Quick Manual

MST DEMO setup

- 3-

© SICK AG · Auto Ident · Germany · All rights reserved

A. Introduction

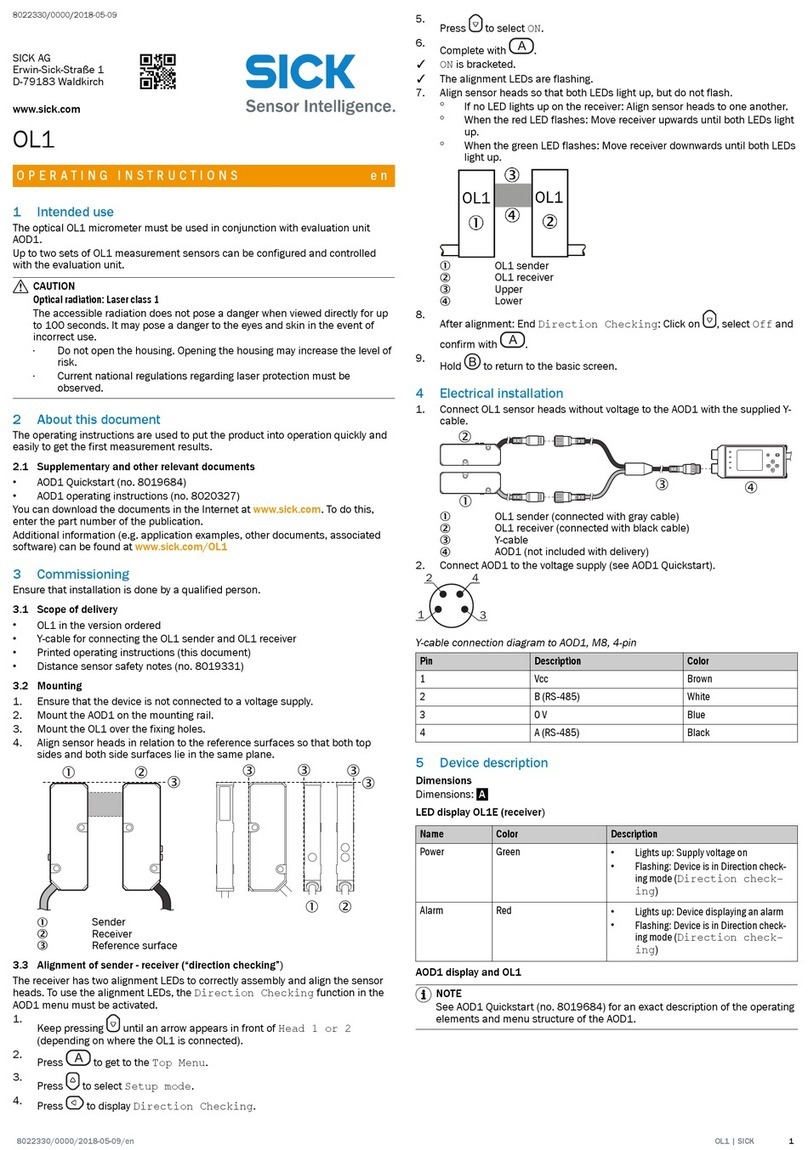

1. Basics of the LMS System

The Laser Measurement System LMS 200, LMS

220, LMS 211, LMS 221, LMS 291 is based on a

time-of-flight measurement principle (Laser Radar).

A single Laser pulse is sent out and reflected by an

object surface within the range of the sensor. The

elapsed time between emission and reception of the

Laser pulse serves to calculate the distance between

object and LMS.

Via a integrated rotating mirror the Laser pulses

sweep a radial range in front of the LMS unit. A 2-

dimensional measurement field / detection area is

defined.

(For further details please refer to the Technical Description

Laser Measurement Systems SICK order no.: 8008970)

Main benefits of this measurement principle are:

•Detection of objects independent of object color

and surface structure

•Reliable detection of object presence

The Laser Measurement System LMS offers a

solution for a large range of applications:

•Determining the volumes of objects (measuring

packages, pallets, containers)

•Determining the position of objects (pallets,

containers, transport vessels)

•Collision prevention for vehicles or cranes

•Controlling docking processes (positioning)

•Classification of objects (vehicle detection, camera trigger)

•Process automation (e.g. calander rollers)

•Checking overhang/area monitoring in automated multi-storey car parks

•Determining the volumes or contours of bulk materials

•Monitoring open spaces for building security (facades, grounds, shafts)

•... and many more

Fig.1: Measurement principle LMS

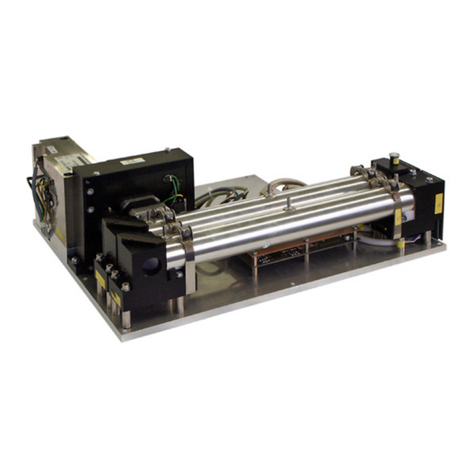

Fig.2: Angular range LMS