0-5

CONTENTS

OPERATION MANUALS.................................................0-1

INSTALLATION REQUIREMENTS.................................0-2

●Moving this machine ....................................................0-3

CAUTIONS......................................................................0-4

CONTENTS ....................................................................0-5

CHAPTER 1

BEFORE USING THE PRODUCT

INTRODUCTION.............................................................1-2

MAIN FEATURES ...........................................................1-3

PART NAMES AND FUNCTIONS ..................................1-4

●Exterior ........................................................................1-4

●Interior..........................................................................1-5

●Part names and functions of peripheral devices..........1-6

●Operation panel ...........................................................1-8

CHAPTER 2

MANAGING THE MACHINE

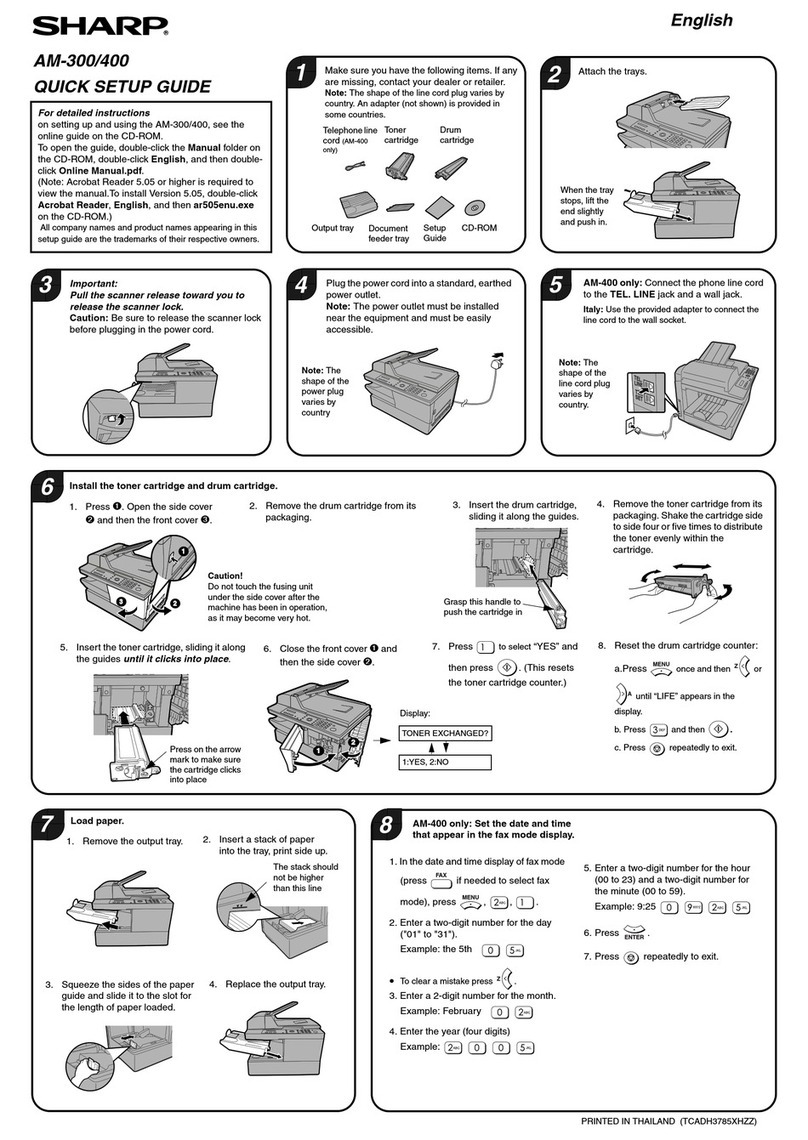

LOADING PAPER...........................................................2-2

●Tray numbers...............................................................2-2

●Loading paper in paper tray 1......................................2-2

●Changing the paper size in paper tray 1......................2-3

●Loading paper in the bypass tray.................................2-4

●Loading paper in the stand/1 x 500 sheet paper

drawer/stand/3 x 500 sheet paper drawer ...................2-7

●Specifications (stand/1 x 500 sheet paper drawer/

stand/3 x 500 sheet paper drawer) ..............................2-7

●Loading paper in the duplex module/2 x 500 sheet

paper drawer................................................................2-8

●Specifications (duplex module/2 x 500 sheet paper

drawer).........................................................................2-8

●Specifications of paper trays........................................2-9

●Structure of the tray setting menu (except for the

bypass tray) ...............................................................2-11

●Setting the paper type (except for the bypass tray) ...2-12

●

Specifying the size when the paper size is set to "Extra"

(except for the bypass tray)

.........................................2-13

●Structure of the bypass tray setting menu .................2-14

●

Setting the paper type and paper size in the bypass tray

...2-15

CUSTOM SETTINGS....................................................2-17

●Basic procedure for custom settings..........................2-17

●Structure of the custom settings menu ......................2-18

●Setting items ..............................................................2-19

REPLACING THE TONER CARTRIDGES ...................2-20

STORAGE OF SUPPLIES ............................................2-22

CLEANING THE CABINET ...........................................2-22

MISFEED REMOVAL....................................................2-23

●Misfeed in the paper feed area ..................................2-24

●

Misfeed in the transport area, fusing area, and exit area

....2-25

●Misfeed in the stand/1 x 500 sheet paper drawer......2-26

●Misfeed in the stand/3 x 500 sheet paper drawer......2-26

●

Misfeed in the duplex bypass/inverter unit and duplex

module/2 x 500 sheet paper drawer............................ 2-27

TROUBLESHOOTING ..................................................2-29

CHAPTER 3

OPERATION CONDITION SETTINGS

CONFIGURING THE OPERATION CONDITION

SETTINGS...................................................................... 3-2

●

Basic procedure for operation condition settings (settings

that can be configured from the operation panel)

........... 3-2

●Structure of the operation conditions menu ................ 3-3

●Default settings ........................................................... 3-4

●PCL settings................................................................ 3-5

●Print PS errors............................................................. 3-6

CHAPTER 4

PRINTING FROM THE OPERATION

PANEL

HOLD JOB LIST

.............................................................. 4-2

CHAPTER 5

PERIPHERAL DEVICES

SADDLE STITCH FINISHER ......................................... 5-2

●Part names.................................................................. 5-2

●Specifications .............................................................. 5-2

●

Staple cartridge replacement and staple jam removal

.. 5-4

●Misfeed in the saddle stitch finisher ............................ 5-7

LARGE CAPACITY TRAY.............................................. 5-9

●Part name.................................................................... 5-9

●Specifications .............................................................. 5-9

●Loading paper ........................................................... 5-10

●Misfeed removal........................................................ 5-11

CHAPTER 6

SPECIFICATIONS

SPECIFICATIONS.......................................................... 6-2

●Printer.......................................................................... 6-2

●Duplex bypass/inverter unit (optional)......................... 6-4

●Print area..................................................................... 6-4

INDEX............................................................................. 6-5