5) The current correction value is displayed on the display section in

two digits.

6) Enter the set value, and press the START key.

The entered correction value is stored and a copy is made.

7) Change the duplex document mode to the simplex document

mode.

The MANUAL lamp lights up, and the current correction value of

the back surface sub scanning direction magnification ratio is dis-

played on the display section in two digits.

8) Enter the set value, and press the SATART key.

The entered correction value is stored and a copy is made.

<Adjustment specifications>

Mode Spec SIM Set value Set range

Magnification ratio adjustment Normal: ±1.0% SIM 48-1

4: SPF surface magnification ratio adjustment

5: SPF back magnification ratio adjustment

Add 1: 0.1% increase

Reduce 1: 0.1% decrease 1 ~ 99

(3) RSPF document off center adjustment

Note: When performing this adjustment, check that the paper off-

center is properly adjusted.

1) Set the center position adjustment test chart (made by yourself) on

the RSPF.

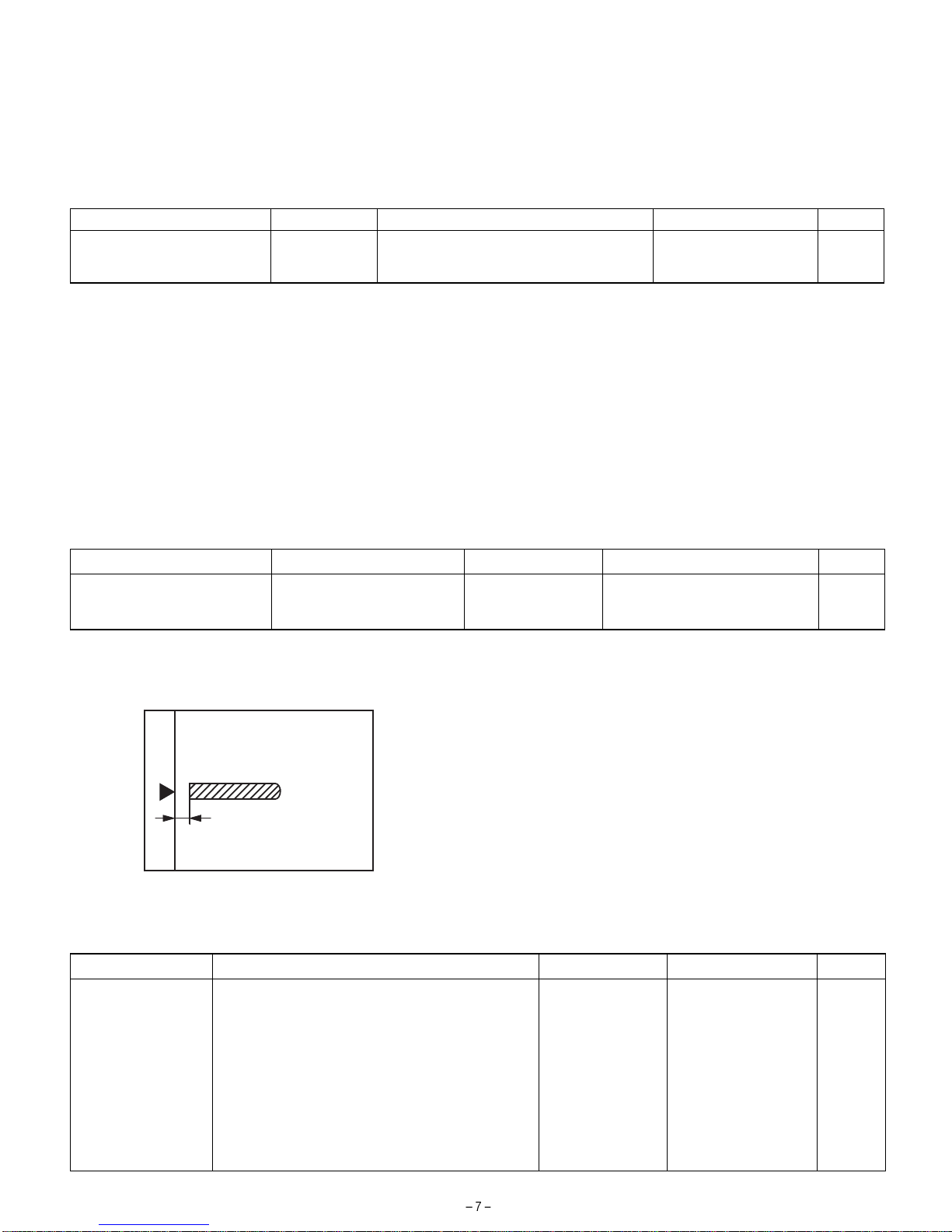

<Adjustment specifications>

Draw a line in the center of paper. (In the scanning direction)

2) Make a normal copy from the manual feed tray, and compare the

copy and the test chart.

If an adjustment is required, perform the following procedures.

3) Execute SIM 50-12.

4) The current off-center adjustment value is displayed on the display

section in two digits.

5) Enter the set value and press the START key.

The entered correction value is started and a copy is made.

<Adjustment specifications>

Mode Specification SIM Set value Set range

Document off-center (RSPF

mode) Simplex: Center ±3.0mm

Duplex: Center ±3.5mm SIM 50-12

2: SPF surface

3: SPF back

Add 1: 0.1mm shifted to R side.

Reduce 1: 0.1mm shifted to L side. 1 ~ 99

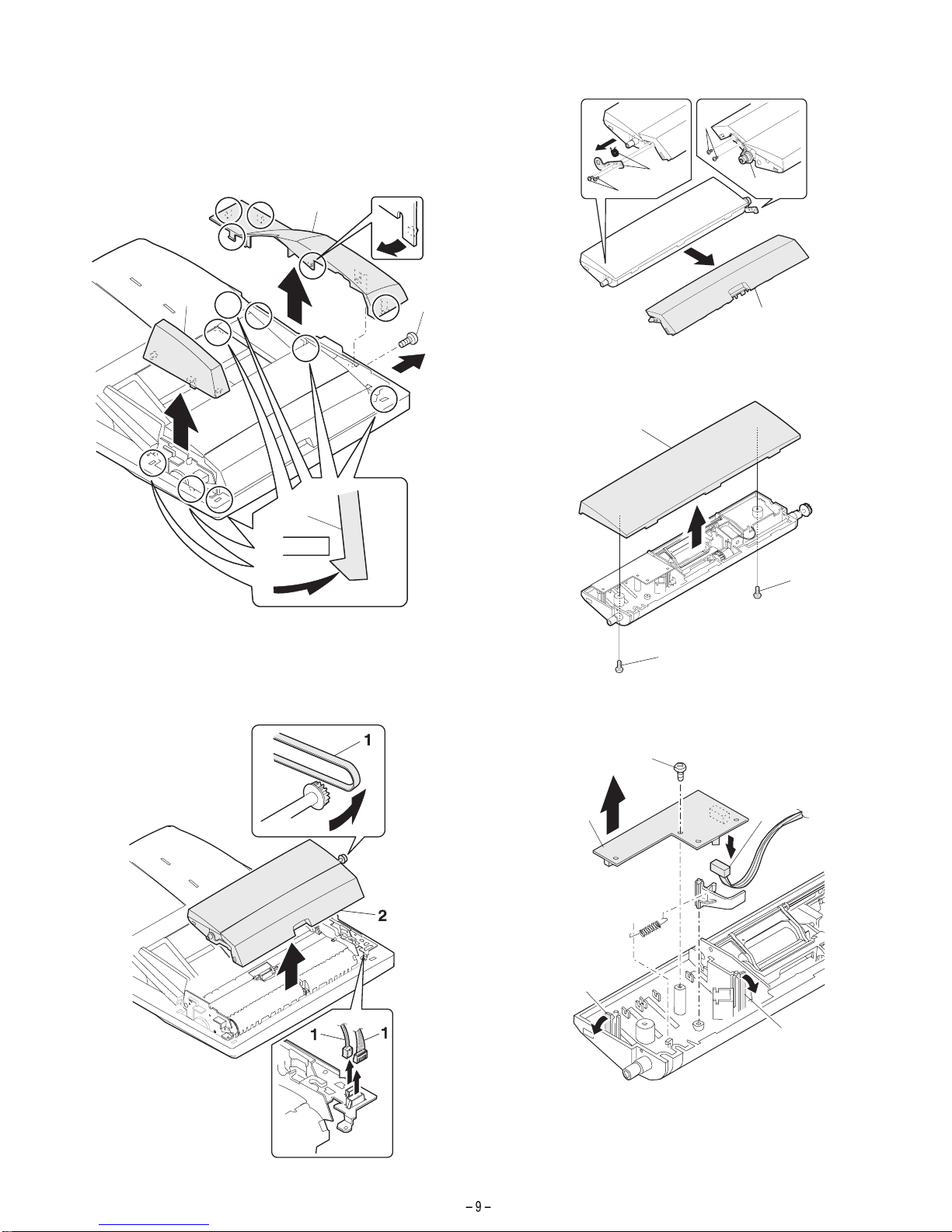

(4) RSPF image lead edge position adjustment

1) Set a scale on the OC table as shown below. 2) Make a copy, and use the copied paper as the document and

make a copy from RSPF again.

3) Check the copied paper. If an adjustment is required, perform the

following procedures.

4) Execute SIM 50-6.

5) Set the SPF lead edge position set value (Exposure display

<MANUAL> ON) so that the image similar to the adjusted image at

the OC image lead edge position described previously is printed.

<Adjustment specifications>

Adjustment mode SIM Set value Specification Set range

RSPF image lead edge

position SIM 50-6

1: Surface document scan start position adjustment value

2: Back document scan start position adjustment value

3: Rear edge void adjustment value (SPF)

4: Surface image loss set value

5: Back image loss set value

6: Surface rear edge image loss set value

7: Back rear edge image loss set value

8: RRC cancel adjustment value (Back of the machine)

9: memory reverse position adjustment value

10: Duplex left edge void adjustment value

1step: 0.127mm shift Lead edge void: 1 ~ 4mm

Image loss: 3mm or less 1 ~ 99

Note: Since the printed paper is used as the test chart,

place the scale in parallel to both sides.