[1] GENERAL

The AR-207 is a revised model of the AR-206 with the E-sort PWB

and RSPF. For the E-sort PWB, refer to the service manual of the

AR-EB3, and for the RSPF the service manual of the AR-RP1.

The AR-F201 is a revised model of the AR-201 with the FAX function.

For the FAX section, refer to the AR-FX2 Service Manual, for the SPF

the AR-SP2 Service Manual, and for the LCD panel the AR-PA1

Service Manual.

1. Note for servicing

Pictogram

This Service Manual uses some pictographs to assure safe opera-

tion.

Please understand the meanings of pictographs before servicing.

WARNING: If this WARNING is ignored, serious injury or death

could occur.

CAUTION: If this CAUTION is ignored, an injury or damage to

property could occur.

A. Warning for servicing

1) Be sure to use the rated voltage and the rated current specified on

the rating label. Avoid complex wiring. It may cause a fire.

2) If smoke or abnormal smell occurs, stop servicing and disconnect

the power plug. It may cause a fire.

3) Be sure to set the ground wire. If not, a fire or an electric shock

may occur. The ground wire is required also for protecting the

machine from lightning.

4) If the ground wire is connected to the following places, an ex-

plosion, fire, or electric shock could result. Be sure to avoid it.

•Gas pipe

•Lightning conductor

•Water pipe (which is not approved as a ground pipe by the

authority), water faucet

•Ground wire for telephone

5) Do not cut or modify the power cord.

Do not put a weight on the power cord. Do not bend or pull it

extremely. These actions could result in fire.

6) Keep the power cord away from a heater or a heated material.

Remove dust from the power plug. If the power plug with dust on

it should be inserted into the power outlet, it may cause a fire or

an electric shock.

7) Do not put a container with water in it, or a small piece of metal on

the machine. If water or a metal piece would drop inside the

machine, it could cause a fire or an electric shock.

8) When touching the power plug, inserting/removing the telephone

line connector, or operating the machine, be sure to dry and clean

your hands to prevent against an electric shock.

B. Cautions for servicing

1) Except when in a communication test or other unavoidable situa-

tions, be sure to disconnect the power plug, the printer cable, the

network cable, and the telephone line from the machine when

servicing.

2) There are several heated areas in the machine, which can cause

a burn if touched. Use great care when servicing.

3) There are some high voltage sections in the machine, which may

cause an electric shock. Use great care when servicing.

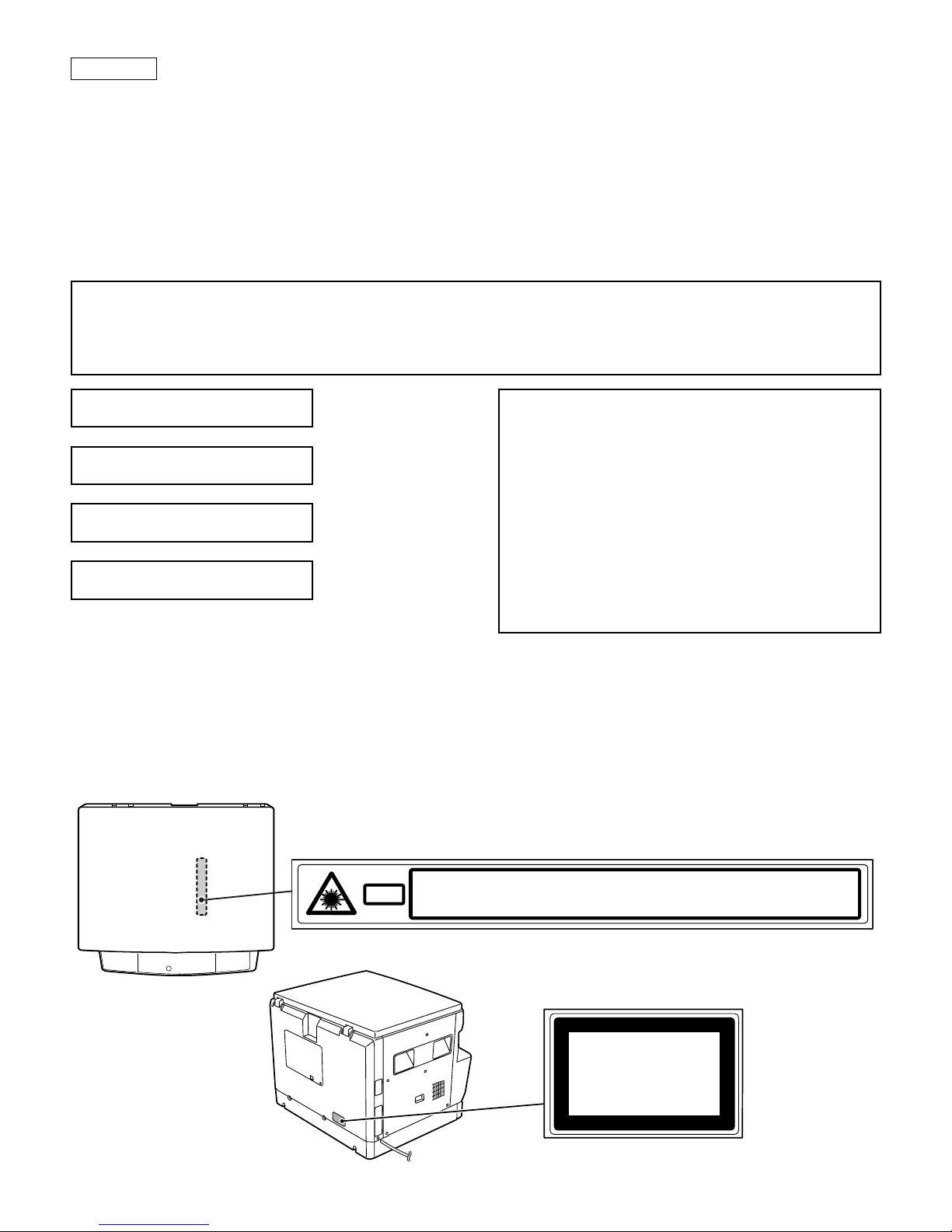

4) Do not disassemble the laser unit. Do not insert a screwdriver or

other reflecting material in the laser path. Reflected laser beam

can cause injury to your eyes.

5) When servicing with the machine operating, use great care not get

caught by chain, belt, gear, of other driving sections.

6) Do not leave the machine with the cabinet removed. If any other

person than the serviceman would touch the machine, he or she

could be injured by fire or electric shock.

7) Be careful to protect your eyes from toner, developing agent, and

ink. Be careful not to inhale them.

If toner, developing agent, or ink should enter your eyes, wash

them with water and consult a doctor if necessary.

8) There are some sharp edges in the machine. Be careful not to

injure your fingers when servicing.

9) Do not put toner or waste toner or a container with toner or waste

toner from the copier into a fire.

10)When replacing the lithium battery attached to the PWB, be sure

to use the one specified. If the specification of the battery is not

the one spcified, the battery may explode causing a breakdown or

malfunction of the machine.

11)When carrying a part of the unit with a PWB or an electronic part,

be sure to put it in an anti-static-electricity bag. Otherwise a break-

down or malfunction may occur.

C. Note for installation place

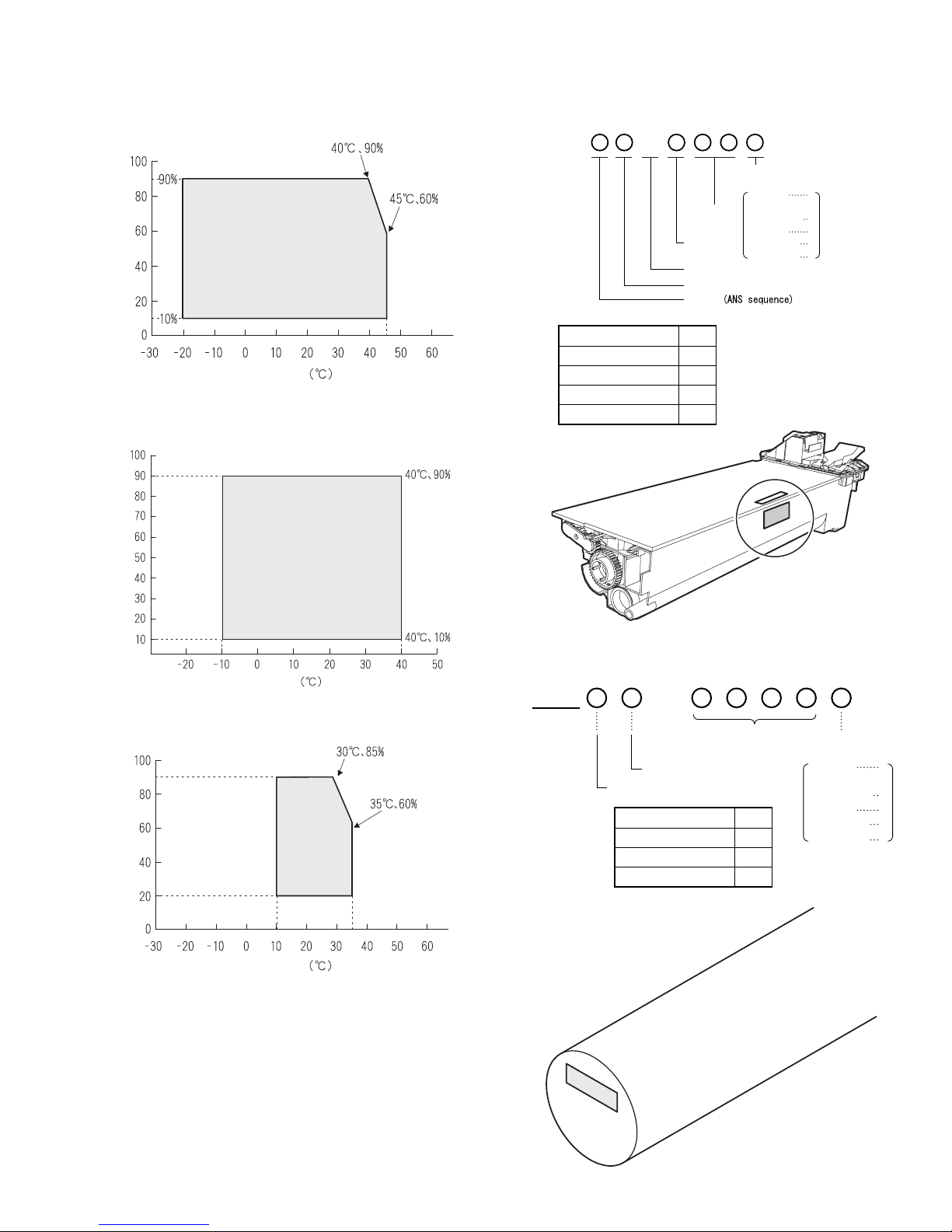

The machine performances depend on the environmental conditions

of the installation areas. Avoid installation in the following areas:

1) Avoid high temperature, high humidity, low temperature, low

humidity.

Avoid areas subject to a rapid change in temperature and

humidity.

If installed in such a place, paper may be dampened and conden-

sation may form inside the machine, causing paper jam or dirty

copy. For use and storage of the machine, refer to the specifica-

tions described below.

2) Avoid areas with excessive vibration. It may cause a breakdown

of the machine.

3) Avoid a poorly ventilated area.

This machine uses the static electricity copy process, ozone is

generated in the machine. The quantity of ozone generated is

designed to a harmless level. If, however, the machine is used

continuously in a poorly ventilated place, there may be a smell of

ozone. Therefore install the machine in a well-ventilated area.

4) Avoid area with direct sunlight.

Direct sunlight may deform plastic parts or discolor and spoil

toner, causing dirty copy or a breakdown of the machine.

5) Avoid area with ammonium or organic gases.

This machine which uses an organic photoconductor (OPC) drum,

the drum may be damaged by ammonium or organic gases.

Avoid installation near a diazo type copier. It may cause dirty copy

or a breakdown of the machine.

6) Avoid a dusty area.

If dust enters the machine, it may cause dirty copy or a break-

down of the machine.

7) Avoid installation near a wall.

Some machines have an exhaust and intake vent. If the exhaust

or intake is obstructed, it may cause dirty copy or a breakdown of

the machine.

8) Avoid installation on an unstable surface. The machine could drop

or tip over causing an injury or a breakdown of the machine. If the

paper feed desk or an option desk is available, it is advisable to

use it. When using an option desk, be sure to fix the adjusters on

the floor and lock the casters.

AR-162 [1] SPECIFICATIONS 11/21/2000

AR-162 GENERAL – 1