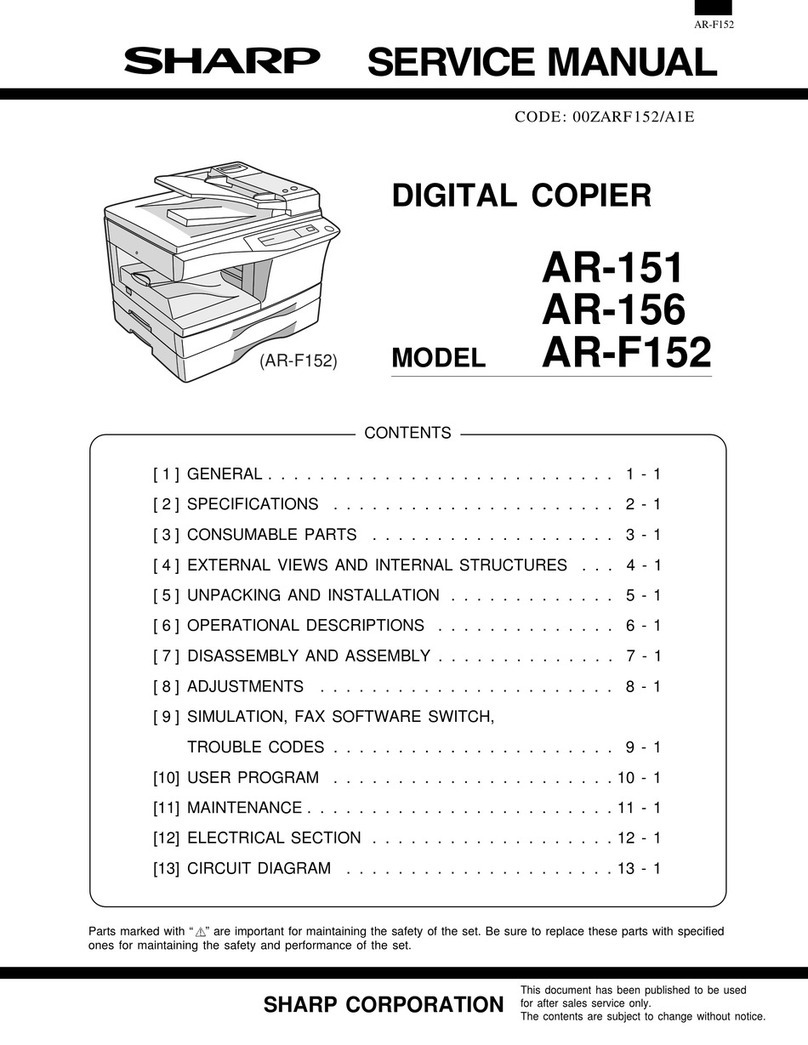

[1] GENERAL

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

2. Target User Copy Volume. . . . . . . . . . . . . . . . . . . . . . . . 1-1

3. Main features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(1) High-speed laser copying . . . . . . . . . . . . . . . . . . . . 1-1

(2) High-quality digital image. . . . . . . . . . . . . . . . . . . . . 1-1

(3) Substantial copying functions . . . . . . . . . . . . . . . . . 1-1

4. Environmental

(1) Normal operating condition . . . . . . . . . . . . . . . . . . . 1-1

(2) Acceptable condition . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(3) Optional condition . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

(4) Supply storage condition . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Operation specification . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

3. Copy performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

4. Others . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

[3] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Production control number (lot No.)identification. . . . . . . 3-1

[4] EXTERNAL VIEWS AND INTERNAL STRUCTURES

1. Appearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

2. Operation panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

3. Internal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

4. Motors and solenoids . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

5. Sensors and switches . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

6. PWB unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

7. Cross sectional view . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

[5] UNPACKING AND INSTALLATION

1. A WORD ON COPIER INSTALLATION . . . . . . . . . . . . . 5-1

2. CHECKING PACKED COMPONENTS AND

ACCESSORIES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

3. UNPACKING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

4. REMOVING PROTECTIVE PACKING MATERIAlS . . . . 5-2

5. INSTALLING THE TD CARTRIDGE . . . . . . . . . . . . . . . . 5-2

6. LOADING COPY PAPER (installing the paper tray) . . . . 5-3

7. PLUGGING IN THE COPIER . . . . . . . . . . . . . . . . . . . . . 5-3

[6] PRINTING PROCESS

(1) Functional diagram . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

(2) Outline of print process . . . . . . . . . . . . . . . . . . . . . . 6-2

(3) Actual print process . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

[7] OPERATIONAL DESCRIPTIONS

(1) Outline of operation . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

(2) Scanner section. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

(2) Laser Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Fuser section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Paper feed section and paper transport section. . . . . . . . . . . 7-5

Process unit new drum detection mechanism . . . . . . . . . . . . 7-8

[8] DISASSEMBLY AND ASSEMBLY

1. High voltage section . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Operation panel section. . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

3. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

4. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

5. Tray paper feed/transport section . . . . . . . . . . . . . . . . . . 8-7

6. Manual paper feed section. . . . . . . . . . . . . . . . . . . . . . . 8-12

7. Rear frame section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-16

8. Power section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-17

[9] ADJUSTMENTS

1. Optical section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

(1) Image distortion adjustment. . . . . . . . . . . . . . . . . . . 9-1

(2) Copy magnification ratio adjustment . . . . . . . . . . . . 9-4

(3) Lens unit attachment reference . . . . . . . . . . . . . . . . 9-6

(4) Image position adjustment. . . . . . . . . . . . . . . . . . . . 9-7

2. Copy density adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

(1) Copy density adjustment timing . . . . . . . . . . . . . . . . 9-8

(2) Note for copy density adjustment. . . . . . . . . . . . . . . 9-8

(3) Necessary tool for copy density adjustment. . . . . . . 9-8

(4) Features of copy density adjustment . . . . . . . . . . . . 9-9

(5) Copy density adjustment procedure. . . . . . . . . . . . . 9-9

3. High voltage adjustment . . . . . . . . . . . . . . . . . . . . . . . . 9-10

(1) Main charger (Grid bias)

(2) DV bias adjustment . . . . . . . . . . . . . . . . . . . . . . . . 9-10

[10] SIMULATION , TROUBLE CODES

1. Entering the simulation mode . . . . . . . . . . . . . . . . . . . . 10-1

2. List of simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

3. Contents of simulations . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

4. Trouble codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

[11] USER PROGRAMS

Function which can be set with the user program. . . . . . . . . 11-1

Charge the setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. Circuit descriptions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

A. Main PWB(MCU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

(1) CPU signal table . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

(2) ASIC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-6

(3) Reset circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

(4) Heater lamp control circuit . . . . . . . . . . . . . . . . . . 12-14

(5) Driver circuit (solenoid). . . . . . . . . . . . . . . . . . . . . 12-15

(6) Toner supply motor drive circuit. . . . . . . . . . . . . . 12-15

(7) Main motor drive circuit . . . . . . . . . . . . . . . . . . . . 12-15

(8) Mirror motor circuit . . . . . . . . . . . . . . . . . . . . . . . . 12-16

(9) Power circuit block diagram . . . . . . . . . . . . . . . . . 12-17

(10) CI invertor PWB (circuit). . . . . . . . . . . . . . . . . . . 12-20

(11) CCD PWB operational description. . . . . . . . . . . 12-20

Operation section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-21

[13] CIRCUIT DIAGRAM

AC INTERLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

MCU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

OPU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-8

POWER SUPPLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-9

ACTUAL WIRING DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . 13-10

CONTENTS

AL-1000/1010