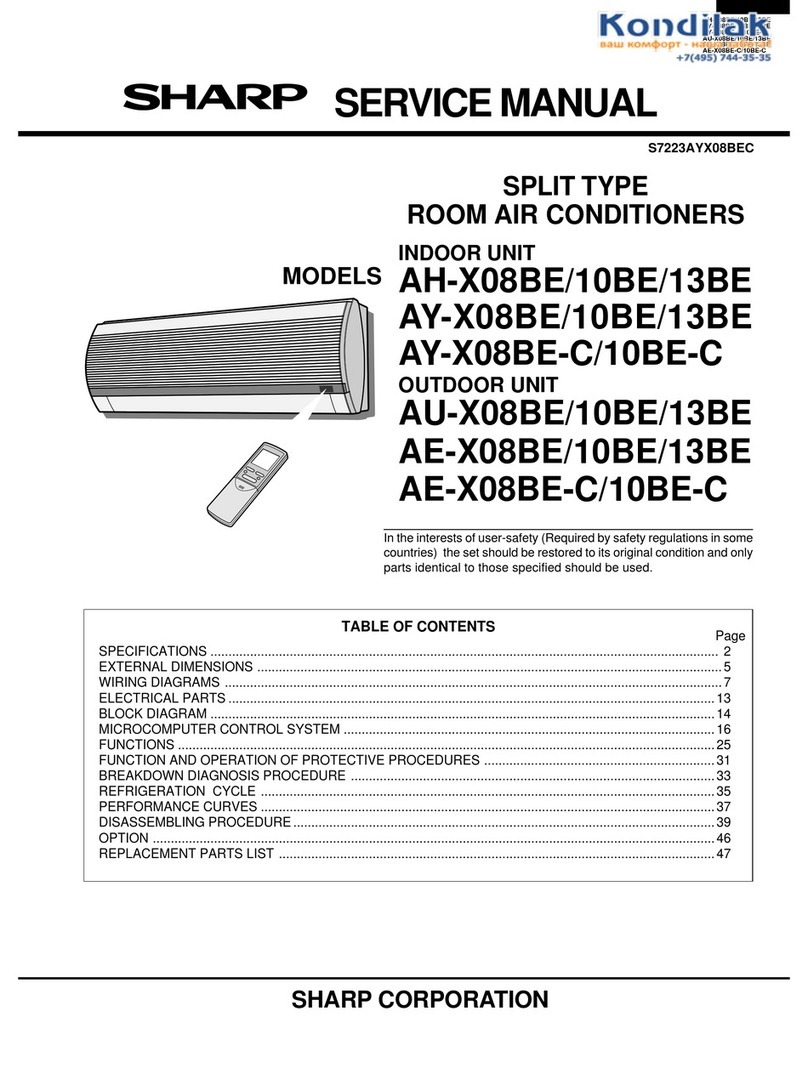

Sharp AU-MP14 User manual

Other Sharp Air Conditioner manuals

Sharp

Sharp AH-X08BE User manual

Sharp

Sharp AY-XM28MCJ User manual

Sharp

Sharp Plasmacluster AE-X12JJ User manual

Sharp

Sharp AY-S2592 User manual

Sharp

Sharp AY-X28MCJ User manual

Sharp

Sharp AE-X127J User manual

Sharp

Sharp AH-X079E User manual

Sharp

Sharp Plasmacluster AE-X12FR User manual

Sharp

Sharp UL-C09EA-W User manual

Sharp

Sharp GX-X18SCR User manual

Sharp

Sharp AH-X127E User manual

Sharp

Sharp AE-X099J User manual

Sharp

Sharp AH-XP10UXD User manual

Sharp

Sharp AH-AP5JHL User manual

Sharp

Sharp AY-AP9KR User manual

Sharp

Sharp GS-XP9FGR User manual

Sharp

Sharp AF-08ERL User manual

Sharp

Sharp AY-XP07ER User manual

Sharp

Sharp CV-P09LX User manual

Sharp

Sharp AY-XP24PU User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions