5

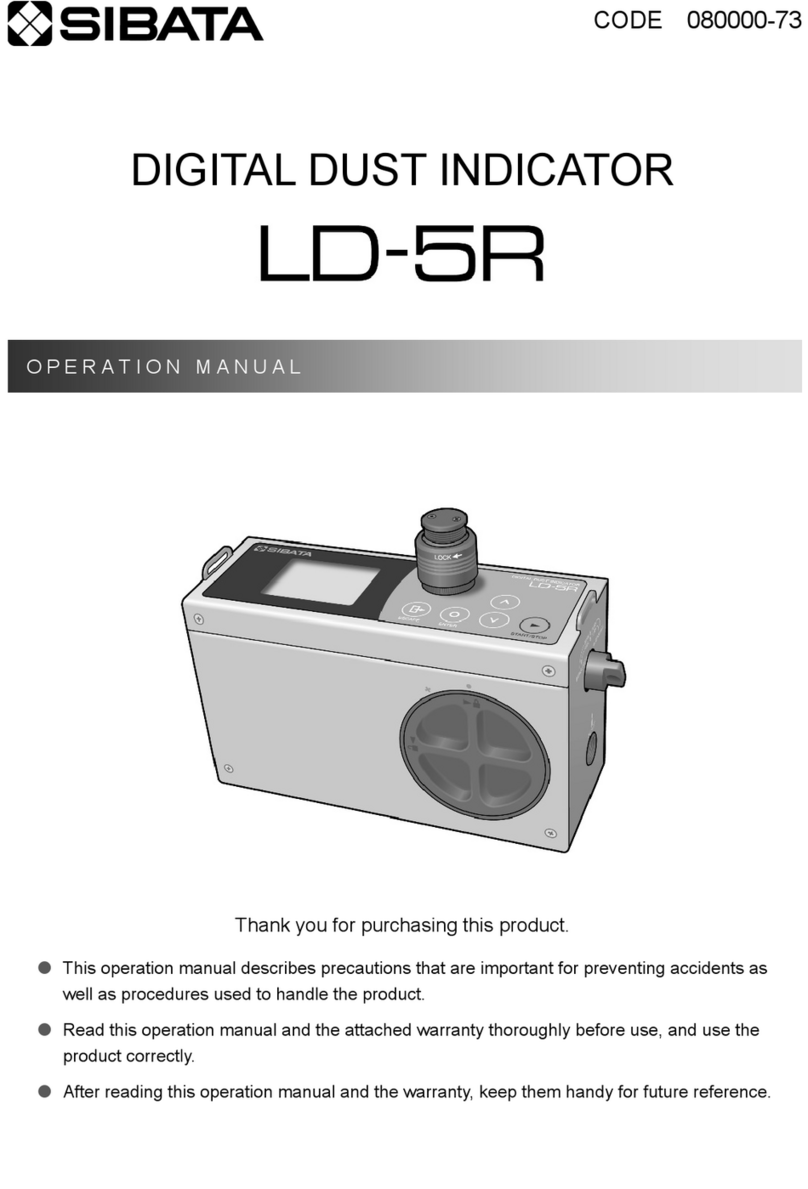

1 Overview

The typical method used for determining the concentration of airborne particulate matter involves using

suction to collect particles directly onto a paper filter and then weighing the filter. However, that method

requires sophisticated measurement technology, complicated operations, and, for low concentrations,

long sampling times. Furthermore, the method cannot be used for continuous measurements of

spatiotemporally instantaneous values.

In such cases, there is an interactive relationship between the airborne particulate matter and,

furthermore, it is probably more appropriate to measure easily-measurable physical quantities. The light

scattering-based detector is designed as a dust concentration indicator for applications such as

atmospheric monitoring and other concentration measurements, for measuring the effectiveness of

filters and other dust removal devices, for controlling concentration levels in dust exposure and animal

inhalation tests, and for evaluating the performance of ventilation and air purification equipment.

It is intended for use in combination with various display devices and data processing equipment.

2 Measurement Principle

The dust indicator is based on the principle that when light is shone on airborne particulate matter in a

dark room, the amount of light that is scattered by the matter is proportional to the mass concentration

of the matter, provided the particulate matter has the same physical properties (such as reflectance,

size, shape, specific weight, and color). The actual system passes the air sample through a stabilized

light beam inside a dark compartment. The light scattered by the airborne particulate matter enters a

photomultiplier tube located in a thermostatic chamber, which converts the light to a photoelectric

current. When the photoelectric current output multiplied by time becomes a constant value, a circuit

that integrates the photometric current for one pulse is used to convert the photometric current into a

pulse that is proportional to the amount of light scattering. Therefore, the relative mass concentration of

airborne particulate matter can be determined by adding up the number of pulses per unit time.

Values measured using this method are referred to as relative concentration values. Since the values

measured by the digital dust indicator have sensitivity values specified in units of mass concentration

(µg/m3), it is unnecessary to measure the absolute quantity of air tested.

3 Sensitivity

Structurally two types of detectors are available (the AP-632T detector connects via tubes, whereas the

AP-632F connects via flanges). These are used in three models (L, M, and H) with different sensitivity

levels.

The standard particles used to determine mass sensitivity values are calibrated based on filtration

collection of monodispersed stearic acid particles with a mean 0.3 µm diameter.

Model Sensitivity

AP-632T (F) L 1CPM = 10 µg/m3

AP-632T (F) M 1CPM = 1 µg/m3

AP-632T (F) H 1CPM = 0.1 µg/m3

(CPM = counts per minute)

The sensitivity of the instrument is determined based on stearic acid particles with a mean diameter of

0.3 µm, but instrument sensitivity is routinely maintained by approximation using an optical attenuator

for relative sensitivity adjustments (hereinafter a "standard scattering plate").

However, it is recommended that the device be calibrated about once a year, due to unavoidable

changes resulting from vibration, changes in the standard scattering plate over time, or other factors.