Sharp CE-150 User manual

Other Sharp Printer manuals

Sharp

Sharp CE-140P User manual

Sharp

Sharp MX-C400P User manual

Sharp

Sharp AR-235 User manual

Sharp

Sharp JX-735 User manual

Sharp

Sharp AR-215 User manual

Sharp

Sharp DX-B350P User manual

Sharp

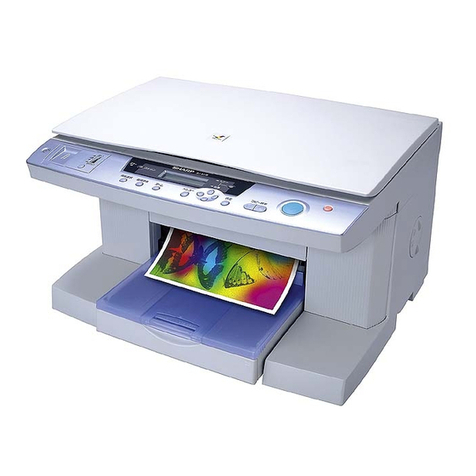

Sharp AJ-6110 Manual instruction

Sharp

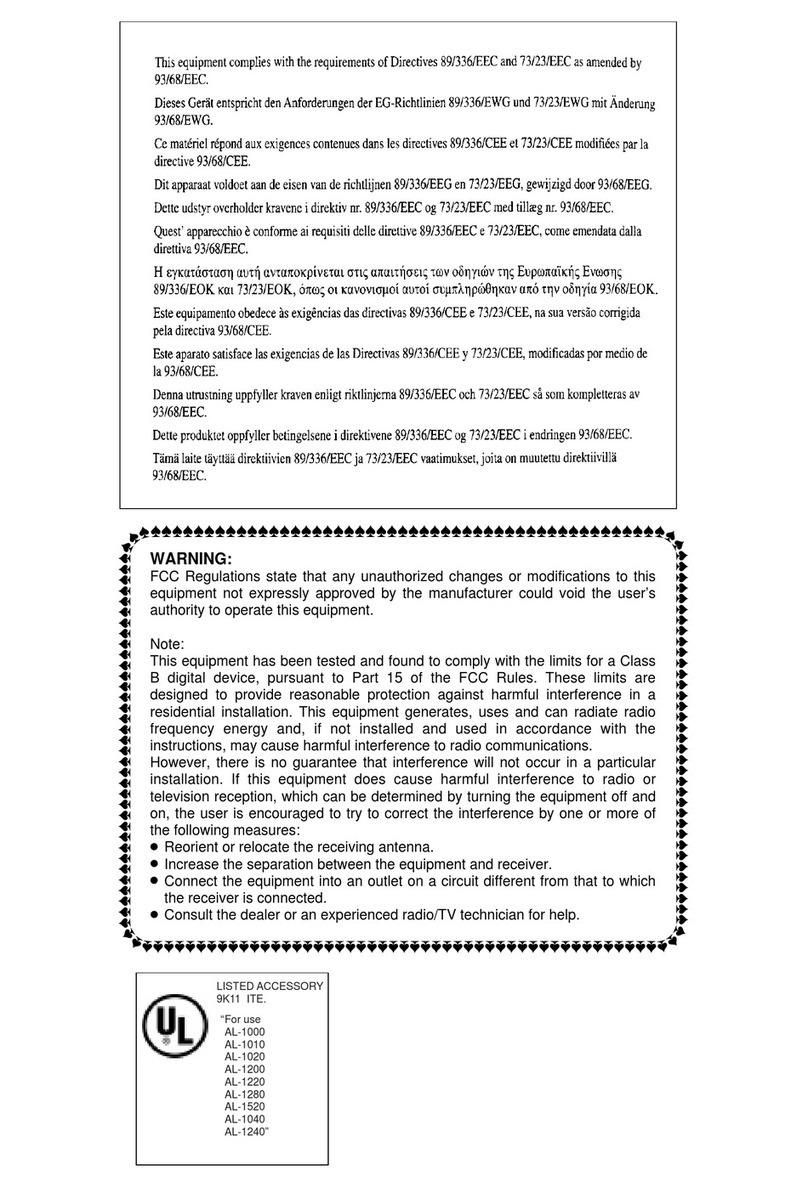

Sharp AL-1000 Series User manual

Sharp

Sharp M-820 User manual

Sharp

Sharp MX-2301N User manual

Sharp

Sharp MX-M350 User manual

Sharp

Sharp AR-CF2 User manual

Sharp

Sharp AR-215 User manual

Sharp

Sharp SF-2014 User manual

Sharp

Sharp AJ-2200 Manual instruction

Sharp

Sharp AR-MS1 User manual

Sharp

Sharp MX-M350-U User manual

Sharp

Sharp AR-M450 Imager User manual

Sharp

Sharp DM-3551 User manual

Sharp

Sharp MX-B467P User manual